#weaving machine manufacturer in India

Text

Which loom machines are used to weave cotton fabric?

Types of Weaving Machines Used in the Cotton Fabric Production

Air Jet Looms – Air jet looms are high-speed weaving machines used to make cotton yarn. Compressed air propels the weft yarn through the warp yarn, producing high-quality fabric. It is best suited to lightweight cotton fabrics like muslin and voile.

Rapier Looms – Rapier looms are fast and efficient weaving machines using a flexible metal device that picks up weft yarn from one side and carries it across to the other. It is suitable for weaving a wide range of cotton fabrics, including terry cloth and corduroy.

Shuttle looms – Shuttle looms are traditional weaving machines that use a shuttle to carry the weft yarn through the warp yarns. They are best suited for weaving heavyweight cotton fabrics, such as twill and drill, and are still used today for certain types of cotton material production.

#power loom manufacturer in surat#yarn weaving machine at best price in india#fabric weaving machine

0 notes

Link

Golden Elegance is one of India’s premier weaving machine manufacturers. They are manufacturers and sellers of weaving machines also known as looms. Apart from selling looms, this company is also responsible for manufacturing sarees. The types of sarees they manufacture are the local weaves such as jamdani, korial, gorodh, etc.

0 notes

Text

Uses and Functions of Non Woven Bag Printing Machine

Introduction

In recent years, the global movement towards sustainability and eco-consciousness has spurred a significant shift in consumer behavior and industrial practices. As businesses strive to reduce their environmental footprint, the demand for eco-friendly alternatives to traditional plastic bags has surged. Enter non-woven bags — lightweight, durable, and reusable alternatives that have gained widespread popularity. At the heart of this eco-friendly revolution lies the non-woven bag printing machine, a marvel of modern engineering that enables the mass production of customized, environmentally responsible bags. Let’s delve deeper into the efficiency and functionality of these innovative machines.

The Rise of Non-Woven Bags

Non-woven bags are crafted from synthetic or natural fibers bonded together through a mechanical, thermal, or chemical process — without the need for weaving. This manufacturing method results in bags that are strong, tear-resistant, and capable of carrying heavy loads. Moreover, non-woven bags are reusable, recyclable, and biodegradable, making them a sustainable choice for environmentally conscious consumers and businesses alike.

Advantages of Non-Woven Bag Printing Machines

Customization: Non-woven bag printing machines offer unparalleled flexibility, allowing businesses to create bespoke designs and branding solutions tailored to their unique requirements.

Speed and Efficiency: With rapid printing capabilities and automated processes, these machines enable high-volume production without compromising on quality or accuracy.

Cost-Effectiveness: By streamlining production workflows and minimizing material waste, non-woven bag printing machines help businesses optimize their operational costs and maximize profitability.

Environmental Sustainability: By facilitating the production of reusable and recyclable non-woven bags, these machines support sustainability initiatives and contribute to the reduction of plastic waste.

Non-woven bag printing machines are the unsung heroes of modern manufacturing, offering a multitude of uses and functions in various industries.

Functions of Non Woven Bag Printing Machine

Customization Made Easy

These machines empower businesses to personalize non-woven bags with logos, designs, and messages, enhancing brand visibility and communication.

Promotional Powerhouses

Ideal for creating branded merchandise, custom-printed non-woven bags serve as effective promotional tools at trade shows, events, and marketing campaigns.

Sustainable Packaging Solutions

In retail, these machines help elevate packaging by customizing non-woven bags with brand aesthetics, product showcases, and eco-friendly messaging.

Memorable Event Souvenirs

From conferences to weddings, custom-printed non-woven bags make practical and memorable giveaways, leaving a lasting impression on attendees.

Environmental Advocacy

By enabling the production of reusable and recyclable bags, these machines contribute to environmental sustainability efforts, promoting eco-conscious consumption.

In essence, non-woven bag printing machines are more than just production tools — they’re enablers of creativity, sustainability, and brand empowerment in a rapidly evolving world.

Best Non Woven Bag Printing Machine Companies in India

If you are looking for a Best Non Woven Bag Printing Machine in India, then look no further than Decent Print Line. Decent prinline is a leading manufacturer and supplier of non woven bag printing machine in India.

For more details, please contact us!

