#high-speed rapier dobby looms

Text

What Are The Different Types Of Weaving Machines?

There are several fabrics getting produced in textile manufacturing industries including woven fabrics, non-woven fabrics, and knitted fabrics. To produce all those fabrics, heavy machinery is used by the textile manufacturing industries of Gujarat. Let's talk about different types of weaving machines in this blog. If you are looking for an industry that deals with those weaving machinery, then you must connect with Weavetech as they are a well-known name for many years in this industry. Presently, there are several weaving machines that are dominating the textile market. However, majorly they are divided into three basic types- Circular, Shuttle, and Narrow Fabric.

Let's Look At Some Weaving Machines

Shuttle loom: This machine is mainly controlled via electronic and used to weave warp and weft patterns. This loom is a kind of micro wood or plastic that contains bobbins that are filled with yarn. It is fluttered across the loom back and forth to form interlacement that helps in producing fabric easily and more efficiently. This is getting used by many of the famous textile manufacturing industries of India as this is cheaper as compared to their counterparts and makes textile production cost-effective. This is also easy to operate and worker-friendly.

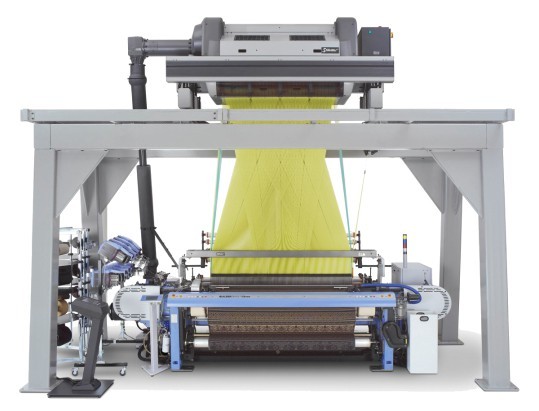

Rapier loom: The rapier loom is one of the most used textile manufacturing machinery in India. This is a kind of special package of yarn that supplies the weft threads for the machine. It has finger-like carriers called rapiers and these are used to carry the filling yarns toward the other end. The rapier loom machine is highly suitable for weaving High GSM & Heavy Density Plain, Twill, and Dobby fabrics like suitings, shirtings, furnishing, liners, etc. Weavetech offers India's fastest & first guideless high-speed rapier dobby looms made with European technology. The rapier loom machine is the largest-selling and most successful Indian Rapier loom and weaving machine.

Projectile loom: A projectile loom is a kind of shuttle less weaving machine that is designed as bullet-shaped metal devices and hence getting known as a projectile loom. This machine can produce different kinds of fashionable fabrics and reduce external noise when in motion. Hence, this feature makes it environmentally friendly and a preferable choice for textile manufacturing industries. Furthermore, the projectile loom is also energy efficient as it consumes approximately 3 Kilo-Watt/Hour which is great compared to other textile machinery. Get in touch with Alidhra Weavetech as they have a complete textile machinery solution.

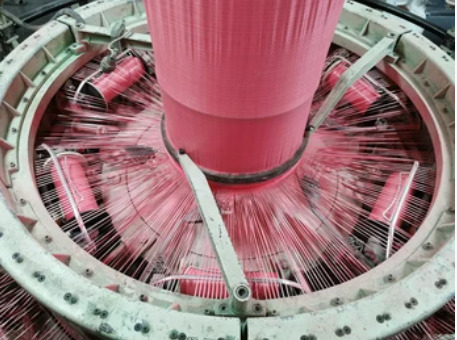

Circular loom: This machine contains several circulating shuttles that move around the periphery disseminating the weft. The major concern of this machine is producing tubular fabric and thereby getting used to produce seamless fabric products such as clothing, fire hose, hosiery, sacks, etc. The modern circular machine uses electromagnets for high-speed fabric production. The speed of this loom is manageable and hence preferred by many of the textile manufacturing industries in Gujarat.

Ribbon loom: A ribbon loom is a kind of narrow fabric loom that is highly efficient to weave more than forty pieces together. This loom has a jacquard fitted at the top of them, which is controlled by a stack of perforated cards. Weavetech offers a Rapier Jacquard Loom / Jacquard Machine (650 RPM). The weaving machine & jacquard machine are perfectly integrated into a seamless single control panel to provide ease of operation while ensuring error-free weaving. Kindly connect with Weavetech today to know more about textile machinery. This fabric loom also helps in the effective processing of complex patterns like brocade and matelassé, etc.

Water jet loom: A water jet loom is similar to an air jet loom that uses water instead of air to transfer the yarn around the shed. This jet loom is faster than any other kind of jet loom and it can weave very quickly whilst the yarn is not damaged here as well. Furthermore, the water jet room is less noisy than the air jet l22oom and rapier loom and consumes comparatively less power. One of the major drawbacks of this weaving machine is that it is suitable for only hydrophobic nature yarns such as polyester PET, Acetate PET, and Polyester PET.

