#stainless steel 304

Text

0 notes

Text

One of the key properties of stainless steel 304 grade is its corrosion resistance. It is highly resistant to corrosion from most oxidizing acids, organic acids, and chloride solutions, making it suitable for a wide range of applications in various industries, including food and beverage, medical, and chemical processing.

1 note

·

View note

Text

Benefits of Stainless Steel 304/304L Coils

Stainless Steel 304/304L Coils are widely utilized in various industries due to their exceptional properties. At Shree Venktesh Wires and Steels Pvt Ltd, we are the leading SS 304/304L Coil suppliers in India, as well as being stockists and exporters of Stainless Steel 304/304L Coils in India, Ukraine, Australia, Syria, Iraq, Iran, Kazakhstan, Russia, Brazil, Armenia, Azerbaijan, Egypt, South Africa, Qatar, Turkey, Oman, Bahrain, and Germany.

In this blog post, we will explore the benefits of Stainless Steel 304/304L Coils and how they can be useful in different industries.

Stainless Steel 304 Coils

Stainless Steel 304 Coils are a type of stainless steel product that is composed of 18% chromium and 8% nickel. These S30400 coils are highly resistant to corrosion, making them ideal for use in harsh environments such as the chemical and food industries. They are also known for their excellent mechanical properties, making them easy to form and weld. Stainless Steel 304 Coils are widely used in various industries due to their versatility, reliability, and sustainability.

Stainless Steel 304L Coils

Stainless Steel 304L Coils are a type of stainless steel product that is similar to SS 304 Coils but with lower carbon content. The lower carbon content in SS 30403 Coils helps to reduce the formation of harmful carbides during welding, making them suitable for welding applications. These SS 30403 Coils also exhibit excellent corrosion resistance, high-temperature strength, and good formability. They are widely used in various industries, including chemical processing, food processing, and medical equipment manufacturing, due to their excellent properties and versatility.

Properties of Stainless Steel 304/304L Coils:

Corrosion resistance is superior to other steels in various Steel

Excellent low-temperature performances

Good welding characteristics

Post-weld annealing is not normally required

Heat resistant performances

Hot workability such as punching or bending

The material used in this stainless steel does not harden during the heat treatment (non-magnetic, uses temperatures -196°C and 800°C)

Applications of Stainless Steel 304/304L Coils:

Due to their exceptional properties, Stainless Steel 304/304L Coils find a wide range of applications in different industries.

Energy and Heavy Industries Such as Oil and Gas, Electrical steel (Silicon Steel)

Solar Board.

Power Plant.

Heat Exchangers, Boilers

Chemical Storage Vessels

Automotive and Transportation

Architectural and Construction

Marine Building

Medical Equipment

Food Machine Manufacturing, Food, and Catering, and many more.

Advantages of Stainless Steel 304/304L Coils:

The durability, high strength-to-weight ratio, aesthetic appearance, ease of fabrication, and recyclability of SS 304/304L Coils make them an ideal choice for various applications. We will discuss these advantages in detail and explain how they can benefit different industries.

Cost-effectiveness of Stainless Steel 304/304L Coils:

They may be more expensive than other materials, but their long-term cost savings make them a cost-effective choice. We will compare the cost of SS S30400/S30403 Coils with other materials and explain why they can be a more economical option in the long run.

Maintenance of Stainless Steel 304/304L Coils:

To ensure the longevity of these coils, proper maintenance is required.

Safety and Health Benefits of Stainless Steel 304/304L Coils:

They offer several safety and health benefits, making them an ideal choice for various applications.

Sustainability of Stainless Steel 304/304L Coils:

They are environmentally friendly and sustainable. We will explore how they contribute to sustainability and compare them with other materials. Additionally, we will discuss the environmental benefits of SS 304/304L Coils.

Limitations of Stainless Steel 304 Coils:

Moreover, they also have some limitations that need to be considered before using them in certain applications.

Chemical Composition of Stainless Steel 304 / S30400 & DIN 1.4301 Coils

C - 0.08 max

Mn - 2.00 max

Si - 1.00 max

P - 0.045 max

S - 0.03 max

Cr - 18.0 - 20.0

Ni - 8.0 - 10.5

Fe - Balance

Chemical Composition of Stainless Steel 304L / S30403 Coils

C - 0.03 max

Mn - 2.00 max

Si - 1.00 max

P - 0.045 max

S - 0.03 max

Cr -18.0 - 20.0

Ni - 8.0 - 10.5

Fe - Balance

Conclusion:

Stainless Steel 304 & 304L Coils offer a wide range of benefits and find numerous applications in various industries. At SV Stainless Steel, we are committed to providing high-quality Stainless Steel 304 & 304L Coils to our clients. We hope this blog post has helped you understand the benefits of SS304 & 304L Coils and how they can be useful in different industries.