Website — https://www.decentprintline.com/

Contact — +91–9911433180

Email — [email protected]

Address — Plot №4, Gali №1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh — 121004, Haryana, India

#Non Woven Bag Printing Machine#Non Woven Bag Printing Machine manufacturer#Non Woven Bag Printing Machine supplier#Non Woven Bag Printing Machine manufacturer in India#Non Woven Bag Printing Machine supplier in India#Decent printline

2 notes

·

View notes

Text

UNDERSTANDING FASHION

Designing, making, and distributing clothing in an ethical manner minimizes the harm done to people and the environment. In a perfect world, it benefits people who work in the supply chain and improves everyone's future, not just that of the wealthy few.

Although the term "ethics" in this context is ambiguous, ethical fashion is concerned with societal impact and the principles that underlie a brand's label. The recently invented expression is regarded as the antithesis of quick fashion. Consumers typically use the term "ethical fashion" to refer to a movement against an industry that is infamous for underpaying workers—and doing so in hazardous conditions.

Questions like "Who created this garment?" and "Is that individual getting a reasonable living wage?" are addressed by ethical fashion. It is, however, much more than that.

Of course, proponents of ethical fashion are hoping for the first scenario, but it may also rely on how rapidly genuine ethical firms can communicate with customers clearly. Consumers frequently become confused and easily susceptible to greenwashing without clear information from fashion companies about how, where, and by whom clothing is made. They may also incorrectly interpret a brand's specific ethics. The best approach for brands to help clear up misunderstanding is through certifications, in-depth reports, and honest responses to consumer questions.

fashion made by hand looms

The foundation of Indian heritage is culture, craft, and textiles. In actuality, India is the world's second-largest exporter of textiles. A nation that has created khadi, ikats, jamdani, Venkatgiri, Chanderi, Kanjeevarams, and so many other types of textiles may confidently assert its self-sufficiency in this area. The Swadeshi Movement, which was started on this day in 1905 in the Calcutta Town Hall to protest against the British Government's division of Bengal, was recognised on August 7 as National Handloom Day.

The power loom is an automated loom that weaves fabric, whereas the hand loom is a manually operated machine for weaving cloth. The textile industry embraced the power loom as a result of the development of technology and machines for more rapid and efficient manufacturing. In exchange, the handloom sector suffered. But recently, with all the buzz about slow-fashion, celebrities and actors have been promoting handloom materials in the fashion industry.

KHADI

Khadi is no longer only a simple, uninteresting alternative; it is now a sustainable and timeless addition to your wardrobe. The khadi has received a fun makeover as a result of the just concluded Lakme Fashion Week highlighting sustainable fashion. You can rely on designers like Abu Jani, Rohit Bal, and Sandeep Koshla to bring grandeur and beauty to our nation's traditional fabric while adding cutting-edge modern twists. Khadi has an enduringly regal appeal, whether it's in the form of lehengas, golden skirts, or billowing gold Anarkalis paired with palazzos. Therefore, if you don't already have this noble cloth in your closet, it's time to buy some.

Here are some styling suggestions for handloom that were inspired by our own local celebrities to seem modern and chic.

Ensure simplicity. Because of the unique beauty and charm of handloom fabrics, it is preferable to play down the outfit. To add some personality to your look, add some statement earrings or a bold lip colour.

Layering with handloom fabrics is a terrific idea, first for their light weight and second for the muted colours they come in.

Play with the shapes; go boxy with loose-fitting kurtis, dresses, or tops.

ACCESSORIES

There are many possibilities available on the market for ethnic jewellery. Wear your handcrafted kurtas with delicate silver jewellery, tribal jewellery, or even the perennially fashionable hoop earrings in a circle shape. Even better, you may accessories them with beads, chaandbalis, or vibrant tassels. Only choose accessories that go with the outfit you are wearing.

You can wear light jhumkas during the day, but you should save your shoulder-grazing hoops and crystal shards for evening wear. Try out slides, mules, jutties, or platforms for your shoes. Try experimenting with geometry and shapes in bags, such as an arc sling or a cube box bag, for your arm candy.

PREDICTING TRENDS

Predicting a market's future is the focus of the field of trend forecasting. Every industry employs trend analysts who use information from previous sales to predict opportunities in the future. Thus, the area of the fashion industry known as fashion forecasting is concerned with foreseeing new fashion trends, including colours, styling techniques, fabric textures, and more, that will pique customer demand. Product developers use the trend forecasts that fashion forecasters publish to build new apparel and accessories for brands.

