#powertrain components

Text

"The Advantages of Powershift Transmissions in the Automobile Industry"

Powershift transmissions are a type of automated manual transmission (AMT) that offer numerous benefits to the automobile industry. Unlike traditional manual transmissions, which require manual shifting of gears, Powershift transmissions use computer controls and hydraulic actuators to change gears. This allows for a more efficient and smoother gear shifting process, leading to improved driving performance and fuel economy. Additionally, Powershift transmissions offer enhanced durability and reliability compared to traditional manual transmissions.

One of the biggest advantages of Powershift and automatic transmission is their ability to improve fuel economy. The computer-controlled shifting process ensures that the engine is always operating at the most efficient RPM range, reducing fuel consumption and emissions. This results in significant cost savings for both the manufacturer and the consumer, making Powershift transmissions an attractive option for the eco-conscious driver.

Powershift transmissions are also favored for their ease of use and comfort. The computer-controlled gear shifting eliminates the need for manual gear shifting, making the driving experience smoother and more enjoyable. This can be especially beneficial for drivers in traffic-heavy areas or on long road trips, as the computer can make gear changes in a fraction of a second, reducing the stress and strain on the driver.

Another advantage of Powershift transmissions is their versatility. They can be used in a variety of vehicles, including passenger cars, SUVs, and light commercial vehicles. This versatility allows manufacturers to offer a range of vehicles with the benefits of Powershift transmissions, making them accessible to a wider range of consumers.

In conclusion, Powershift and automatic transmission offer numerous benefits to the automobile industry, including improved fuel economy, ease of use, comfort, and versatility. These benefits, combined with their durability and reliability, make Powershift transmissions a popular choice for the modern driver.

#auto components manufacturers in india#automatic transmissions#transmission components#transmission parts manufacturer#powershift transmissions#transmission gears and shafts#precision auto components#powertrain components

0 notes

Text

How does an engine contribute to a car's powertrain?

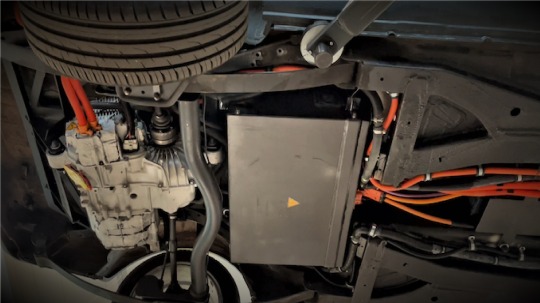

The powertrain in a vehicle is the system responsible for generating power and delivering it to the wheels to propel the vehicle forward. The operation of a powertrain can vary depending on whether the vehicle is powered by an internal combustion engine (ICE) or an electric motor (in the case of electric vehicles). Here's a general overview of how a powertrain works in both types of vehicles:

Internal Combustion Engine (ICE) Vehicle - Combustion Process: In an ICE vehicle, the powertrain starts with the combustion process in the engine. Fuel (gasoline or diesel) mixes with air in the combustion chamber and is ignited by spark plugs (in gasoline engines) or compression (in diesel engines).

Power Generation: The combustion process generates energy in the form of mechanical power, causing pistons to move up and down within the cylinders of the engine. This motion drives the crankshaft, converting linear motion into rotational motion.

Transmission: The rotational motion from the crankshaft is transmitted to the transmission, which consists of gears that allow the driver to select different ratios (speeds). This enables the engine to operate efficiently across a range of vehicle speeds.

Drivetrain: The transmission sends power to the drivetrain components, including the driveshaft, differential, and axles, which transfer power to the wheels. The differential allows the wheels to rotate at different speeds, enabling smooth turns.

Wheel Movement: The power transmitted through the drivetrain causes the wheels to rotate, propelling the vehicle forward or backward depending on the gear selection and throttle input from the driver.

Electric Vehicle (EV) -

Battery Pack: The primary source of power for the EV, storing electricity in chemical form.Powers the electric motor and provides electricity for all electronic devices within the EV.

Battery Management System (BMS): Monitors battery cell conditions, including voltage, current, temperature, and state of charge (SoC).It protects the battery against overcharging, deep discharging, and overheating and helps balance the charge across cells. Ensures optimal performance and longevity of the battery by regulating its environment.

Inverter: Converts DC from the battery pack into AC to drive the electric motor.Adjusts the frequency and amplitude of the AC output to control the motor’s speed and torque. Critical for translating electrical energy into mechanical energy efficiently.

Onboard Charger: Facilitates the conversion of external AC (from the grid) to DC to charge the battery pack. Integrated within the vehicle, allowing for charging from standard electrical outlets or specialized EV charging stations. Manages charging rate based on battery status to ensure safe and efficient charging.