If you have any questions or would like to learn more about our products, please do not hesitate to contact us.

0 notes

Photo

"SS 304 Round Bars Manufacturer & Exporter."

Bhansali Enterprise is specialized in manufacturing Stainless Steel 304 Bar that are in high demand in many applications such as Chemical Processing, Marine, Navy, Petrochemical & Refining and Oil & Gas markets. We have a comprehensive inventory of 304 Stainless Steel Favorized Bar, 304 Stainless Steel Round Bar, 304 Stainless Steel Nerf Bar & Stainless Steel 304 Round Bar in a large variety of types, schedules, sizes, and pressures. The company plant is equipped with a range of machines and advanced processing facilities that give tremendous flexibility to meet the exact needs of our clients. We have Become No 1 Stainless Steel 304 Cold Finish Round Bar Exporter in India, We are Largest Stainless Steel 304 Cold Drawn & Polished Square Bars Distributors. We are Known as Stainless Steel 304 Hexagonal Bar Stockist.

#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india#stainless steel 304 price per kg in delhi#stainless steel 304#manufacturer of stainless steel in india#stainless steel rod 304 price per kg in india#stainless steel round bar

0 notes

Text

#309 stainless steel round bar#stainless steel round bar#manufacturer of stainless steel in india#stainless steel 304

0 notes

Text

5 Factors to Consider When Choosing a 304 Stainless Steel Tube Supplier

2 notes

·

View notes

Text

https://sigmapipes.com/the-uses-of-square-pipes-or-tubes/

Square tubing’s versatility makes it attractive to many industries. A square tube’s performance, durability, and long-lasting nature have made it a popular metal product. Decorative dividers or modern metal gates and entries are just a few of the many applications for square tubes.

3 notes

·

View notes

Text

A Guide To Stainless Steel 304 Pipes

Introduction:

Stainless steel 304 is a type of stainless steel that is widely used in the manufacture of pipes, fittings, and other products. It is an alloy of iron, chromium, and nickel, and is known for its excellent corrosion resistance, strength, and durability.

Advantages of Using Stainless Steel 304 Pipes:

Corrosion resistance: Stainless steel 304 has excellent corrosion resistance in a wide range of environments, including exposure to water, chemicals, and high temperatures. This makes it ideal for use in many applications, including plumbing, water treatment, and food processing.

Strength and durability: Stainless steel 304 is known for its high strength and durability, making it resistant to deformation and damage. This makes it suitable for use in applications where the pipes may be subjected to high levels of stress or pressure.

Non-toxic: Stainless steel 304 is non-toxic and does not leach any harmful chemicals into the materials it comes into contact with. This makes it suitable for use in applications where the pipes may come into contact with food or potable water.

Easy to clean: Stainless Steel 304 Pipe has a smooth, non-porous surface that is resistant to bacteria and other contaminants. This makes it easy to clean and maintain, which is important in applications where hygiene is a concern.

Versatility: Stainless steel 304 is a versatile material that can be used in a wide range of applications, including piping, fittings, and other products. It is available in a variety of sizes and shapes, making it easy to find a product that meets the specific needs of your project.:

Stainless Steel 304 Pipes Are Used In a Wide Range of Applications

Plumbing: Stainless steel 304 pipes are often used in plumbing systems due to their corrosion resistance and durability.

Water treatment: Stainless steel 304 pipes are commonly used in water treatment plants due to their corrosion resistance and ability to withstand high temperatures.

Food processing: Stainless steel 304 pipes are often used in food processing plants due to their non-toxic properties and ability to withstand high temperatures.

Chemical processing: Stainless steel 304 pipes are resistant to corrosion and are often used in chemical processing plants.

Marine applications: Stainless steel 304 pipes are used in marine environments due to their corrosion resistance.

Weight:

Stainless Steel Pipe 304 Grade weight will depend on its size and thickness. As a general rule, the weight of a stainless steel 304 pipe can be calculated by multiplying its length by its wall thickness and then multiplying the result by the density of stainless steel, which is about 8 grams per cubic centimeter.