If you are looking for the best textile machinery in India, then get in touch with Weavetech today. Alidhra Weavetech is a global and leading organization grounded in 25 years of experience in supplying indigenously designed weaving and twisting machinery solutions to the world.

#textile manufacturing industries#textile manufacturing industries of India#rapier loom machine#high-speed rapier dobby looms

0 notes

Text

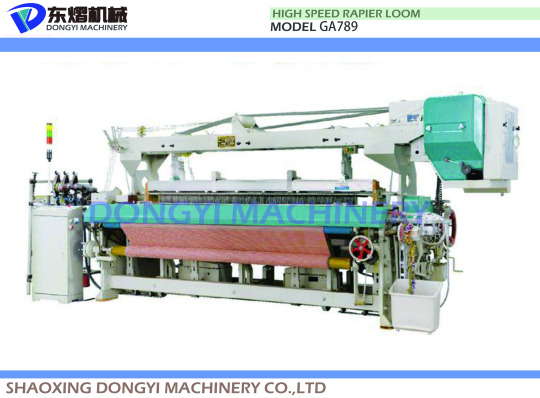

GA789 rapier loom with cam shedding and dobby and jacquard. Weaving machine. Shuttless loom

Model GA789 rapier loom is 6 color weft selector, single weft color change, can be equipped with dobby, jacquard, and automatic pick finding device. Thus the production can be increased, product quality can be improved, and a wide range of applications, improve the working environment, reducing the labor intensity, widely applicable by small and medium-sized textile factory.

This machine is suitable for weaving of natural fibers, chemical fiber, blended yarn and other fabrics.

#rapier loom#high speed rapier loom#weaving machine#rapier loom with dobby#textile machinery#cam rapier loom#shuttleless loom#china rapier loom

1 note

·

View note

Text

Weaving Machinery

As an integrated supplier of weaving machines, we are now providing high speed rapier looms, low speed rapier looms, jacquard looms, terry towel looms, industrial fabric looms and air jet looms. These weaving looms have the features of Europeans looms, and also contain domestic design and technique. Diversified product range, reasonable price and first class quality have enabled us to provide specialized and right solutions for both domestic and overseas customers.

Textile Machinery Parts

Sino textile machinery has gathered the best textile spare parts manufacturers, aiming to be the leading supplier of loom spare parts, dobby spare parts, jacquard spare parts and other textile spares and services for the China textile manufacturing industry.

ABOUT US

It is not an easy task to order or purchase from distant supplier, especially in international trade. This is especially the case with China, due to different barriers in both culture and language.

Be Our Agent

Sino Textile Machinery is looking for agents that sell China low speed rapier looms, high speed rapier loom, air jet looms, jacquard looms, towel looms, industrial fabric looms around the globe. We hope to build long-term win-win cooperation with our partners. Should you have any interest, please contact us.

http://www.sinotextilemachinery.com/

0 notes

Photo

JW Polyester Fabric Loom

Wide Rapier Loom Supplier

higher efficiency Wide Rapier Loom

JW series polyester fabric loom, a new electromechanical product, is improved in main drive power on the basis of TW series copper fabric loom with stable frame, reliable take-up and let-off, and is entirely more stable by adopting crankshaft four-bar linkage for once beating-up. The advanced PLC is possible to automatically control motions such as line pressing, picking, weft holding, shuttle braking and shutdown on mis-picks, easy to operate and effective to improve efficiency over 30%. It can make common forming fabric and common dryer fabric, and is ideal for our paper making fabric industry with very high cost performance.1、Reed Width: 3.2~7.2m.

2、geotextile Wide Rapier Loom Speed: 22~35rpm

3、Machine Weight: About 20~50T.

4、Drive: One-sided motor, pneumatic clutch brake, motor power 5.5~11KW.

5、Shedding: Double dobby shedding, 8 pieces of heald frames.

6、Weft Insertion: Pneumatic shooting-in, automatic weft holding by projectile shuttle, pneumatic shuttle braking.

7、Beating-up: Crankshaft four-bar linkage for once beating-up, or multi-section split four-bar linkage for once beating-up on wider reed width.

8、Take-up: Mechanical semi-active take-up.

9、Let-off: Mechanical active let-off.

1、Reed Width: 3.2~7.2m.

2、Machine Speed: 22~35rpm

3、Machine Weight: About 20~50T.

4、Drive: One-sided motor, pneumatic clutch brake, motor power 5.5~11KW.

5、Shedding: Double dobby shedding, 8 pieces of heald frames.

