#shipyard cranes Singapore

Text

Looking for Shipyard Cranes in Singapore

A shipyard crane is a large and powerful machine used in shipbuilding and other heavy industrial construction. A typical shipyard crane in Singapore has a lifting capacity of tens of tonnes and is operated by a skilled crane operator. Shipyard cranes are used to move large pieces of steel and other construction materials around a shipyard. There are three main types of shipyard cranes: the crawler crane, the jib crane and the tower crane. Visit the website to explore more wide range of shipyard cranes. Contact us now!

#overhead travelling cranes#scissor lift platform hire#scissor lift platform supplier#telehandler suppliers in Singapore#Wheel Loader Singapore#shipyard cranes Singapore

0 notes

Text

Essential Insights on Wire Rope Hoists, Jib Cranes, Overhead Cranes, and Gantry Cranes in Singapore

Introduction:

In Singapore’s bustling industrial landscape, various lifting and material-handling equipment play a crucial role in optimizing efficiency and safety. Among these, wire rope hoists, jib cranes, overhead cranes, and gantry cranes have emerged as indispensable solutions.

This article delves into the functionalities and applications of these lifting systems, highlighting their significance in Singapore’s industrial sectors.

Wire Rope Hoists:

Wire rope hoists are robust lifting devices designed to transport heavy loads vertically. They employ high-tensile wire ropes wound around a drum, powered by an electric motor.

Wire rope hoists are known for their strength, durability, and versatility, making them ideal for various industrial applications, including construction, manufacturing, and warehousing.

2. Jib Cranes:

Jib cranes are versatile lifting mechanisms characterized by a horizontal boom, known as a jib, which supports a movable hoist. They are commonly used in workshops, docks, and warehouses to handle loads in a limited working area. Jib cranes offer 180-degree or 360-degree rotation, providing flexible and precise lifting and positioning capabilities.

These cranes consist of a bridge beam that traverses horizontally along elevated runways, with a hoist and trolley system for vertical and horizontal movements. Overhead cranes offer exceptional load capacities and can cover large areas, making them suitable for handling bulky and heavy objects.

4. Gantry Cranes:

Gantry cranes are similar to overhead cranes but operate on a different structure. Instead of runways, gantry cranes have supporting legs or columns that allow them to move on ground-level rails or wheels.

Gantry cranes excel in outdoor settings, such as shipyards, construction sites, and container terminals, where the need for mobility and flexibility is paramount.

Significance in Singapore’s Industrial Landscape:

The industrial sectors in Singapore greatly benefit from these lifting systems, playing a vital role in enhancing productivity, efficiency, and safety.

Wire rope hoists facilitate vertical material transportation in factories, construction sites, and logistics centers. Jib cranes offer optimal maneuverability, enabling precise and quick loading and unloading of goods.

Overhead cranes provide heavy-lifting capabilities for tasks involving large machinery or containers. Gantry cranes deliver the versatility required in outdoor environments, facilitating the efficient handling of cargo and materials.

Conclusion:

Wire rope hoists, jib cranes, overhead cranes, and gantry cranes are essential components of Singapore’s industrial infrastructure. Their diverse applications and functionalities cater to the unique lifting needs of different sectors.

By utilizing these advanced lifting systems, businesses in Singapore can enhance productivity, streamline operations, and ensure the safety of workers.

As technology continues to evolve, these lifting solutions will continue to play a pivotal role in Singapore’s industrial growth, contributing to a more efficient and prosperous economy.

0 notes

Text

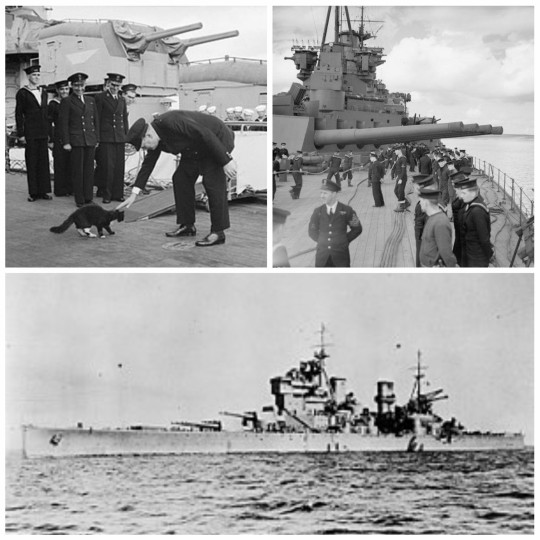

• HMS Prince of Wales

HMS Prince of Wales was a King George V-class battleship of the British Royal Navy. She had an extensive battle history, first seeing action in August 1940 while in her drydock when she was attacked by German aircraft.

In the aftermath of the First World War, the Washington Naval Treaty was drawn up in 1922 in an effort to stop an arms race developing between Britain, Japan, France, Italy and the United States. This treaty limited the number of ships each nation was allowed to build, and capped the tonnage of all capital ships at 35,000 tons. These restrictions were extended in 1930 through the Treaty of London, however, by the mid-1930s Japan and Italy had withdrawn from both of these treaties, and the British became concerned about a lack of modern battleships within their navy. As a result, the Admiralty ordered the construction of a new battleship class: the King George V class.

The main armament of the class was limited to the 14-inch (356 mm) guns prescribed under these instruments. They were the only battleships built at that time to adhere to the treaty, and even though it soon became apparent to the British that the other signatories to the treaty were ignoring its requirements, it was too late to change the design of the class before they were laid down in 1937. Prince of Wales was originally named King Edward VIII but upon his abdication the ship was renamed before she had been laid down. This occurred at Cammell Laird's shipyard in Birkenhead on January 1st, 1937, although it was not until May 3rd, 1939 that she was launched. She was still fitting out when war was declared in September, causing her construction schedule, and that of her sister, King George V, to be accelerated. During early August 1940, while she was still being outfitted and was in a semi-complete state, Prince of Wales was attacked by German aircraft. One bomb fell between the ship and a wet basin wall, narrowly missing a 100-ton dockside crane, and exploded underwater below the bilge keel. Buckling of the shell plating took place over a distance of 20 to 30 feet (9.1 m), rivets were sprung and considerable flooding took place in the port outboard compartments in the area of damage, causing a ten-degree port list. The flooding was severe, due to the fact that final compartment air tests had not yet been made and the ship did not have her pumping system in operation. The water was pumped out through the joint efforts of a local fire company and the shipyard, and Prince of Wales was later dry docked for permanent repairs. This damage and the problem with the delivery of her main guns and turrets delayed her completion. As the war progressed there was an urgent need for capital ships, and so her completion was advanced by postponing compartment air tests, ventilation tests and a thorough testing of her bilge and fuel oil systems.