Conclusion:

Overall, Stainless Steel 304 is a popular choice for use in piping and other applications due to its excellent corrosion resistance, strength, and durability. It is widely used in a variety of industries, including plumbing, water treatment, food processing, chemical processing, and marine applications. I hope this information is helpful! Let me know if you have any other questions.

#Stainless Steel Pipe 304 Grade#Stainless Steel Pipe 304#Stainless Steel Pipe#SS 304 pipes#SS 304 pipe

2 notes

·

View notes

Text

0 notes

Text

Reliable Overseas - Leading Supplier of Stainless Steel 446 Round Bars

Reliable Overseas stands as a premier supplier of stainless steel 446 round bars, providing high-quality materials for a range of industrial applications. The significance of stainless steel 446 lies in its exceptional resistance to oxidation and sulfidation, making it a preferred choice for environments subjected to high temperatures and corrosive elements.

Company Overview

History and Establishment

Reliable Overseas was established in 2010, with a mission to deliver top-notch steel products to various industries. Over the years, the company has built a reputation for reliability and excellence in the supply chain.

Core Values

Quality Assurance: Committed to providing only the best quality products.

Customer Satisfaction: Focused on building long-term relationships with clients.

Innovation: Continuously improving and adapting to market needs.

Market Reach

With a global footprint, Reliable Overseas serves clients across multiple continents, ensuring timely delivery and robust after-sales support.

Product Specifications

Material Composition

Stainless steel 446 is an alloy primarily composed of:

Iron (Fe)

Chromium (Cr): 23-27%

Molybdenum (Mo): Enhances corrosion resistance

Physical Properties

Density: 7.7 g/cm³

Melting Point: 1425-1510°C

Thermal Conductivity: 26 W/m·K at 100°C

Mechanical Properties

Tensile Strength: 485 MPa

Yield Strength: 275 MPa

Elongation: 20%

Applications

Industrial Uses

Stainless steel 446 round bars are ideal for:

High-Temperature Furnaces: Due to their excellent heat resistance.

Chemical Processing Equipment: Resistant to aggressive chemicals.

Petrochemical Industry: Withstands corrosive environments.

Construction

Used in the construction of:

Bridges and Structures: For durability and longevity.

Architectural Applications: Provides a sleek and modern aesthetic.

Benefits of Stainless Steel 446

Corrosion Resistance

Stainless steel 446 offers superior resistance to oxidation and sulfidation, extending the lifespan of components exposed to harsh conditions.

Heat Resistance

Capable of withstanding high temperatures, it is suitable for applications involving extreme heat.

Longevity and Durability

The material's robust nature ensures a longer lifespan, reducing the need for frequent replacements and maintenance.

Quality Assurance

Certification

Reliable Overseas adheres to international quality standards, including:

ISO 9001: Ensuring consistent quality management.

ASTM Standards: Compliant with ASTM A276 and A479 specifications.

Testing and Inspection

Each batch undergoes rigorous testing, including:

Chemical Analysis: Verifying material composition.

Mechanical Testing: Ensuring strength and durability.

Visual Inspection: Checking for surface defects.

Customer Testimonials

Case Study 1: Chemical Plant

A leading chemical plant reported a significant increase in equipment lifespan after switching to stainless steel 446 round bars supplied by Reliable Overseas, highlighting the material's superior performance.

Case Study 2: Heat Treatment Facility

A heat treatment facility praised the high-temperature resistance of the stainless steel 446 round bars, noting improved operational efficiency and reduced downtime.

Expert Insights

Metallurgist's Perspective

Dr. John Doe, a renowned metallurgist, emphasizes the advantages of stainless steel 446 in high-temperature applications, citing its stable microstructure and resistance to thermal fatigue.

Industry Analyst

Jane Smith, an industry analyst, notes the growing demand for high-performance materials like stainless steel 446 in emerging markets, driven by advancements in industrial technologies.

Conclusion

Reliable Overseas is your trusted partner for high-quality stainless steel 446 round bars. With a commitment to excellence and a focus on customer satisfaction, they provide materials that meet the highest standards of performance and reliability.

#Stainless Steel 422 Bright Bars#Stainless Steel 316L Round Bars#Stainless Steel 304 Round Bars#Stainless Steel 446 Round Bars#Super Duplex Steel UNS S32760 Round Bars#Monel 400 Round Bars#Inconel 600 Round Bars#Hastelloy C276 Round Bars#Stainless Steel 446 Tubes#Stainless Steel 446 Sheets and Plates

0 notes

Text

Exploring the Difference: 304 vs. 316 Stainless Steel Pipes

Introduction: Stainless steel pipes are essential components in various industries, known for their durability, corrosion resistance, and versatility. Among the most commonly used grades are 304 and 316 stainless steel. In this blog, we delve into the differences between these two grades of stainless steel pipes to help you make informed decisions for your construction projects.