DC-DC Converter: Steps down the high-voltage DC from the battery pack to the lower-voltage DC needed for the vehicle's auxiliary systems, such as lighting, infotainment, and climate control. Ensures compatibility between the high-voltage battery system and low-voltage electronic components.

Electric Motor: Converts electrical energy into mechanical energy to propel the vehicle. It can be of various types, such as induction motors or permanent magnet synchronous motors, each offering different efficiencies and characteristics. Typically provides instant torque, resulting in rapid acceleration.

Vehicle Control Unit (VCU): The central computer or electronic control unit (ECU) that governs the EV's systems. Processes inputs from the vehicle’s sensors and driver inputs to manage power delivery, regenerative braking, and vehicle dynamics. Ensures optimal performance, energy efficiency, and safety.

Power Distribution Unit (PDU): Manages electrical power distribution from the battery to the EV’s various systems. Ensures that components such as the electric motor, onboard charger, and DC-DC converter receive the power they need to operate efficiently. Protects the vehicle's electrical systems by regulating current flow and preventing electrical faults.

In both ICE vehicles and EVs, the powertrain's components work together to convert energy into motion, enabling the vehicle to move efficiently and effectively. However, the specific technologies and processes involved differ significantly between the two propulsion systems.

#electric powertrain technology#conventional powertrain#Electric vehicle components#revolo hybrid car kit#ev powertrain development services#software (SW) platforms for all Electric vehicles components#Battery Management Systems#Inverter#Smart Charger#VCU solutions

0 notes

Text

Hybrid Vehicle Powertrain Component Market Outlook, Industry Trends, Forecast 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, expects global hybrid vehicle powertrain component market size to zoom at a robust CAGR of 28.22% during the forecast period between 2023 and 2029. Major growth drivers for global hybrid vehicle powertrain component market include rising demand for vehicles that are both fuel-efficient and environmentally friendly, as well as increasing fuel costs. Hybrid powertrain components are utilized in hybrid vehicles to enhance fuel efficiency and provide power. Likewise, government regulations aimed at reducing carbon emissions, significant investments in charging infrastructure development, and an increasing demand for green vehicles are also driving the market growth. Also, technology advancements have led to the development of more efficient and reliable powertrain components, which are expected to contribute to the market's growth during the forecast period. However, shortage of semiconductors in the global market is anticipated to restrain the growth of the market.

Global Hybrid Vehicle Powertrain Component Market – Overview

A hybrid vehicle powertrain component is a combination of mechanical, electrical, and electronic systems that work together to power a hybrid vehicle. It includes the components that convert the energy stored in the battery or fuel cell into mechanical power that propels the vehicle. Hybrid vehicle powertrain components typically consist of an electric motor, battery or fuel cell, power electronics, transmission or gearbox, and other auxiliary components, such as regenerative braking systems and cooling systems. The powertrain components in a hybrid vehicle are designed to work in a highly integrated manner to optimize fuel efficiency and reduce emissions while still providing the necessary power and performance for the vehicle. The hybrid vehicle powertrain component market includes the production and sale of these components for use in hybrid vehicles.

Impact of COVID-19 on Global Hybrid Vehicle Powertrain Component Market

COVID-19 had a detrimental impact on the hybrid vehicle powertrain component market. The pandemic caused disruptions in the supply chain, manufacturing operations, and a decline in demand for hybrid vehicles. The global lockdowns and travel restrictions led to a reduction in production capacity and disrupted the supply chain of components and raw materials. As a result, the production of hybrid vehicles was delayed, leading to a decline in sales and revenue for manufacturers. Also, the pandemic caused a decline in consumer demand for hybrid vehicles as the economic uncertainty led to a decrease in purchasing power. Many customers postponed their plans to buy a hybrid vehicle due to financial constraints, which resulted in a drop in sales. However, the pandemic has also brought opportunities for the hybrid vehicle powertrain component market. The shift towards remote work and the increased focus on sustainability have led to a growing interest in hybrid and electric vehicles. The pandemic has also led to increased government support and incentives for the adoption of electric and hybrid vehicles, which could help to drive the market growth.

Global Hybrid Vehicle Powertrain Component Market – By Component

Based on component, global hybrid vehicle powertrain component market is divided into Battery, Motor, Controller, Engine, and Transmission segments. The battery segment holds the highest share in the global hybrid vehicle powertrain component market. Hybrid vehicles rely on a combination of electric motor and internal combustion engine (ICE), and the battery is an essential component that powers the electric motor. It is responsible for storing and providing energy to the electric motor, thereby reducing the reliance on the internal combustion engine and improving the fuel efficiency of the vehicle. The increasing demand for hybrid vehicles has led to a surge in demand for batteries, and battery manufacturers are investing in research and development to improve the efficiency and durability of batteries used in hybrid vehicles. Moreover, governments across the world are offering subsidies and incentives to promote the adoption of electric and hybrid vehicles, which is expected to drive the growth of the battery segment in the global hybrid vehicle powertrain component market.