She was powered by Parsons geared steam turbines, driving four propeller shafts. Steam was provided by eight Admiralty boilers which normally delivered 100,000 shaft horsepower (75,000 kW). This gave Prince of Wales a top speed of 28 knots (52 km/h; 32 mph). She also carried 180 long tons (200 t) of diesel oil, 256 long tons (300 t) of reserve feed water and 444 long tons (500 t) of freshwater. Prince of Wales had a range of 3,100 nautical miles (5,700 km; 3,600 mi) at 27 knots (50 km/h; 31 mph). Prince of Wales mounted 10 BL 14-inch (356 mm) Mk VII guns. The 14-inch guns were mounted in one Mark II twin turret forward and two Mark III quadruple turrets, one forward and one aft. The secondary armament consisted of 16 QF 5.25-inch (133 mm) Mk I guns which were mounted in eight twin mounts, weighing 81 tons each. Along with her main and secondary batteries, Prince of Wales carried 32 QF 2 pdr (1.575-inch, 40.0 mm) Mk.VIII "pom-pom" anti-aircraft guns. She also carried 80 UP projectors, which were short range rocket firing anti-aircraft weapons used extensively in the early days of the Second World War.

On May 22nd, 1941, Prince of Wales, the battlecruiser Hood and six destroyers were ordered to take station south of Iceland and intercept the German battleship Bismarck if she attempted to break out into the Atlantic. Captain John Leach knew that main-battery breakdowns were likely to occur, since Vickers-Armstrongs technicians had already corrected some that took place during training exercises in Scapa Flow. The next day Bismarck, in company with the heavy cruiser Prinz Eugen, was reported heading south-westward in the Denmark Strait. At 20:00 Vice-Admiral Lancelot Holland, in his flagship Hood, ordered the force to steam at 27 knots (50 km/h), which it did most of the night. His battle plan called for Prince of Wales and Hood to concentrate on Bismarck, while the cruisers Norfolk and Suffolk would handle Prinz Eugen. However the two cruisers were not informed of this plan because of strict radio silence. At 02:00, on 24 May, the destroyers were sent as a screen to search for the German ships to the north. At 05:37 an enemy contact report was made, and course was changed to starboard to close range. Neither ship was in good fighting trim. Hood, designed twenty-five years earlier, lacked adequate decking armour and would have to close the range quickly, as she would become progressively less vulnerable to plunging shellfire at shorter ranges. She had completed an overhaul in March and her crew had not been adequately retrained. Prince of Wales, with thicker armour, was less vulnerable to 15-inch shells at ranges greater than 17,000 feet (5,200 m), but her crew had also not been trained to battle efficiency.

At 05:53, despite seas breaking over the bows, Prince of Wales opened fire on Bismarck at 26,500 yards (24,200 m). There was some confusion among the British as to which ship was Bismarck and thirty seconds earlier Hood had mistakenly opened fire on Prinz Eugen as the German ships had similar profiles. Hood's first salvo straddled the enemy ship, but Prinz Eugen, in less than three minutes, scored 8-inch-shell hits on Hood. The first shots by Prince of Wales two three-gun salvoes at ten second intervals were 1,000 yards over. The sixth, ninth and thirteenth salvos were straddles and two hits were made on Bismarck. One shell holed her bow and caused Bismarck to lose 1,000 tons of fuel oil, mostly to salt-water contamination. The other fell short, and entered Bismarck below her side armour belt, the shell exploded and flooded the auxiliary boiler machinery room and forced the shutdown of two boilers due to a slow leak in the boiler room. Both German ships initially concentrated their fire on Hood and destroyed her with salvoes of 8- and 15-inch shells. Prince of Wales fired unopposed until she began a port turn at 05:57, when Prinz Eugen took her under fire. After Hood exploded at 06:01, the Germans opened intense and accurate fire on Prince of Wales, with 15-inch, 8-inch and 5.9-inch guns. A heavy hit was sustained below the waterline as Prince of Wales manoeuvred through the wreckage of Hood. At 06:02, a 15-inch shell struck the starboard side of the compass platform and killed the majority of the personnel there.

At 06:05 Captain Leach decided to disengage and laid down a heavy smokescreen to cover Prince of Wales's escape. Following this, Leach radioed the Norfolk that Hood had been sunk and then proceeded to join Suffolk roughly 15 to 17 miles (24 to 27 km) astern of Bismarck. Throughout the day the British ships continued to chase Bismarck until at 18:16 when Suffolk sighted the German battleship at 22,000 yards (20,000 m). Prince of Wales then opened fire on Bismarck at an extreme range of 30,300 yards (27,700 m), she fired 12 salvos but all of them missed. After losing Bismarck owing to poor visibility and after searching for 12 hours, Prince of Wales headed for Iceland and took no further part in actions against Bismarck.

Following repairs at Rosyth, Prince of Wales transported Prime Minister Winston Churchill across the Atlantic for a secret conference with US President Franklin D. Roosevelt. On August 5th, Roosevelt boarded the cruiser USS Augusta from the presidential yacht Potomac. Augusta proceeded from Massachusetts to Placentia Bay and Argentia in Newfoundland with the cruiser USS Tuscaloosa and five destroyers, arriving on August 7th. On August 9th, Churchill arrived in the bay aboard Prince of Wales, escorted by the destroyers HMS Ripley, HMCS Assiniboine and HMCS Restigouche. At Placentia Bay, Newfoundland, Roosevelt transferred to the destroyer USS McDougal to meet Churchill on board Prince of Wales. The conference continued from 10 to 12 August aboard the heavy cruiser USS Augusta and, at the end of the conference, the Atlantic Charter was proclaimed.

In September 1941, Prince of Wales was assigned to Force H, in the Mediterranean. On September 24th, Prince of Wales formed part of Group II, led by Vice-Admiral Alban Curteis. The force provided an escort for Operation Halberd, a supply convoy from Gibraltar to Malta. On September 27th, the convoy was attacked by Italian aircraft, with Prince of Wales shooting down several with her 5.25-inch (133 mm) guns. Later that day there were reports that units of the Italian Fleet were approaching. Prince of Wales, the battleship Rodney and the aircraft carrier Ark Royal were despatched to intercept, but the search proved fruitless. The convoy arrived in Malta without further incident, and Prince of Wales returned to Gibraltar.

On October 25th, Prince of Wales and a destroyer escort left home waters bound for Singapore, there to rendezvous with the battlecruiser Repulse and the aircraft carrier Indomitable. Indomitable however ran aground off Jamaica a few days later and was unable to proceed. Prince of Wales reached Colombo, Ceylon, on November 28th, joining Repulse the next day. On December 2nd, the fleet docked in Singapore. Prince of Wales then became the flagship of Force Z, under the command of Admiral Sir Tom Phillips. Japanese troop-convoys were first sighted on 6 December. Two days later, Japanese aircraft raided Singapore; although the Prince of Wales's anti-aircraft batteries opened fire, they scored no hits and had no effect on the Japanese aircraft. A signal was received from the Admiralty in London ordering the British squadron to commence hostilities, and that evening, confident that a protective air umbrella would be provided by the RAF presence in the region, Admiral Phillips set sail. The object of the sortie was to attack Japanese transports at Kota Bharu, but in the afternoon of 9 December the Japanese submarine I-65 spotted the British ships, and in the evening they were detected by Japanese aerial reconnaissance. By this time it had been made clear that no RAF fighter support would be forthcoming. At midnight a signal was received that Japanese forces were landing at Kuantan in Malaya. Force Z was diverted to investigate. At 02:11 on December 10th, the force was again sighted by a Japanese submarine and at 08:00 arrived off Kuantan, only to discover that the reported landings were a diversion.

