#ss round bar

Photo

"Monel Alloy 400 Manufacturer."

Monel Alloy 400 is almost immune to chloride associated ion pressure corrosion cracking in ordinary environments. Although, its corrosion resistance is very good in reductive environments, it’s far taken into consideration to be bad in oxidative conditions. Monel Alloy 400 Rod is known to have great mechanical properties at even at subzero temperatures. The alloy can be used in temperatures up that go to 1000° F. Monel 400 has a high melting point, it melts between the temperature range of 2370° F – 2460° F. Since alloy 400 has low strength in an annealed condition , a variety of tempering techniques may be used to increase the tensile strength.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#ss round bar#monel metal composition#monel 400#monel metal#polished stainless steel#stainless steel manufacturers in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor

0 notes

Text

An Overview of Stainless Steel Round Bars

Introduction:

Stainless steel round bars are cylindrical bars made from stainless steel. They are an essential component in many applications, due to their strength, corrosion resistance, and ability to withstand high temperatures. There are several types of stainless steel round bars, including austenitic, ferritic, martensitic, and duplex. Stainless steel round bars are available in a variety of grades and finishes, including annealed, cold-drawn, and heat treated.

What are the Applications of SS Round Bars?

Stainless steel round bars are used in a wide range of industries, including construction, automotive, medical, food processing, and chemical processing. They are commonly used in the production of parts and components, such as automotive exhaust systems, medical instruments, food processing equipment, and chemical processing tanks.

What are the Advantages of SS Round Bars?

There Are Several Advantages To Using Stainless Steel Round Bars, Including:

Corrosion resistance: Stainless steel has excellent resistance to corrosion, making it suitable for use in a wide range of environments.

Strength: Stainless steel round bars are strong and durable, making them suitable for use in high-stress applications.

High-temperature resistance: Stainless steel has a high melting point and is able to withstand high temperatures, making it suitable for use in high-temperature environments.

Non-toxic: Stainless steel is non-toxic and does not leach any harmful chemicals, making it suitable for use in the food industry.

Recyclable: Stainless steel is 100% recyclable, making it an environmentally friendly choice.

Weight of Stainless Steel Round Bar :

Stainless Steel Round Bar Weight is determined by multiplying the density of the material by the volume of the bar. The density of stainless steel is generally between 8 and 8.5 g/cm3. To find the weight of a round bar, you need to know the diameter and length of the bar.

Conclusion:

In conclusion, stainless steel round bars are an essential component in many applications due to their strength, corrosion resistance, and ability to withstand high temperatures. They are used in a wide range of industries and offer several advantages, including corrosion resistance, strength, high-temperature resistance, non-toxicity, and recyclability.

0 notes

Text

#stainless steel round bar#stainless steel 304#stainless steel round bar manufacturer in india#ss round bar#309 stainless steel round bar

1 note

·

View note

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Stainless Steel 422 Bright Bars Suppliers | Reliable Overseas

Discover top-quality Stainless Steel 422 Bright Bars from Reliable Overseas. Trusted suppliers for your industrial needs.

#Stainless Steel 422 Bright Bars#Stainless Steel 422 Bright Bars Suppliers#ASTM A276 SS 422 Round Bars#Stainless Steel 422 Round Bar#Stainless Steel 422 Hex Bar#Stainless Steel 422 Square Bar

1 note

·

View note

Text

A comprehensive guide on Stainless Steel Round Bar

Stainless steel round bars have become indispensable in various industries due to their exceptional strength, corrosion resistance, and versatility. As a leading SS round bars Manufacturer, Supplier, Stockist, and Exporter on a global scale, Bullion Pipes & Tubes LLP takes pride in offering an extensive range of stainless steel round bars tailored to meet diverse project requirements.

In this comprehensive guide, we'll delve into the world of stainless steel round bars, exploring their composition, properties, applications, and key factors to consider when selecting the right round bar for your specific needs.

Stainless Steel Round Bars

Stainless steel round bars are solid cylindrical bars made from stainless steel, an alloy of iron, chromium, nickel, and other elements. The combination of these elements imparts unique properties to stainless steel, making it a preferred choice in diverse applications.

Composition and Grades:

Stainless steel round bars come in various grades, each with its own set of properties and applications. Common grades include Stainless Steel 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 904L and 446 Round Bars. The grade you choose depends on factors such as corrosion resistance, temperature resistance, and mechanical properties required for your specific application.

