#hydraulic oil filter

Text

What is varnish and its effects

The condition of the oil in lubrication and hydraulic systems is indicative of the health of the entire system. There are two essentials for ensuring productivity, for avoiding malfunctions and for reducing operating costs:

Monitoring the fluid condition

Continuous maintenance of operating equipment

Varnish is a soluble and insoluble contaminant made up of by-products of oil degradation and oxidation. It can appear as a gel-resin like consistency or resemble solid deposits in the oil, or which plates out on the metal surfaces of lube systems. It can be the result of several possible root causes, including high temperatures, electrostatic discharges, lubricant degradation and micro dieseling. Varnish can produce a number of problems related to machine operation, such as valve stiction, lubricant flow restriction, clogged filters, etc.

How is varnish different from sludge?

Varnish is a tough, adherent oxide or carbonaceous material that coats internal machine surfaces. Hot surfaces and/or time will often cure varnish to a hard/brittle consistency.

In contrast, sludge, which is sometimes a precursor to varnish, is soft and sticky and can move about the system until finally coming to rest at sump bottoms, troughs, strainers, filters, and narrow fluid passages.

To know more follow:

https://www.linkedin.com/company/minimacsystemsprivatetlimited

What are the main causes of varnish in your system?

To summarize the prime reasons for varnish generation is following:

Pressure-induced thermal degradation.

Pressure-induced dieseling

Oxidation

Is your system susceptible?

There are a number of reasons why lube oils suffer from high rates of varnish contamination. If your system ticks any of these boxes, then you should test your oil for varnish potential:

for Oil Check call +91 8975150700

Visible deposits or discoloration of lube circuit components

If you switched from group I to group II oil, or if you have blended oils

The high flow rate of lube oil from a small lube oil reservoir

High operating temperature

A gas turbine, gas compressor, or hydraulic system

How to physically identify if there is a change in chemical composition?

The following can be the warning signs that the oil has undergone chemical changes:

Change in oil colour

Strong odour

Change in oil consistency

Sludge and hard deposits on metal surfaces

Visible contaminants in oil samples

If you are facing varnish deposits, two actions are recommended to control it. First, identify the root causes. This will require a systematic study of the possible factors supported by oil analysis. Next, remove the existing varnish in the machine.

At Minimac Systems, we offer flushing services and filter check services which ensure a clean system including oil tanks and lines. Book an appointment with our technical expert by clicking on https://www.linkedin.com/company/minimacsystemsprivatetlimited or call +91 89751 50700

Like, Comment, Share this article to spread awareness and sensitize the reader for Zero Mechanical Breakdown.

#frf#oil flushing#minimac systems#power#oil & gas#hydraulic oil#lube oil filter#minimac#contamination#hydraulic oil filter#coalescer separator#transformer oil#diesel oil purification#lube oil flushing#hydraulic oil filter#hydraulic oil flushing#chemical cleaning#moisture contamination#contamination ocd#contamination control

0 notes

Text

Common Signs of Hydraulic Filter Issues You Shouldn't Ignore

Hydraulic filters play a vital role in maintaining the integrity of industrial machinery. In this blog, we will discuss common signs that indicate potential hydraulic filter issues. Ignoring these signs can lead to severe damage and increased maintenance costs.

Decreased Performance:

A noticeable decline in the performance of your hydraulic system, such as slower operation or reduced power, can indicate a clogged or damaged hydraulic filter. Regular monitoring is crucial to identify and address performance issues promptly.

Unusual Noises:

Strange noises, like whining or grinding, may signal problems with the hydraulic filter. Contaminants or damaged filter media can lead to increased friction and noise within the system.

Increased Operating Temperature:

If you observe a sudden rise in the operating temperature of your hydraulic system, it could be a sign of filter issues. Overheating may result from reduced fluid flow caused by a clogged filter.

Visible Contamination:

Inspect the hydraulic fluid for visible contaminants or discoloration. Dirty or contaminated fluid indicates that the hydraulic filter is not effectively trapping impurities, risking damage to system components.

Conclusion:

Recognizing and addressing signs of hydraulic filter issues is essential for preventing extensive damage to industrial machinery. Regular maintenance, including filter checks and replacements, is key to ensuring a smooth and efficient hydraulic system.

Contact Us: For prompt solutions to hydraulic filter issues in India, contact India Filters at https://www.indiafilters.com/.

0 notes

Text

5 Maintenance Tips for Extending the Lifespan of Your Hydraulic Oil Filter Machine

We at Sumesh Petroleum recognise how crucial it is to maintain the efficiency of your hydraulic systems. A well-maintained hydraulic oil filter machine is essential to accomplishing this. You may assure optimal performance for years to come and prolong the lifespan of your machine by adhering to these easy suggestions.

1. Adopt a Prevention Mentality: Regular Maintenance Is Essential

Your Hydraulic Oil Filter Machine depends on regular maintenance, just like your car does. Make a timetable for cleanings, filter changes, and inspections by consulting the instructions that came with your machine. By taking a proactive stance, you can spot small problems early on and take action before they become bigger ones.

2. Filter Frenzy: Choosing the Correct Filter and Changing It When Needed

Not every filter is made equally! Make sure the filter type you're using is the right one that the maker of your machine recommends. This ensures maximum filtering effectiveness and shields your system from impurities. It's important to follow the suggested filter change schedule. A clogged filter strains your system and decreases flow.

3. Oil Analysis: An Insight into the Health of Your System

Think about putting in place a routine programme for oil analysis. It is possible to obtain important information about the condition of your hydraulic system by submitting oil samples to a laboratory. Oil analysis enables you to take corrective action before significant harm happens by early detection of degradation, contamination, and other equipment problems.

4. Maintaining Cleanliness: The Enemy Is Contamination

Hydraulic systems can become contaminated by moisture, dirt, and debris. The longevity of your equipment may be considerably shortened by this contamination. To reduce the danger of contamination, keep the area around your hydraulic oil filter machine clean and make sure that the oil and filters are stored properly.

5. Pay Attention! Pay Attention to Odd Sounds

Your Hydraulic Oil Filter Machine uses audio to communicate. Observe the sounds it makes when it operates normally. Any strange noises, such as excessive clanging, grinding, or whining, may be signs of an impending issue. Please do not hesitate to contact a competent technician for an inspection if you hear something unusual.

You can increase the longevity of your hydraulic oil filter machine, maximise performance, and guarantee the smooth running of your hydraulic systems by according to these easy maintenance guidelines. Get in touch with Sumesh Petroleum right now for more details on hydraulic oil filter machines or preventative maintenance schedules!

0 notes

Text

Top Quality Hydraulic Oil Filter Machine Manufacturers

Rayon India's Hydraulic Oil Filter Machine ensures seamless filtration, keeping your machinery running smoothly. With user-friendly design, it efficiently removes contaminants, extending equipment lifespan. Simplify maintenance with our reliable solution. Trust Rayon India for hassle-free filtration, optimizing performance and reducing downtime.