1. Composition and Properties:

304 Stainless Steel Pipes:

Comprised of 18% chromium and 8% nickel.

Excellent corrosion resistance in most atmospheric conditions and many corrosive media.

Suitable for various applications, including food processing equipment, kitchen appliances, architectural trim, and chemical processing equipment.

316 Stainless Steel Pipes:

Contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum.

Enhanced corrosion resistance, particularly against chlorides and acids.

Ideal for marine environments, pharmaceutical equipment, chemical processing, and medical devices.

2. Corrosion Resistance:

304 stainless steel offers good corrosion resistance in mildly corrosive environments.

316 stainless steel provides superior corrosion resistance, making it ideal for use in aggressive environments exposed to chlorides, acids, and saline solutions.

3. Strength and Durability:

Both 304 and 316 stainless steel pipes exhibit high strength and durability, suitable for demanding applications.

However, due to the presence of molybdenum, 316 stainless steel offers slightly higher strength and improved resistance to pitting and crevice corrosion.

4. Cost Considerations:

In general, 304 stainless steel pipes are more cost-effective than 316 stainless steel pipes.

The higher nickel and molybdenum content in 316 stainless steel contribute to its increased cost but also provide enhanced performance in corrosive environments.

5. Applications:

304 stainless steel pipes are commonly used in a wide range of applications, including plumbing, automotive, construction, and decorative purposes.

316 stainless steel pipes are preferred in industries where corrosion resistance is paramount, such as marine, chemical processing, pharmaceuticals, and medical devices.

6. Maintenance and Care:

Both grades of stainless steel pipes require regular maintenance and cleaning to preserve their appearance and performance.

Routine cleaning with mild soap and water, followed by thorough rinsing and drying, helps prevent staining and corrosion.

Conclusion: In summary, while both 304 and 316 stainless steel pipes offer excellent corrosion resistance and durability, the choice between them depends on the specific requirements of your application. For general-purpose applications where cost-effectiveness is crucial, 304 stainless steel may suffice. However, for environments exposed to harsh chemicals, saltwater, or high chloride levels, the superior corrosion resistance of 316 stainless steel makes it the preferred choice.

#Best Plumbing Fittings#Best plumbing pipes#Stainless Steel Pipes#304 and 316 Stainless Steel pipes#Best Stainless Steel Plumbing Fittings#Stainless Steel Plumbing Fittings