Competitive Landscape

Major players operating in global hybrid vehicle powertrain component market include Robert Bosch GmbH, BorgWarner Inc., Magna International Inc., Hitachi Automotive Systems Ltd, Cummins Inc., ZF Friedrichshafen AG, Mitsubishi Electric Corp., Schaeffler AG, Continental AG, Marelli Holdings Co. Ltd, Tianjin Santroll, Allison Technologies, Bosch, ALTe Technology, and Voith. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

The Oldsmobile Golden Rocket

The Oldsmobile Golden Rocket was a two-seater show car built by Oldsmobile for the 1956 General Motors Motorama. The radically styled fiberglass concept, designed to resemble a rocket on wheels, was revised several times and displayed at various other auto shows, most notably at the 1957 Paris Motor Show where it generated much fanfare, 18 months after it was first revealed. The car was featured in the promotional short film Design for Dreaming along with the rest of the 1956 General Motors lineup.

Exterior

Similar to other Space Age show cars, the Golden Rocket was heavily influenced by the themes of aviation and space exploration. Its sleek, aerodynamic body was made entirely of lightweight fiberglass and finished in metallic bronze paint. Bullet-shaped chrome pieces resembling Dagmar bumpers were integrated into the front fenders in place of headlights as well as the sweeping rear fenders, giving the car an overall rocket-like appearance. Other notable features include a swept-back wrap-around windshield, which had already become a common design element by the mid-1950s, less prominent tailfins by contemporary standards and a split-window fastback roof design presaging the 1963 Chevrolet Corvette Stingray. It rode on unique "dotted-line" whitewall tires. A later photo taken inside the GM Design Center in Warren, Michigan shows the car sporting a blue paint scheme.

Interior

The leather upholstery was finished in blue and gold. When a door was opened, the two-piece roof panel rose automatically in a similar manner to the Mercedes-Benz 300 SL's gull-wing doors. The seats were raised up by three inches and swiveled outwards by 45 degrees, enabling easier access to the passenger compartment. One of its most pioneering innovations was the button-controlled tilt steering wheel, making it one of the first vehicles with such a feature. The speedometer was placed at the center of the foldable two-spoke steering wheel. The futuristic center console and control levers were inspired by an aircraft cockpit.

Powertrain

The car was powered by an upgraded 324-cubic inch Rocket V8 engine tuned to produce 275 horsepower (205 kW). According to interior photos, the Golden Rocket had an automatic transmission like all other Motorama show cars. Details on other internal components, however, are unavailable.

Design legacy

An early styling mock-up of the 1958 Chevrolet Corvette, built around 1956, depicted a fixed-roof fastback coupe with a rear design taken almost directly from the Golden Rocket show car, right down to the torpedo-shaped rear fenders and subtle tail fins. However, this design proposal never reached beyond the clay model stage and a more conventional design was used on the production model instead.

Seven years later, under the direction of General Motors head of design Bill Mitchell, the split rear window design would reappear on the 1963 Corvette Stingray coupe. It lasted for one model year before being changed to a single-piece rear window due to a problem of poor rear visibility.

Current status

It is unclear if the Golden Rocket still exists today. A common practice of General Motors in the 1950s was to destroy show cars after they fell out of usage in order to avoid liability concerns; however, the Golden Rocket is still unaccounted for with no confirmation it was crushed. There is photographic evidence that the car still existed as late as 1962, while several other show cars were scrapped earlier in 1959. The car was reportedly located somewhere in New Jersey, however the rumor still remains unconfirmed even after extensive investigation. Motorama historian David W. Temple believes that the Golden Rocket, along with other lost show cars, will likely never resurface again.

80 notes

·

View notes

Photo

Piper GTT

Before the dominance of the big conglomerate car manufacturers took hold in the late 1960s, there was room in the market for niche companies whose products fulfilled the demands of a few drivers who wanted something a little different to the everyday, somewhat bland mainstream offering. Some companies such as Lotus thrived and are still with us while the likes of TVR have come and gone (several times), hopefully to return. Others had their day in the sun but ultimately disappeared after a relatively brief but bright life; Piper sits firmly in the later camp. Though the end results were fairly diverse, these companies’ approaches had remarkable commonality with cheap to produce fiberglass bodies (no need for expensive tooling which required high production volumes to amortise its costs) sitting on bespoke chassis while their running gear, which was financially impossible for a small business to develop and manufacture, was sourced from the industry’s major players.