OVER TIME

Macro trends, which are significant changes in fashion that will be important for longer than two years, are what long-term forecasting is all about. The broad trends that shape the fashion industry include shifts in lifestyle, demographics, and the method that clothing is produced and distributed.

LIMITED TIME

Micro trends have to deal with short-term forecasting. Season to season, short-term projections vary and are often influenced by color, style, pop culture, and current events.

Forecasting Trends for Fashion Brands

Every brand has a different method for predicting trends. Because womenswear firms typically release more collections per year than masculine brands, they frequently invest more in micro trend monitoring. The size of the business and its target market can affect forecasting, but there are a number of trustworthy techniques that brands can use to predict trends.

Employing internal trend forecasters Large fast-fashion companies frequently have internal trend predicting capabilities because of their vertical integration. In order to design new items, this enables the fashion forecasters to collaborate directly with product development teams.

With a trend forecasting agency: Bigger brands without vertical integration frequently seek out the knowledge of trend forecasting agencies, which charge a fee for their trend research reports.

By attending fashion shows: Prior to the development of the Internet, trend forecasters conducted the majority of their research at fashion shows, where they took note of the most promising looks. They then forwarded this information to product developers at chain stores and fashion publications like Vogue. This type of forecasting, known as "top-down" forecasting, is based on how trends in fashion spread from high-end runways to department stores

By paying attention to influencers: In the modern world, trend forecasters are more likely to consult blogs, street style, and influencers for the most recent trends. This type of forecasting, known as "bottom-up" forecasting, entails attentively watching a target market to forecast demand for emerging trends.

By observing other sectors: Small independent fashion designers might forego trend spotting altogether and instead create mood boards based on literature, cinema, and the outdoors to inform their distinctive collections.

To predict the future of fashion, the majority of trend forecasters combine "top-down" and "bottom-up" forecasting techniques with in-depth knowledge of the fashion industry and personal intuition.

2 notes

·

View notes

Text

Unraveling the Utility: Exploring the Versatility of FIBC Jumbo Sling Bags

In the realm of modern packaging solutions, Flexible Intermediate Bulk Containers (FIBC), commonly known as bulk bags or jumbo bags, have emerged as a versatile and efficient choice for transporting and storing various materials. Among the leading manufacturers in India, Singhal Industries Private Limited stands out for its commitment to quality and innovation in FIBC production. In this blog, we delve into the fascinating world of FIBC bags manufacturer, exploring their uses, manufacturing process, and the key features that make Singhal Industries a top player in the market.

Understanding FIBC Bags

Flexible Intermediate Bulk Containers, or FIBC bags, are large, flexible containers designed for the transportation and storage of dry, flowable products such as sand, fertilizers, chemicals, grains, and more. These bags typically range in size from 500 kg to 2000 kg capacity, making them ideal for handling bulk materials. FIBC bags offer several advantages over traditional packaging methods, including ease of handling, cost-effectiveness, and reusability.

Manufacturing Process

The production of FIBC bags involves several key steps, each crucial to ensuring the quality and durability of the final product. Singhal Industries employs state-of-the-art manufacturing processes to create FIBC bags that meet the highest standards of performance and safety.

Material Selection: FIBC bags are typically made from woven polypropylene (PP) fabric, chosen for its strength, durability, and resistance to tears and punctures. Singhal Industries sources high-quality PP material to ensure the longevity and reliability of their bags.

Weaving: The selected PP fabric is woven into large, seamless panels using specialized weaving machines. These panels form the body of the FIBC bag and are capable of withstanding the weight and pressure of bulk materials.

Cutting and Sewing: Once the panels are woven, they are cut and sewn together according to the desired dimensions and specifications of the FIBC bag. Singhal Industries employs skilled technicians and modern sewing equipment to ensure precise construction and seam strength.

Fittings and Accessories: Depending on the intended use of the FIBC bag, various fittings and accessories such as lifting loops, discharge spouts, and top closures are added during the manufacturing process. These components enhance the functionality and versatility of the bag.

Quality Control: Throughout the manufacturing process, rigorous quality control measures are implemented to detect and address any defects or inconsistencies. Singhal Industries adheres to strict quality standards to deliver FIBC bags manufacturers in india that meet or exceed customer expectations.