6、Weft Insertion: Pneumatic shooting-in, automatic weft holding by projectile shuttle, pneumatic shuttle braking.

7、Beating-up: Crankshaft four-bar linkage for once beating-up, or multi-section split four-bar linkage for once beating-up on wider reed width.

8、Take-up: Mechanical semi-active take-up.

9、Let-off: Mechanical active let-off.

0 notes

Link

Apparel Industry

Suiting

Shirting

Linen

Light Denim

Sarees

Dress Materials

Corduroy

Bottom weight

Synthetic Sportswear

Household Fabrics

Furnishing

Bed sheets

Shawls

Curtains

Technical Fabrics

Glass Fiber

Leno / Gauze fabric

Nets

Packaging Fabrics

High Density Poly Ethylene (HDPE)

High Tenacity Poly Propylene (HTPP)

APPARELSCorduroy

Corduroy is a fabric, usually made of cotton, with a cut-pile weave construction. Extra sets of filling yarns are woven into the fabric to form ridges of yarn on the surface. The ridges are made so that clear lines can be seen when the pile is cut.

This particularly dense fabric construction is ideally suited for production on the SHIVA DR II PLUS machine. when equipped with a dobby. All type of corduroy weave is possible.

Light Denim

Denim was originally workwear. Fashion shifted from blue open-end jeans to different colors and a softer touch (lyocell, ring spun), elastic jeans (elastane), jeans with quite different fashion yarns.

SHIVA DR II PLUS Rapier Weaving Machine

Light Denim can be woven on the SHIVA DR II PLUS machine i.e. 190 cm wide loom. Equipped with a double pressure roller on the sand roller take-up, which prevents any reverse slippage of the fabric.

Handkerchief & fancy poplin

Handkerchief may be plain or barred and can be white, dyed or printed. Poplin is a medium spun style, with rectangular construction, mostly plain weave.

Trendy Rapier Weaving Machine The Trendy Rapier Weaving Machine has acquired a reputation for efficient weaving of fine cotton fabric constructions, such as fancy shirting and handkerchiefs. The shed geometry and the gripper and tape guiding system lend themselves to dobby weaves with a large number of harnesses. Constructions with quite different warp tension levels in the main body of the fabric and a border or rib with another weave pattern are handled easily. The SHIVA DR II PLUS is designed to allow the weaver maximum freedom with textile settings.

High twist

High twist is a light filament style. It is also called crepe or crepe de chine and is mainly used in ladies’ wear.

SHIVA DR I Rapier Weaving Machine Crepe-like fabrics with highly twisted warp and weft yarns in extremely complex harness and draw patterns are ideally suited for the SHIVA DR I Machines. They show good performance figures, as their maximum speed is always attainable, even when the shedding motion is made to work very hard.Man-made fibre suitings:

Suiting is a general term for fabrics used for coats and suits for both men and women. Man-made fibre suiting fabrics can either be woven with airjet or rapier weaving technology.

SHIVA DR I & SHIVA DR II PLUS rapier weaving machine Weaving synthetic suiting materials is fairly straightforward and poses no problem with the SHIVA DR I weaving machine. To add value to such fabrics, dobby and the name selvedge is often used. This makes the fabric look as if it were produced with all the attention normally devoted to worsteds.

An enhancement is possible by creating a name selvedge. This can be done in a limited way using extra harnesses from the dobby.

The Elecronic Piezo Sensor (weft braking sensor), with which the SHIVA DR I is equipped to weave such fabrics, also helps to give the fabric that essential touch by making it possible to modify the weft tension during insertion and thereby the hand of the fabric.

Sport shirting, Gingham & Poplin

Poplin is a medium-spun style, with rectangular construction, mostly plain weave. Gingham is yarn-dyed or printed medium poplin. It is a medium-weight, plain-weave fabric with a plaid or check pattern. Poplin is popular for shirting, as also is fancy poplin.

Trendy, SHIVA DR I, SHIVA DR II PLUS rapier weaving machine

The shed geometrics of the SHIVA DR II PLUS are designed to yield the best possible treatment of the warp yarns. With finer yarn counts, this immediately results in fewer warp stops.Worsted & Wool-like Fabrics

Worsted is a tightly woven fabric made by using only long staple, combed wool or wool-blend yarns.

SHIVA DR II PLUS Rapier Weaving Machine

Wool-like fabrics are made from worsted blends. They are very much the vogue today since the major fibers used – nylon and polyester – provide very good service to the consumer.

