#industrial manufacturing

Text

Revolutionizing Manufacturing: The Power of Fiber Laser Cutting Machines

In the realm of modern manufacturing, precision, efficiency, and versatility are paramount. As industries evolve, so do the technologies that drive them forward. One such innovation that has been making waves in the manufacturing world is the Fiber Laser Cutting Machine.

Understanding Fiber Laser Cutting Machines

Fiber laser cutting machines utilize the power of laser technology to precisely cut through various materials with unmatched accuracy and speed. Unlike traditional cutting methods, such as mechanical cutting or plasma cutting, fiber laser cutting machines offer several distinct advantages:

High Precision: Fiber lasers can achieve incredibly fine cuts, allowing for intricate designs and complex shapes with minimal material waste.

Speed and Efficiency: With rapid cutting speeds, fiber laser machines enhance productivity and streamline manufacturing processes, reducing lead times and increasing output.

Versatility: These machines can cut through a wide range of materials, including metals like steel, aluminum, and copper, as well as non-metal materials like plastics and composites.

The Rise of Fiber Laser Cutting Machine Manufacturers

In recent years, the demand for fiber laser cutting machines has surged, leading to a burgeoning market of manufacturers catering to diverse industry needs. Among these manufacturers, Metweld stands out as a leader in delivering cutting-edge solutions that redefine the standards of precision and performance.

Why Choose Metweld Fiber Laser Cutting Machines?

Advanced Technology: Metweld’s fiber laser cutting machines are equipped with state-of-the-art technology, ensuring exceptional cutting quality and consistency.

Customization Options: With customizable features and configurations, Metweld machines can be tailored to meet specific application requirements, providing versatility and flexibility on the production floor.

Reliability and Support: Backed by comprehensive customer support and maintenance services, Metweld ensures uninterrupted operation and maximum uptime for its cutting-edge machines.

Related Keywords and Their Significance

In the competitive landscape of manufacturing, optimizing online visibility is crucial for manufacturers and suppliers alike. By incorporating related keywords strategically, businesses can improve their search engine rankings and attract relevant traffic to their websites.

Fiber Laser Cutting Machine: This primary keyword encapsulates the core topic of the blog and serves as a focal point for discussing the technology and its benefits.

Fiber Laser Cutting Machine Manufacturers: By including this keyword, we highlight the importance of choosing reliable and reputable manufacturers like Metweld for superior quality and service.

Conclusion

Fiber laser cutting machines represent a paradigm shift in modern manufacturing, empowering industries to achieve unprecedented levels of precision, efficiency, and productivity. As the demand for these advanced cutting solutions continues to rise, choosing the right manufacturer becomes increasingly crucial. With its commitment to innovation, quality, and customer satisfaction, Metweld emerges as a trusted partner in driving manufacturing excellence.

In conclusion, embracing the transformative power of fiber laser cutting machines is not just a competitive advantage—it's a necessity for staying ahead in today's dynamic manufacturing landscape.

Check out Metweld’s Fiber Laser Cutting Machines and embark on a journey towards precision and efficiency in manufacturing.

#fiberlasercuttingmachine#fiberlasercuttingmachinemanufacturers#industrialproducts#metweld#industrial manufacturing#products

0 notes

Text

Join Us at Our Upcoming Exhibitions!We are excited to announce our participation in two major events this May:Solar & Storage Live Philippines 2024📅 Date: May 20 - 21, 2024🏢 Venue: SMX Convention Centre, Manila (Philippines)🎪 Hall: 01, Stall: B09EL Asia Bangalore 2024📅 Date: May 24 - 26, 2024🏢 Venue: Bangalore International Exhibition Centre🎪 Hall: 02, Stall: K12Come visit our stalls to learn more about our latest products and innovations. We look forward to seeing you there!#Exhibition #SolarStorageLive #ELAsia #TrinityTouch #RenewableEnergy #Technology

#solar power#solar#solar system#green environment#Exhibition#industrial manufacturing#Components#manufacturer#renewable energy#green energy#solarsolutions#electronic components#Electrical Components#solarenergy

0 notes

Text

Harvesting Machine Belts

Our Endless or Open Roll V Belts are specifically designed for crop harvesters of root vegetables and other plant harvesting machines. Primarily found in the produce of Radish, Carrots, Cabbage, Celery, Beets, Turnips, Parsnips, & Leek with a dirt hopper system, our V belts can also be found in use at flower and tree nurseries, as well as industrial harvest machine.