0 notes

Photo

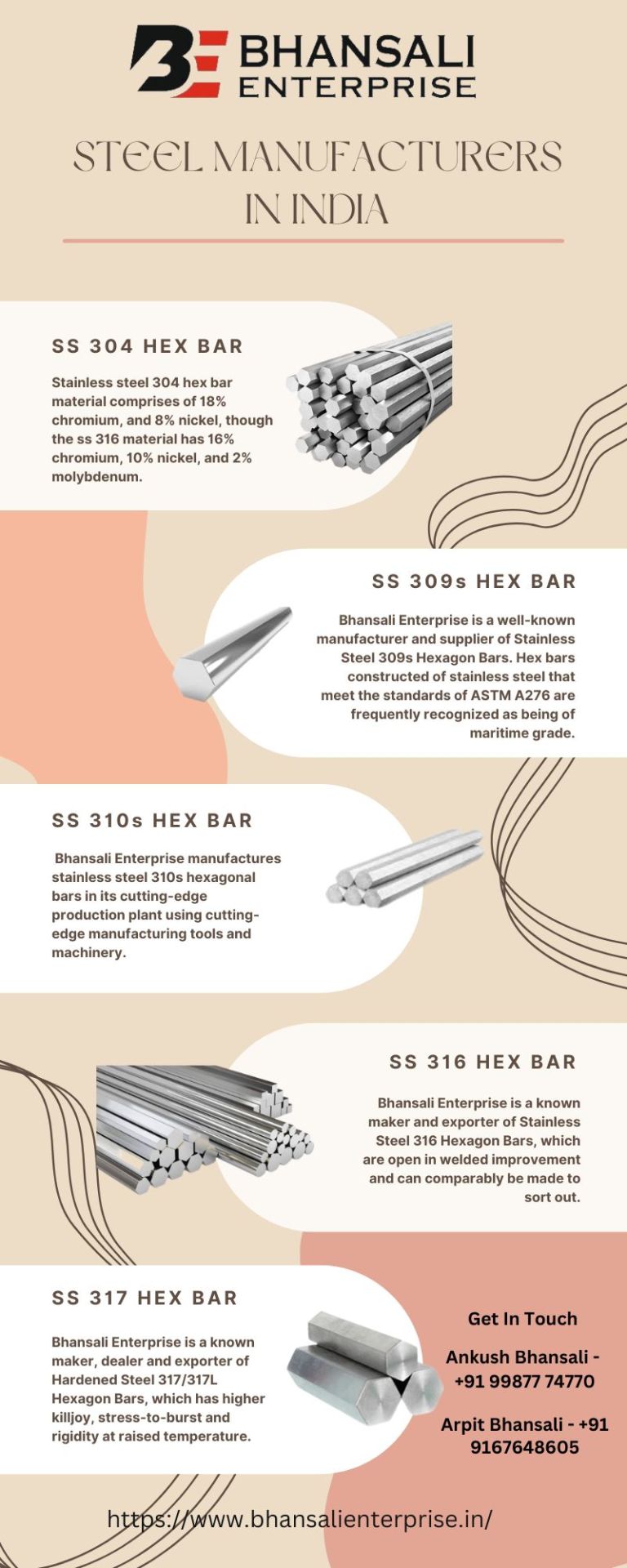

"SS Hex Bars Manufacturers & Exporter."

The Stainless Steel Hex Bars have improved strength and for that reason they are utilized in many applications. The extra strength is because of the mathematical state of the hex bars. On the off chance that the hex bar is made of austenitic treated steel, they have more prominent strength and higher erosion opposing properties. The Stainless Steel Hex Bars can be altered to various shapes and sizes as per the particular necessities. Bhansali Enterprise manufactures ASME SA276 Stainless Steel 309s Hex Bars using state-of-the-art tools and machinery to guarantee complete dimensional accuracy. Customers can choose from a variety of ASTM A276 SS 309s Hexagon Bars at Bhansali Enterprise. We produce 310 stainless steel hexagonal bars that fulfil national and international quality standards using only the best raw materials. Bhansali Enterprise is known in the business for the reliability of the goods we offer. Bhansali Enterprise is a known maker and exporter of Stainless Steel 316 Hexagon Bars, which are open in welded improvement and can comparably be made to sort out. SS 316 Hexagon Bar is utilized in blend process gear; tank trucks; propeller screws, and spent atomic fuel part recuperation. Bhansali Enterprise is a known maker, dealer and exporter of Hardened Steel 317/317L Hexagon Bars, which has higher killjoy, stress-to-burst and rigidity at raised temperature. SS 317 Hex Bars doesn’t respond to warm treatment, which can be additionally solidified by chilly working.

#stainless steel round bar#stainless steel 316l#stainless steel 304#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#steel grades#round bar#polished stainless steel#stainless steel 304 price per kg in delhi#stainless steel manufacturers in india#flange manufacturer in india

0 notes

Text

Top Manufacturer of Stainless Steel 304 Pipes & Tubes | Bhagya Laxmi industrial

Bhagyalaxmi Industrial is a leading manufacturer of Stainless Steel 304 Pipes & Tubes.Our high-quality products are durable and corrosion-resistant, making them ideal for various industrial applications. Visit our website to browse our wide range of pipes and tubes that are manufactured to the highest standards. With a focus on quality and reliability, Bhagyalaxmi Industrial ensures that all Stainless Steel 304 Pipes & Tubes meet industry standards.Our products are designed to withstand harsh environments and provide long-lasting performance. Check out our website for more information on our products and services.

0 notes

Text

#stainless steel round bar#stainless steel 304#stainless steel round bar manufacturer in india#ss round bar#309 stainless steel round bar

1 note

·

View note

Text

Calico Metal Alloys LLP is one of the main Manufacturers, Suppliers and Exporters of top notch Duplex 2205, UNS S31803, UNS S32205, UNS S32750, UNS S32760, Duplex 2202, Duplex 2304 pipe, Tube, sheet, plates, Coil, Shim Sheet flanges, fasteners in India at low price.

#ASTM A312 TP 304/304H Stainless Steel#Titanium Grade 1 Pipes & Tubes#Nickel Alloy 200/201#Aluminium Alloy 2014#Copper and Brass Alloys#Duplex Steel 2205#Titanium Alloys#Cobalt Alloys#Silver and Gold Brazing Alloys supplier from Mumbai#India.

0 notes