Piper were kept pretty busy trying to build cars so production records are sketchy to say the least and it is thought that just eighty road cars and some twenty racers were built making them rare beasts today, though their survival rate is undoubtedly higher than that of propriety sports car such as say MGBs.

Formed in 1966 by ex-racer George Henrotte, owner of Campbell’s Garage (hence the Scottish Piper logo and company name) in Hayes, Kent with the able assistance of engineer Bob Gayler (ex Harry Weslake), machinist Ken Packham and artist come designer Tony Hilder who had been responsible for the McLaren M1A, their first ‘whole car’ effort started as an evenings and weekends project until a customer, Gerry Hall, showed an interest in buying one. With his role as Works Gemini Formula Junior team manager winding up, Henrotte gave the green light for a limited production run of the pretty sports racers with four being completed for customers to add their powertrain of choice to; Hall put an Alfa Twin Cam in his, Bobby Bell a Lotus Twin Cam while racer Jerry Titus opted for a Buick V8. With a Mallite (balsawood/alloy sandwich) monocoque F3 car another Piper product, the company was building a reputation as a hotbed of outside the box thinking and a road-usable GT car was the next project. Approached by some Austin Healey Sprite racers who were looking for a light and sleek home for their running gear, a mock-up of what was to become the Piper GTT was shown at the 1967 Racing Car Show, apparently yielding an impressive seven hundred enquiries.

With Henrotte being kept busy with the tuning side of the Piper business, there was a timely intervention by Clubman racer Brian Sherwood who had not only bought a Piper GT but as the Sprite guys gradually fell by the wayside, was instrumental in more suitable Ford components being introduced at the expense of the BMC kit. With Sherwood now very much hands on, the Company was split with car production moving to his Wokingham premises while Henrotte concentrated on the aftermarket components business, though the companies remained closely linked both financially and practically. Through the late 1960s production increased from a drip to a trickle until Bill Atkinson, an enthusiastic GTT owner who had joined the company in the summer of 1969 as Works Manager, and Tony Waller (Sherwood Holdings’ Company Secretary) made great strides getting the GTT into some sort of series production.

Instrumental in saving Piper’s car business, Sherwood was at heart a racer and he took them on an ultimately ill-fated foray to Le Mans in 1969 with the ultra-low, mid-engined GTR, an ambitious project that is thought to have cost £250,000. His untimely death late that year coupled with strikes at Ford ultimately resulted in the company being wound up in June 1971, despite the strong progress being made by Atkinson and Waller on the car production and development front (the longer wheelbase P2 was eventually launched in early 1971). However, this was not quite the end of the road for Piper; reborn as Emmbrook Engineering under the same management team, the Piper P2 remained in production until 1974.

38 notes

·

View notes

Text

AMG S63 E PERFORMANCE „The Boss“.

Mercedes-AMG S63 E PERFORMANCE (combined fuel consumption, weighted: 4.4 l/100 km; combined CO2 emissions, weighted: 100 g/km; combined power consumption, weighted: 21.4 kWh/100 km)[1] with AMG hybrid technology once again sets the benchmark in the segment. The E PERFORMANCE model combines the AMG 4.0-litre V8 biturbo engine with the AMG-specific hybrid powertrain and a new expansion stage of the AMG high-performance battery.

The focus of the powertrain, however, is less on electric range and more on best-in-class performance. With 590kW (802hp) of system output and 1430Nm of system torque, the saloon sets new standards in the segment. The acceleration of 3.3 seconds to 100km/h and the optional top speed of 290km/h underline the superior, dynamic driving performance. Systems such as the AMG RIDE CONTROL+ suspension, AMG ACTIVE RIDE CONTROL roll stabilisation and rear-axle steering as standard ensure a wide spread between driving dynamics and comfort.

A central component of the P3 hybrid powertrain is the AMG 4.0 V8 biturbo engine, in this case producing 450kW (612hp). It provides a maximum torque of 900Nm, which is available over a wide speed range. The engine's most important design features include the two twin-scroll turbochargers, which are located in the hot inner-V. The position between the two cylinder banks shortens the paths of the exhaust gases to the turbocharger and the compressed fresh air to the combustion chamber.

The result is a very immediate response. Another important feature is the belt-driven starter-generator (RSG), which is integrated into the 400-volt electrical system. This combines the starter and alternator into one unit, and has sufficient power to always start the V8 at once.

Mercedes-AMG One man, one engine Handcrafted by Michael Kübler @f1mike28 in Germany Affalterbach. Driving Performance is our Passion!

Mercedes-AMG the Performance and Sports Car Brand from Mercedes-Benz. Mercedes-AMG Handcrafted by Racers.

5 notes

·

View notes

Text

Ferrari unveiled the '296 Challenge' at the Finali Mondiali race at Mugello Circuit. The car is scheduled to debut in the Ferrari Challenge in the 2024 season and is the ninth model in the history of the single-make championship hosted by Ferrari. The Ferrari Challenge is currently in its 32nd season.