Address : KHASRA NO. 1318,Morta Industrial Area,Near Hotel VivaanMeerut Road, Morta,GHAZIABAD - 201003 U.P

Hydraulic Oil Filter Machine Manufacturers

0 notes

Text

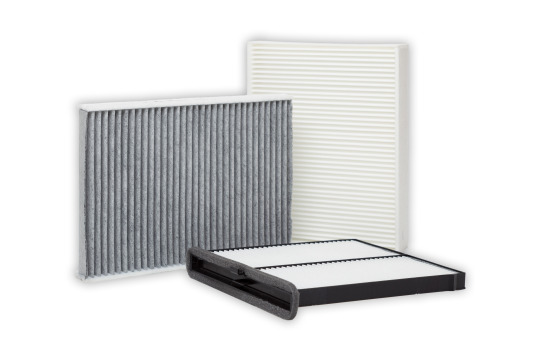

Cabin Filters and Fuel Filters Breathe Fresh, Drive Smooth with Action Group

Action Group's Cabin and Fuel Filters are made for maximum performance and best possible vehicle health. They will enhance your driving experience. Our Cabin Filters guarantee that your car's inside is clean and comfortable while capturing dust, pollen, and other pollutants to provide you a breath of fresh air. Our selection of fuel filters protects your engine by keeping contaminants from getting to vital parts, guaranteeing a smooth and effective fuel delivery system. You can rely on Action Group to provide high-quality filters that prolong the life of your car and improve driving comfort. Take a look at our selection now and benefit from improved engine performance and cleaner air. Drive with assurance and the Action Group at your side.

Company Name: ACTION GROUP

Phone No: +60362585868

#Cabin Filters#fuel filtes#Coolant filters#MANN+HUMMEL#Industrial Filters#OE Filters#car filters#Cabin filters#Car AirCon Filter#Car Replacement Filters#Fuel Filter#Heavy Duty Filters#Filtration Solutions#Aftermarket Filters#High Efficiency Filters#Auto filters#Hydraulic Filters#Air Oil Separator#Oil Filters#MANN FILTER#Car Air Filters#Performance Filters

0 notes

Text

How to clean a hydraulic oil filter ?

Cleaning a hydraulic oil filter typically involves removing the filter from the hydraulic system and then using appropriate methods to remove the accumulated dirt and debris. Here’s a general guide on how to clean a hydraulic oil filter:

Ensure safety: Before starting any maintenance on hydraulic systems, make sure the system is depressurized and the equipment is turned off.

Locate the filter: Identify the location of the hydraulic oil filter in your system. It is usually found in the hydraulic reservoir or in-line with the hydraulic lines.

Remove the filter: Depending on the type of filter, you may need to use a wrench or other tools to loosen and remove the filter from its housing. Be cautious to avoid spillage of hydraulic oil during this process. It’s a good idea to have a drain pan or absorbent materials ready to catch any oil that may leak.

Inspect the filter: Examine the filter for signs of damage or excessive contamination. If the filter is damaged or clogged beyond cleaning, it may need to be replaced instead of cleaned.

Pre-clean the filter: Before performing a thorough cleaning, you can use compressed air or a soft brush to remove loose debris and dirt from the filter. Be careful not to damage the filter media during this step.

Clean the filter: There are different methods to clean a hydraulic oil filter, depending on the type and level of contamination. Some common cleaning methods include:

Soaking: Submerge the filter in a cleaning solution recommended by the filter manufacturer or use a suitable solvent to dissolve the contaminants. Gently agitate the filter to help loosen the debris. Follow the manufacturer’s instructions for the appropriate soaking time.

Backflushing: If the filter is designed for backflushing, use a low-pressure source of clean hydraulic fluid to flush the filter in the opposite direction of the normal flow. This helps dislodge and remove contaminants from the filter media.

Ultrasonic cleaning: In some cases, ultrasonic cleaning machines can be used to clean the filter. These machines use sound waves to create high-frequency vibrations that help dislodge contaminants from the filter media.

Rinse and dry: After cleaning, thoroughly rinse the filter with clean water or a suitable cleaning solution to remove any remaining cleaning agents. Allow the filter to air dry completely before reinstalling it.

Reinstall the filter: Once the filter is dry, carefully reinstall it into its housing or mounting location. Make sure it is properly seated and securely fastened according to the manufacturer’s instructions.

Dispose of waste properly: Properly dispose of the used cleaning solution, contaminated filters, and any other waste materials according to local regulations and guidelines.

It’s important to note that not all hydraulic oil filters are designed to be cleaned and reused. Some filters are intended for one-time use and should be replaced when they become clogged or damaged. Always refer to the manufacturer’s recommendations and guidelines for proper maintenance and cleaning procedures specific to your hydraulic oil filter.

1 note

·

View note

Text

They say, ‘prevention is better than cure’, but when it comes to hydraulic rams, you need both." When dealing with hydraulic rams, you need a reliable source for the Best Hydraulic Ram Repairs. Look no further than Hyspec Fluid Power. Our experienced technicians use state-of-the-art equipment to diagnose and repair all types of hydraulic rams. We offer timely and cost-effective repairs, ensuring that your equipment is back up and running in no time. Contact us today to learn more about our hydraulic ram repair services and keep your operations running smoothly.

#hydraulic#hydraulic power units#industrial#business#hydraulic filters#hydraulic-oil#hydraulic cylinders#hydraulic power packs

0 notes

Text

How to Choose the Right Hydraulic Filter for Your Business

If you're like most business owners, you're always looking for ways to save money and improve efficiency. One way to do both of those things is to make sure you are using the right hydraulic filter for your business. There are a lot of different factors to consider when choosing a hydraulic filter, and it can be tough to know where to start. That's why we've put together this guide - to help make the process easier for you. By following these simple tips, you'll be able to choose the perfect hydraulic filter for your needs!

5 Simple Tips How To Choose Hydraulic Filter

First, consider the type of fluid you will be filtering. Different fluids require different types of filtration, so it's important to make sure your filter is compatible with the fluid in question.

Next, think about the operating conditions and environment in which your filter will be used - this can affect both the type and size of filter needed. Finally, consider the efficiency and pressure drop requirements for your application.

By taking all of these factors into consideration, you'll be able to choose the right hydraulic filter for your business and keep it running smoothly. Happy filtering!

Another tip to consider is the compatibility of the filter with your hydraulic system. Make sure to check that the filter will fit properly and won't cause any issues with your equipment. Also, don't forget about maintenance - choose a filter that is easy to clean and replace when necessary. Happy filtering!

And remember, it's always a good idea to consult with a professional or do some additional research before making your final decision on a hydraulic filter. They are an important component of your machinery and it's worth taking the time to make sure you choose the right one. Happy filtering!