Properties that Set Stainless Steel Round Bars Apart:

Corrosion Resistance: Stainless steel round bars are known for their excellent corrosion resistance, making them ideal for applications in harsh environments, such as marine and chemical industries.

High-Temperature Resistance: The alloy's ability to withstand high temperatures without losing its structural integrity is a crucial factor in applications like heat exchangers and exhaust systems.

Strength and Durability: Stainless steel round bars exhibit high tensile strength and durability, ensuring a long lifespan and minimal maintenance requirements.

Specifications of Stainless Steel Round Bars

Standard

ASTM, ASME, AISI A 276, SA 276, A 479, SA 479, ASTM, ASME A276/SA 479

Dimensions

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size

18mm – 47mm (11/16″ to 1-3/4″)

Range

3.17 MM TO 350 MM DIA

Stainless Steel Round Bars

SS 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 904L and 446 Round Bars

Length

1 to 6 Meters, Custom Cut Lengths

Condition

Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished

Finish

Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Form

Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc

Applications of Stainless Steel Round Bars Across Industries:

Stainless steel round bars find extensive applications across various industries due to their unique properties, making them a versatile and popular choice for different purposes. Here are some key applications across industries:

Construction and Architecture

Automotive Industry

Oil and Gas Industry

Chemical Processing

Food and Beverage Industry

Medical and Pharmaceutical

Aerospace Industry

Power Generation

Marine Industry

General Manufacturing

Other Applications

Choosing the Right Stainless Steel Round Bar:

When selecting a stainless steel round bar, consider factors such as:

Grade: Choose a grade based on the specific requirements of your application.

Diameter and Length: The size of the round bar should align with your project specifications.

Surface Finish: Depending on the application, you may need a polished or rough surface finish.

Final Words!

Bullion Pipes & Tubes LLP stands as the industry leader in providing top-notch stainless steel round bars exporters globally in various countries like Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia, and many other regions. Our commitment to quality, extensive product range, and customization options make us the preferred choice for customers across diverse industries. Contact us today at [email protected] or [email protected] and experience the excellence of stainless steel round bars that elevate your projects to new heights.

0 notes

Text

Top Supplier SS Round Bars in Karnataka

Top Supplier SS Round Bars in Karnataka:

Saraswati Steel and Engineering Co.

Founded in 2011, Saraswati Steel and Engineering Co. is a prominent metal importer, stockholder, and supplier.

The company specializes in various stainless steel products, including angles, channels, pipes, fittings, flanges, dairy valves, fasteners, UPVC pipes, industrial valves, bars, and wire rods.

Stainless steel…

View On WordPress

0 notes

Text

Characteristics of 316L SS Round Bar Suppliers

What are 316L Stainless Steel Round Bar Suppliers?

316L Stainless Steel Round Bar Suppliers are companies or individuals that specialize in supplying 316L stainless steel materials to various industries.

This type of steel round bar is a low-carbon version of 316 steel, which makes it more resistant to corrosion and rust. The round bar is typically available in various sizes ranging between 1/16 inches to 30 inches.

Applications of 316L Stainless Steel Round Bar Suppliers

Due to its properties, the 316L stainless steel round bar is a versatile material used in various industries. Its corrosion-resistant nature makes it ideal for marine and industrial applications, such as chemical processing, pharmaceuticals, and food processing.

It is also commonly used in construction as a reinforcement material, architectural structures, and in the fabrication of machine components.

Benefits of Using 316L Stainless Steel Round Bar Suppliers

There are several benefits of using 316L stainless steel round bar suppliers' products, including:

Corrosion and rust resistance: The 316L round bar's low carbon content makes it resistant to corrosion and rust, making it the perfect candidate for harsh environments.

High-temperature resistance: The round bar is also resistant to high temperatures, making it ideal for high-temperature applications such as heat exchangers.

Durability: The 316L stainless steel is highly durable, which means it can withstand the test of time, making it a cost-effective option.

Easy to fabricate: Due to its malleable nature, the 316L round bar is easy to fabricate into various shapes, making it a versatile option for various applications.

How to Choose a 316L Stainless Steel Round Bar Supplier

Choosing the right 316L stainless steel round bar supplier is essential to ensure you get high-quality steel products that meet your needs. When selecting a supplier, consider the following factors:

Material quality: Ensure the supplier's materials meet the required quality standards.

Experience: Choose a supplier with several years of experience supplying 316L stainless steel material.

Customer service: A supplier with excellent customer service is essential to ensure a smooth and hassle-free purchasing process.

Pricing: Choose a reasonably priced supplier that offers value for your money.