As riders around the world became more skilled and competitive, the 296 Challenge attempted to make bigger changes than the original model. The 296 Challenge continues Ferrari's long tradition of developing cars for gentleman drivers, but draws on the expertise accumulated in the '296 GT3' more than any other model. The 296 Challenge is a vehicle for drivers who are passionate about future GT racing. During the development of the 296 Challenge we made significant changes, not just minor changes to the model of the production car, but to make it a vehicle optimized for track driving. An extreme form of the vehicle was developed that improves overall performance while maintaining consistency and repeatability for testing and competition.

The 296 Challenge is the first car in Ferrari's single-brand range to be equipped with a V6 engine. So far, all models participating in the Challenge have been equipped with V8 engines. The biggest change compared to the 296 GTB is the elimination of the hybrid powertrain like the 296 GT3. As a result, while reducing the weight of the vehicle, the power output was increased to 700 horsepower (cv), setting a new record in this segment with an output of 234 horsepower per liter. In terms of aerodynamics, solutions derived from the 296 GT3 were taken and pushed to the extreme to achieve unprecedented downforce figures. These include the "S-shaped duct" (which draws air into the central radiator and exhausts it through the vents on the bonnet), the "swan-neck rear wing layout (another element inspired by the development of the 296 GT3)", and the A device that maximizes the stability of downforce generated in different trim conditions.

The braking system has also been completely redesigned. It's the first to feature the new "CCM-R PLUS" disc, which features technology derived from extreme track applications. New Pirelli tires developed specifically for the 296 Challenge also contributed significantly to improved performance. After its debut at the "2019 Finali Mondiali", the 296 Challenge set a record at the Mugello circuit approximately 2 seconds faster than its predecessor "488 Challenge Evo" which debuted in the 2020 season. From the early stages of development, the 296 Challenge discussed removing all hybrid components from the V6 powertrain, as in the 296 GT3. The electric motor and high-voltage battery have been eliminated, and the output of the twin-turbo V6 engine has been increased to 700 cv. This approach helps limit vehicle weight and overall unit complexity, which are fundamental factors in track driving.

Ferrari unveils '296 Challenge' race car with F1 technology

#cars#ferrari#ferrari f1#formula 1#scuderia ferrari#formula one drivers#formula one#296 Challenge#car

8 notes

·

View notes

Text

Kickstarter Project: The Thelen drive train: Powerful electric conversion:

A state-of-the-art, flexible and eco-friendly powertrain for high performance electric conversion for all kinds of vehicles.

Game Geeks News is proud to bring you another exciting new project currently live on Kickstarter. Darian Thelen (Mayen, Germany) has a workshop near Koblenz and a Bachelor's degree. The conversion of his classic car from 1988, which was converted into a high-performance and future-oriented electric car, was successfully completed. Darian's goal with the help of Kickstarter is to use the high-performance powertrain for as many vehicles as possible. For a quieter and more environmentally friendly future.

Sustainable, powerful, and flexible powertrain by Thelen Electric Conversion.

The product is a powertrain with state-of-the-art technology that can be used flexibly. In addition, it is the most environmentally friendly way to convert vehicles and thus cause fewer emissions when driving in the future.

Thelen is a German manufacturer, located in the Eifel region, close to the heart of German motorsport, the Nürburgring Nordschleife. Thelen has started to manufacture a flexible powertrain for a large number of different vehicles. This was successfully used in a test vehicle, tested and proved its worth. With this powertrain, existing resources can be further utilized.

In order to demonstrate and test the enormous performance capability of the powertrain, the initial focus was on the conversion of classic cars and sports cars. This is what can be seen in the video below to demonstrate what the Thelen drive train is capable of. This is best shown in motorsports or sports cars. As well as with highly individual vehicles like classic cars. However, the drive train has been designed and developed from the ground up to be flexible, so that a number of different vehicles can be converted.

But why convert vehicles to electric drive? Millions of cars, buses, and trucks are on the road every day, emitting pollutants with every kilometer they travel. Scrapping all these vehicles in order to build new ones cannot be the most sensible solution. Many of the vehicles on the road still have excellent substance. Conversion saves far more emissions here than disposing of the old car and rebuilding the new one.

youtube

But what makes the powertrain and the conversions special? The highly complex components used were developed by the manufacturer for perfect functionality in the vehicles intended for this purpose. and this is exactly where Thelen comes in. With a control unit including its own software from the professional supplier ESDI EV, also from Germany, the components are strapped in such a way that the functionality in the powertrain is exactly as in the original vehicle. This means that as soon as the components are installed in your new vehicle, the cooling, power control, and safety functions work exactly as the manufacturer intended.