Depending on the application, our cord or ply structure machine belts will ensure low elongation and high tension to ensure the highest harvest yield. The high-wear rubber compounds have been designed to resist UV exposure and the harsh working conditions of inground harvesting.

If you manufacture conveyors for the food industry or are in need of one. You are in the right place. Rainbow Rubber & Plastics is one of the leading food conveyor belt suppliers in North America. We manufacture the highest quality food conveyor belts for grain and harvest machine belts.

#RainbowRubberPlastics#Reading#Pennsylvania#Conveyor Belts#Conveyor Belt Solutions#industrial machinery#industrial manufacturing#agriculture#agriculture technology

0 notes

Text

The Power of Capstan Lathe Machines

Capstan lathe machines represent the pinnacle of precision engineering in the realm of industrial manufacturing. These cutting-edge tools have revolutionized the production process, offering unparalleled levels of accuracy, speed, and versatility. From rapid tool changes to seamless machining operations, capstan lathe machines empower manufacturers to achieve exceptional results with utmost efficiency. Let's delve into the world of capstan lathe machines and uncover the myriad benefits they bring to the manufacturing landscape.

0 notes

Text

Imperial Associates is one of the best spout pouch filling machine manufacturers in India. You can start your business anywhere by purchasing a machine from here. All India delivery facility is also available here. Their supported team will guide you from starting your business to building your brand and you can contact them 24*7 anytime for technical issues. Visit the website now for more information.

#industrial#industrial machinery#industrial business#industrial manufacturing#spout pouch filling machine

1 note

·

View note

Text

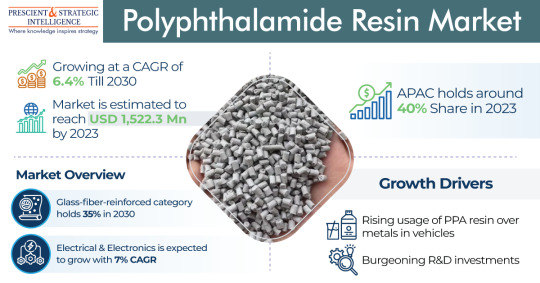

Polyphthalamide Resin Market Insights and Growth Prospects

Introduction

In the dynamic landscape of polymer resins, Polyphthalamide (PPA) emerges as a key player, offering a myriad of applications across various industries. This article delves into the intricacies of the Polyphthalamide Resin Market, shedding light on its burgeoning growth, market dynamics, and future prospects.

The polyphthalamide resin market witnessed a size of USD 1,522.3 million in 2023. Projections indicate a steady advancement with a compound annual growth rate (CAGR) of 6.4% anticipated during the period from 2024 to 2030. By 2030, it is forecasted to reach a substantial value of USD 2,320.6 million.

Understanding Polyphthalamide Resin

Polyphthalamide resin, a high-performance thermoplastic resin, exhibits exceptional mechanical, thermal, and chemical properties, making it suitable for demanding applications. With its superior strength, stiffness, and dimensional stability, PPA finds extensive usage in automotive, electrical, electronics, and industrial sectors.

Market Segmentation

1. Automotive Industry

Polyphthalamide Resin plays a vital role in the automotive industry, where lightweight, high-performance materials are essential for enhancing fuel efficiency and reducing emissions. From engine components to under-the-hood applications, PPA offers excellent heat resistance and mechanical strength, making it an ideal choice for critical automotive parts.

2. Electrical and Electronics Sector

In the realm of electrical and electronics, Polyphthalamide Resin serves as a reliable material for connectors, sockets, and circuit boards. Its ability to withstand high temperatures, moisture, and chemical exposure makes it indispensable for electronic devices, ensuring reliable performance and longevity.

3. Industrial Applications

In industrial settings, Polyphthalamide Resin finds diverse applications in machinery, equipment, and tooling components. Its exceptional mechanical properties, including high tensile strength and abrasion resistance, make it well-suited for demanding industrial environments, where durability and reliability are paramount.

Market Trends and Growth Drivers

The Polyphthalamide Resin Market is driven by several key trends and factors, including technological advancements, increasing demand for lightweight materials, and growing emphasis on sustainability. As industries strive for enhanced performance and efficiency, the demand for high-performance thermoplastics like PPA continues to rise, propelling market growth.