The Applications of FIBC Bags

FIBC bags find application across a wide range of industries due to their versatility and adaptability to different products and environments. Some common uses include:

Construction: FIBC bags are used for transporting and storing construction materials such as sand, gravel, and aggregates. Their large capacity and robust construction make them ideal for handling heavy loads on construction sites.

Agriculture: In the agricultural sector, FIBC bags are employed for storing and transporting grains, seeds, fertilizers, and other agricultural products. Their UV-resistant properties help protect contents from sunlight exposure during storage.

Chemicals: FIBC bags are widely used for handling various chemicals and hazardous materials. Their static dissipative properties and ability to withstand harsh chemical environments make them essential for safe chemical transport and storage.

Food and Pharmaceuticals: In industries where hygiene and contamination control are critical, such as food processing and pharmaceuticals, FIBC bags provide a clean and sanitary packaging solution. They are often used for bulk transportation of ingredients, powders, and pharmaceutical products.

Singhal Industries: Leading the Way

Singhal Industries Private Limited has established itself as a trusted manufacturer and supplier of high-quality FIBC bags in India. With a focus on innovation, reliability, and customer satisfaction, Singhal Industries has earned a reputation for excellence in the industry. Here are some key factors that set them apart:

Quality Assurance: Singhal Industries maintains stringent quality control measures at every stage of the manufacturing process to ensure that each FIBC bag meets the highest standards of quality and durability.

Customization Options: Recognizing that different industries have unique requirements, Singhal Industries offers customization options for FIBC bags, including size, capacity, fabric weight, and additional features such as liners and coatings.

Compliance and Certification: Singhal Industries adheres to international standards and regulations governing the production and use of FIBC bags. They are ISO certified and ensure compliance with industry-specific requirements for safety and performance.

Customer Support: Singhal Industries is committed to providing exceptional customer service, from initial inquiry to after-sales support. Their knowledgeable team is available to assist customers in selecting the right FIBC solution for their needs and addressing any concerns or inquiries.

Conclusion

Flexible Intermediate Bulk Containers (FIBC) bags have revolutionized the way bulk materials are transported and stored, offering a versatile, cost-effective, and environmentally friendly packaging solution for a wide range of industries. As a leading manufacturer in India, Singhal Industries Private Limited continues to drive innovation and excellence in FIBC production, ensuring that customers receive top-quality bags tailored to their specific needs. Whether it's construction, agriculture, chemicals, or food and pharmaceuticals, FIBC jumbo bags from Singhal Industries are trusted by businesses across the globe for their reliability, durability, and performance.

Frequently Asked Questions (FAQs)

What is the maximum weight capacity of FIBC bags?

FIBC bags can typically hold anywhere from 500 kg to 2000 kg of material, depending on their design and construction. Singhal Industries offers a range of FIBC bags with different weight capacities to suit various applications.

Are FIBC bags reusable?

Yes, one of the key advantages of FIBC bags is their reusability. With proper handling and maintenance, FIBC bags can be used multiple times, making them a cost-effective and sustainable packaging solution.

Do FIBC bags come with liners?

FIBC bags can be equipped with optional liners made from materials such as polyethylene or aluminum foil. Liners provide an additional layer of protection against moisture, contamination, and product leakage, making them ideal for certain applications such as food and pharmaceuticals.

Are FIBC bags recyclable?

Yes, most FIBC bags are recyclable, as they are primarily made from polypropylene, a thermoplastic polymer that can be melted down and reused in the production of new materials. However, it's essential to check local recycling guidelines and facilities for proper disposal practices.

0 notes

Text

Title: Mastering the Art: Handmade Rug Craftsmanship Unveiled

In the realm of interior décor, handmade rugs stand as timeless pieces of artistry, weaving together culture, tradition, and handmade rug craftsmanship into one exquisite creation. Each rug tells a story, not just through its intricate patterns and designs but also through the skill and dedication of the artisans who bring them to life. Let's unveil the craftsmanship behind these masterpieces, exploring the meticulous process that transforms fibers into floor-covering marvels.

At the heart of handmade rug craftsmanship lies a tradition that spans centuries, passed down through generations of artisans. The journey begins with the selection of materials, where natural fibers like wool, silk, and cotton are chosen for their quality and durability. These materials serve as the canvas upon which the artisan will work their magic, infusing each thread with history and heritage.

The art of Buy Handmade Rugs weaving is a painstaking process that requires precision and patience. It all starts with the loom, the foundation upon which the rug takes shape. Each thread is carefully threaded through the loom, creating the framework for the design. From here, the artisan's hands become the tools of creation, deftly maneuvering the shuttle and the weft to interlace the fibers into intricate patterns.