By supporting this crowdfunder Darian wishes to continue to improve and expand the successfully tested drive train so that it can be integrated into all vehicles. You can read more in-depth on Kickstarter. Rewards include a virtual meeting, consultation, and feasibility study of your project, a test drive in a vehicle in which a version of the high-performance powertrain has been used, and a step-by-step guide to build a drive-train outside Germany, with detailed step-by-step instructions.

For more information visit Kickstarter and help support this project.

Source

10 notes

·

View notes

Text

Saturn Aura XR Mid Sized Sedan Concept

What if... Saturn returned to the automobile market and brought back the Aura midsized sedan? In this scenario, the Aura would be above the ION series sedans but below the Celeste Full sized sedan (showing later in this blog). While being an independent company, it still has collaborated efforts from others to include Toyota as well as Chevrolet. The Aura would share some components with Toyota, mainly from a chassis perspective. The engine would be an in house built V6 as well as Turbo 4 cylinder equipped with 8-speed automatic transmission as well as a 6-speed manual transmission. Unfortunately, this will be offered as a front wheel drive powertrain, and maybe later in an all wheel drive powertrain.

#autos#cars#automotive#classic car#sedan#luxury car#sports cars#chevrolet#saturn ion#general motors#toyota#toyota cars

2 notes

·

View notes

Text

Driving the Future as an EV Gearbox Manufacturer in India

In the transformative landscape of electric vehicles (EVs), AVTEC stands as a beacon of innovation, reshaping the Indian automotive industry as a leading EV gearbox manufacturer in India. With a deep commitment to sustainability and cutting-edge technology, AVTEC is driving the nation towards a greener, more efficient future.

Innovative EV Gearbox Solutions

AVTEC's prowess as an EV gearbox manufacturer lies in its ability to create innovative and efficient solutions for the evolving EV market. By engineering gearboxes tailored specifically for electric vehicles, AVTEC ensures seamless power transmission, maximizing the performance and range of EVs. These gearboxes are not just components; they are the driving force behind the smooth, powerful acceleration and enhanced energy efficiency in electric vehicles.

Local Expertise, Global Impact

AVTEC's impact stretches far beyond the borders of India. As a local manufacturer with global standards, AVTEC's EV gearboxes are crafted with precision and excellence, meeting international quality benchmarks. By contributing to the global EV market, AVTEC is showcasing India's capability to produce cutting-edge, sustainable automotive solutions.

Fostering Sustainable Mobility

AVTEC's role as an EV gearbox manufacturer in India is pivotal in fostering sustainable mobility practices. By facilitating the transition from traditional combustion engines to electric powertrains, AVTEC is reducing carbon footprints and paving the way for eco-friendly transportation in India. This commitment aligns with the country's vision for a sustainable future, making AVTEC a key player in India's green mobility revolution.

Embracing a Greener Tomorrow

AVTEC's EV gearboxes are not just mechanical components; they are the embodiment of a greener tomorrow. By manufacturing high-quality, reliable, and efficient gearboxes for electric vehicles, AVTEC is inviting a wave of change, encouraging individuals and businesses to embrace EV technology. This shift towards sustainable transportation is not only environmentally responsible but also economically viable, making AVTEC's offerings increasingly attractive to a wide and discerning audience.

In conclusion, AVTEC's role as an EV gearbox manufacturer is pivotal in shaping India's automotive future. Through innovation, quality, and a steadfast commitment to sustainability, AVTEC is not just driving electric vehicles; it's driving a transformative shift towards a cleaner, greener, and more efficient tomorrow.

#auto components manufacturers in india#automatic transmissions#powershift transmissions#transmission parts manufacturer#transmission components#transmission gears and shafts#precision auto components#powertrain components#engine parts manufacturers in india#powertrain manufacturer in india

0 notes

Text

Kalyani Mobility Drivelines -Introduction

Kalyani Group was established in 1979, as a part of the $ 3 Billion conglomerate Kalyani Group which has manufacturing business and a customer base across the globe.

Kalyani Group’s engineering and manufacturing centers in India, the USA, Germany, and Sweden specialize in complete end-to-end products and solutions for chassis and powertrain components and assemblies serving global OEM’s & Tier-1 suppliers. Over the last decade, with organic growth and acquisitions, Kalyani Group has transformed itself into a eMobility powertrain and chassis products and solutions provider.

1 note

·

View note

Text

Elon Musk hasn’t been sighted at the picket lines in Missouri, Ohio, or Michigan, where autoworkers are striking against the Big Three US carmakers. Yet the influence of Musk and his non-unionized company Tesla have been everywhere since the United Auto Workers called the strike last week. In some ways, Tesla—the world’s most valuable automaker by market capitalization—set the whole thing in motion.