At 11:00 that morning the first Japanese air attack began. Eight Type 96 "Nell" bombers dropped their bombs close to Repulse, one passing through the hangar roof and exploding on the 1-inch plating of the main deck below. Despite reports to the contrary, Prince of Wales was struck by only one torpedo. Meanwhile, Repulse avoided the seven torpedoes aimed at her, as well as bombs dropped by six other "Nells" a few minutes later. The torpedo struck Prince of Wales on the port side aft, abaft "Y" Turret, wrecking the outer propeller shaft on that side and destroying bulkheads to one degree or another along the shaft all the way to B Engine Room. This caused rapid uncontrollable flooding and put the entire electrical system in the after part of the ship out of action. Lacking effective damage control, she soon took on a heavy list. A fourth attack was conducted, this one scored hits on Repulse and she sank at 12:33. Six aircraft from this wave also attacked Prince of Wales, hitting her with three torpedoes, causing further damage and flooding. Finally, a 500-kilogram (1,100 lb) bomb hit Prince of Wales's catapult deck, penetrated to the main deck, where it exploded, causing many casualties in the makeshift aid centre in the Cinema Flat. Several other bombs from this attack scored very 'near misses', indenting the hull, popping rivets and causing hull plates to 'split' along the seams and intensifying the flooding. At 13:15 the order to abandon ship was given, and at 13:20 Prince of Wales capsized and sank; Admiral Phillips and Captain Leach were among the 327 fatalities.

Prince of Wales and Repulse were the first capital ships to be sunk solely by naval air power on the open sea (albeit by land-based rather than carrier-based aircraft), a harbinger of the diminishing role this class of ships was to play in naval warfare thereafter. It is often pointed out, however, that contributing factors to the sinking of Prince of Wales were her surface-scanning radars being inoperable in the humid tropic climate, depriving Force Z of one of its most potent early-warning devices and the critical early damage she sustained from the first torpedo. The wreck lies upside down in 223 feet (68 m) of water at 3°33′36″N 104°28′42″E. A Royal Navy White Ensign attached to a line on a buoy tied to a propeller shaft is periodically renewed. The wreck site was designated a 'Protected Place' in 2001 under the Protection of Military Remains Act 1986, just prior to the 60th anniversary of her sinking.

#second world war#world war 2#royal navy#british#british history#wwii#ww2#naval history#prince of wales#british navy

19 notes

·

View notes

Text

EVERYTHING ABOUT ABG SHIPYARD; INDIA’S BIGGEST BANK FRAUD

The Central Bureau of Investigation (CBI) has booked ABG Shipyard Limited, its previous Chairman and Managing Director Rishi Kamlesh Agarwal, alongside a few others including Executive Director Santhanam Muthaswamy, Directors Ashwini Kumar, Ravi Vimal Nevetia, and Sushil Kumar Agarwal for supposedly swindling a consortium of banks drove by State Bank of India of over Rs. 22,842 crore, making it India's greatest instance of bank extortion.

"Look were led on Saturday at 13 areas in the premises of denounced including privately owned business, chiefs at Surat, Bharuch, Mumbai, Pune, and so on which prompted the recuperation of implicating archives," said the CBI in a proclamation.

The SBI bank recorded the very first objection in 2019 on November eighth on which the CBI had looked for certain clarifications on March 12, 2020. A new grievance was again recorded in the long stretch of August around the same time. Subsequent to researching the case for oneself and a half years, the CBI followed up on the objection recording a FIR on February 7, 2022.

As per figures from the criminological review that were remembered for the CBI grumbling, ABG Shipyard Limited owed 70.89 billion rupees to ICICI Bank, 36.34 billion rupees to IDBI Bank, 29.25 billion rupees to the State Bank of India, 16.14 billion rupees to Bank of Baroda, 12.44 billion rupees to Punjab National Bank and 12.28 billion rupees to Indian Overseas Bank.

ABOUT ABG SHIPYARD?

It was March 15, 1985, when ABG Shipyard Limited (ABGSL) was consolidated with its enlisted office in Ahmedabad, Gujarat. It is a leader endeavor of the ABG Group, initially advanced by Rishi Agarwal. It is occupied with the matter of shipbuilding and boat fix. It has shipyards situated at Surat and Dahej in Gujarat with the ability to develop vessels to 18,000 extra weight (DWT) at Surat Shipyard and 1,20,000 extra weight (DWT) at Dahej Shipyard.

Since the foundation of the organization, it has built north of 165 vessels over the most recent 16 years including specific vessels like newsprint transporters, interceptor boats, drifting cranes, stacking mass concrete transporters, pusher pulls, dynamic situating plunging support vehicles, and so on

ABG SHIPYARD FRAUD: WHAT EXACTLY HAPPENED?

ABG Shipyard experienced gigantic accomplishment for certain years yet ran into tough situations from the year 2012. The credits were given to the organization between 2005-2010 by the banks.

The organization's credit account was first announced as NPA in July 2016. NPA alludes to Non-Performing Asset; it is a credit for which the head or interest installment is late for 90 days.

The review by Ernst and Young referenced that between 2012-2017, "the blamed have conspired together and serious criminal operations including redirection of assets, misappropriation and criminal break of trust and for purposes other than for the reason for which the assets are delivered by the Bank."

In April 2019, the National Company Law Tribunal (NCLT) requested the liquidation of the organization under the Insolvency and Bankruptcy Code (IBC).

In November 2019, SBI documented its first grievance against the organization.

"From the underlying examination, apparently the credits were endorsed somewhere in the range of 2005 and 2010. Apparently the cash was given out without due steadiness from the banks. The misrepresentation sum being scrutinized could be pretty much than what is reflected at this moment," said a CBI source.

Budget summaries uncovered that the organization redirected the advances it took from different Indian banks to buy inclination partakes in ABG Singapore worth $43.5 million.

0 notes

Text

Former SP Leader Amar Singh Passes Away At 64 In Singapore After Prolonged Illness

Former SP Leader Amar Singh Passes Away At 64 In Singapore After Prolonged Illness

[ad_1]

New Delhi: Former Samajwadi Party (SP) and Rajya Sabha MP Amar Singh passed away on Saturday in Singapore after prolonged illness. Singh, 64, was ill from sometime and was undergoing medical treatment at a hospital in Singapore since past few months. ALSO READ | Visakhapatnam: 11 Workers Crushed To Death After Massive Crane Collapses At Hindustan Shipyard

As per reports, Singh was…

View On WordPress

#Amar Singh#Amar Singh age#Amar Singh dead singapore#Amar Singh death#Amar Singh health#Amar Singh passed away#Amar Singh politician#Amar Singh rajya sabha#Amar Singh samajwadi party

0 notes

Link

0 notes

Text

Maximizing Efficiency with an Overhead Traveling Crane, Hoist Crane, and Gantry Crane

Wire rope hoist

A wire rope hoist is a type of lifting equipment that utilizes wire rope to lift and move heavy loads. Wire rope hoists are commonly used in various industries such as construction, manufacturing, and transportation due to their advanced lifting capabilities, ease of load handling, and repeated duty cycles.