0 notes

Text

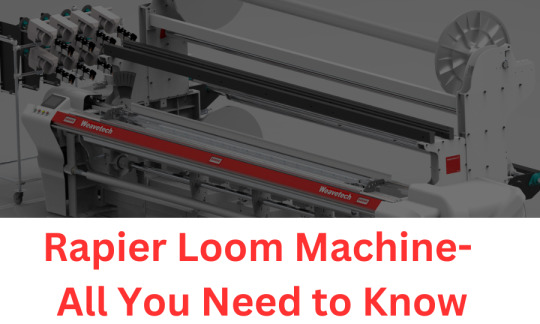

Rapier Loom Machine- All You Need to Know

In the mid-20th century, the textile industry witnessed a transformative leap with the advent of Rapier Loom Machines. Born out of a need for enhanced efficiency and precision in weaving, these machines quickly evolved, embracing mechanical and electronic innovations. This brief exploration traces the concise history that propelled Rapier Loom Machines into the forefront of modern textile manufacturing. Discover accuracy and effectiveness with Weavetech, your reliable textile manufacturing partner. Being one of Gujarat’s top manufacturers of rapier loom machines, we put innovation at the center of your output. With our cutting-edge rapier loom machines, which are built for dependability, speed, and versatility, you may enhance your weaving experience.

What is the Rapier Loom Machine?

A Rapier Loom Machine is a textile weaving device that uses a rapier a thin, flexible rod or tape to insert the weft yarn across the warp threads during fabric production. Renowned for their precision and versatility, these machines have evolved, incorporating electronic controls for enhanced efficiency in the weaving process.Single rapier machines use one rapier for weft insertion, while double rapier machines use two. The dual-rapier system in double-rapier machines offers increased versatility and efficiency, particularly for intricate weaving patterns. The choice depends on the fabric’s complexity and production requirements.

What are the features of the Rapier Loom machine?

Here are some prominent features commonly associated with modern rapier loom machines:

Rapier System: The most distinctive feature of a rapier loom is the use of a rapier or a rigid or flexible rod to carry the weft yarn across the warp threads.

Flexible Rapier: Some rapier looms use a flexible rapier, which is a tape or band that can bend around the loom to carry the weft through the shed.

Rigid Rapier: In contrast, rigid rapiers are straight and do not bend. They move horizontally to insert the weft through the shed.

Shedding Mechanism: Rapier looms employ shedding mechanisms to create an opening (shed) through which the weft can be inserted. Common shedding mechanisms include dobby or cam shedding.

Electronic Jacquard Attachment: High-end rapier looms may have an electronic jacquard attachment for more complex and intricate fabric patterns.

Speed and Efficiency: Rapier looms are known for their high weaving speed and efficiency, making them suitable for large-scale production of fabrics.

Versatility: Rapier looms can be used to weave a variety of fabrics, including plain weaves, twills, and complex patterns. They are versatile and can handle a range of yarn types.

Automatic Functions: Many modern rapier looms are equipped with automatic functions such as automatic warp and weft replenishment, automatic pick finding, and automatic tension control.

Easy Set-Up and Operation: Rapier looms are generally considered easier to set up and operate compared to some other types of looms, making them popular in industrial textile production.

Monitoring and Control Systems: Advanced rapier looms may include monitoring and control systems that help in detecting and correcting weaving defects.

Double Rapier System: Some rapier looms use a double rapier system, where two rapiers work in coordination to insert the weft simultaneously. This can increase the weaving speed and efficiency.

Warp Stop Motion: A warp stop motion system is often integrated into rapier looms to detect and stop the loom in case of warp yarn breakage.

These features collectively contribute to the efficiency, flexibility, and advanced capabilities of modern rapier loom machines in the textile industry. Weavetech, the top manufacturer of Rapier Loom Machines in Gujarat, will help you up your weaving game. Our state-of-the-art machinery guarantees quick, accurate, and adaptable textile production.

What clothes are made by Rapier Loom machine?

Rapier Loom machines produce a variety of fabrics, including cotton, polyester, wool, silk, denim, and more, used for diverse clothing items such as shirts, dresses, jeans, and formalwear.

What is Rapier fabric?

Rapier fabric is woven using a Rapier Loom machine, incorporating diverse materials like cotton, polyester, and silk, to create versatile textiles for clothing and other applications. The evolution of Rapier Loom machines has undeniably left an indelible mark on the textile industry. From the simplicity of single-rapier systems to the enhanced capabilities of double-rapier machines, these looms have redefined efficiency, precision, and versatility in fabric production. The ability to weave a spectrum of fabrics, from everyday cotton to luxurious silk, highlights the adaptability of Rapier Looms in meeting the diverse demands of the fashion world. As technology continues to advance, these machines stand poised at the forefront of innovation, driving the industry forward. In essence, the journey of Rapier Loom machines is not just a story of mechanical ingenuity but a testament to their integral role in shaping the very fabric of our textile landscape.

