#injection blow moulding

Text

Pharma Pet Bottle Mould Manufacturer in In India

Awanti Polymoulds Pvt Ltd is a manufacturer and exporter of PET blow molds for a variety of products like carbonated soft drinks and fruit drinks, water, edible oil, liquor and pharma. Our customer base includes beverage giants like Coca-Cola, Bisleri, Parle Agro and AJE. Our moulds are running successfully on linear and rotary blowing machines like Sidel, Krones, KHS, SACMI, Techlong, Electropneumatics and Shyam Plastic. We supply to over 200 locations in India and 15 countries world-wide. Our facility in Pune (Maharashtra) is equipped with CNC machines, CADCAM softwares and an international-standard test laboratory.

#PET bottles#blow moulds#pharma pet bottle moulds#bottle moulds#injection blow moulding#mould manufacturer in india#awantipolymoulds

0 notes

Text

China Sanshun is offering the best quality SHE1200V Variable Energy Saving Injection Molding Machine. This machine is designed for creating high-quality plastic products. It features a shaking ejector for multi-cavity molds, low-pressure mold protection, a hydraulic tank with low oil level alarming, and precise injection device control.

Contact us today to learn more and get the latest pricing!

Website: - https://www.china-sanshun.com/

#led bulb cover making injection blow machine#injection blow molding machine#plastic auxiliary machine#injection moulding machine#high speed machine

0 notes

Text

Experience precision moulding with the top injection blow moulding machine manufacturer. Our advanced machines deliver exceptional accuracy and efficiency for a variety of production needs.

0 notes

Text

Introduction to Mould Manufacturing 2024

Plastic mould manufacturing is the process of creating mould or tools for the production of plastic parts. The mould are designed to shape and form plastic materials into specific shapes and sizes, allowing for the production of identical parts at a rapid pace. This process is widely used in various industries, including automotive, medical, and consumer goods.

The fundamental principle behind plastic mould manufacturing is to create a negative impression of the desired product, which is then used to cast the final product. The mould are made from high-quality materials such as steel or aluminum, which are capable of withstanding high temperatures and pressure. The mould are designed to accommodate the specific properties of the plastic material, including its melting point, viscosity, and shrinkage rate.

There are two primary types of plastic mould manufacturing: injection moulding and compression moulding. Injection moulding involves injecting molten plastic material into a mould cavity, which is then cooled and solidified to create the final product. This process is highly efficient and produces high-quality parts at a rapid pace. Compression moulding involves heating plastic pellets and then placing them into a heated mould cavity, which is then compressed to form the final product. This technique is used for larger parts or when the part requires greater strength and durability.

Plastic mould manufacturing has a wide range of applications, from the production of small plastic components to large automotive parts. The process allows for the creation of complex parts with intricate shapes and sizes. The ability to create identical parts at a rapid pace makes it an essential process in modern manufacturing.

In conclusion, plastic mould manufacturing is a crucial process in the manufacturing industry. It allows for the production of high-quality plastic parts at a rapid pace, making it a highly efficient and cost-effective process. The use of advanced technology and high-quality materials has made plastic mould manufacturing an essential process in various industries, including automotive, medical, and consumer goods.

Mould Manufacturing Process

The process of manufacturing a mould is a complex one, and it's important to note that not all plastic mould manufacturers use the same methods.

The most common method used by manufacturers is CNC machining, which involves using computer-controlled machines to carve out the shape of your product in thin layers. This technique has been around for decades and allows for greater precision than other methods like EDM (electrical discharge machining) or grinding.

Plastic mould manufacturing is a complex process that involves several steps to create high-quality mould for various industries. The process begins with designing the mould using computer-aided design (CAD) software. This software allows engineers to create a detailed 3D model of the mould, including all the intricate details required for the final product.

Once the design is complete, it's time to move onto the manufacturing stage. The first step in manufacturing is to create a mould base using steel or aluminum. This base is what will hold all the various components of the mould together. The base must be designed to withstand the high pressure and temperature required for the moulding process.