They are available in a variety of designs and functionalities, including basic hoist units for integration into plant and machinery, as well as lifting units for hazardous environments and spark resistance. Some of the leading manufacturers of wire rope hoists include Demag Cranes and Components, ACCO Material Handling Solutions, Yale, Harrington Hoists, and McMaster-Carr.

Overhead traveling crane

An overhead traveling crane, also known as a bridge crane or suspended crane, is a type of crane that is used to lift and move heavy loads horizontally. It consists of a bridge that spans the width of the work area and moves along rails mounted on a runway beam. The hoist and trolley are mounted on the bridge and move along the length of the bridge to lift and transport the load. Overhead traveling cranes are commonly used in manufacturing, construction, and transportation industries for heavy-duty material handling operations.

Hoist crane

A hoist crane, also known as a chain hoist, is a type of crane that is used to lift and move heavy loads vertically. It consists of a hoist unit that is mounted on a frame or stationary structure and a chain or wire rope that is used to lift and lower the load. Hoist cranes are commonly used in industries such as automotive, construction, and logistics for material handling operations that require lifting and lowering of heavy loads.

Gantry crane

A gantry crane is a type of crane that is used to lift and move heavy loads horizontally and vertically. It consists of a bridge that spans the work area and is supported by two or more legs that run on rails or wheels. The hoist and trolley are mounted on the bridge and move along the length of the bridge to lift and transport the load.

Gantry cranes are commonly used in shipyards, construction sites, and manufacturing plants for material handling operations that require lifting and transporting heavy loads over a wide area.

In summary, each type of crane has its unique features and applications. Overhead traveling cranes are suitable for heavy-duty material handling operations that require horizontal movement of heavy loads. Hoist cranes are ideal for lifting and lowering heavy loads vertically. Gantry cranes are versatile and can be used for both horizontal and vertical movement of heavy loads over a wide area.

Jib crane Singapore

Jib cranes are a popular type of lifting equipment used in Singapore. Shin Guan Singapore offers wall-mounted and pillar jib cranes, which have a load capacity of up to 2,000 kg and a slewing motion that can reach up to 300 degrees with a pillar jib and 270 degrees with a wall-mounted jib.

The cranes have multiple designs for jib arms based on customer requirements. Shin Guan also provides slewing jib cranes that are efficient for spot-loading activities, such as assembling and repairing pumps, valves, and motors.

Shin Guan Cranes offers Jib cranes that provide lifting in a single workstation for compact and easy installation. These cranes can be used as a small capacity cranes for workstation lifting systems for maintenance, assembly, or QC type of operation.

Overhead crane

Overhead cranes are another commonly used type of lifting equipment in Singapore. These cranes are installed on the ceiling or roof of a building and are used to lift and move heavy loads in a horizontal direction.

Overhead cranes are commonly used in manufacturing plants, warehouses, and construction sites.

Shin Guan Singapore provides a range of overhead cranes, including single-girder, double-girder, and underslung cranes.

These cranes have a load capacity of up to 10,000 kg and can be customized to meet specific customer requirements. The company also offers automated cranes that can be programmed to perform repetitive tasks, which can improve productivity and reduce labor costs.

Another company that provides overhead cranes in Singapore is Street Crane. They offer a range of overhead cranes, including single-girder, double-girder, and underslung cranes.

The company also provides automated cranes that can be programmed to perform specific tasks, such as material handling and assembly line operations.

Several other companies in Singapore provide overhead cranes, including Hitachi Industrial Equipment Systems, Mitsubishi Electric Asia, and Demag Cranes & Components. These companies offer a range of cranes with different specifications and features, allowing customers to choose the crane that best suits their specific needs.

Overall, overhead cranes are an important type of lifting equipment used in Singapore, and several reputable companies provide these cranes to customers.

0 notes

Text

NYK Names New LNG Carrier ‘Marvel Crane’ At MHI

On February 21, a naming ceremony was held in Nagasaki at the Koyagi Shipyard of Mitsubishi Heavy Industries Ltd. for a new liquefied natural gas (LNG) carrier that NYK will charter to Mitsui & Co., Ltd. under a long-term contract.

On February 21, a naming ceremony was held in Nagasaki at the Koyagi Shipyard of Mitsubishi Heavy Industries Ltd. for a new liquefied natural gas (LNG) carrier that NYK will charter to Mitsui & Co., Ltd. under a long-term contract.

At the ceremony, the ship was named “Marvel Crane” by Hiroyuki Kato, Counselor of Mitsui & Co., Ltd., and the ceremonial rope holding the vessel in place was cut by Mr. Kato’s wife. From NYK, Hitoshi Nagasawa, representative director and executive vice-president corporate officer, was in attendance.

Following the delivery of Marvel Falcon last year, Marvel Crane is the second LNG vessel for which NYK has concluded a long-term time-charter contract with Mitsui & Co., Ltd. for the Cameron LNG Project. After the delivery of Marvel Crane on March 28, the ship will begin to transport LNG from the U.S. state of Louisiana and other locations around the world for up to 25 years, including optional extension periods. The NYK Group will be responsible for ship management.

The new vessel has apple-shaped tanks that have greater LNG-carrying capacity, and the vessel is equipped with a hybrid propulsion system combining a steam turbine and engines that can be fired by gas (STaGE; Steam Turbine and Gas Engines), resulting in dramatic cuts in fuel consumption and CO2 emissions.

In accordance with its medium-term management plan “Staying Ahead 2022 with Digitalization and Green,” the NYK Group seeks to secure stable freight rates through long-term contracts and continue its efforts to contribute to a stable supply of LNG as environment-friendly energy.

Outline of Marvel Crane

Length overall: 293.0 meters

Breadth: 48.94 meters

Gross tonnage: 142,500 tons

Main engine: STaGE (Steam Turbine and Gas Engines)

Cargo tank capacity: 177,000 cubic meters

Shipbuilder: Mitsubishi Shipbuilding Co. Ltd.

Flag: Singapore

Press Releases: nyk.com

Photo Courtesy: nyk.com

The post NYK Names New LNG Carrier ‘Marvel Crane’ At MHI appeared first on Maritime Manual.

from WordPress https://www.maritimemanual.com/nyk-names-new-lng-carrier-marvel-crane-at-mhi/

0 notes

Text

JD Neuhaus: ‘Our values will deliver our vision’

When a company sells a division, the restructuring that follows often creates a chance to review its values and vision, as JD Neuhaus UK managing director Steve Walker explains.