#Benefits of Using 316L Stainless Steel Round Bar Suppliers#Applications of 316L Stainless Steel Round Bar Suppliers#Characteristics of 316L SS Round Bar Suppliers#What are 316L Stainless Steel Round Bar Suppliers

0 notes

Text

Prominent Suppliers Of Stainless Steel Round Bar In India

Mehran Metals & Alloys is the one of the well known Stainless Steel Round Bar Supplier in India. We supply various types of stainless steel round bar including Stainless Steel 304 Round Bar, Stainless Steel 310 Round Bar, Stainless Steel 316L Round Bar and many other types are available from us. We supply high-quality SS round bars to a variety of sectors worldwide.

We dominate the industry as the country's best Stainless Steel Round Bar Supplier.Our products are made from high-quality material, and because of this, we are a well-known Stainless Steel Round Bar manufacturer in Mumbai.

For more details;

Website: mehranmetals.com

Product source: Stainless Steel Round Bar Manufacturers in India

0 notes

Photo

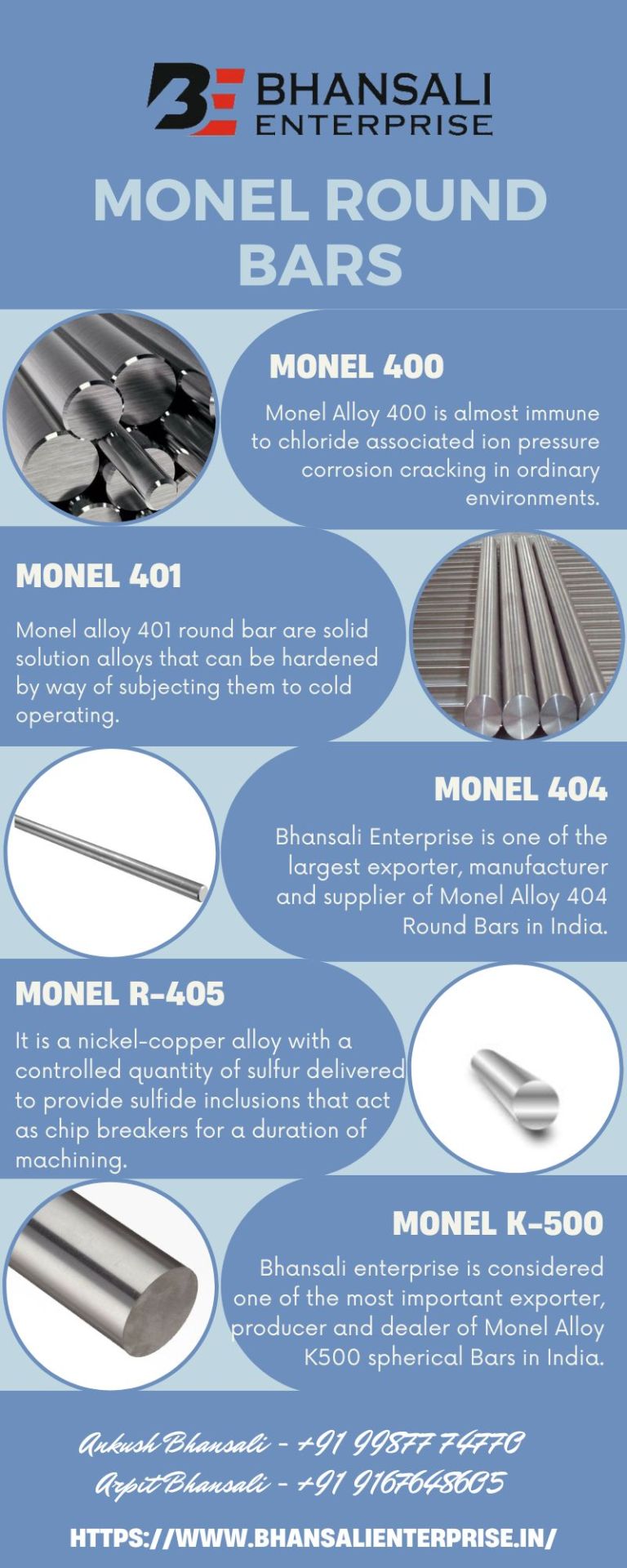

"Monel Round Bars."