With Weavetech, the Best Textile Machinery Manufacturer in Gujarat, you can unleash the potential of textile production in the future. Our cutting-edge Rapier Loom Machines guarantee quick and accurate weaving while redefining efficiency. Improve your manufacturing skills by getting in touch with Weavetech right away.

This Blog Originally Posted Here:

https://www.weavetech.com/rapier-loom-machine-all-you-need-to-know/

0 notes

Text

Types of Weaving Solutions from Alidhra Weavetech

Alidhra Weavetech is one of the best weaving machine manufacturers in India, dealing in the global market for the last 25 years. Weavetech is providing the most energy-efficient twisting and weaving solutions in India. Also, the innovation and excellence policy of Weavetech is encouraging a free flow of knowledge and a better exchange of ideas in the engineering industry. Let's find out how many types of weaving solutions are being provided by Weavetech and how efficient they are as compared to others.

Warp Tying / Knotting Machine

This weaving machine is mainly used for warp installation on the loom and comes under the best-selling product of Weavetech. This machine is also known as the Warpmatic machine which is efficiently designed for universal use in warp change to install new beams which are produced on warping machines. It holds numerous benefits such as improved labor efficiency, ease of setup, improved productivity, ease of operation, and many more. This helps in reliably tying a wide range of standard yarns and also allows the tying of single knots, double knots, or both.

If you also are looking for the Knotting Machine in India, then get in touch with Alidhra Weavetech as we have several types of machinery to solve winding, weaving, and twisting work. One of the best features of this machine is that the machine stops in case of three continuous ineffective knots. The application of this machine is highly reliable and it eliminates the need for workers as well along with providing error-free warp change. This machine also has the capability of reduction in double threads and redirected warp threads that enable high efficiency and productivity of the weaving machines.

Rapier Jacquard Loom:

Rapier Jacquard Loom / Jacquard Machine (650 RPM) is the most advanced kind of weaving machine which enables wide widths of up to 360 cm and 10,000 hooks. This weaving machine is effectively integrated into a single control panel that offers ease of operation along with offering no-error weaving. This is mainly getting used for manufacturing sarees and home furnishing fabrics as well as some fancy garments. In addition to that, this product is manufactured under an ITEMA-SULTEX license that offers the best metallurgy and longest life span to the weaving machine. The major benefit of this machine is that it left no fabric marks or any kind of strain. The maintenance cost of this machine is zero as it wears fewer tapes. The textile manufacturing industries of India can buy this as it avoids disturbance of warp sheets and less breakage that usually occurs in other machines when operating at a higher speed. Furthermore, heavy and sturdy frames are used in this machine which ensures vibration-free operation even at higher speeds. Give a call to Weavetech today to know more about weaving and twisting machinery solutions available across the globe.

Rapier Weaving Machine (500 RPM):

This is India's first fastest and guideless high-speed weaving loom machine which has been made using European technology. This is offering the best return on the investment and the best performance as compared to other machines. Moreover, a wide range of options is available which offers the highest versatility. This weaving machine is most suitable for weaving high GSM and heavy-density plain, dobby fabrics and twills such as shirting, suiting, liners, and furnishing. This machine is using guideless rapier technology on the rapier weaving machine that allows the weaving of extremely delicate warp yarns like viscose rayon, silk, and so on. The speed of this machine is around 500 RPM and 1050 meters per min and hence offers an ideal performance ratio along with enabling less maintenance cost. This also leaves no stains or fabric marks and zero noise disturbance.

Rapier Weaving Machine (250 RPM): This is a kind of rapier dobby loom weaving machine which is highly suitable for light GSM fabric. GSM fabric is currently being produced using power and ordinary shuttle loom. 250 RPM rapier machine is available in a wide range at weavetech. If you are looking for a textile manufacturing machinery industry in India then don't look further and connect with Weavetech today. This is highly suitable for lightweight fabric, and light GSM garments based on the fabrics that are covering filaments, viscose, spun, fancy yarns, and rayon. In addition to that, this Indian Rapier Loom is the largest-selling and most successful product of the company. This weaving machine is offering the heaviest and sturdiest rapier with 2 tons weight and more than 9000 rapiers are running successfully in this machine. This machine also reduces the number of operators compared to the power loom and enables energy savings as compared to the power loom.

Alidhra Weavetech is one of India's Premier Weaving Machine manufacturers. We provide various kinds of weaving, twisting, and winding machinery such as high-speed rapier loom, rapier plain shedding model, electronic jacquard, electronic high-speed jacquard, and so on. Get in touch with us immediately to know more about textile manufacturing machines.

This blog is originally posted here: https://www.weavetech.com/blog-detail/23/types-of-weaving-solutions-from-alidhra-weave/

1 note

·

View note

Text

What Are The Different Types Of Weaving Machines?