More than a year ago JD Neuhaus (JDN) sold the UK rental division of the company to LGH UK, but the business continues to serve the oil and gas sector with class-leading technology.

By selling the rental fleet, Steve Walker was afforded the opportunity to allow the company to refocus on JDN Group’s global values from its head office in Germany.

“I am of the firm belief that our specific values in the UK team will ensure we deliver our vision of growth over the next two to three years,” he said.

JDN UK has spent the last year shaping and leading the team in the UK while moving into, and kitting out, their refurbished facilities in Kirkton Avenue to suit their needs.

“We decided it was important to remain in the same area of the city to ensure that we can provide our customers with the same high level of service they have always received from us in the past,” said Mr Walker.

With more than 200 employees across the JDN worldwide group, JDN has been at the vanguard of hoist and crane technology for more than 270 years, whether for moving heavy or light loads.

Products are manufactured from a state-of-the-art facility in Witten, Germany.

This globally unique specialisation means JD Neuhaus has set the quality standard for the market, a move that has seen the company become the established global leader in its technology field with customers in more than 90 countries worldwide.

In the UK, JDN is highly focused on applications, sales and after-sales, including service and parts.

The company has a streamlined and highly efficient workshop staffed by engineers and supported by a team comprising sales, after-sales, accounts and administration staff.

JDN’s UK-based engineers also work in the field, providing customers with any required hoist or crane support.

Strong relationships with oil and gas operators and service companies have allowed JDN to enhance its global reputation as industry leader for hoist and monorail systems.

Very much part of JDN’s global brand and strategy, the UK business remains as robust as ever. Despite the sale of the rental business, the firm continues to grow its other UK divisions, which include sales and repair.

Safety and reliability are primary requisites in the oil and gas sector.

Here, JDN is adept at supplying hoists with a lift capacity from 125kg up to 115 tonnes, in line with ATEX certification.

Its hoists are high-durability products rated as explosion-proof/spark-resistant and powered by compressed air or hydraulics, with corrosion-resistant options available

Furthermore, the 100% duty-free cycle of the equipment, which can be used directly in applications or as part of OEM material-handling devices, allows operatives around the world to work longer and harder.

Customised lifting and control systems can be accommodated with load-test certifications available through DNV, ABS, Lloyds and others.

Typical offshore equipment loads include BOP handling, FPSO vessel mooring/tensioning, and a wide range of general materials handling requirements on jack-up rigs, semi-submersibles and drill ships.

On a global basis, the company has a worldwide sales, service and support network, working with major clients across the oil and gas sector. Recent service exchange contracts have taken place with major drilling companies such as Ensco, Maersk, Rowan and Shelf.

JDN products were recently involved in preparation of the major decommissioning project in the North Sea for Shell’s Brent Delta platform.

Mr Walker said the Brent Delta project was a unique chance for JDN to solve a major problem for its client with a bespoke hoist-and-trolley combination arrangement.

“Our R&D team in Germany designed a trolley which allowed our 25-tonne hoists to operate safely at an angle of up 30 degrees while hanging off the underside of the rig,” he said.

“This in turn reduced the amount of equipment required on site as well as the time taken to complete the particular work scope our hoists were involved with.”

Brent Delta was the single biggest lift carried out in the North Sea sector.

With a heavy focus on R&D, JDN ensures its range continues to evolve.

Its latest products have been engineered to offer extended service life, simple operation and ecological compatibility, all without any compromise in safety or performance.

The latest innovations from JDN include a remote-control concept that brings exceptional ease of use and convenience to users. Comprising a transmitter and receiver, the JDN-RC (remote control) is available for new and retrofit applications.

Mr Walker said: “JD Neuhaus will be 275 years old in 2020. We are still a family owned company which brings a sense of tradition to the group. We are extremely proud of this fact but this does not mean that we are always looking in the past. Quite the contrary, one of our goals is to always do things a little better than they need to be. It is a tradition in our group to think ahead.”

The company’s range is broad and feature-rich, so virtually every type of general application can be served.

Products include pneumatic cranes, C-rail/light crane systems, pneumatic hoists (PROFI, Mini and M ranges), manipulators, trolleys (including low-headroom versions), big bag handling hoists, ratchet hoists and monorail hoists.

Mr Walker said: “In addition to the oil and gas sector our products are in use in a vast range of areas throughout the world, ranging from food and pharmaceutical production, right through general manufacturing and on to heavy industries such as the chemical industry, mining, steelworks and shipyards.”

JDN was OEM supplier for the QUAD 204 project turret hoists. Mr Walker said: “This was an example of the JDN group working together to meet ongoing requirements at various stages of a key project.

“Initially supplying the hoists through our French sister company for the construction phase, JDN UK became involved in terms of offering engineering support for the commissioning and final testing phase in the Norway.

“We then supported the project with planned maintenance routine visits on location to ensure these key pieces of equipment were ready to operate when called upon by the QUAD 204 team.”

He said JDN Germany provided technical support for both offices throughout the project from

design straight through to the final sign-off.

JDN has facilities in many of the world’s major oil and gas markets, including the US, Singapore, France, UK and Germany. All its products are engineered for extremes, and are proven to withstand the harsh operating environments associated with working offshore.

The post JD Neuhaus: ‘Our values will deliver our vision’ appeared first on Energy Voice.

from Oil & Gas – Energy Voice https://ift.tt/2RCuasl

0 notes

Text

Our wedding video No Further a Mystery | +91-880-011-9847

This article originally appeared on the We coordinate together with your place supervisor/ Resourceful director to strategically photograph your facility and merchandise.For Out Of The Case And Customized Styles Of Wedding Photography Just Call At +91-880-011-9847.

So, it covers multidisciplinary types of photography collectively.If you would like get live photography instantly then head to wedlockcapture.com which delivers very best live photography in Singapore.

Logistics and transportation of Container Cargo ship and Cargo plane with working crane bridge in shipyard at sunrise, logistic import export and transport industry qualifications

We appreciate that some processes can’t simply be interrupted – Our pics are taken all through regular Functioning or ‘away from hrs’.

According to the shoppers necessity we do needed web-site go to and accordingly we shoot for his or her reason. According to the topic and with the help on the Artwork Office we make the product.

Industrial photography calls for an knowledge of your necessity and enterprise the shoot accordingly. Our goal is to accommodate your prerequisites and supplyprofessional wedding photography that matches in with all your programs.

Together with the safety gear, I arrive Outfitted which has a 4WD so access to the remotest areas is rarely a problem. Camping out is usually needed to ensure I’m up and ready to shoot at sunrise or to shoot night time time functions.

What?????? Following reading your blog site for the last two times and hearing about the Artistic songs and musicians you so pretty meticulously chose, I could barely wait for the video. What???!? Canned tunes??? Make sure you convey to me you've got the natural and organic video/audio somewhere! If you are doing…you should publish!!!!