One last tip - consider the cost of the filter, but also think about its long-term value. A slightly more expensive filter may end up saving you money in the long run by being more efficient and lasting longer. Keep this in mind as you make your decision. Happy filtering!

Bonus Tip: Consider purchasing a hydraulic filter from a reputable brand with a good track record. This can give you peace of mind and ensure that the filter meets high quality standards. Happy filtering!

Note: This blog post is for informational purposes only and does not constitute professional advice. Please consult a specialist for specific recommendations for your business. Happy filtering! See you next time. -end-

0 notes

Text

Letters from Watson: The Engineer's Thumb

Part 1: The Fun Bits

Hatherly is "exceedingly pale" and Watson mentions agitation as a cause even though he's already noted the possibility for excessive blood loss, and that railway cases are "seldom trivial." Hooray for Victorian medicine.

Fun fact: if you're fainting from blood loss you already need a transfusion. As of '89 we are two decades before safe (relatively) blood transfusions, when the ABO clotting factors were discovered. However, given the pain and stress, the cause of Hatherly's fainting doesn't have to be hypovolemic shock. Hatherly did just lose a thumb.

A carbolised bandage would have been a bandage treated with phenol (carbolic acid) as a disinfectant. I would not recommend raiding Watson's stash for it, as carbolic acid can cause chemical burns.

I cannot decide if Holmes' habit of smoking all the leftovers of his previous day's pipes is gross or endearing.

In two years, Hatherly has earned 27 pounds and 10 shillings. (Using the trusty Bank of England inflation calculator, which does not DO fractions of a pound, this is just over 2,870 modern pounds, or $3590) He is not having a great start.

Reminder that a guinea is 1 pound, one shilling. 50 guineas is almost double the amount Hatherly has ever made in his entire practice. And yet the thing that actually makes him suspicious is that the consultation is scheduled for late at night, after the trains have stopped running.

Fuller's earth is a white, highly absorbent clay, used as a chemical filter and absorber. Actual mineral composition may vary, but the use it was named for was when wool processors (Fullers) would use it to clean oils and dirt from wool. This step would have been prior to spinning or felting the fiber.

A hydraulic press would be extremely unnecessary for shaping any kind of clay, since it's... clay. The first time I read this I confused Fuller's Earth with Diatomaceous earth, which is powdery in structure and therefore might need some kind of squishing to be formed into a brick.

I was unable to find any town or city named Eyford, so I'm assuming it's another slightly fictionalized location.

The horse trick here has always struck me as a clever insight on Holmes' part: of course, he is already aware that this is a scam of some kind, and that the secrecy measures would include a lot of misdirection

13 notes

·

View notes

Text

Bad Memories

Summary: The first time Bastion saw the armor, they ran. The second time, they froze. And present at both was a man with more compassion than common sense.

(Author's note: this fic was written before the story announcement trailer showed that Reinhardt was not, in fact, okay with Omnics, so that's the reason he's fairly out of character here.)

---

The first time Bastion saw the armor, they ran.

The day had otherwise been peaceful. Happy, even. Two new friends had arrived, friends of Torbjorn’s, which of course made them both Bastion’s friends by default. There was the tall, enormous man named Reinhardt, with a loud voice and a big smile. Then there was his smaller companion, a woman named Brigitte, with long red hair and a smaller but still muscular build. Torbjorn seemed equally fond of both.

After the introductions, Brigitte and Winston had brought something in from the outside. Something big and covered in a tarp. Brigitte had smiled and pulled the tarp down. Silver glinted off metallic angles, twinkling, catching Bastion’s attention. They couldn’t look away.

The crested helmet and bulky frame crawled from their optic and into the deep recesses of their memory bank. It reached in and pulled forth shambling strings of a memory that might not have been their own, pulling, pulling, until the fire licked the edges of their vision and warnings spilled throughout their most primal systems.

Crusader.

It was suicide to turn one’s back on a Crusader. Bastion’s systems told them that. Their legs did not want to move and their torso did not want to turn, but a last-ditch override took care of that. Diverting power from threat analysis to hydraulics was also a horrible idea, but they did so anyway.

Active processing began to null as more power transferred, their speed picking up. The door ahead did not open so they tore it down with their momentum.

They were bathed in sunlight and their optic adjusted to the outside. They barreled past further buildings in the complex before thinking to take shelter. Too many open angles, too many lines of sight. They turned, sliding across the ground as they readjusted their trajectory, to an alley between buildings.

The alleyway ended in a solid wall which housed a decrepit dumpster, which they noticed too late. Bastion crashed into it and it crinkled like a leaf underfoot in the fall. The impact rattled loose the protocol they had been trying their hardest to avoid.

The transformation sent old damage warnings shooting up their frame as they configured into sentry mode. Their barrel swung around to the entrance of the alley.

The Crusader was coming, it had to be coming, but Bastion couldn’t tell whether the thundering they heard came from its footfalls or from their own shaking as they spun their barrel up.

No threats registered. No threats registered. As long as it stayed that way, then they wouldn’t do something that they knew they would regret.

Footsteps from the other end of the alley.

“Bastion, luv. Bastion! Where did you go? No need to be scared. It’s all okay.”

A blink of blue. Target registered. Bastion fired.

The vibration of their firing pins hitting the ends of cartridges, one by one by one, was a well-oiled symphony. It felt familiar. Bastion hated how it almost felt good. It was their purpose, after all- raining metal hell upon whatever was down range.

The chorus stopped. Their clip had run out.

Nothing followed but silence.

The urge to reload was mounting the longer they stayed configured, but a quick justification- the target is gone, must go find -let them transform back to recon mode.

But they did not investigate. That urge was far more easily quelled. Instead, they turned to face the wall. With no visuals to distract, they focused on turning off their combat protocols. They dug in their memory banks and brought up images of the forest. Sunlight filtering through trees. Butterflies sunning themselves on rocks by a stream.

With a click, their targeting overlay disappeared. The commands keeping their body rigid disappeared, and they sagged forward, letting their gun arm sink towards the ground and putting their hand against the wall to steady themselves. They stayed there until their cooling fans spun on, venting the heat from the strain from their systems.

A small background notification appeared and they let it through without thinking. Target confirmed eliminated?

Bastion jolted and turned their head down the alley. Immediate visual scans did not turn up a body.

“B-bastion, luv?” called a meek voice from the other end of the alley.

A head poked around the corner, just revealing a set of eyes, before jerking back again. Then it crept out once more.

Bastion didn’t know what to do.

“Lena, get away from the thing! Now!”

Bastion recognized Torbjorn’s voice. It scared them to hear the man so angry and afraid.

The peeking person disappeared. There was more conversation in quieter tones that Bastion could not pick up on, so they came forwards. They at least tried to muffle their footsteps.