Challenges and Opportunities

While the Polyphthalamide Resin Market presents lucrative opportunities for manufacturers and suppliers, it is not without its challenges. Factors such as fluctuating raw material prices, regulatory compliance, and competition from alternative materials pose significant hurdles. However, proactive strategies, such as product innovation, market diversification, and strategic partnerships, can help industry players overcome these challenges and capitalize on emerging opportunities.

Polyphthalamide Resin Market: FAQs

What are the key properties of Polyphthalamide Resin? Polyphthalamide Resin exhibits exceptional mechanical, thermal, and chemical properties, including high strength, stiffness, and heat resistance.

What are the primary applications of Polyphthalamide Resin? Polyphthalamide Resin finds usage in automotive, electrical, electronics, and industrial sectors for components requiring high performance and reliability.

Is Polyphthalamide Resin recyclable? Yes, Polyphthalamide Resin is recyclable, offering sustainable solutions for various applications and industries.

What factors drive the growth of the Polyphthalamide Resin Market? Technological advancements, increasing demand for lightweight materials, and stringent regulatory standards contribute to the growth of the Polyphthalamide Resin Market.

How do manufacturers ensure the quality of Polyphthalamide Resin products? Manufacturers employ stringent quality control measures and testing protocols to ensure the quality and consistency of Polyphthalamide Resin products, meeting industry standards and customer expectations.

What are the emerging trends in the Polyphthalamide Resin Market?

Emerging trends include the development of bio-based Polyphthalamide Resins, advancements in compounding technologies, and expanding applications in emerging sectors such as 3D printing.

#Polyphthalamide resin market#Insights#Growth prospects#Automotive#Electrical and electronics#Industrial manufacturing#Mechanical properties#High temperature resistance#Chemical resistance#Product design#Market dynamics

0 notes

Text

Explore our range of high-quality weight machines for sale at Symphony Weighing. From precision scales to industrial weighing solutions, we offer reliable products to meet your needs.

#weighingscale#weighing machine#weight loss#industrial machinery#industrial manufacturing#kitchen scales#electronic scale#electronic#weight management#balance#business

0 notes

Text

Key Benefits Of Adhesives In The Manufacturing Industry

Discover the types of adhesives used in manufacturing industries. Learn about the performance and structural benefits they offer with our blog. Read now!

https://www.kohesibond.com/benefits-of-adhesives-in-the-manufacturing-industry/

0 notes

Text

On-the-Move Precision Portable CNC Plasma Cutting Machine

Introducing the On-the-Move Precision Portable CNC Plasma Cutting Machine, a cutting-edge solution for your fabrication needs. As a leading Portable CNC Plasma and Profile Cutting Machine Manufacturer, we take pride in delivering high-quality, versatile equipment designed for optimal precision. Our CNC Plasma Cutting Machine ensures seamless, efficient cuts, making it an essential tool for various industries.

At the core of our innovation is the Portable CNC Plasma and Profile Cutting Machine, a testament to our commitment as a CNC Plasma Cutting Machine Manufacturer. This state-of-the-art equipment empowers businesses with flexibility and accuracy, enabling on-the-go operations without compromising precision. Whether you're a small workshop or a large-scale manufacturing unit, our CNC Plasma Cutting Machine caters to your diverse cutting requirements.

Choose reliability and performance with our CNC Plasma Cutting Machine. As a trusted CNC Plasma Cutting Machine Manufacturer, we prioritize durability, efficiency, and customer satisfaction. Invest in the future of fabrication technology and experience the difference that the On-the-Move Precision Portable CNC Plasma Cutting Machine can bring to your operations.

#portablecncplasmaandprofilecuttingmachine#cncplasmacuttingmachine#cncplasmacuttingmachinemanufacturer#industrial manufacturing#industrialmetal#metweld

0 notes

Text

Shaping the Future: Insights into the Isostatic Pressing Market

The global isostatic pressing market is projected to be USD 13,568.1 million by 2030 growing at a CAGR of 7.0% during the forecast period. sectors including energy, aerospace, medical devices, automotive, and manufacturing regularly use isostatic pressing. In this regard, the requirement for such technology is significantly impacted by the growing requirement for contemporary materials and…

View On WordPress

#advanced forming technology#advanced materials#aerospace industry#automotive components#ceramic components#engineering ceramics#high-pressure manufacturing#industrial manufacturing#industry trends#isostatic pressing#isostatic pressing applications#isostatic pressing process#manufacturing efficiency#market growth#material compaction#metal parts production#powdered metals#precision engineering

0 notes

Link

High-Quality AFCS Thermoforming Cut & Stack Machines | Ridat

Discover Ridat's Automatic Thermoforming Cut and Stack (AFCS) machines, designed for cost-effective production of vacuum-formed components and clamshells. Our AFCS-P series offers precise product definition, robust construction, and flexible operation. Contact us at +44 (0)20 8458 6485 or [email protected] to elevate your thermoforming capabilities. Serving global industries with over 60 years of expertise.