Next, the mould is assembled, which involves attaching various components such as the ejector pins, the sprue bushing, and the runner system. These components are essential for the mould to function correctly during the moulding process.

The next step is to machine the mould. This involves using specialized equipment to create the cavities and cores required for the final product. This process involves a high level of precision, and any errors or imperfections can result in a faulty mould.

Once the mould is machined, it's time to test it. This involves running a trial batch of plastic through the mould to ensure that it produces the desired product. Any issues with the mould or the moulding process can be addressed in this stage.

Finally, after the mould is tested and approved, it's ready for production. The mould is attached to an injection moulding machine, and plastic is injected into the cavities to create the final product. This process can be repeated thousands of times to create a large number of identical products.

Overall, plastic mould manufacturing is a complex and intricate process that requires a high level of skill and expertise. From designing the mould to running production, every step of the process must be executed with precision to ensure a high-quality final product.

1. Introduction

Mould manufacturing is an essential process in the production of various products, including automotive parts, consumer goods, and medical devices. Identifying different types of mould is crucial to ensure that the correct type is used for each product. In this guide, we will discuss the different types of mould prevalent in the mould manufacturing industry, their unique characteristics, materials they are best suited for, and the benefits and drawbacks of each type.

2. Types of Mould

Plastic Injection Mould:

Thermoset Compression Mould:

Blow Mould:

Rotational Mold:

3. Precautions and Safety Measures

Different types of mould have different safety considerations, but in general, it is important to wear appropriate personal protective equipment (PPE) when working with mould, such as gloves, goggles, and respirators. It is also important to follow proper handling and storage procedures to prevent mould contamination and ensure optimal mold performance.

Conclusion

Identifying different types of mould and understanding their unique characteristics, materials they are best suited for, and the benefits and drawbacks of each type is crucial to ensure that the correct type is used for each product. Proper maintenance and cleaning of mould are also essential to prevent mould contamination and ensure optimal mould performance. By implementing the knowledge gained in this guide, manufacturers can improve their mould manufacturing processes and produce high-quality products with greater efficiency and consistency.

#mold manufacturing#mould manufacturing#plastic molding#thermoset compression mould#cnc machining#injection molding#3d printing#manufacturing#compression molding#mumbai#india#blow mould#rotational molding

1 note

·

View note

Text

Injection Molding Process, Definition ,Types and Products

Injection moulding is most generally used method of producing parts of thermoplastic and more recently, thermosetting resins as well.

The molten material cools and solidifies to form the desired shape. This process is widely used for producing plastic parts in various industries due to its efficiency, repeatability, and ability to produce complex shapes with high precision.

Read More

#injection moulding machine#blow moulding machines#engineering#mechanical#mechanical design#mechatronics#fluid dynamics

0 notes

Text

The Essence of Inspection Machines in Modern Industries

In the dynamic landscape of modern industries, the role of inspection machines has become increasingly vital. As technological advancements continue to revolutionize manufacturing processes, the significance of maintaining high standards in quality control cannot be overstated. In this blog post, we delve into the world of inspection machines, understanding their purpose, types, and the pivotal role they play in ensuring precision and efficiency. Let's embark on a journey to unravel the essence of inspection machines and their impact on various sectors.

Understanding Inspection Machines :

Inspection machines are sophisticated tools designed to assess and verify the quality, accuracy, and integrity of products during the manufacturing or production process. These machines employ advanced technologies to detect defects, inconsistencies, or deviations from established standards, ensuring that only products meeting the desired criteria reach the market.

Types of Inspection Machines

1. Vision Inspection Systems:

Vision inspection systems utilize cameras and image processing software to scrutinize products for defects. These systems are highly versatile, capable of identifying irregularities in size, shape, color, and surface characteristics.