I’ve study many of the weblogs around the wedding, and now to begin to see the video I come to feel like I was a Exclusive guest at your wedding ! These types of a gorgeous working day stuffed with so much appreciate! Congratulations.

In the beginning, I used to be really adamant about not using a wedding. I imply I actually fussed and fought The concept. I assumed going to the courthouse can be simpler considering the fact that my mother is partying it up in Heaven and couldn’t enable it to be. The concept of her not being capable to witness her preferred Lady’s Exclusive day was quite a bit for me to bear.

My most loved point on the globe is paying time within the desk with excellent folks and good foods. So I established this website comprehensive of wedding photography simple, fast, and irresistibly delicious recipes which might be great for sharing with These you like. ♥ more details on me.

Candid wedding photographer, Wedding photographer,8800119847,high-end wedding photographer, pre-wedding photography, wedding photographer in Delhi NCR,Wedding photography packages, high-end wedding photographer, wedding photographer in Delhi NCR,Candid wedding photographer,8800119847, pre-wedding photography, wedding photographer in Delhi NCR,,pre-wedding photography.

Key Features

Candid wedding photographer,

Wedding photography packages in India

Indian wedding photography price,

Wedding photographer,

High-end wedding photographer

This article originally appeared on the http://photography-agency.blogspot.com/2018/05/our-wedding-video-no-further-mystery-91.html

#Candid wedding photographer#Wedding photographer#High-end wedding photographer#Wedding photography packages in India#wedding photographer in Delhi NCR

0 notes

Text

Jurong Shipyard fined S$230,000 over fatal accident

Jurong Shipyard fined S$230,000 over fatal accident

SINGAPORE: Jurong Shipyard has been fined S$230,000 for a fatal incident in 2015, in which a worker died from injuries sustained after he was struck and caught between a gantry crane and a manifold, the Ministry of Manpower (MOM) said on Monday (Jun 4).

In a press release, MOM said Jurong Shipyard had pleaded guilty to an offence of failing to take reasonably practicable measures to ensure that…

View On WordPress

0 notes

Text

Transocean Announces 5-Year USD 830 Million Drilling Contract For Newbuild Ultra-Deepwater Drillship

Transocean Ltd. announced that it has signed a rig design and construction management contract, as well as a five-year drilling contract, with Chevron USA, Inc. (“Chevron”) for one of its two dynamically positioned ultra-deepwater drillships (“the drillship”) currently under construction at the Jurong shipyard in Singapore. The drilling contract has an estimated backlog of $830 million USD, excluding mobilization and reimbursables. The drilling contract is subject to design, construction, and delivery requirements set forth in the construction contract.

The rig will be the first ultra-deepwater floater rated for 20,000 psi operations and is expected to commence operations in the Gulf of Mexico in the second half of 2021.

In the event of termination for convenience by the customer, Transocean will be compensated for its incremental 20,000 psi subsea investment in the rig. Additionally, a termination for convenience occurring after April 2020, would result in a substantial termination fee.

The drillship will feature the most advanced capabilities and state-of-the-art technology available including dual 20,000 psi blowout preventers, net hook-load capacity of three million pounds, 165-ton active heave compensating crane, and an enhanced dynamic positioning system. The rig’s high reliability power plant will also be configured to comply with Tier III International Maritime Organization emissions standards.

“We are extremely pleased to announce that we have entered into an agreement with Chevron to construct and operate the industry’s most capable ultra-deepwater drillship,” said Jeremy Thigpen, President and CEO. “Transocean has a long and storied history of introducing new technologies that enable our customers to safely and efficiently access the world’s most challenging reservoirs. Adding to that history, we are proud to be delivering the industry’s first rig capable of drilling and completing wells requiring subsea equipment rated to 20,000 psi.”

Thigpen concluded: “On behalf of Transocean, I thank Chevron for their long-standing partnership, and trust in our capabilities. I also thank the members of the Chevron and Transocean teams who have spent countless hours on the development of this game-changing solution.”

Press Releases: deepwater.com

Photo Courtesy: deepwater.com

The post Transocean Announces 5-Year USD 830 Million Drilling Contract For Newbuild Ultra-Deepwater Drillship appeared first on Maritime Manual.

from WordPress https://www.maritimemanual.com/transocean-announces-5-year-usd-830-million-drilling-contract-for-newbuild-ultra-deepwater-drillship/

0 notes

Text

Breaking Barriers

Growing-up in Boston in the 1990s, the coastal landscape featured a Goliath-sized crane, a 3,000-ton gantry crane at General Dynamics’ Fore River Shipyard.

“It’s the second largest crane in the world,” my father would tell me. “The biggest one is in Russia.” I don’t know if that last part was true, but it’s a fond memory of my father. What I do know is that the massive Fore River crane was a phenomenal piece of machinery that was also completely unemployed and useless in all the years I looked at it. When I was 20, the majestic beast was finally dismantled and eventually reassembled in Romania at the Magnolia Shipyard, but not before taking the lives of three local New Englanders working on its dismantling between 2005 and 2008.

As a child, looking up at the Goliath crane was awe-inspiring. As an adult, I consider it kind of depressing – and certainly in a financial sense. During its time in Boston, that crane spent 11 years working, constructing eight LNG tankers and five maritime prepositioning ships, followed by 22 years of sitting idle as a 100-meter-tall piece of art.

Shipyard owners, terminal operators and vessel owners may well appreciate art as much as anyone, but it’s generally not what they’re looking for when buying cranes for their facilities and ships. In an age of rapidly developing technology, practicality is still paramount.

For example, smart or intelligent features such as target positioning, sway control, 3D wire monitoring, automatic cooling and many other automated or semi-automated technologies stand to improve safety and efficiency. Likewise, cranes are lifting heavier loads with wider radii under more extreme conditions and with greater mobility and versatility.

Environmentally friendly options are also on the rise. Yet the realistic goal for marine crane manufacturers is most often to simply find the right fit for the customer. Appropriately, the crane manufacturing industry is advancing in this way, offering sustainable machines and long-lasting value.

Custom Builds

Dario Ricci, CEO of Heila Cranes, says it’s a matter of knowing what’s relevant in the maritime industry, of being able to offer proven solutions to his customers. Heila competes with larger-sized crane manufacturers by having the expertise to personalize custom marine cranes, fitting them to a great variety of vessels (including yachts) across several maritime sectors.

Providing quality customization often means knowing what questions to ask of the customer and having the experience to notice opportunities and discrepancies while in the design phase. Fitting a crane to the park space of a vessel, meeting the needs of classification societies, knowing the trade-offs of a design model and taking into account protocols, servicing and revisions – there’s a lot more than just technology at play in the making of a custom-built crane.

Specifically, the telescopic knuckle boom crane is an area where Heila leads the market. Developed in 2018, the HLRM 1000-6S, a 70-ton foldable knuckle telescopic crane, boasts a rating of 1,000 tons per meter. Dario says this crane “will dramatically change the heavy-duty crane market. It’s equipped with a telescopic arm that can extend to a maximum radius of 30 meters. In a stored position, however, the crane requires only minimal space.”