Monel Alloy 400 Rod is known to have great mechanical properties at even at subzero temperatures. The alloy can be used in temperatures up that go to 1000° F. Monel 400 has a high melting point, it melts between the temperature range of 2370° F – 2460° F. Since alloy 400 has low strength in an annealed condition , a variety of tempering techniques may be used to increase the tensile strength. MONEL 401 is designed to be used in unique electric powered and digital applications. The common kinds of MONEL 401 alloy are strip and wire. This datasheet will look at the chemical composition, properties and applications of MONEL 401 alloy. Bhansali Enterprise is one of the largest exporter, manufacturer and supplier of Monel Alloy 404 Round Bars in India. Monel 404 Round Bars is more resistant to nickel under reducing environments and more resistant than copper under oxidizing environments, where it does exhibit however improved resistance to reducing media than oxidizing. Monel Alloy 404 Rods is a Nickel-Copper alloy, resistant to sea water and steam at elevated temperatures, in addition to caustic and salt solutions. Monel Alloy R-405 is the unfastened machining model of Monel 400. It is a nickel-copper alloy with a controlled quantity of sulfur delivered to provide sulfide inclusions that act as chip breakers for the duration of machining. Bhansali enterprise is considered one of the most important exporter, producer and dealer of Monel Alloy K500 spherical Bars in India.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#ss round bar#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#monel metal composition#monel metal#stainless steel manufacturers in india#polished stainless steel

0 notes

Text

A Complete Guide on Bright Round Bars

In India and worldwide, stainless steel bright round bar come from SS Engineering Work. They provide high-quality bright bar steel to various industries. Contact them if you need stainless steel from a reliable bright bar supplier in India. Get more info: https://www.ssengineeringwork.in/stainless-steel-bright-round-bar.php

#stainless steel bright round bar#bright bar manufacturing#bright bar manufacturers#s.s. engineering works#ss engineering work#ssengineeringworks#ss engineering works

1 note

·

View note

Text

Stainless Steel 904L Fittings: A Comprehensive Guide

Stainless steel 904L fittings are essential components in various industries, offering exceptional corrosion resistance, high strength, and durability, making them suitable for various industries, including oil and gas, chemical, petrochemical, and many more.

Jay Steel Corporation is a prominent Stainless Steel 904L Fitting Supplier, Manufacturer, Stockist, and Exporter in India. Our comprehensive range of SS fittings is meticulously crafted to meet the diverse requirements of various projects. We maintain an extensive inventory comprising different grades of Stainless Steel, including the highly sought-after 904L Stainless Steel fittings. Our unwavering commitment to quality and customer satisfaction has established us as trusted SS Fittings manufacturers in India, as well as esteemed 904L Fittings stockists and exporters worldwide.

The purpose of this blog post is to ensure you have a complete understanding of the features, applications, and benefits of Stainless Steel 904L fittings. So let's dive right in!

Stainless Steel 904L Fittings

Stainless Steel 904L is a super austenitic stainless steel alloy known for its exceptional corrosion resistance, high strength, and excellent weldability. It contains high levels of chromium, nickel, and molybdenum, along with copper, which enhances its resistance to various corrosive environments, including acids, pitting, and crevice corrosion. The addition of copper also provides excellent resistance to reducing acids such as sulfuric acid.

Stainless Steel 904L Fittings, manufactured using this premium-grade alloy, offer outstanding performance in demanding applications where resistance to corrosion and extreme temperatures is paramount. These fittings are widely used in industries such as chemical processing, oil and gas, pharmaceuticals, food processing, and many others.

Key features of Stainless Steel 904L Fittings

Stainless steel 904L fittings possess several properties that make them highly suitable for demanding applications:

Corrosion Resistance: Stainless steel 904L exhibits excellent resistance to various corrosive environments, including sulfuric acid, phosphoric acid, and chloride solutions. It is particularly resistant to pitting and crevice corrosion.

High Strength and Durability: With its higher alloy content, stainless steel 904L fittings offer superior strength and durability, enabling them to withstand high-pressure and high-temperature conditions.

Heat Resistance: These fittings can operate at elevated temperatures without losing their mechanical properties, making them suitable for applications involving heat transfer.

Low Maintenance: Stainless steel 904L requires minimal maintenance, reducing downtime and associated costs.

Types of Stainless Steel 904L Fittings

We provide a diverse range of Stainless Steel 904L Fittings to cater to different application requirements. Here are some commonly available types:

Elbow: Used for changing the direction of fluid flow, elbows are available in various angles to suit specific piping configurations.

Tee: Tees allow the connection of three pipes or tubes at right angles, facilitating branching connections in piping systems.