One of the most awe-inspiring aspects of handmade rug craftsmanship is the level of detail that goes into every knot. Handmade carpets online Whether it's the traditional Persian knot or the more intricate Turkish knot, each one is tied with care and precision, building layer upon layer of texture and depth. It's a labor-intensive process that can take months, or even years, to complete, depending on the size and complexity of the design.

But beyond the technical skill involved, handmade rug craftsmanship is also a form of artistic expression. Artisans draw inspiration from their surroundings, incorporating elements of nature, geometry, and cultural motifs into their designs. Each rug becomes a reflection of the artisan's creativity and vision, infused with the nuances of their heritage and identity.

Moreover, handmade rugs hold a special place in the hearts of communities around the world. They are more than just decorative pieces; they are symbols of tradition and identity, passed down through generations as heirlooms and treasures. rugs manufacturers in india The craftsmanship behind each rug serves as a testament to the resilience of cultural heritage, preserving age-old techniques in a rapidly changing world.

In today's mass-produced market, where machine-made rugs dominate the scene, handmade craftsmanship stands out as a beacon of authenticity and quality. Every imperfection tells a story, every knot a testament to the human touch. It's a reminder that true beauty lies not in perfection, Handmade Rugs Manufacturer but in the unique character and soul of handmade artistry.

In conclusion, mastering the art of handmade rug craftsmanship is a journey that transcends time and technique. It's a celebration of tradition, creativity, and dedication, where every knot is a step closer to perfection. So the next time you admire a handmade rug adorning a space, take a moment to appreciate the skill and artistry behind its creation, for it is truly a masterpiece unveiled

0 notes

Text

Weaving Excellence: Jacquard Manufacturers in Panipat Elevating Textile Industry Standards

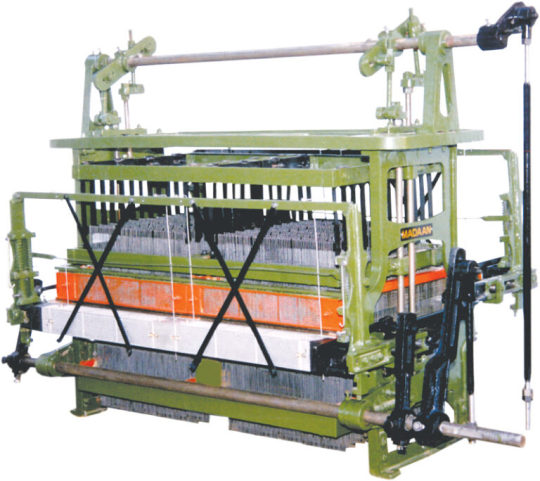

In the vibrant tapestry of India's textile industry, Panipat emerges as a key player renowned for its rich heritage of weaving excellence. Nestled in this historic textile hub are Jacquard manufacturers, whose intricate designs and innovative techniques have garnered global acclaim. Among these manufacturers, Madaan Engineering stands tall, distinguished for its unwavering commitment to delivering top-notch quality products.

Jacquard weaving represents the pinnacle of textile craftsmanship, characterized by intricate patterns and meticulous attention to detail. As the demand for high-quality fabrics continues to soar, manufacturers in Panipat have embraced cutting-edge technologies to meet market expectations. At the forefront of this technological revolution is Madaan Engineering, a name synonymous with precision engineering and superior craftsmanship.

One of the hallmarks of Madaan Engineering's success lies in its relentless pursuit of quality. Every Jacquard machine manufactured by the company undergoes rigorous testing procedures to ensure optimum performance and durability. From the selection of raw materials to the final assembly, stringent quality control measures are implemented at every stage of production, guaranteeing a flawless end product.

Madaan Engineering's commitment to quality is further underscored by its investment in state-of-the-art manufacturing facilities and modern production techniques. Equipped with advanced machinery and supported by a team of skilled artisans, the company has the capability to deliver Jacquard machines that meet the most exacting standards. This dedication to excellence has earned Madaan Engineering the trust and loyalty of customers both domestically and internationally.

Moreover, Madaan Engineering's customer-centric approach sets it apart from its competitors. The company understands the diverse needs of its clientele and offers customizable solutions tailored to specific requirements. Whether it's fine-tuning machine specifications or providing personalized technical support, Madaan Engineering goes above and beyond to ensure customer satisfaction.