Tesla’s pioneering electric vehicles kicked off a new era that has turned the entire auto industry on its head. In a scramble to compete with Tesla and make that transition, the legacy automakers targeted by the current strike, General Motors, Ford, and Stellantis, have each pledged billions in global investment and have begun dramatically restructuring their operations. For workers, the “green jobs” being created can be scarcer and worse paying.

Electric vehicle powertrains have many fewer moving parts than conventional gas-powered ones, and so they require 30 percent fewer vehicle assembly hours, according to one estimate. Plants that make EV batteries are generally outside the core, unionized auto supply chain. The United Auto Workers has seen a dramatic drop in membership due to jobs moving outside the US—it lost 45 percent of its members between 2001 and 2022. A future with more electric vehicles could mean fewer union jobs overall. “This strike is about electrification,” says Mark Barrott, an automotive analyst at the Michigan-based consultancy Plante Moran.

The new assembly plants that the legacy automakers need to pull off the transition have been stood up mostly in US states hostile to union organizing, such as Kentucky, Tennessee, and Alabama. And because many of these plants are joint ventures between automakers and foreign battery companies, they are not subject to previous union contracts.

The UAW did not respond to a request for comment, but UAW president Shawn Fain told CNBC last week that the electric transition can’t leave workers behind. “Workers deserve their share of equity in this economy,” he said.

Tesla’s rise over recent years has also put ever-ratcheting pressure on the legacy automakers to cut costs. Including benefits, Musk’s non-unionized EV company spends $45 per hour on labor, significantly less than the $63 per hour spent in the Big Three, according to industry analysts.

Musk’s willingness to upend auto manufacturing shibboleths has also forced his legacy competitors to seek new efficiencies. Tesla led the way in building large-scale car casts, stamping out very large metal components in one go rather than making a series of small casts that have to be joined together. And it pioneered an automotive chassis building process that can be easily adapted to produce different makes and models.

Tesla’s Silicon Valley roots also helped it become the first automaker to envision the car as a software-first, iPhone-like “platform” that can be modified via over-the-air updates. And the company aims to automate more of its factories, and extract more of the materials it needs to build its batteries itself.

Tesla’s novel production ideas could soon lead the company to put even more pressure on legacy automakers. Musk said earlier this year that Tesla plans to build a new, smaller vehicle that can be made for half the production cost of its most popular (and cheapest) vehicle, the Model 3.

Musk says a lot of things, and many don’t come to pass. (The world is still waiting for the 1 million Tesla robotaxis promised by the end of 2020.) But Tesla has been disruptive enough to leave legacy automakers, including Detroit’s Big Three, “in a quest for capital,” says Marick Masters, who studies labor and workplace issues at Wayne State University's School of Business. Detroit’s automakers have made good money in the past decade—some $250 billion in profits—but also paid a significant chunk of it out in dividends. Pressure from Tesla and the EV transition it catalyzed has left them feeling as if they need every penny they can corral to keep afloat as the industry changes.

“They have little money to concede for union demands,” says Masters. The UAW’s wants include significantly higher wages, especially for workers who have joined the companies since their Great Recession and bankruptcy-era reorganizations, which left some with less pay and reduced pension and health benefits.

So far, the UAW has shown little patience for the idea that the automakers it is pressuring are cash-strapped and under competitive pressure. “Competition is a code word for race to the bottom, and I'm not concerned about Elon Musk building more rocket ships so he can fly into outer space and stuff,” UAW president Fain told CNBC last week when asked about pressure from Tesla. He has argued that production workers should receive the same pay raise received by auto executives over recent years.

When automakers have taken the opposite tack, insisting that they’re well capitalized and making plans to put them ahead of the electric car maker—well, that set up conditions for this strike too. The three American automakers are forecasted to make $32 billion in profits this year, a slight dip from last year’s 10-year high. “The more they toot their own horns about profitability, the more the union looks at them and says, ‘We want our rightful share,’” says Masters.

Tesla did not respond to a request for comment, but Musk has, in typical fashion, chimed in. He posted on X last week to compare working conditions at his companies with the competition, apparently seeking to turn the dispute he helped foment into a recruiting pitch. “Tesla and SpaceX factories have a great vibe. We encourage playing music and having some fun,” he wrote. “We pay more than the UAW btw, but performance expectations are also higher.” A UAW attempt to organize Tesla workers in 2017 and 2018, as the company struggled to produce its Model 3, failed. The National Labor Board ruled that Tesla violated labor laws during the organizing drive; the carmaker has appealed the decision.

5 notes

·

View notes

Text

It's been a while since my last rant about automotive industry, but here we go again.

As a premise, i must say that this will probably be more valid for EU than for the rest of the world. Also expect a LONG post. So.