Cross: Cross fittings are designed to connect four pipes or tubes, ensuring efficient flow distribution.

Pipe Cap: Pipe caps are used to seal the end of a pipe, providing protection and preventing the ingress of contaminants.

Reducers: Reducers are employed to connect pipes or tubes of different diameters, facilitating smooth fluid flow transition.

Benefits of using Stainless Steel 904L fittings

Using Stainless Steel 904L fittings provides numerous advantages for various applications. Some notable benefits include:

Corrosion resistance: Stainless Steel 904L fittings offer exceptional resistance to corrosion, enabling them to withstand harsh environments and corrosive substances.

Durability: These fittings have excellent strength and durability, ensuring a long service life and reducing maintenance requirements.

Low maintenance: Stainless Steel 904L fittings are relatively low maintenance, saving time and resources in the long run.

Versatility: They can be used in diverse applications due to their high-temperature resistance, making them suitable for a wide range of industries.

Specifications and Standards of Stainless Steel 904L Fittings

Specifications: ASTM A403 / ASME SA403, ASTM A182 & ASME SA182

Forged Fittings Standards: ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Buttweld Fittings Dimensions: ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Buttweld Fittings Size: 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated)

Forged Fittings Size: 1/8” NB to 4” NB (Socketweld & Screwed-Threaded)

Buttweld Fittings Type: Seamless / Welded / Fabricated

Forged Fittings Type: Socketweld Fittings, Screwed-Threaded Fittings

Forged Fittings Class: 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

Buttweld Fittings Bending Radius: R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Buttweld Fittings Thickness: Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

Choosing the Right Stainless Steel 904L Fittings

Selecting the right Stainless Steel 904L Fittings for your project is essential to ensure optimal performance and longevity. Consider the following factors during the selection process:

Application Requirements: Evaluate the operating conditions, including temperature, pressure, and corrosive environment, to determine suitable fittings.

Size and Configuration: Determine the required size, type, and configuration of fittings based on your piping system design.

Standards and Specifications: Refer to the relevant standards and specifications to ensure compliance and product quality.

Supplier Reliability: Choose a trusted Stainless Steel 904L Fitting supplier like Jay Steel Corporation, renowned for delivering high-quality SS Fittings that meet international standards.

Installation and Maintenance

Proper installation and regular maintenance play a crucial role in maximizing the performance and lifespan of Stainless Steel 904L Fittings. Follow these guidelines for installation and maintenance:

Proper Handling: Handle the fittings with care during transportation and installation to avoid any damage or scratches.

Correct Installation: Ensure accurate alignment and secure connection of fittings using appropriate installation techniques and tools.

Regular Inspection: Conduct periodic inspections to check for any signs of corrosion, leaks, or damage, and promptly address any issues.

Maintenance Practices: Follow recommended maintenance practices, including cleaning, lubrication, and corrosion prevention methods, to extend the service life of the fittings.

Applications of Stainless Steel 904L Fittings

Stainless Steel 904L fittings are widely used in various industries due to their excellent corrosion resistance and high strength properties. Here are some applications where Stainless Steel 904L fittings are commonly used:

Chemical Processing

Oil and Gas Industry

Pharmaceutical Industry

Desalination Plants

Food and Beverage Industry

Power Generation

Marine Applications

Water Treatment and many more

Final Thoughts!..

Stainless Steel 904L Fittings provide outstanding resistance against corrosion, exceptional strength, and unparalleled versatility, making them highly suitable for a wide array of applications. Whether your operations are in the chemical, oil and gas, pharmaceutical, or food processing industries, you can rely on Jay Steel Corporation to supply you with top-notch Stainless Steel 904L Fittings tailored to your project's specific requirements. Our comprehensive selection encompasses various sizes, forms, specifications, standards, and types, ensuring you receive fittings that are both dependable and long-lasting. We proudly serve customers all across the globe, including locations such as Thailand, Singapore, Malaysia, Germany, Russia, France, Nigeria, Tunisia, USA, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, Jordan, Bahrain, Russia, Germany, the United Kingdom, and Italy. Rest assured, our fittings comply with international standards and are meticulously packaged to ensure secure transportation.

Get in touch today and discover the excellence of Stainless Steel 904L Fittings delivered by our team.