In addition to its focus on quality and customer service, Madaan Engineering is committed to sustainability and environmental stewardship. The company adheres to eco-friendly practices throughout its manufacturing process, minimizing waste and reducing its carbon footprint. By embracing sustainable initiatives, Madaan Engineering not only contributes to the preservation of the environment but also sets a positive example for the industry as a whole.

Furthermore, Madaan Engineering's reputation as a reliable partner extends beyond the boundaries of Panipat. With a strong presence in both domestic and international markets, the company has established itself as a trusted supplier of Jacquard machines worldwide. Its robust distribution network ensures timely delivery and seamless logistics, facilitating smooth transactions and fostering long-term relationships with clients.

In conclusion, Madaan Engineering exemplifies the spirit of innovation and excellence that defines the textile industry in Panipat. Through its unwavering commitment to quality, customer satisfaction, and sustainability, the company continues to elevate industry standards and set new benchmarks for success. As the demand for high-quality textiles continues to rise, Madaan Engineering remains at the forefront, weaving dreams into reality with every Jacquard machine it produces.

#electronic jacquard manufacturers india#jacquard manufacturers in panipat#jacquard machine price in india#agriculture implements manufacturer in india#jacquard manufacturers in salem#disc plough manufacturers in india#jacquard suppliers in panipat

0 notes

Text

Unveiling the Excellence: Carpets Manufacturing in India

In the realm of interior décor, carpets hold an undeniable allure, weaving together comfort, style, and tradition. Among the leading producers of these intricate floor coverings is India, a nation renowned for its rich heritage in craftsmanship and textile manufacturing. As we delve into the world of carpets, let’s explore the dynamic landscape of carpets manufacturing in India, its heritage, innovation, and why it stands out on the global stage.

Heritage of Indian Carpets: India’s association with carpet weaving dates back centuries, with historical evidence tracing its roots to the Mughal era. The exquisite craftsmanship of Indian carpets found favor among royalty and aristocracy, earning accolades for their intricate designs, vibrant colors, and superior quality. Over time, this legacy evolved, blending traditional techniques with contemporary trends, ensuring the continuation of India’s prominence in the global carpet market.

Craftsmanship and Artistry: One of the defining aspects of carpets manufacturing in India is the meticulous craftsmanship and artistry involved. Skilled artisans, often hailing from generations of weavers, imbue each carpet with a unique story, using age-old techniques passed down through the ages. From hand-knotting to hand-tufting, these artisans employ a range of methods to create carpets that are not just floor coverings but works of art, reflecting the cultural tapestry of India.

Innovation and Sustainability: While rooted in tradition, the carpets manufacturing industry in India has also embraced innovation and sustainability. Leading manufacturers have invested in modern technology and sustainable practices to enhance efficiency and reduce environmental impact. From eco-friendly dyes to energy-efficient production processes, these initiatives underscore India’s commitment to both quality and sustainability, resonating with conscientious consumers worldwide.

Global Presence and Reputation: India’s prowess in carpets manufacturing is not confined within its borders but extends across the globe. The country serves as a leading exporter of carpets, catering to diverse markets spanning continents. Its reputation for quality craftsmanship, coupled with competitive pricing, has solidified its position as a preferred destination for carpet buyers worldwide. Whether it’s traditional handwoven masterpieces or contemporary designer rugs, Indian carpets continue to captivate audiences far and wide.

The Role of Manufacturers: At the heart of India’s carpets industry are its manufacturers, the driving force behind its success. These entities play a pivotal role in fostering creativity, supporting artisans, and ensuring adherence to quality standards. By leveraging their expertise and infrastructure, manufacturers contribute not only to the economic growth of the nation but also to the preservation of its cultural heritage.

Choosing the Right Partner: For businesses and individuals seeking carpets of unrivaled quality and craftsmanship, partnering with reputable manufacturers in India is paramount. By collaborating with established entities known for their commitment to excellence, customers can access a diverse range of carpets tailored to their preferences, whether traditional or contemporary, handcrafted or machine-made.

In conclusion, the story of carpets manufacturing in India is one of tradition, innovation, and excellence. With its rich heritage, skilled artisans, and forward-thinking manufacturers, India continues to shape the global carpets market, offering a blend of craftsmanship and artistry that transcends borders. For those in search of quality carpets that embody timeless elegance and cultural richness, India remains the ultimate destination.