Heila offers crane options from stock or with quick delivery in addition to its custom builds. The many types they manufacture include offshore cranes, lattice boom cranes and truck-mounted cranes. With input from customers, these cranes can be customized as to length, lifting capacity and sea-state working conditions.

Heila’s research, development and manufacturing are all located in Reggio Emilia, Italy, near Parma. Service branches are located in the Netherlands and Singapore, providing quality after-sales service. Commissioning, inspections, revisions and managing spare parts are all part of the Heila package, making it a leading crane manufacturer – proven solutions done right.

3D-Printed Crane Hooks

Netherlands-based Huisman is a household name in cranes, and lately it’s been innovating crane manufacturing with the use of 3D printing. The American Bureau of Shipping recently certified a 3D-printed, 36,000-kilogram crane hook from Huisman, and the Netherlands-based manufacturer has more scheduled for production.

For many, it’s a sensational thing to be able to 3D-print anything. While 3D-printable wrenches and screwdrivers might be considered a technological marvel, 3D-printed heavy machinery starts to feel like we’re living in a science fiction movie. Perhaps we’ll soon be building ships with 3D printing. Perhaps in the galley we’ll soon replace our cooks with 3D printers that can create hamburgers from seaweed.

Moreover, it often seems like the maritime industry is implementing technologies that have already been proven elsewhere. But in this case Huisman’s groundbreaking 3D crane hooks will be used offshore with the maritime industry setting the pace for innovation.

This particular 3D printing technology was developed by Cranfield University, located about 50 miles north of London. It’s called Wire Arch Additive Manufacturing (WAAM), and Huisman is using it to produce parts that are stronger than those made with traditional casting methods. The technology might be understood as a highly sophisticated application of the traditional use of wire feedstock to weld repairs.

It’s certainly interesting to think about the implications of being able to 3D-print heavy equipment. Costs for warehousing and logistics and the ways in which designs are sold and delivered are just a few aspects of how the industry could change with this technology. Let’s see what happens.

Huisman also recently contributed to the creating of a new world record. Two Huisman 10,000-ton revolving cranes, featured on the Heerema semi-submersible vessel Sleipnir, carried out the largest lift ever by a crane vessel. The Sleipnir broke the world record with a tandem lift of 15,300 tons, which was a single portion of the combined 24,000-ton topside installation for the Leviathan gas field off the coast of Israel. The 24,000-ton operation was completed in an amazing 20 hours.

Everything’s Bigger in Texas

Welcoming the challenge of exotic requests for custom crane manufacturing is ACE World Companies. The American company manufactures more than 85 percent of the components used in its machines – they even create their own software – and love it when a customer presents a challenge by asking, “Can it be done?”

Headquartered in Fort Worth, Texas, the old adage “Everything’s bigger in Texas” may be applicable to ACE’s founding principles. Established in 1987, the company’s vision was to differentiate itself from other American builders by specializing in the biggest and most complicated jobs, manufacturing the designs that no one else wanted to attempt.

Ace provides crane solutions internationally. For ports, it offers smooth-functioning Electric Overhead Traveling gantry cranes ranging from 10 to 400 tons. Providing solutions to industry demands, these machines are built to be quick and reliable in harsh conditions. Given its size and experience, ACE is able to serve many different industries with proven solutions.

German/Swiss Giant

Another household name in cranes is Liebherr, the Swiss-based company with German roots that makes some of the biggest cranes in the world. The numbers show Liebherr’s Mobile Harbor Cranes (MHCs) of various sizes are in high demand. Liebherr’s influence is far-reaching, and it’s involved in developing new port capabilities in places like inland India and Africa. Recent sales of its world’s largest MHC, the LHM 800, include ports in Qatar, Mexico, Italy and Uruguay.

In August, Liebherr inaugurated a TCC 78000, a streamlined new rail-mounted traveling gantry crane, at the port of Rostock, Germany. With a lifting capacity of 1,600 tons, the TCC 78000 is a heavy-duty crane and a heavy-duty investment for the port. Before the end of 2019, the Rostock TCC 78000 is expected to install an even more powerful Liebherr crane onto the bed of the Orion, a DEME 216.5-meter offshore installation vessel.

Bigger, Faster, Safer

In 2018 and 2019 crane manufactures broke several barriers, increasing lift capacities of telescopic and mobile cranes, setting a record for a lift by a crane vessel, implementing 3D-printed, heavy-duty equipment, and providing solutions in developing areas of the world – going bigger, faster and safer.

There was also the development of fiber line-using cranes, such as the MacGregor FirbreRope Off-Shore crane, which uses a Lankhorst fiber rope that is environmentally friendly in that it requires no greasing. This lightweight and neutral-buoyant fiber rope ultimately increases the lifting capacity of small vessels. There was also the continued development of all-electric cranes like the Liebherr LPS 420 E, which contributes to the feasibility of all-electric port facilities.

At this rate of innovation, perhaps I will one day be writing an article on marine cranes that feature heavy load-lifting laser beams and anti-gravity technology. In the meantime, here’s to the proven solutions that are safe and reliable as well economically and environmentally practical! – MarEx

Joey Pessa holds an MBA from Texas A&M at Galveston and is an officer in the Strategic Sealift Ready Reserve Group.

from Storage Containers https://www.maritime-executive.com/article/breaking-barriers

via http://www.rssmix.com/

0 notes

Text

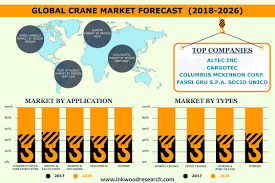

Industrial crane market is expected to witness market growth at a rate of stable CAGR in the forecast period of 2021 to 2028.|Key Competitors Konecranes, Sumitomo Heavy Industries Material Handling Systems Co., Ltd., GORBEL INC., North American Industries, ElectroMech

Industrial crane market is expected to witness market growth at a rate of stable CAGR in the forecast period of 2021 to 2028. Data Bridge Market Research report on industrial crane market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecast period while providing their impacts on the market’s growth. A crane is an automobile armed with wires, chains, or ropes to lift and lower materials or displace materials that are heavy and beyond human physical ability. Cranes comes in a different of sizes and are used in industries for example construction, mining, and marine. An industrial crane is advanced to bear heavy materials from one place to another. It involves with wire ropes, chains, sheaves, and hoist rope. It is chiefly utilized in industries, for instance metal production, railways, construction, petrochemical, and mining.

The growing of the manufacturing industry and other combined industries are factors further expected to boost the growth of the industrial crane market in the forecast period. The increase of the construction industry and swift modernization are further estimated to fuel the growth of the industrial cranes market during the forecast period. Factors such as rapid industrialization, the growing need of industrial crane from several, end industries are anticipated to further propelled the growth of the industrial crane market during the forecast period. Moreover, the increasing technological developments and rising of the construction and mining industry are the one of the major factors expected to further cushion the growth of the industrial crane market in the forecast period. Despite that, the high manufacturing price is most likely expected to become a hindrance in the growth of the industrial crane market. Furthermore, high maintenance cost, absence of competent and adept professional are also factors expected to further hamper the growth of the industrial crane market.