2. X-ray Inspection Machines:

X-ray inspection is particularly valuable in industries where internal defects or inconsistencies need to be identified without compromising the integrity of the product. This method is commonly used in the food, pharmaceutical, and electronics industries.

3. Ultrasonic Inspection Machines:

Ultrasonic inspection involves the use of high-frequency sound waves to detect defects or inconsistencies beneath the surface of materials. This method is frequently applied in assessing the structural integrity of components in industries such as aerospace and automotive.

4. Eddy Current Inspection:

Eddy current inspection is employed for assessing the conductivity and integrity of conductive materials. This method is extensively used in the manufacturing of metal components, including tubes and pipes

The Role of Inspection Machines in Industries :

1. Quality Assurance:

Inspection machines are instrumental in maintaining and assuring product quality. By identifying and rectifying defects early in the production process, manufacturers can prevent substandard products from reaching consumers.

2. Efficiency Improvement:

Efficient production is a key goal for any manufacturing process. Inspection machines contribute to efficiency by automating the quality control process, reducing the need for manual inspection and minimizing production delays.

3. Cost Reduction:

Detecting defects early in the production cycle helps in minimizing waste and reducing the overall cost of production. This not only benefits manufacturers but also contributes to sustainability efforts.

4. Compliance with Standards:

In industries with stringent regulations and standards, inspection machines play a crucial role in ensuring compliance. This is particularly important in sectors such as healthcare and aerospace, where adherence to specific standards is paramount.

Industries Benefiting from Inspection Machines :

1. Automotive:

Inspection machines are extensively used in the automotive industry to assess the quality of components, ensuring the safety and reliability of vehicles.

2. Pharmaceutical:

The pharmaceutical industry relies on inspection machines to guarantee the accuracy and integrity of medicinal products, from tablets to packaging.

3. Food and Beverage:

In the food and beverage sector, inspection machines are employed to identify contaminants, ensure proper packaging, and maintain quality control throughout the production process.

4. Electronics:

Precision is critical in the electronics industry, and inspection machines help in identifying defects in circuit boards, components, and final products.

Conclusion :

In conclusion, inspection machines play a pivotal role in today's industrial landscape, contributing to the enhancement of product quality, efficiency, and compliance with standards. As technology continues to advance, the capabilities of inspection machines will evolve, further solidifying their importance in various sectors. Manufacturers embracing these technologies are better positioned to deliver products that meet and exceed customer expectations, fostering trust and loyalty in an increasingly competitive market.

To explore advanced inspection solutions for your industry, visit Mitchell Industries - injection moulding machines . Stay tuned for more insights into the innovative world of manufacturing and quality control.

#injection moulding#injection moulding machines#moulding machine#blow moulding machine alphamac#recycling machine

0 notes

Text

https://www.dowellmoulds.com/blog/processes-for-molding-thermosetplastics-and-thermoplastics

#Dowell Moulds#plastic mould manufacturers in India#Injection molding#Compression molding#Transfer molding#Blow molding#Extrusion molding#Thermoset#Thermoplastic#Mold cavity#Gate#Pellets

0 notes

Text

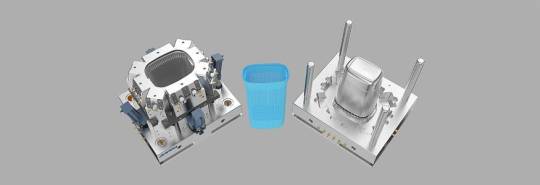

How to Choose a Reliable Houseware Mould Manufacturer?

Experience and Expertise:

One of the first factors to consider is the manufacturer’s experience and expertise in the industry. Look for a company with a solid track record and a long history of manufacturing houseware mould. An experienced manufacturer will have a deep understanding of mould design, materials, and manufacturing processes, ensuring the production of high-quality mould.

R. D. Mould & Industries boasts a rich history spanning several years, demonstrating their deep understanding of mould design, materials, and manufacturing processes.