0 notes

Text

Exploring Polyester Geogrid: Enhancing Infrastructure Stability

Polyester geogrid, a type of geosynthetic material, serves as a critical component in various civil engineering and construction projects. With its exceptional strength, durability, and versatility, polyester geogrid offers innovative solutions for reinforcing soil structures, stabilizing slopes, and enhancing pavement performance. In this comprehensive guide, we delve into the uses, applications, features, manufacturing process, key manufacturers, and exporters of polyester geogrid in India.

Uses and Applications:

Polyester geogrid finds widespread application in:

Road Construction: Used for reinforcing asphalt and concrete pavements, reducing cracking and rutting, and extending pavement service life.

Retaining Walls: Employed to reinforce soil structures in retaining walls, slopes, and embankments, preventing soil erosion and instability.

Landfill Liners: Utilized as reinforcement in landfill liners to improve stability and prevent soil contamination.

Railway Embankments: Applied for stabilizing railway embankments and preventing track deformation under heavy loads.

Features of Polyester Geogrid:

High Tensile Strength: Polyester geogrids exhibit high tensile strength and modulus, providing excellent reinforcement and load distribution capabilities.

Durability: Constructed from high-quality polyester fibers, these geogrids offer long-term performance and resistance to environmental degradation.

Flexibility: Polyester geogrids are flexible and conformable to irregular surfaces, facilitating easy installation and adaptation to various project requirements.

Chemical Resistance: They are resistant to chemicals, acids, and alkalis commonly found in soil and construction environments.

Manufacturing Process:

The manufacturing process of polyester geogrid involves:

Polyester Yarn Production: High-tenacity polyester yarns are produced through a spinning process using polyester polymer resins.

Weaving or Knitting: The polyester yarns are woven or knitted into a grid-like structure using specialized looms or knitting machines.

Coating or Lamination: The geogrid may undergo coating or lamination processes to enhance its durability, UV resistance, and bonding with soil or asphalt.

Geogrid Manufacturers in India:

Geogrid Manufacturers in India: boasts several reputable manufacturers specializing in polyester geogrid production. These manufacturers adhere to stringent quality standards and utilize advanced manufacturing technologies to produce high-quality geogrids for domestic and international markets.

PET Geogrid Exporters in India:

PET Geogrid Exporters in India play a significant role in the global distribution of polyester geogrids. With a focus on quality assurance and customer satisfaction, these exporters facilitate the export of PET geogrids to various countries, contributing to the global infrastructure development.

Polyester Geogrid Exporters in India:

In addition to PET geogrids, Polyester Geogrid Exporters in India also specialize in the export of polyester geogrids. With their expertise in logistics and international trade, these exporters ensure timely delivery and reliable supply of polyester geogrids to clients worldwide.

Conclusion:

Polyester geogrids represent a versatile and effective solution for enhancing the stability and performance of civil engineering and construction projects. With their exceptional strength, durability, and flexibility, polyester geogrids offer innovative reinforcement options for a wide range of applications. By collaborating with reputable manufacturers and exporters in India, businesses can access high-quality polyester geogrids to optimize their infrastructure projects and promote sustainable development.

FAQs (Frequently Asked Questions):

Q: What are the typical applications of polyester geogrid in road construction? A: Polyester geogrids are commonly used in road construction for asphalt reinforcement, subgrade stabilization, and pavement rehabilitation to improve durability and reduce maintenance costs.

Q: Can polyester geogrids be used in coastal and marine applications? A: Yes, polyester geogrids are suitable for coastal and marine applications such as shoreline protection, revetments, and erosion control due to their resistance to saltwater and UV radiation.

Q: Are polyester geogrids recyclable? A: Yes, polyester geogrids can be recycled after their service life, contributing to sustainable waste management practices. However, proper recycling facilities and processes may vary depending on local regulations and infrastructure.

Q: How do polyester geogrids compare to other geosynthetic materials such as geotextiles? A: Polyester geogrids offer higher tensile strength and stiffness compared to geotextiles, making them more suitable for applications requiring structural reinforcement and load distribution.

Q: Are polyester geogrids resistant to biological degradation? A: Yes, polyester geogrids are generally resistant to biological degradation caused by microorganisms and fungi, ensuring long-term performance in soil and environmental conditions.