Bastion peered out of the alleyway. Torbjorn and- their processor finally cleared enough to recall -Tracer huddled against the front of the building. Her chronal accelerator glowed only a faint, dusty blue.

The blink of blue. She was. . . unscathed.

Bastion let out a whine of relief. This caused the both of them to turn. Torbjorn flinched and his mouth opened, curses pouring out. Bastion ran back into the alley. They thought up pictures of the forest again, as a precaution. Just in case. Just in case.

There was a pitter patter of footsteps. Torbjorn had followed.

“Damned Omnic! You were supposed to be peaceful! You weren’t supposed to have any battle protocols!” He shook his fist in the air.

Every declaration bit into them worse than a bullet ever could.

“You could have killed her!”

Bastion turned off their audio sensors. They watched as Torbjorn circled around them, his eyes wide with anger, his mouth opening and closing in sharp rhythms that caused him to spit.

He stopped mid-syllable, before giving a glare. Then he pointed a finger right into Bastion’s chest and yelled. The vibration traveled through their plating and they flinched away at the unexpected sensation. Torbjorn’s fury only grew. Soon he was pounding a fist against their leg.

They knew they deserved this. He had every right to be angry. They had lost control.

Bastion slowly turned their audio sensors back on to ease into the man’s voice again. At a certain point they realized that they were whining out loud. They silenced themselves.

“So you’ve finally decided to listen again, hmm?” Torbjorn said.

Bastion made a sad, downturned noise. A noise of regret. There had been no place for regret in a vocabulary made for war, so they had invented the noise in the forest. They had given it to the animals many times. It was the first time they had given it to a human.

“So sorry, aren’t you?” Torbjorn’s tone was mocking.

Bastion nodded.

“Like I’d believe that. You’re one of mine. I should have known you were programmed like the rest.”

Bastion shook their head.

“Come on. No more frolicking around for you. You’re going into my workshop and staying there.”

Bastion knew they deserved it but they didn’t want to go.

“I said, come on, you lump of lugnuts!”

Torbjorn was behind them now, and kicking at their back legs.

“Did you turn off your audio sensors again? Damn tin can-!”

“My friend, stop.”

Bastion whirled their torso around. A new person had come around the corner. It was the tall man, Reinhardt, only he was not smiling now.

“Reinhardt! What are you doing here? You need to get out of here. It might kill you if it gets the chance!” Torbjorn shouted.

“Says the one who’s kicking the Bastion.” Reinhardt replied.

This caused Torbjorn to pause. “Touche.”

Whereas Torbjorn was all hard lines and tension, Reinhardt was calm. He was muscled and large, trained for combat, Bastion’s targeting system added unhelpfully, but he didn’t register as a threat. His movements were slow and thoughtful and the only defined lines on his face weren’t from a harsh expression- they were wrinkles, wrinkles from smiles and laughter past, gently juxtaposed with the scar that went down his eye.

Reinhardt walked towards them. Bastion stepped around to meet him.

“Hello, friend.” Reinhardt spoke to them. His tone was as gentle as wind ruffling the grass.

“Wait, are you talking to it?” Torbjorn said.

“I’m sorry to have scared you.” He continued.

Bastion at first thought the apology was meant for Torbjorn, but the man’s steady gaze into their optic told otherwise. Bastion could only cock their head in response.

“The armor holds many bad memories for you, doesn’t it?”

Crusader. Bastion chirped as the word appeared again in their processor. They nodded.

“Reinhardt, it wasn’t scared. Don’t be silly. Given its origins, it’s programmed to engage combat protocols when it sees your armor.” Torbjorn huffed.

“Then why did it run?” Reinhardt asked.

Torbjorn opened his mouth to retort but no words came out. He shut it again and frowned, before kicking the ground.

The hostile motion caused a flutter of activity in Bastion’s threat analysis systems. They began to glance around and realized they were cornered.

“Easy, my Omnic friend! You are not trapped.” Reinhardt took one step aside.

Bastion took a small step. Torbjorn conceded his space as well and went beside the wall. Bastion walked forward, exiting the shade and dark of the alley and entering into the bright sunlight once again.

It was late afternoon, they noticed. The wind whistled across the rooftops, carrying the songs of birds from the sea below. Details they hadn’t noticed before.

“Better?” Reinhardt asked from behind.

The pavement lined with metal had some cracks, from which dandelions grew. The walls of the buildings were soft gray with accents of blue and orange. There was a peculiar pattern in the wall right ahead, many holes upon holes-

The realization was instantaneous. Bastion sunk down with a long, dull whine.

“You are ashamed.”

The statement was not framed as a question. It was a statement of fact, to which Bastion did not know how to respond. They were somewhat certain that regret and shame were similar, but where one ended and the other began was a mystery.

“The war left its impact on us all.” Reinhardt continued. “It took me some time before I could look an Omnic in the optic. Forgiveness comes slow. It can take even longer for the fear to fade.”

The statement, though softly spoken, was unsettling. Bastion looked at Reinhardt’s height again, this time taking an exact measurement. They recalled Torbjorn’s use of a certain possessive in regards to the armor. The armor. Its height. The measurement.

His armor.

“Crusader?” Bastion sputtered in Omnicode, their first comprehensible code in a while.

Reinhardt gave a sad nod. “You used that phrase when you saw my armor. I take it you figured out who I am?”

It didn’t make sense. It didn’t make sense. The man before them was kind and gentle. He couldn’t be, it couldn’t be.

“Does it make you afraid?”

Bastion looked him up and down. They tried to run a threat analysis, but it fizzled out when they saw his face where a steel helmet should be. They started the program again, and again, and again, but there was no conclusion.

Eventually, they shook their head.

“That is good to hear.” Reinhardt placed a hand upon their shoulder pad and grasped it firmly. “It means we have a place to start.”

Bastion tensed. They did not move.

“That is alright as well. I understand you may not be ready to be too friendly yet.” He dropped his hand.

“Are you done coddling it?” Torbjorn asked.

Bastion turned their head around and realized Torbjorn was behind them. Likely, he had been back there for some time.

“Maybe. Are you done scolding it?” Reinhardt replied.

Torbjorn gave a huff. “Yes.”

“Very well. I shall give it back to you.”

Torbjorn came in front of Bastion. “You’re following me. Back to my workshop. Clear?”

Bastion gave a glance to Reinhardt, before nodding.

Without another word, Torbjorn marched in the direction of a nearby building. Bastion hesitated, before urging their legs to move.

“Wait, my patient Omnic friend!”

Bastion turned their torso around to look.

“Take good care of Torbjorn for me. Make sure he doesn’t stay up all night working on you!” Reinhardt laughed, before growing serious again. “And when you are ready to try and overcome your fear, I am here.”

Bastion paused. Reinhardt wore a close-lipped smile. There was something in his eyes. Something knowing. Bastion nodded.

“Come on, rustbucket!” Torbjorn called.