Customization Capabilities:

Every houseware product is unique, and a reliable mould manufacturer should be able to accommodate customization. R. D. Mould & Industries understands the importance of tailored solutions and offers customization options to meet diverse client requirements. Their team of skilled professionals works closely with clients to ensure that the mould are designed and manufactured to precise specifications.

Materials and Durability:

R D Mould & Industries involves considering the materials used by the manufacturer to make the mould. Material selection can significantly affect mould durability and lifespan. Trusted household mould manufacturers will have knowledge of different materials and recommend the most suitable options for your specific houseware mould products.

Product Range and Specialization:

Consider the product range and specialization of the manufacturer. R. D. Mould & Industries offers a diverse range of houseware mould, catering to various product categories such as kitchenware, storage containers, and more. Their specialization in houseware mould manufacturing ensures that they understand the specific requirements and challenges of this industry.

Conclusion:

Choosing a reliable houseware mould manufacturer is crucial for the success of your product manufacturing. R. D. Mould & Industries stands out as a trusted and reputable choice in the industry. With their extensive experience, specialization, customization capabilities, and commitment to quality, they are well-equipped to meet your houseware mould requirements. By partnering with R. D. Mould & Industries, you can have confidence in the reliability, precision, and timely delivery of your houseware mould.

#Houseware Mould#Plastic Houseware Mould#Houseware Mould Manufacturer#Houseware Mould Exporters#Plastic Food Container Mould Manufacturer#Houseware Injection Mould#Houseware Blow Mould

0 notes

Text

Get The Best Blow Mold Design From The Leading Provider of Plastic Injection Molds

With the rise of the plastic industry, many automotive injection moulding companies near you offer a wide variety of services. Plastic Injection Molds are a leading automotive injection moulding company provider that can provide you with high-quality blow mold design. We have a track record of providing our customers with high-quality goods and services. To find out more about our services and how we can assist you in growing your company, get in touch with us right away.

0 notes

Photo

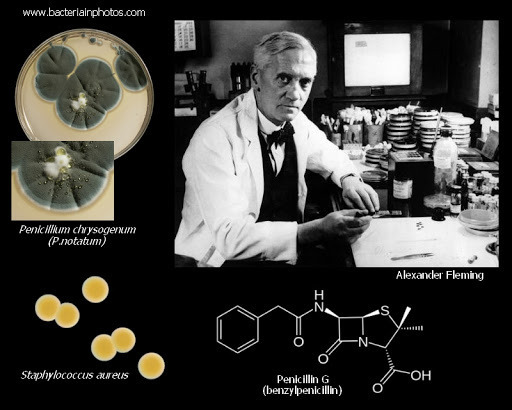

On 28th September 1928 Alexander Fleming, a Scottish researcher discovered penicillin.

I know we all like to blow our own trumpets and us, as Scots gave the world a lot, certainly punching above our weights, per head of population, but let’s be honest, Fleming never had much of a clue what to do with his discovery at first.

Often described as a careless lab technician, oor Alex returned from a two-week holiday to find that a mould had developed on an accidentally contaminated staphylococcus culture plate. Upon examination of the mould, he noticed that the culture prevented the growth of staphylococci. Staphylococcus is a bacteria that can be found normally in the nose and on the skin.

That’s not to say he wasn’t clever, he knew this was something special and in an article he had published in the British Journal of Experimental Pathology in 1929 he wrote;

“The staphylococcus colonies became transparent and were obviously undergoing lysis … the broth in which the mould had been grown at room temperature for one to two weeks had acquired marked inhibitory, bactericidal and bacteriolytic properties to many of the more common pathogenic bacteria.”

At the time Fleming was actually working on the flu virus, penicillin was a bi-product of what most of us men are guilty of, - not doing the washing up!