There are several fabrics getting produced in textile manufacturing industries including woven fabrics, non-woven fabrics, and knitted fabrics. To produce all those fabrics, heavy machinery is used by the textile manufacturing industries of Gujarat. Let’s talk about different types of weaving machines in this blog. If you are looking for an industry that deals with those weaving machinery, then you must connect with Weavetech as they are a well-known name for many years in this industry. Presently, there are several weaving machines that are dominating the textile market. However, majorly they are divided into three basic types- Circular, Shuttle, and Narrow Fabric.

Let’s Look At Some Weaving Machines

Shuttle loom: This machine is mainly controlled via electronic and used to weave warp and weft patterns. This loom is a kind of micro wood or plastic that contains bobbins that are filled with yarn. It is fluttered across the loom back and forth to form interlacement that helps in producing fabric easily and more efficiently. This is getting used by many of the famous textile manufacturing industries of India as this is cheaper as compared to their counterparts and makes textile production cost-effective. This is also easy to operate and worker-friendly.

Rapier loom: The rapier loom is one of the most used textile manufacturing machinery in India. This is a kind of special package of yarn that supplies the weft threads for the machine. It has finger-like carriers called rapiers and these are used to carry the filling yarns toward the other end. The rapier loom machine is highly suitable for weaving High GSM & Heavy Density Plain, Twill, and Dobby fabrics like suitings, shirtings, furnishing, liners, etc. Weavetech offers India’s fastest & first guideless high-speed rapier dobby looms made with European technology. The rapier loom machine is the largest-selling and most successful Indian Rapier loom and weaving machine.

Projectile loom: A projectile loom is a kind of shuttleless weaving machine that is designed as bullet-shaped metal devices and hence getting known as a projectile loom. This machine can produce different kinds of fashionable fabrics and reduce external noise when in motion. Hence, this feature makes it environmentally friendly and a preferable choice for textile manufacturing industries. Furthermore, the projectile loom is also energy efficient as it consumes approximately 3 Kilo-Watt/Hour which is great compared to other textile machinery. Get in touch with Alidhra Weavetech as they have a complete textile machinery solution.

Circular loom: This machine contains several circulating shuttles that move around the periphery disseminating the weft. The major concern of this machine is producing tubular fabric and thereby getting used to produce seamless fabric products such as clothing, fire hose, hosiery, sacks, etc. The modern circular machine uses electromagnets for high-speed fabric production. The speed of this loom is manageable and hence preferred by many of the textile manufacturing industries in Gujarat.

Ribbon loom: A ribbon loom is a kind of narrow fabric loom that is highly efficient to weave more than forty pieces together. This loom has a jacquard fitted at the top of them, which is controlled by a stack of perforated cards. Weavetech offers a Rapier Jacquard Loom / Jacquard Machine (650 RPM). The weaving machine & jacquard machine are perfectly integrated into a seamless single control panel to provide ease of operation while ensuring error-free weaving. Kindly connect with Weavetech today to know more about textile machinery. This fabric loom also helps in the effective processing of complex patterns like brocade and matelassé, etc.

Water jet loom: A water jet loom is similar to an air jet loom that uses water instead of air to transfer the yarn around the shed. This jet loom is faster than any other kind of jet loom and it can weave very quickly whilst the yarn is not damaged here as well. Furthermore, the water jet room is less noisy than the air jet l22oom and rapier loom and consumes comparatively less power. One of the major drawbacks of this weaving machine is that it is suitable for only hydrophobic nature yarns such as polyester PET, Acetate PET, and Polyester PET.

If you are looking for the best textile machinery in India, then get in touch with Weavetech today. Alidhra Weavetech is a global and leading organization grounded in 25 years of experience in supplying indigenously designed weaving and twisting machinery solutions to the world.

#weaving machine#textile manufacturing machine#machine manufacturing#textile machine#twisting machine#rapier loom

0 notes

Text

What Are The Different Types Of Weaving Machines?

There are several fabrics getting produced in textile manufacturing industries including woven fabrics, non-woven fabrics, and knitted fabrics. To produce all those fabrics, heavy machinery is used by the textile manufacturing industries of Gujarat. Let's talk about different types of weaving machines in this blog. If you are looking for an industry that deals with those weaving machinery, then you must connect with Weavetech as they are a well-known name for many years in this industry. Presently, there are several weaving machines that are dominating the textile market. However, majorly they are divided into three basic types- Circular, Shuttle, and Narrow Fabric.