Bastion turned back around again and jogged to catch up. Torbjorn opened a big steel door and they followed through. The door shut behind them, sealing the sunlight away. There was only the dim light of fluorescent bulbs overhead. Torbjorn began to navigate down the many halls.

“. . . I suppose he thinks he’s getting closure.” He mumbled as they both traveled.

Bastion gave an inquisitive chirp.

“Nothing. Forget it.”

But Bastion did not forget.

---

The second time they saw the armor, they froze.

It was a few weeks after the first time. Bastion had gained their peaceful reputation back, for the most part. Tracer was quick to forgive (“Poor thing, just startled, that’s all”) and the armor had been hustled away to some deep recess of the Watchpoint, out of sight and out of processor.

So Bastion did not have any incidents and was allowed to leave Torbjorn’s workshop.

They did notice, however, that people kept an eye on them. There were more people now. Torbjorn didn’t know all of them. New members, he called them. The only thing they all had in common was that they all looked at Bastion whenever they entered a room.

Humans told a lot of emotions through their eyes. Bastion was programmed to read eyes for hostile signs, so they knew a thing or two about what the eyes said. They knew that some eyes were kind and some eyes were angry, but everything else was more difficult to discern.

The constant gaze of the eyes, demanding to be read, was exhausting. They did not spend much time among the others during what was considered their ‘down time’. Instead, they set about exploring the complex they now called home base.

That was when they had found the auxiliary workshop. That was when they had found the suspicious-looking tarp, with its telltale peaks and valleys, laid across a platform.

Bastion turned the lights on. The room was bathed in lights brighter than those out in the halls. Light beams reflected off of the plastic-coated tarp, accentuating the mass that laid beneath.

They were not stupid. They knew that shape. Their threat analysis systems ticked on in the background, heightening their senses. The buzzing of the light bulbs above was the only sound, and the tarp, like any normal tarp, lay unmoving.

Bastion walked forward. They grabbed the edge of it.

They pulled.

Their systems screamed in perfect harmony as the glint of an orange visor appeared. Threat analysis, targeting overlay, engagement protocols. A thousand different strategic choices bombarded them from every direction- stay, fight, transform, run -and in an instant their processor had selected for them the best course of action. This action, of course, was to fill the room with lead.

They did not want to do that. They remembered the consequences.

Their systems scrambled to find an alternative. Target within melee range. Door is four meters away.

Bastion dismissed those thoughts and every thought that followed with the same reasoning. Consequences.

And they stayed very, very still.

Moments passed like great big clouds rolling across the sky on a sunny afternoon. Their targeting reticule, an angry red symbol brimming in omnicode threats, remained trained on the helmet of the armor. There was no movement. There was no other sound besides the buzzing of the bulbs.

The buzzing became louder. Louder. Their audio sensors maxed their limits. Missing a single sound could mean death.

But there was nothing more than the vibrations that traveled through the floor as the building shifted on its foundation. Nothing more than the faint whistle of air circulation units. Nothing.

Their targeting reticule faded from red, to orange, to a dull yellow, but it did not disappear. It was still a threat. . . but not an active one.

Bastion realized their cooling fans had spun on, providing some relief from the tension in their frame. With a deep intake of air, they continued pulling off the tarp.

They disposed of the tarp to the side. The Crusader lay bare before them on the platform. They poked at its side, and their targeting reticule flashed back to red, causing them to flinch backwards, but the armor did not move, so they approached it again. They prodded it again, more firmly. Nothing.

They picked up one of its limbs. It did not resist, and as far as they could tell, it contained no power or life. They let it drop out of their hand and back onto the platform. The sound boomed in their audio sensors before they recalibrated back to normal levels.

They traveled around to the helmet. They tapped the orange visor with their finger. They grabbed the crest that extended from its forehead and pulled. Without much tension, the helmet popped from its mounting.

Their targeting reticule disappeared. Target eliminated. Bastion could only chirp in confusion.

They looked down to the helmet, then back to the rest of the body. There was no obvious connection port as far as they could tell. They picked the helmet up off the ground and examined it. No results either.

They pressed the empty opening of the helmet back against the empty hole in the armor, but this did not cause the two to join. They pushed harder, then let go, but it fell to the floor again. They tried twisting it, turning it, tilting it, all to no avail. When gravity reunited the helmet with the floor once more, Bastion beeped and kicked the thing with their foot.

It bounced along the concrete floor before rattling to a stop. Bastion beeped at it again for good measure.

“Having fun?”

Bastion flinched and turned to look. In the doorway stood. . . Reinhardt.

They walked over to the helmet and picked it up again, bleating out apologetic noises as they did so. They glanced over to Reinhardt and the power of the man’s gaze pinned them to their spot.

“I. . . understand if that’s how you feel about me.” He said, his voice like a winter wind.

Bastion jerked and shook their head. “Negative, negative,” they told in Omnicode.

They walked back towards the armor. With every step, they looked back to Reinhardt. His expression did not change.

Bastion pressed the helmet back onto the hole, then let go. The helmet fell down again. Bastion then gestured at it with their hand and made the same beep they had at the helmet before.

Reinhardt’s features unfroze. The corners of his eyes crinkled as his lips formed a smile. He let out a laugh that rang from floor to ceiling, punctuated by thuds as he slapped his hand against his thigh.

Bastion found that they were imitating a giggle as well.

“Ha! That helmet never stayed on right.” Reinhardt pointed as he strode into the room.

He was filled with such vigor and speed and volume that Bastion took a step back. Reinhardt paid no mind, grabbing the helmet out of their hand. He held it out, the crest pointing towards his chest and the open end presented to Bastion.

“See, right here?” He pointed to the rim of the inside. “There’s a little lever you must push.”

If Bastion focused their optic, they could see a tiny mechanism flipping back and forth as Reinhardt pressed on it. They nodded.

Reinhardt tossed the helmet in his grip before aligning it with the rest of the armor. With both hands, he shifted it until the two finally joined. When he let go, the helmet stayed in place.

“A finicky thing, that helmet is!” Reinhardt gestured.

Bastion nodded. They looked at the complete armor, then to Reinhardt, then back again.

Their targeting overlays sputtered on and off again, never on the man, but on the armor. With the head back on, it was a full suit again, and therefore dangerous, but other observations clearly contradicted that conclusion. With one final notification, the overlay turned off, and stayed off. Bastion could relax again.

When they looked to Reinhardt again, he had taken a step back and his expression no longer bore such joy. Bastion took a step towards him and gave an inquisitive chirp.

“Your optic.”

Their optic. What about it? They reached their hand up and trailed their fingers across the glass of their optic. They couldn’t detect any changes. They repeated their chirp.

“You do not know?”

Bastion brought their hand back to their side, then imitated a shrug.

Reinhardt laughed, but it was a different laugh than before. Something much shorter and more abrupt, but it eased the tension in his shoulders. Then he brought a hand to his chin.