#Thermoforming machinery#Vacuum forming#Packaging equipment#Industrial manufacturing#Flexible operation

0 notes

Text

Rainbow Rubber & Plastics: Contact Us

In need of custom belt solutions or simply have more questions about our process? Contact our team. Rainbow Rubber & Plastics will be happy to assist you with any questions regarding rubber belts and how we can help your business.

Fill our contact form to get in touch. We’ll get back to you within 1-2 business days.

#RainbowRubberAndPlastics#contact us#conveyor belts#manufacturing#industrial manufacturing#custom belt solutions

0 notes

Text

What is Cable Gland?

A cable gland is a device used to secure and protect the end of an electrical cable or wire where it enters an enclosure or piece of equipment. The cable gland provides a seal around the cable, preventing the ingress of dust, dirt, moisture, and other contaminants into the enclosure or equipment.

Cable glands come in various sizes and materials, and are often made of metal, plastic, or rubber. They typically consist of a threaded cylinder that screws onto the outside of the enclosure or equipment, a compression ring that secures the cable, and a sealing element that provides the waterproof seal.

Usage of Cable Gland:

The main usage of a cable gland is to provide a secure and reliable method for routing and connecting electrical cables through an enclosure or piece of equipment. Here are some of the key uses of cable glands:

Protecting cables from environmental factors: Cable glands are used to protect cables from various environmental factors such as dust, dirt, water, and other contaminants. This helps to ensure the safe and reliable operation of the electrical system.

Providing strain relief: Cable glands provide strain relief to cables, which helps to prevent damage to the cable caused by pulling or twisting forces. This can help to extend the life of the cable and prevent premature failure.

Creating a seal: Cable glands create a seal around the cable, preventing moisture, dust, and other contaminants from entering the enclosure or equipment. This can help to prevent corrosion, short circuits, and other issues that can affect the performance of the electrical system.

Meeting safety standards: Cable glands are often required to meet certain safety standards in order to ensure that the electrical system is safe and compliant with regulations. For example, explosion-proof cable glands are required in hazardous environments to prevent sparks or flames from escaping through the cable entry point.

Providing grounding: Some cable glands are designed to provide grounding for the cable, which can help to protect against electrical interference and reduce the risk of electrical shock.

Overall, cable glands are a critical component of many electrical systems, providing a secure, reliable, and safe method for routing and connecting cables through enclosures or equipment.

Types of Cable Glands?

PVC Gland: A PVC gland is a type of cable gland that is made from polyvinyl chloride (PVC) material. PVC glands are commonly used in indoor applications and provide good resistance to moisture, chemicals, and UV light. They are generally less expensive than other types of cable glands but may not be suitable for outdoor or harsh environments.

Nylon cable gland: Nylon cable glands are made from a type of thermoplastic material called nylon. They are lightweight, durable, and provide good resistance to chemicals, oil, and UV light. Nylon cable glands are commonly used in outdoor applications and are suitable for a wide range of cable sizes.

Polyamide cable gland: Polyamide cable glands are similar to nylon cable glands in terms of their material and properties. They are commonly used in harsh environments where there is exposure to extreme temperatures, chemicals, and UV light. Polyamide cable glands provide good mechanical strength and are available in a wide range of sizes.

Metallic cable gland: Metallic cable glands are made from materials such as brass, stainless steel, or aluminum. They provide good mechanical strength, resistance to corrosion, and are suitable for use in harsh environments. Metallic cable glands are commonly used in industrial applications and may be required in certain hazardous environments.

EMC cable gland: An EMC (electromagnetic compatibility) cable gland is designed to provide shielding against electromagnetic interference (EMI) and radio frequency interference (RFI). EMC cable glands provide a low-resistance electrical connection to the cable's shielding, which reduces the risk of EMI.