Let's Look At Some Weaving Machines

Shuttle loom: This machine is mainly controlled via electronic and used to weave warp and weft patterns. This loom is a kind of micro wood or plastic that contains bobbins that are filled with yarn. It is fluttered across the loom back and forth to form interlacement that helps in producing fabric easily and more efficiently. This is getting used by many of the famous textile manufacturing industries of India as this is cheaper as compared to their counterparts and makes textile production cost-effective. This is also easy to operate and worker-friendly.

Rapier loom: The rapier loom is one of the most used textile manufacturing machinery in India. This is a kind of special package of yarn that supplies the weft threads for the machine. It has finger-like carriers called rapiers and these are used to carry the filling yarns toward the other end. The rapier loom machine is highly suitable for weaving High GSM & Heavy Density Plain, Twill, and Dobby fabrics like suitings, shirtings, furnishing, liners, etc. Weavetech offers India's fastest & first guideless high-speed rapier dobby looms made with European technology. The rapier loom machine is the largest-selling and most successful Indian Rapier loom and weaving machine.

Projectile loom: A projectile loom is a kind of shuttleless weaving machine that is designed as bullet-shaped metal devices and hence getting known as a projectile loom. This machine can produce different kinds of fashionable fabrics and reduce external noise when in motion. Hence, this feature makes it environmentally friendly and a preferable choice for textile manufacturing industries. Furthermore, the projectile loom is also energy efficient as it consumes approximately 3 Kilo-Watt/Hour which is great compared to other textile machinery. Get in touch with Alida Weavetech as they have a complete textile machinery solution.

Circular loom: This machine contains several circulating shuttles that move around the periphery disseminating the weft. The major concern of this machine is producing tubular fabric and thereby getting used to produce seamless fabric products such as clothing, fire hose, hosiery, sacks, etc. The modern circular machine uses electromagnets for high-speed fabric production. The speed of this loom is manageable and hence preferred by many of the textile manufacturing industries in Gujarat.

Ribbon loom: A ribbon loom is a kind of narrow fabric loom that is highly efficient to weave more than forty pieces together. This loom has a jacquard fitted at the top of them, which is controlled by a stack of perforated cards. Weavetech offers a Rapier Jacquard Loom / Jacquard Machine (650 RPM). The weaving machine & jacquard machine are perfectly integrated into a seamless single control panel to provide ease of operation while ensuring error-free weaving. Kindly connect with Weavetech today to know more about textile machinery. This fabric loom also helps in the effective processing of complex patterns like brocade and matelassé, etc.

Water jet loom: A water jet loom is similar to an air jet loom that uses water instead of air to transfer the yarn around the shed. This jet loom is faster than any other kind of jet loom and it can weave very quickly whilst the yarn is not damaged here as well. Furthermore, the water jet room is less noisy than the air jet l22oom and rapier loom and consumes comparatively less power. One of the major drawbacks of this weaving machine is that it is suitable for only hydrophobic nature yarns such as polyester PET, Acetate PET, and Polyester PET.

If you are looking for the best textile machinery in India, then get in touch with Weavetech today. Alidhra Weavetech is a global and leading organization grounded in 25 years of experience in supplying indigenously designed weaving and twisting machinery solutions to the world.

0 notes

Text

DW200 Heavy Duty Ring Woven Press Felt Loom

Paper Machine Clothing Loom Factory

Paper Making Rapier Loom Supplier

This is applicable to weave high-strength paper making woven press felt with true selvage, especially for ring woven press felt.

1、Range of Polyester Monofilament: 0.10~0.5mm or 0.2mm× 6 ply.

2、Weft density: 50~360 picks/10cm.

3、Warp density: 60~180 ends/10cm.

4、Reed Width: 10m-20m.

5、Economic Speed: 25-30 rpm.

6、Motor power: about 40KW.

7、Weight: About 80T.

1、Framework: The main wallboard adopting iron box structure, the complete machine installed on the whole basement.

2、Dryer Fabric Paper Making Rapier Loom Main Drive: Adopting bilateral motor two-sided coaxial drive,motor power is 11KW, double pneumatic clutch and the main driving box adopts ellipse gear variable.

3、Shedding Mechanism: Adopting bilateral broda blade side-drawing dobby device, 12 heald frames.

4、Weft Insertion Mechanism: Adopting hydraulic picking mode, two-sided 2×2 shuttle box shuttle-changing weft selector.

5、Beating-up Mechanism:Adopting multi-fissions combined crank four-linkage variable speed weft beating.

6、Take-up Mechanism: Adopting electronically control three-roller positive take-up, the upper rollers are separately driven by servo motor.

7、Let-off Mechanism: Adopting external central positive let-off (single warp beam,flange-separating warping).

8、Web-rolling Mechanism: Adopting external superficial web rolling driven by independent torque motor.

9、Lubricating System: The high-density Paper Making Rapier Loom adopts automatic grease lubrication and hand oil lubrication.