“Bastion, did you know that your optic has a habit of turning red?”

Bastion knew a bit about what they looked like, based on what they saw of their reflection in ponds and streams and what they could see when looking down. They knew that their optic was about the same blue hue as the sky.

Then again, Reinhardt hadn’t said ‘just red’. He had said it ‘turned’.

Either way, to answer the question, Bastion shook their head.

“It tends to do so whenever you are, shall we say, distressed?” Reinhardt continued.

The targeting overlay. It had to be the targeting overlay. With the way it changed their vision and how sometimes there was a distinct clicking noise when it turned on and off. Bastion nodded, and imitated a noise they had seen Torbjorn do whenever he made a realization.

“Ah, you are aware!” Reinhardt nodded along.

Bastion searched their vocabulary for a string of codes they could use to tell him exactly what they meant, but all they could pull together was “Danger-warning-moving-sensor.”

Reinhardt’s eyebrows furrowed. Bastion repeated the phrase and tapped their head.

“Apologies, but I only know a few phrases of yours.” He said.

Bastion gave a warm tone with no meaning and nodded. Reassurance, hopefully.

He seemed to get the intent. “Thank you.”

They stood in silence for a few beats, before Reinhardt stooped down to pick up the tarp from the ground. He talked as he did so.

“Brigitte always covered my armor in this tarp when we transported it in the van. I, at first, objected. Who would not want to see such a shining beacon of justice?”

He shook the tarp with one motion, and specks of dust went flying into the air.

“But as we traveled, she proved to be correct. Some of the places we traveled were not so hospitable. They did not want our help. It hurt, seeing my own countrymen reject me.”

He reached over to lay the tarp back down across the armor, but stopped.

“I realize now that I- my face, the armor, my legacy -only reminded them of the hardships of the past. When they saw me, they only saw the war. I cannot blame them for that.”

With great care, he spread the tarp across the great frame. The silvery metal disappeared from the light. Reinhardt put a hand on where the armor’s shoulder pauldron was.

Bastion brought up their own hand. They closed it into a fist, then opened it again. They then looked to their other arm. The arm that caused people to scream and run whenever it even twitched.

They remembered the barrel on their back that everyone else could see but they could only notice if they turned their head around. They remembered how others would flinch at the sound of their footfalls.They remembered just how tall they were compared to most humans, and that alone was enough to make them shrink away.

Yet, they certainly weren’t laying under a tarp in Torbjorn’s workshop.

Bastion grabbed the edge of the tarp and gave a tug. Reinhardt let go, startled.

“Are you sure?”

“Affirmative,” they coded with a nod.

Reinhardt joined in unveiling the armor. This time, there was no target overlay. No threat analysis, no combat protocols. The metal was empty, and there was no fear.

#overwatch bastion#the last bastion#e-54#bastion overwatch#reinhardt#reinhardt wilhelm#overwatch#overwatch fanfiction

28 notes

·

View notes

Text

Hydraulic fluid and base stock options

Hydraulic machines produce a lot of excess heat during routine operations, often caused by inefficiencies of the components, like pumps and motors. Without a way to carry heat away from these components, it could result in overheating issues with resulting damage of seals and internal components, especially as a result of low local viscosity. As oil returns to the reservoir, it often passes through a cooler to help maintain optimal temperature range before it is pumped back out to the system. Conversely, hydraulic fluid can carry heat into a system during cold starts, when needed

Hydraulic oil is prepared by the addition of additives in the base stock according to usage, area of usage, ambient condition of usage, the criticality of machines. There can be a variety of base stocks such as mineral oils, synthetic oils, vegetable oils, water-based oils. These base oils can be also further segregated as follows:

Mineral Oils: Group I, Group II, Group III. Mineral oils are used in a variety of industries in various forms such as laxative in biomedicines, veterinary, etc as common ingredients in cosmetics, lubricant, and coolant in mechanical & electrical industries.

Synthetic Oils: Halogenated compounds, Polyglycols (PAG), Polyether, Poly- alpha-olefin(PAO), Polyether, Silicones, Esters, Phosphate Esters, Polyol & Dibasic acid esters. Synthetic oils can be used as a substitute for petroleum refined oils in extreme temperature operations. One of the major advantages of synthetic oil is its ability to resist chemical decomposition in the presence of water, it also separates from water easily and can operate at higher pressures.

Vegetable Oils: Natural vegetable oils such as Canola Oil, Soyabean Oil, Sunflower Oil, Cornflower Oil. Vegetable oils are mainly used in the food industry, they are also used in personal care and cosmetic industries, paint industries. They are also used in electrical industries as insulators due to their non-toxic nature.

Water-Based Oils: Water Glycols, Emulsions, Synthetic Solutions. Water-based oils such as water glycols, emulsions have excellent fire-resistant properties. Excellent fire-resistant properties along with good cost and performance make it the right choice for many industrial applications. They also have good operating pressure and temperature ranges.

Thus from the above illustrations, we can identify different types of base stocks and their segregations, and use of these segregations according to the customized needs.

Also read: https://www.linkedin.com/pulse/functions-hydraulic-oil-reasons-its-contamination-anshuman-agrawal/

Minimac focuses on lubrication reliability and contamination control - Clean Oil, Healthy Machine! Call +91 7030901266 for Condition Monitoring.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil condition monitoring#frf condition systems#coalescer separator#oil dehyration#electrostatics lube cleaner#transformation oil purification#diesel oil purification#oil filtration system#oil purification system#lube oil flushing#chemical cleaning#oil filteration#oil filtration#filtration skid

1 note

·

View note

Link

Your hydraulic system has ended up with a problem, and everything has come to a standstill. The modern hydraulic system appears to be extremely complex and finding out the problem behind its improper working is the key to accurately troubleshooting the hydraulic system.

Here we list down some of the top hydraulic mistakes and their best solutions:

1. Poor Troubleshooting Techniques

2. Poor Hydraulic Reservoir and Oil Maintenance

3. Lack of Hydraulic Safety Procedure

4. Wrong Filter Locations

5. Failed Hydraulic Components

0 notes

Text

Heavy Equipment Inspection Checklist Before and After Operation

What are the heavy equipment inspection checklist before and after operation?Operators of construction machineshave a huge impact on their personal safety and the safety of everyone else on the job site, as well as the maintenance costs and life of the machines they employ. All of this strength stems from the ability to conduct quick but thorough heavy equipment inspections both before and after operations.

These checks are essential for worker safety near machinery and are an important component of preventive maintenance. Before and after getting into any taxi, operators should glance at and for the items listed below. Of course, some heavy equipment has unique parts, functionality, or other variables that demand specialist inspection regions; for specific instructions and recommendations, see the machine’s operator’s manual.

It should also go without saying that equipment that show signs of damage or have any other issues should not be used until the situation is fully resolved. Nonetheless, we stated it. Because it is crucial.