Nickel Plated cable gland: A nickel-plated cable gland is a type of metallic cable gland that has a coating of nickel on its surface. The nickel plating provides additional corrosion resistance and improves the durability of the gland. Nickel-plated cable glands are commonly used in outdoor and harsh environments.

Brass cable gland: A brass cable gland is a type of metallic cable gland that is made from brass material. Brass cable glands provide good mechanical strength, corrosion resistance, and are suitable for a wide range of applications. They are commonly used in industrial and outdoor applications.

Why choose Trinity Touch?

Trinity Touch is an Indian-based company that specializes in the manufacturing of cable glands and other related products. The company was established in 1993 and has since become a leading player in the Indian market. Here are some reasons why Trinity Touch may be considered one of the best cable gland companies in India:

Wide range of products: Trinity Touch offers a wide range of cable glands to suit various applications and cable types. They have products for standard cables, armoured cables, EMC cables, and more.

Quality and reliability: Trinity Touch has a reputation for producing high-quality products that are reliable and durable. They use advanced technology and rigorous quality control processes to ensure that their products meet the required standards.

Compliance with standards: Trinity Touch products are designed to comply with various national and international standards such as UL, CE, and ATEX. This ensures that their products meet the required safety and regulatory standards.

Customer service: Trinity Touch has a strong focus on customer service and support. They offer technical assistance, training, and product customization to meet the specific needs of their customers.

Industry recognition: Trinity Touch has received various industry awards and accolades for their products and services, which further highlights their position as a leading player in the market.

Overall, Trinity Touch's focus on quality, compliance, customer service, and innovation has helped them establish a strong position in the Indian cable gland market.

#cable glands#Cable Gland#cable glands brass#What is cable gland#Usage of cable gland#types of cable glands#tumblog#electrical industry#industrial manufacturing#Trinitytouch

1 note

·

View note

Text

5 Industry Applications That Hydraulic Cylinder Manufacturers Supply To

Hydraulic cylinder manufacturers cater to a wide range of industries for different applications, some of the major ones including shipbuilding, iron and steel, aerospace and defense, etc. From diaphragm actuators to hydraulic cylinders, the manufacturing companies design and engineer various products to meet those needs of the industry.

• Ship Equipment

From side gangways to rudder adjustment to moving stern applications, hydraulic cylinders are utilized in shipbuilding, including yachts, submarines, naval ships and vessels. Maritime applications of robust designs and operational availability help deliver high-quality performance. Precisely designed and engineered solutions accommodate the requirements of equipment at the right time and make them seamless.

• Iron & Steel

For several of its processes, iron and steel industry utilizes hydraulic cylinders. Electro-hydraulic with the help of PLC and linear scale applications have transformed. Hydraulic cylinder manufacturers produce maximized goods for steel mills, hot strip rolling mills, rebar production facilities, continuous casting plants and blast furnaces. If most of the iron and steel industry would be analyzed, a huge cache of machinery account for hydraulic-driven equipment.

• Defense

Crossing $20bn industry in 2023, the market of hydraulic cylinder in the aerospace and defense industry is set to create a revolution. From engines and ramps to flight controls, hydraulic cylinders are major components and play a critical role in most of it. Whether landing gears or systems and control surfaces, hydraulic cylinder remains on top of the demand in the defense industry.

• Engineering

As they generate mechanical force, hydraulic cylinders are utilized in various marine and offshore engineering applications. Typically, heavy pulling or pushing or lifting requires exceptional force and those operations can effectively work out with the help of these cylinders.

• Construction

Industrial manufacturing in the construction industry including excavators, bulldozers and attachments utilize hydraulic cylinders for a wide variety of functions. These cylinders have accumulator station and other components for operational requirements.

0 notes

Text

youtube

Hello and welcome to this video, where we'll be showing you How To Design And Manufacture An Iron Bench and Complete Iron Bench Making Process. Designing and manufacturing an iron bench requires a combination of creativity, welding and fabrication skills, and a deep understanding of metalworking. The process begins with creating a plan and design, which is then followed by the selection of materials and cutting, shaping, and welding of the metal pieces. Once the pieces are assembled, finishing and treatment of the metal should be done to ensure its durability and longevity. Finally, the bench should be painted or coated for a decorative and protective finish.

#iron garden bench#industrial manufacturing#metal bench outdoor#manufacture an iron bench#how to make a bench#cast iron bench restoration#how to design and manufacture an iron bench#iron bench design#how to make a iron bench#iron bench making process#how to make a black iron bench#Youtube

0 notes