10、Controlling System: With OMRON PLC computer control system, the complete machine can freely set up various parameters and automatically display faults.

0 notes

Link

Apparel Industry

Suiting

Shirting

Linen

Light Denim

Sarees

Dress Materials

Corduroy

Bottom weight

Synthetic Sportswear

Household Fabrics

Furnishing

Bed sheets

Shawls

Curtains

Technical Fabrics

Glass Fiber

Leno / Gauze fabric

Nets

Packaging Fabrics

High Density Poly Ethylene (HDPE)

High Tenacity Poly Propylene (HTPP)

APPARELS

Corduroy

Corduroy is a fabric, usually made of cotton, with a cut-pile weave construction. Extra sets of filling yarns are woven into the fabric to form ridges of yarn on the surface. The ridges are made so that clear lines can be seen when the pile is cut.

This particularly dense fabric construction is ideally suited for production on the SHIVA DR II PLUS machine. when equipped with a dobby. All type of corduroy weave is possible.

Light Denim

Denim was originally workwear. Fashion shifted from blue open-end jeans to different colors and a softer touch (lyocell, ring spun), elastic jeans (elastane), jeans with quite different fashion yarns.

SHIVA DR II PLUS Rapier Weaving Machine

Light Denim can be woven on the SHIVA DR II PLUS machine i.e. 190 cm wide loom. Equipped with a double pressure roller on the sand roller take-up, which prevents any reverse slippage of the fabric.

Handkerchief & fancy poplin

Handkerchief may be plain or barred and can be white, dyed or printed. Poplin is a medium spun style, with rectangular construction, mostly plain weave.

Trendy Rapier Weaving Machine The Trendy Rapier Weaving Machine has acquired a reputation for efficient weaving of fine cotton fabric constructions, such as fancy shirting and handkerchiefs. The shed geometry and the gripper and tape guiding system lend themselves to dobby weaves with a large number of harnesses. Constructions with quite different warp tension levels in the main body of the fabric and a border or rib with another weave pattern are handled easily. The SHIVA DR II PLUS is designed to allow the weaver maximum freedom with textile settings.

High twist

High twist is a light filament style. It is also called crepe or crepe de chine and is mainly used in ladies’ wear.

SHIVA DR I Rapier Weaving Machine Crepe-like fabrics with highly twisted warp and weft yarns in extremely complex harness and draw patterns are ideally suited for the SHIVA DR I Machines. They show good performance figures, as their maximum speed is always attainable, even when the shedding motion is made to work very hard.

Man-made fibre suitings:

Suiting is a general term for fabrics used for coats and suits for both men and women. Man-made fibre suiting fabrics can either be woven with airjet or rapier weaving technology.

SHIVA DR I & SHIVA DR II PLUS rapier weaving machine Weaving synthetic suiting materials is fairly straightforward and poses no problem with the SHIVA DR I weaving machine. To add value to such fabrics, dobby and the name selvedge is often used. This makes the fabric look as if it were produced with all the attention normally devoted to worsteds.

An enhancement is possible by creating a name selvedge. This can be done in a limited way using extra harnesses from the dobby.

The Elecronic Piezo Sensor (weft braking sensor), with which the SHIVA DR I is equipped to weave such fabrics, also helps to give the fabric that essential touch by making it possible to modify the weft tension during insertion and thereby the hand of the fabric.

Sport shirting, Gingham & Poplin

Poplin is a medium-spun style, with rectangular construction, mostly plain weave. Gingham is yarn-dyed or printed medium poplin. It is a medium-weight, plain-weave fabric with a plaid or check pattern. Poplin is popular for shirting, as also is fancy poplin.

Trendy, SHIVA DR I, SHIVA DR II PLUS rapier weaving machine

The shed geometrics of the SHIVA DR II PLUS are designed to yield the best possible treatment of the warp yarns. With finer yarn counts, this immediately results in fewer warp stops.

Worsted & Wool-like Fabrics

Worsted is a tightly woven fabric made by using only long staple, combed wool or wool-blend yarns.

SHIVA DR II PLUS Rapier Weaving Machine

Wool-like fabrics are made from worsted blends. They are very much the vogue today since the major fibers used – nylon and polyester – provide very good service to the consumer.

#Worsted is a tightly woven fabric made by using only long staple combed wool or wool-blend yarns. SHIVA DR II PLUS Rapier Weaving Machine Wo#weaving machine manufacturer in India#Textile Machinery Manufacturers#Textile Machinery Spare Part Manufacturers#Shuttle Loom Manufacturers#Textile Machinery Part Dealers#Textile Machinery Spare Part Dealers#Loom Manufacturers#Dobby Machine

0 notes