Checklist for Heavy Equipment Inspections

Make sure there are no apparent leaks or pools of fluid under the machine; if there are, the cause must be identified, and the leak fixed.

Examine the tires, rims, and undercarriage for dirt or debris accumulation, excessive wear, and any visible damage. These issues can cause major safety risks and reduce the machine’s performance.

Check the fluid levels to ensure that there is adequate engine oil, hydraulic oil, coolant, diesel, diesel exhaust fluid (DEF), and other essential fluids, as they are the lifeblood of any piece of heavy equipment; too little, and performance suffers, and there’s a chance of costly damage.

Remove any dirt, mud, debris, and materials from around the radiator and other engine parts, as well as from the engine compartment; all engine parts must be able to move, breathe, and cool properly, but any foreign matter might obstruct this.

Examine the air, gasoline, oil, and other filters for damage or leaks; replacing a faulty filter is usually inexpensive and simple, but that isn’t always the case with the harm that untreated filter problems can do.

Check the fan, alternator, and other belts for wear, frays, or other damage; much like with the filters, it’s far better if belt problems are identified and fixed early in terms of machine downtime and expense.

To guarantee smooth, efficient operations and prevent undue wear and damage, inspect the heavy equipment’s greasing points, grease joints, and high-friction locations as needed. The grease points and frequency are detailed in every operator’s manual.

Check hydraulic connections, pressure, and the complete coupling structure; remember to let go of pressure while removing attachments.

Check buckets, teeth, and other ground tools for breaks or damage; these issues can severely restrict productivity, as well as fuel efficiency and safety, and can lead to structural wear and damage.

Check for a flush and fully engaged coupler, as well as securely linked hydraulic hoses and electrical connections, on the attachment mount-up.

Take a few minutes to inspect the machine’s whole structure for wear, damage, and other issues.

Check the operator’s cab for anything that doesn’t belong and remove it.

Before beginning operations, inspect the operator controls, indicator and warning lights, and make sure lighting and safety features such as the backup alarm and rear-view camera are operational; inspect and set the mirrors for best visibility.

Source

#motorgrader#heavyequipmentcompany#whobuysheavyequipmentsherman#whobuysheavyequipmenthouston#whobuysbackhoes#machinerytrader#bobcat#webuytruck#sellyourconstructionequipment#whobuysbulldozers#whobuysingersollrand#skidsteerbuyer#whobuystruckhoes#constructionequipmentcompany#whobuyscaterpillarequipment#equipment#whobuyusedconstructionequipment#wheretosellheavyequipment#ihaveconstructionequipmenttosell#whobuysjohndeereequipment#whobuyscompactors#whobuysoilfilledequipment#wheretheworldbuyheavyequipment#heavyequipmentbuyers#wheretosellusedequipment#topdollarforyourusedmachine#skidsteerbuyers#whobuysheavyequipmentfortworth#whobuysheavyequipmentdallas#whobuysheavyequipmentoklahoma

2 notes

·

View notes

Text

Maximize Your Vehicle’s Fuel Efficiency with High-Performance Car Air Filters

High-performance air filters are a vital component of a car's engine system, and their role in enhancing fuel efficiency is often underestimated. These filters are engineered to provide a superior level of air filtration compared to standard air filters. In this article, we will explore the critical role of high-performance air filters in improving fuel efficiency and how they contribute to a more environmentally friendly and cost-effective driving experience.

The combustion process in a car's engine requires a precise mixture of air and fuel to produce power. High-performance Car Air Filters optimize this mixture by allowing a greater volume of clean air to flow into the engine. Unlike standard filters, which may become clogged with contaminants over time, high-performance filters are designed to maintain consistent airflow. This unrestricted airflow ensures that the engine receives the right amount of oxygen, which is essential for efficient combustion.

Efficient combustion results in improved fuel efficiency. When the air-fuel mixture is precisely balanced, the engine burns fuel more effectively, extracting the maximum energy from each drop of gasoline or diesel. As a result, you get more miles per gallon, saving money on fuel costs while reducing your carbon footprint. This improved fuel efficiency is not only economically beneficial but also environmentally responsible, contributing to reduced greenhouse gas emissions.

High-performance air filters achieve their superior filtration capabilities through advanced materials and design. Many of these filters use synthetic filter media, which is more efficient at trapping microscopic particles and contaminants. This design helps protect the engine from harmful debris that can cause wear and tear, while still delivering a higher volume of clean air.

Furthermore, high-performance air filters are often washable and reusable, which is another aspect of their eco-friendly nature. This not only reduces the frequency of filter replacement but also minimizes the impact of disposable filters on the environment. By choosing a washable high-performance filter, you contribute to reducing the amount of filter waste that ends up in landfills.

Apart from improving fuel efficiency, high-performance air filters can also enhance engine power and responsiveness. With more oxygen-rich air entering the engine, it can generate greater horsepower and torque. This means that you not only save on fuel costs but also enjoy a more spirited and dynamic driving experience.

High-performance air filters, including quality Aftermarket Filters, play a significant role in improving fuel efficiency in vehicles. Their ability to provide a consistent and unrestricted flow of clean air to the engine results in more efficient combustion, better mileage, and cost savings for the vehicle owner. Additionally, high-performance filters are eco-friendly, reducing waste and contributing to a cleaner environment. So, if you're looking to enhance your car's performance and save on fuel costs, upgrading to a high-performance air filter is a wise choice.

#Aftermarket Filters#Car Air Filters#Cabin filters#Fuel Filter#Filtration Solutions#Hydraulic Filters#Air Oil Separator#Performance Filters

0 notes

Text

Selection and Application of Liquid Flowmeter

Reading guide: The liquid volume flowmeter consists of a chamber with a known volume and moving parts. The liquid passing through the flow is calculated by determining the volume of the container and the number of movements of the moving parts. According to the characteristics of liquid volume flowmeter, it can be divided into the following types: waist wheel flowmeter, oval gear flowmeter, scraper flowmeter, double rotor flowmeter, reciprocating piston flowmeter, rotary piston flowmeter, screw flowmeter, etc.

Structure and principle of the liquid volumetric flowmeter calibration device

The liquid accumulation calibration device consists of the quick connector, hydraulic hose, hydraulic filter, standard flowmeter, temperature transformer, pressure transformer, computer system, hydraulic source, etc. The hydraulic oil source also includes a hydraulic oil tank, variable frequency motor, hydraulic variable pump, hydraulic safety valve, and other components. The main features are compact installation, easy use, the same calibration medium, strong movement ability, and the ability to provide hydraulic oil. The working mode of the liquid flow controller is as follows: match through quick connection and replacement, and lead the hydraulic hose into the displaced liquid flow controller calibration device; The hydraulic power converter of the investment department generates clean and stable liquid flow through the hydraulic pump, hydraulic filter, etc. Capture the cumulative flow value determined by the computer system using the calibrated flowmeter and the standard flowmeter, and capture the temperature and pressure on the calibrated flowmeter and the standard flowmeter; The measured value error of calibrated flow is determined by the computer software system.