#Stainless Steel 904L Tube & Pipe#Stainless Steel 904L plate#Stainless Steel 904L Round Bar#Stainless Steel 904L Fitting Supplier#SS Fittings manufacturers in India#904L Fittings stockists and exporters#904L Stainless Steel fittings#Stainless Steel 904L Fitting supplier

1 note

·

View note

Text

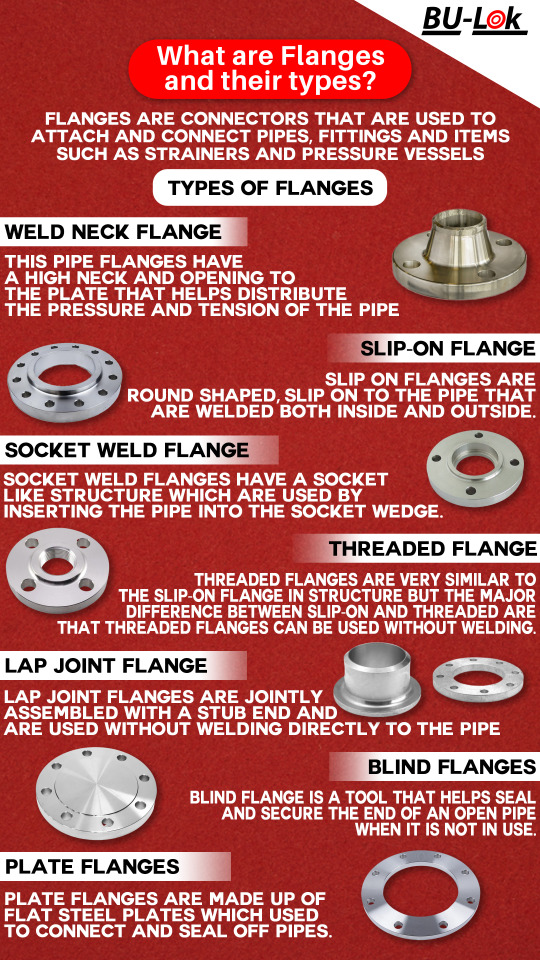

Stainless Steel Flanges in India

Looking for top-quality stainless steel flanges in India. Bu-Lok is one of the best SS flanges manufacturers in Mumbai. Bu-Lok also supplies flanges, fasteners, plates, round bars, and stainless steel forged pipe fittings. Call us at +918888944449.

#stainless steel flanges in India#SS flanges manufacturers in Mumbai#fasteners#round bars#stainless steel forged pipe fittings

0 notes

Text

Stainless Steel Round bars Suppliers in Mumbai

Discover round bars online in India. Call MV Super Alloys, which provides the best round bars in different types of materials and also supplies nickel alloys, stainless steel, duplex steel, and alloy steel. It is the best stainless steel round bar supplier in Mumbai.

0 notes

Text

SS Round Bars Supplier in Ahmedabad

SS Round Bars Supplier in Ahmedabad:

One of the largest manufacturers, suppliers, exporters, and stockists of round bars in India is Elenox Steel. We provide Stainless Steel Round Bars of the highest quality to numerous industries across the world. Our expertise in heat treatment places us in a favored position for producing and exporting Round Bars with a close-by and specific chemistry and for…

View On WordPress

#SS Round Bars Supplier in Ahmedabad#SS Round Bars Supplier in Asarva#SS Round Bars Supplier in Bakrol#SS Round Bars Supplier in Chhatral#SS Round Bars Supplier in Daskroi#SS Round Bars Supplier in Dhandhuka#SS Round Bars Supplier in Dholka#SS Round Bars Supplier in Kadi#SS Round Bars Supplier in Kalol#SS Round Bars Supplier in Kathwada#SS Round Bars Supplier in Kerala#SS Round Bars Supplier in Naroda#SS Round Bars Supplier in Narol#SS Round Bars Supplier in Odhav#SS Round Bars Supplier in Rakhial#SS Round Bars Supplier in Sanand#SS Round Bars Supplier in Singarva#SS Round Bars Supplier in Vani#SS Round Bars Supplier in Vatva#SS Round Bars Supplier in Viramgam

0 notes

Text

Stainless Steel Round Bars Manufacturers in India SPP Metal and Alloys

We are well-known our round bars exports, and we provide our services all over the world. Manufacturers prominently utilize our round bars. SPP Metals and Alloys are leading Round Bars manufacturers in India. Stainless Steel Round Bars are the most used among round bars. We are prominent in steel exports, and our services are provided all over the world.

#Stainless Steel Round Bars#Steel Round Bars#SS Bars India#Metal Manufacturing Companies in India#Round Bars manufacturers in India#Stainless Steel Manufacturers India

0 notes