Global Industrial Crane Market, By Configuration (Single Girder Cranes, Double Girder Cranes, Gantry Cranes, Jib Cranes, Shipyard Cranes, Stacker Crane, Others), Hoist Arrangement (Top Running Type, Under Hung Type), Movability (Mobile Cranes, Fixed Cranes, Others), End-Use Industries (Metal Production Industries, Waste Management Industries, Ports & Ship Terminals Industries, Railway, Manufacturing Industries, Construction & Infrastructure Industries, Petrochemical Industries, Others Industries), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028 This industrial crane market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on industrial crane market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Get Sample PDF of Industrial crane market Report (including COVID19 Impact Analysis) @ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-industrial-crane-market

Industrial Crane Market Scope and Market Size:

The industrial crane market is segmented on the basis of configuration, hoist arrangement, movability and end-use industries. The growth among segments helps you analyze niche pockets of growth and strategies to approach the market and determine your core application areas and the difference in your target markets.

Based on the configuration, the industrial crane market is segmented into single girder cranes, double girder cranes, gantry cranes, jib cranes, shipyard cranes, stacker crane, others.

Based on the hoist arrangement, the industrial crane market is segmented into top running type, under hung type. Based on the movability, the industrial crane market is segmented into mobile cranes, fixed cranes, others. Based on the end-use industries, the industrial crane market is segmented into metal production industries, waste management industries, ports and ship terminals industries, railway, manufacturing industries, construction and infrastructure industries, petrochemical industries, other industries.

Key Market Competitors:

The major players covered in the industrial crane market report are Konecranes, Sumitomo Heavy Industries Material Handling Systems Co., Ltd., GORBEL INC., North American Industries, ElectroMech, Terex Corporation., Street Crane Company Limited, Kundel Industries, American Crane, Uesco Cranes, Whiting Corporation, Asian Cranes & Elevators, Lampson International LLC, and Liebherr.

MAJOR TOC OF THE REPORT:

Chapter One: Industrial Crane Market Overview

Chapter Two: Manufacturers Profiles

Chapter Three: Industrial Crane Market Competition, by Players

Chapter Four: Industrial Crane Market Size by Regions

Chapter Five: Industrial Crane Market Revenue by Countries

Chapter Six: Industrial Crane Market Revenue by Type

Chapter Seven: Industrial Crane Market Revenue by Application

Chapter Eight: Industrial Crane Market Revenue by Industries

Chapter Nine: Industrial Crane Market Revenue by Deployment Model

Chapter Ten: Industrial Crane Market Revenue by End User

Get Table of Content on Request https://www.databridgemarketresearch.com/toc/?dbmr=global-industrial-crane-market

Reasons for buying this Industrial Crane Market Report

Laser Capture Industrial Crane Market report aids in understanding the crucial product segments and their perspective.

Initial graphics and exemplified that a SWOT evaluation of large sections supplied from the Laser Capture Industrial Crane Market industry.

Even the Laser Capture Industrial Crane Market economy provides pin line evaluation of changing competition dynamics and retains you facing opponents.

This report provides a more rapid standpoint on various driving facets or controlling Medical Robotic System promote advantage.

This worldwide Locomotive report provides a pinpoint test for shifting dynamics that are competitive.

The key questions answered in this report:

What will be the Market Size and Growth Rate in the forecast year?

What is the Key Factors driving Laser Industrial Crane Market?

What are the Risks and Challenges in front of the market?

Who are the Key Vendors Industrial Crane Market?

What are the Trending Factors influencing the market shares?

What is the Key Outcomes of Porter’s five forces model

Access Full Report @ https://www.databridgemarketresearch.com/reports/global-industrial-crane-market

Browse Related Report:

Electric Vehicle Connectors Market

Alternator Market

Bow and Stern Thrusters Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

0 notes

Photo

Shipyard

Zürichsee-Schifffahrtsgesellschaft in Zürich-Wollishofen, Switzerland Gdynia Shipyard Constanța Shipyard, Romania Shipyards and dockyards are places where ships are repaired and built. These can be yachts, military vessels, cruise liners or other cargo or passenger ships. Dockyards are sometimes more associated with maintenance and basing activities than shipyards, which are sometimes associated more with initial construction. The terms are routinely used interchangeably, in part because the evolution of dockyards and shipyards has often caused them to change or merge roles. Countries with large shipbuilding industries include China, Singapore, South Korea, Japan, Russia, Germany, Netherland, Sweden, Ukraine, Finland, Denmark, Australia, India, Brazil, Taiwan, Romania, Poland . The shipbuilding industry tends to be more fragmented in Europe than in Asia. In European countries there are a greater number of small companies, compared to the fewer, larger companies in the shipbuilding countries of Asia. Most shipbuilders in the United States are privately owned, the largest being Huntington Ingalls Industries, a multibillion-dollar defense contractor, and the oldest family owned shipyard being Colonna's Shipyard in Norfolk, VA. The publicly owned shipyards in the US are Naval facilities providing basing, support and repair. Shipyards are constructed nearby the sea or tidal rivers to allow easy access for their ships. In the United Kingdom, for example, shipyards were established on the River Thames (King Henry VIII founded yards at Woolwich and Deptford in 1512 and 1513 respectively), River Mersey, River Tees, River Tyne, River Wear and River Clyde – the latter growing to be the World's pre-eminent shipbuilding centre. Sir Alfred Yarrow established his yard by the Thames in London's Docklands in the late 19th century before moving it northwards to the banks of the Clyde at Scotstoun (1906–08). Other famous UK shipyards include the Harland and Wolff yard in Belfast, Northern Ireland, where Titanic was built, and the naval dockyard at Chatham, England on the Medway in north Kent. The site of a large shipyard will contain many specialised cranes, dry docks, slipways, dust-free warehouses, painting facilities and extremely large areas for fabrication of the ships. After a ship's useful life is over, it makes its final voyage to a shipbreaking yard, often on a beach in South Asia. Historically shipbreaking was carried on in drydock in developed countries, but high wages and environmental regulations have resulted in movement of the industry to developing regions.

More details Android, Windows

0 notes

Photo

Nice view from the office ⛓💥⛓ @jarkdred @jarkdred ⛓💥⛓ #oil #oilrig #oilfield #oilandgas #oilmarket #offshore #offshorework #offshorelife #offshorelifestyle #singapore #asia #shipyard #jackup #rig #picoftheday #worktime #picoftheday #legs #oilfield #oilfieldlife #oilpicture #helideck #crane #derrick #oilfieldlife

#worktime#offshorelife#oilfieldlife#asia#crane#jackup#legs#picoftheday#offshore#helideck#shipyard#rig#offshorework#oilrig#oilandgas#oilfield#derrick#oil#offshorelifestyle#oilmarket#oilpicture#singapore

0 notes