Hybrids and EVs are surely more efficient and "clean" than the average ICE car. But, as a car enthusiast, i'm very aware that technology end efficiency are expensive, definitely not for everyone. Here where i live we get bonuses for changing old cars with brand new "eco-friendly" ones, but only if they are old enough. Bonuses that, anyway, even in best cases will cover less than a quarter of the price of a new vehicle.

Most importantly, and that's something i learned the hard way, no institution will give you a single cent for the running costs - and they're high running costs. And about (stupidly heavy) EVs, electricity now is so expensive that the cost-per-km is the same of regular gasoline, so no real advantage. I remember when the seller told us that the simplicity of the powertrain meant less service costs, it was quite the opposite. Moreover, we were forced to service the car at their shop, at their prices, because they were the only ones who knew how to work on those components. Oh, and it was the only way to keep the warranty valid on expensive parts, too.

I had a (second hand) hybrid, like my parents. But i went from precarious worker to student and i'm unable to find a proper job while i'm studying due to some issues with my mental health, so my income suddenly dropped to zero. Keeping the car is expensive and in three years, when the warranty expires, the value will decrease drastically (a new battery could cost until 8k euros, nobody would buy a car with that risk). So i planned ahead and sold the hybrid car to get a cheaper one with decent quality and safety, reasonable running costs, free from the blackmail of our official dealer and easily fixable by any mechanic.

The problem: the most reliable and most fuel-saving version of that model on the second-hand car market (and well, basically the only one i found nearby) was a Diesel one. And Diesels are EU's scapegoat for the increasing air pollution, so Countries are forced to make laws to stay within certain limits - that's not bad itself. The problem is that private cars, depending on the sources, are only between 10% and 20% of the total greenhouse gas emissions.

But it's easier to wage war against citizens than corporations who are truly responsible for that 80-90%. And i'm not talking about those wealthy citizens who already got their fancy Tesla, but those who literally can't afford a new car (for any reason). This is a class problem.

There are "old" Diesel cars which still require less fuel than modern, high-end Diesels that satisfy the new requirements for mass production. A 10 years old 1.4 Diesel will always require less fuel and pollute less than a 2-tonne mild-hybrid "environmentally friendly" 3.0 Diesel BMW or Audi. Oh wait, it gets better: ironically an Euro 5 Diesel could be stopped from traffic while a brand new 1500 hp quad-turbo W16 Bugatti Chiron can roam around in the city centre on the very same day. But hey, the Chiron is not an evil Diesel. Once again, this. Is. A. Class. Problem.

Forcing people to go hybrid/electric with restrictions is repression against low-income classes. There could be so much more that can be done if private transport really is the root of all evil. Like a bonus that covers 100% the price of a new car (oh btw, an Euro 5 Diesel is old enough to get stopped on certain conditions, but not old enough to receive a bonus). Or investing in bio/synthetic fuels so people can run their older cars with carbon neutral emissions - but that'd make the poor automakers angry as they couldn't sell their new hypertechnological cars. Or provide new catalysts for free to install on older cars - but also that would make automakers quite angry. Or governments could also consider doing something about intensive farming (y'know, that thing that sends methane into atmosphere which is 84 times worse for global warming than CO2), or better public transport, or heavy industry, or invest in nuclear so we can stop burning fossil fuels for energy (i know this is gonna cause a shitstorm lmao, i believe safely stocking radioactive material under layers of rocks in sterile zones is better than keeping on produce greenhouse gases), or anything that doesn't involve the private life of people already struggling with ever-increasing prices of goods.

"B-but there are exceptions to traffic restrictions" sure, but it's hard to satisfy all of the requirements. One of them is quite easy to get anyway: it's a certificate that you're on the route from home to work or viceversa - you can pollute if you produce. Using an old car for free-time? Nope. Getting groceries? Nope. Sounds dystopic as hell, innit?

Don't get me wrong, technology and research are good, hybrids and EVs are fascinating and surely relatively more efficient. But not affordable by everyone, nor a permanent solution for environmental problems: not only for batteries, but also for the energy required to charge them, and the fossil fuels still needed for hybrids. A lot of research is still needed but, while we wait, we should stop pointing the finger at who can't afford to buy and sustain a new car.

Now, i know what you're thinking: "but you could've got another non-Diesel model and save even more money" maybe you're right, but for me the choice of the car is very personal and important, there are many criteria i have, picking any cheap shitbox is not an option for me if i have a decent budget. Laws can change, safety and reliability don't. There are good cars out there which only problem is bad laws made against them. Cars that can perfectly run and could end up in a junkyard only because of these laws, that's the opposite of sustainability, that's forced consumerism. Plus, it's not only about me, but also and most importantly about the millions of people that get screwed everyday and have no fucking choice.

10 notes

·

View notes