Fleming’s laboratory notebooks are sketchy, and his subsequent accounts of the discovery are contradictory. The evidence of the first culture, which he photographed, indicated that he observed lysis, the weakening and destruction of bacteria—as in his lysozyme studies. But sometimes he described the key observation as an instance of inhibition or prevention of bacterial growth in areas affected by the mould “juice,” evidenced by a clear zone surrounding the mould.

Although these two effects occur under quite different conditions, Fleming probably forgot which observation came first, for in the months subsequent to the original observation he conducted many experiments while varying conditions systematically.

He discovered that the antibacterial substance was not produced by all moulds, only by certain strains of Penicillium, namely, Penicillium notatum. Although he could not isolate it, he named the active substance “penicillin.” He studied methods of producing the impure product and determined its stability at different temperatures and over various lengths of time. He investigated its effect on many microbes, curiously omitting the familiar spirochete that causes syphilis (which Salvarsan controlled but did not eliminate). He tested its toxicity on a laboratory mouse and a rabbit. Forever after, it has been a puzzle why he did not inject these or other laboratory animals with staphylococcus or other disease-causing bacteria before injecting them with the fluid containing penicillin. Perhaps the explanation lay in his belief that cures come from within the body itself, rather than from an external agent. So he was not looking for a curative agent but rather focused on his new find as a topical antiseptic. In later years he claimed that the difficulties he had experienced in isolating and stabilizing penicillin, let alone the problems of producing sufficient quantities for clinical trials, had prevented him from realising the full fruits of his research.

So the main point of me saying this is it looks like he ran out of ideas because come 1931 he had stopped working with penicillin. In fact apart from his own work, little notice was taken by the scientific community of the paper he published.

However his research was continued and finished by Howard Flory and Ernst Chain, researchers at University of Oxford who are credited with the development of penicillin for use as a medicine in mice. It wasn’t until 1939 that Florey and Chain, led a team of British scientists who successfully manufactured the drug from the liquid broth in which penicillin grows.

They, along with Fleming, were given the 1945 Nobel Prize in Physiology or Medicine for their roles in the discovery and development of this agent, and the pair deserve as much credit for carrying on with the development of penicillin, so yes well done Alexander Fleming, but let’s not forget the others.

265 notes

·

View notes

Photo

What are the Plastic Mould Steels? What is meant by plastic moulding?

Are you looking for P20 and P20 + Ni Plastic Mould Steels?

Plastic mould steels are a type of steel that has been used to make molds for plastic parts, such as car bumpers. These steels have high strength and good wear resistance, which makes them an excellent choice for the production of plastic moulds. The plastic in these molds can be made from various resins, such as polyester and polypropylene.

Plastic moulding is the process of shaping plastic using a rigid frame or mould.The technique allows for the creation of objects of all shapes and sizes with huge design flexibility for both simple and highly complex designs.

Tempered and Pre-hardened is done to 1000Mpa.Whenever for plastic processing mould carrier large moulds ( over 400mm thickness) is used.Pre-hardened plastic mould steels are widely used for manufacturing mould for plastic.

High grade mould base for mirror surface & EDM requirement, rubber moulds, Injection moulds for bottle crates, TV sets housing frames, refrigerator doors, bucket and automobile related compartments, electrical and audio visual related compartments etc.

PROPERTIES & CHARACTERISTICS

- Wear Resistance

- Mould Frames

- Machine Tool Engineering

- Die Casting Industry

- Mould Parts

- Preform Dies

APPLICATIONS:

Generally used for mechanical engineering & tool manufacture.

Injection moulds, blow moulds, forming tools, press brake dies.

PRODUCT SPECIFICATIONS OF PLASTIC MOULD STEEL -

1. P20 + Ni - Used for various large-size mirror plastic mould, precision plastic mould, like: cars accessies, home appliances, electronic equipment plastic mould.

2. P20 - Plastic moulds, mould frames for plastic moulds and pressure casting moulds and recipient sleeves.

Virat Special Steels is the largest stockist and supplier of P20 + Ni and P20 tool steel in flat, square and round bars. We provide steel in all sizes as your requirements. P20 steel is available in flat, square and round shape.