Main characteristics and application of common liquid flowmeter

Volumetric flowmeter

Volumetric flow meters (also called volume-specific flow values) are general-purpose instruments with the highest accuracy. The measured components can also be divided into the following main features: pitch circle (two rotors), plate flow measurement, oval gear flow measurement, rotary piston flow measurement, circulation flow measurement, etc.

① Advantages: high measurement accuracy; It can be used for measuring high viscosity fluid and simple phase fluid; The instrument does not need external energy to directly record the total flow. It is easy to install without special requirements for front and rear tangent lines.

② Disadvantages: not suitable for high temperature and low temperature; Type of measuring center with limited diameter; Pressure drop; Periodic calibration is required.

③ Application: Volume traffic signs, due to their high-precision measurement in energy, petroleum, medicine, food, chemistry, and other fields, especially raw materials and other fields, must be measured for storage, transfer, and distribution, and used as the basis for a financial settlement, or as a legal indicator of the contract between two tax dealers.

Differential

The differential is one of the most commonly used flowmeter types, which can be divided into diverter flowmeter, Venturi flowmeter, average line current, etc. according to the test piece (inlet instrument). The main features are:

① Advantages: single-phase fluid has a wide range of measurement methods, some mixed fluids; Simple structure, easy maintenance, the long service life of control components and detonators, display equipment produced by different manufacturers, improving economies of scale.

② Disadvantages: general customization accuracy; Large pressure loss (orifice plate, nozzle, etc.) The assembly constraint shall be high, and there shall be enough straight pipelines before and after assembly.

③ Nozzle: When measuring the flow in the closed pipe for the first time, the differential can be used for projects under different conditions where the flow is about 1/4-1/3 of the total flow.

Ultrasonic assistance

The ultrasonic flowmeter can be generally divided into plug-in type, pipe section type, external clamp type, and portable type.

① Advantages: large diameter non-contact measurement, large flow calculation; Pressure loss, no fluid disturbance; Suitable for every liquid, easy to install and maintain.

② Disadvantages: When the measured liquid contains bubbles or noise, the measurement accuracy will be affected; The temperature range of the measured liquid is limited by the heat of the ultrasonic protection and the communication materials between the switch and the line, and the original data for measuring the high temperature of the liquid is incomplete.

③ Application: Ultrasonic velocimeter is often used in petroleum, chemistry, metal, electric power, and other fields, and is often used to measure the emission reduction of gas pipelines in factories, fluids, and work areas.

Turbine speed

Intel Remax accelerated technology plan has been expanded to multiple categories in mass production, and its main features are as follows:

① High precision, usually ± 0.25% r - ± 0.5% r, up to ± 0.25% r - ± 0.5% r; Repeat at most 0.05% r-0.2% r for a short time; Zero contact movement, sturdy and durable.

② Disadvantages: The physical characteristics of the liquid have a great influence on the flow characteristics; Calibration characteristics cannot be saved for a long time.

③ Application. A turbine flow counter is usually used to measure oil, organic liquid, inorganic liquid, and liquid frozen body. The first terminal of the main raw material pipeline is used for commercial calculation of automobile exhaust, gas stations, and light hydropower plants.

Vortex flowmeter

The vortex flowmeter is the latest flowmeter, but it has developed rapidly and has become a common category. Its main characteristics are as follows. ① Advantages: wide application range, liquid, gas, and steam flow measurement can be used; Small pressure loss; Easy installation, simple and durable structure. ② Disadvantages: poor anti-interference ability; Straight pipe section is required before and after installation; The application experience in pulsating flow and multiphase flow is still lacking.

③ Application: Vortex flowmeter has a wide range of applications, usually used in the factory water supply system, and its application will be limited in the case of high viscosity, low flow rate, and small diameter.

General criteria for flowmeter selection and calibration device

Determine the technical requirements for flow measurement and the correctness of the flowmeter, that is, the accuracy requirements for measuring liquid; The flow measurement is repeated, that is, the same measurement is performed multiple times under specific conditions to repeat the same measurement. The expression of flow measurement, that is, whether the flow is mass flow or flow, real-time flow, or cumulative flow. Command and remove the transmission function if necessary. Specifies whether the flow measurement is displayed as a mechanical or electronic title. If the flowmeter does not meet the technical requirements of the measured liquid, measurement errors may also occur.

For the description of the flow calibration liquid calibration device, according to the flow requirements in jgg667-2010:

① The expanded uncertainty of the standard setting should generally not exceed 1/3 of the maximum allowable flow, because the expanded rate of the calibration device is 0.22%.

② Output or. The input line in the equipment used for online identification shall not include redirection between the flowmeter and the equipment designed as a locked cabinet without intermediate circuit.

③ "When the flowmeter is greater than 1.0, the flowmeter and liquid temperature must be measured according to the standard, and the temperature and pressure shall be measured near the standard flowmeter or calibrated flowmeter. Therefore, the liquid flow controller is applicable to the acceptance accuracy standard of Class 1.0 (allowable deviation ± 1.0%) and subsequent fluid calculation.

Conclusion

In the process of liquid flow measurement, a liquid flowmeter is a major measuring tool and has been widely used in metallurgy, pharmacy, paper making, water conservancy, environmental protection, petrochemical, and other fields. In the actual online calibration process, the standard volume method, the standard meter method, and the electrical parameter method are all feasible online calibration methods. However, they all have different use conditions, which requires the staff to constantly summarize and analyze the use of online calibration methods for liquid flow meters, so that the calibration methods can be improved.

Article from: supmeaflow.com

2 notes

·

View notes

Video

youtube

We are thrilled to introduce ourselves as a quality manufacturer of replacement filter elements for hydraulic, lube oil, air, fuel, and gas applications. At Fluid-Air, we utilize imported filtering media such as resin-impregnated cellulosic paper, microfine glass fibre, and woven stainless steel mesh. These materials come in different micron ratings and properties to ensure precise media that meets import substitution standards. Our filters are bonded with a two-pack plastic-mastic adhesive, designed to perform in even the most adverse conditions.

At Fluid-Air, we can manufacture filter elements of any shape and size, equivalent to well-known imported brands like Pall, Parker, Hydac, Inter-norman, and Fairy-Airlon. Our commitment to prompt delivery and competitive pricing, combined with our focus on quality, makes us a reliable partner in the industry.

Our team comprises experienced engineers dedicated to manufacturing and marketing industrial products, with a special emphasis on filters and filter elements. Discover the Fluid-Air difference and experience unparalleled quality and service.

Join us on our journey to revolutionize the filter manufacturing industry with innovative solutions and a commitment to excellence.

0 notes