Consult our team who will assist you for the Plastic Mould Steels query.

Learn more :

https://www.viratsteels.com/plastic-mould-steel.html

Any queries feel free to contact us :

[email protected] or on mobile number +91-9814021775

#plasticmouldsteels#metalworking#metallurgy#iso9001#engineering#steel#alloy steel#cold work steel#die steels#high speed steel#mouldsteelstockist

2 notes

·

View notes

Photo

The company is located in Pune,India. The company can point to over 30 years of experience and has been actively exporting moulds. We offer the best quality range of Injection Moulding Dies for our valued clients.

Contact Us on - 8888875295

0 notes

Text

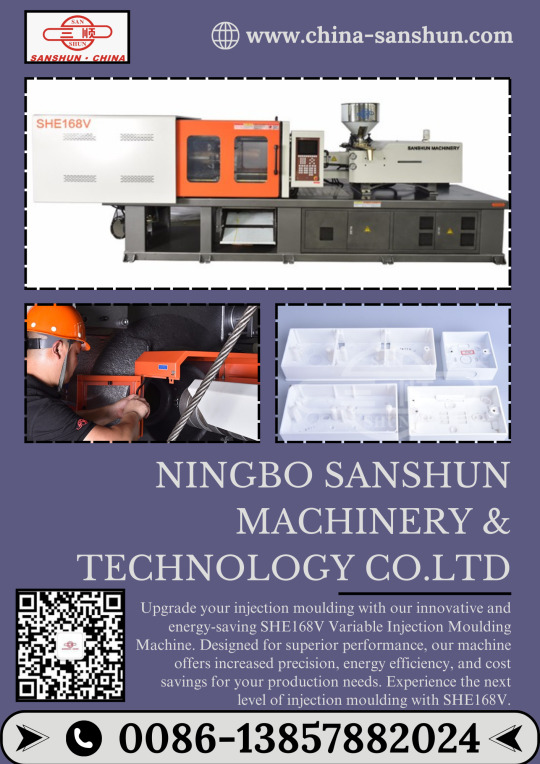

China Sanshun offers the SHE168V Variable Energy Saving Injection Moulding Machine for plastic product manufacturing. Featuring Hard-Chrome Plated High-Tensile Steel Tie-Bars and a Low-pressure mold protection device, this machine guarantees efficient production.

Contact us today for more information and latest pricing details.

Website: - https://www.china-sanshun.com/

#high speed machine#injection blow molding machine#injection moulding machine#plastic auxiliary machine#led bulb cover making injection blow machine#SHE168V Variable Energy Saving Injection Moulding Machine#Energy Saving Injection Moulding Machine

0 notes

Text

Craft excellence with premier injection blow moulding machine manufacturers. Our cutting-edge technology and meticulous craftsmanship deliver top-quality machines for precise and efficient production processes.

#injection blow moulding machine manufacturers#injection moulding machine manufacturers#injection blow moulding machine manufacturers in india

0 notes

Text

100w 2000w SK15 infrared heat lamps used in the Stretch Blow Moulding Machines Injection Blow Molding Machine

HalogenBulbs#infraredlampgoodprices#heaterinfrared#halogeninfraredheater#infraredcuringlamp#replacementinfraredhalogenlamp#electricinfraredheater#irlamp#carbonfiberheaterinfrared#quartzhalogenlamp

0 notes

Text

Blowing Machine

Yosion Machinery is a nearly 30-year-old supplier of PET bottle production line, which specializes in the research and manufacture of two-step PET/PP bottle blowing machine and its related PET preform moulds, cap moulds and bottle blowing moulds, and has successfully sold WELLTEC PET special injection moulding machine as an agent, providing one-stop service for the manufacturers of PET plastic bottles.

cosmetics bottle blowing machine

1 note

·

View note