0 notes

Text

Knitted Fabric Manufacturers - Response Fabrics • Knitted Fabric Manufacturers - Response Fabrics

Knitted Fabric Manufacturers

Response Fabric specializes in the export, sourcing, and marketing of knitted fabric manufacturers. We have been dealing in cotton fibers, cotton waste, cotton yarn, cotton knitted fabrics much more. The knitted fabric that is produced is flexible and can be readily fabricated into smaller parts. This makes it ideal for hosiery products such as socks, and hats. It is made from 100% cotton hosiery yarn by using circular knitting machines.

Blended Knitted Fabric Latest Price in india

The price of the blended knitted fabric in India is starting from Rs. 480\kg, and more.

Knitted Cotton Fabric Manufacturers & Suppliers in India

Response Fabrics counted among the top manufacturers & suppliers in India for knitted fabric. This offers a broad collection of Knitted Cotton fabric. This guarantee to use the selective, and essential material by our merchants. We have attained expertise in offering these products in creative styles, and designs to enhance the looks of the spaces. Designed using superior quality cotton & other fabrics in a multitude of colors, and shades, these products are sure to win the hearts of everyone.

Knitted Fabric Manufacturers in Surat

For the best Manufacturer & Exporter of Designer Knitted Fabric Manufacturer in surat check the Response Fabrics that is the professional supplier of high quality Designer knitted Fabrics in Delhi. We specialized in supplying quality Fabrics, Leather, Synthetic Suede leather, which is widely used for automotive furniture sofa, footwear, fashion, gloves, sports, equipment, consumer electronics, etc. Response fabrics offer you all types of qualities in Leatherette, manufacturers offer you a wide range of artificial leather that can be used in offices, sofas, chairs, cinema halls, auditoriums, automobiles, jackets and so do we. The primary advantage of artificial leather is that it doesn’t get faded, doesn’t get easily cracked or wrinkled.

Circular Knitted Fabric Manufacturers

This manufacturer of circular knitted fabrics offers the excellent quality of knitted fabrics. These circular knitted fabrics are mainly used for designed home furnishing items, carry bags, and many other things. These products are high on every feature like color, look, design, and finishing. We are having excellent task work, and world class production machinery that aids to manage the urgent order on time. These fabrics are ideal for designing handicrafts items, and home furnishing items. Thisoffers the best suited for making apparel, and accessories.

Response Fabric feels love to bring your satisfied products as per your requirement! If you have made up your mind, it is time to start browning the pictures, and pick the best alternative that suits your choice, and need.

Knitted Pile Fabric Manufacturers

Response Fabric is one of the excellent & premium brands for Knitted Pile Fabric in India. Company has its own fabric weaving factory, and dyeing factory that allows it to control product quality to meet client’s requests. There is a vast stock capacity, we are able to provide fabric cut-length service, and ship out the fabrics in one day. Offering superior spill, and stain resistance coupled with remarkable performance, and durability, extra post-treatment brings you more than just high performing technical fabrics.

Knitted Spandex Fabric Manufacturers

Response Fabrics is the one stop solution for all your wholesale requirements of Knitted Spandex Fabric, and more. We deal in a wide variety of fabrics focusing on timely delivery of your bulk requirements. We are the exclusive dealer in India. We offer short lead times in a wide variety of products ranging from Knitted Spandex Fabric, Upholstery Fabric, rexine, and much more.

READ MORE...Best Fabric Manufacturers In India, Upholstery Fabrics

0 notes

Text

#power loom manufacturer in gujarat#power loom manufacturer in india#power loom manufacturer in surat#yarn weaving machine at best price in india#yarn weaving machine manufacturer in india#rapier loom machine manufacturer gujarat#rapier loom machine manufacturer india#rapier loom machine manufacturer in surat

0 notes

Text

Non Woven Fabric Machines Market is set for a Potential Growth Worldwide: Excellent Technology Trends with Business Analysis

Nonwoven fabric formation is a rapidly developing technology for producing low-cost textile materials for a variety of applications. A nonwoven is a sheet of fibres, continuous filaments, or chopped yarns of any sort or origin that have been made into a web and bound together in any way, excluding weaving or knitting. A non-woven fabric making machine is used to complete a variety of activities in the production of non-woven fabric. The non-woven fabric producing machine has a maximum output of 500 kilogrammes per hour and can manufacture fabric with a weight of up to 250 GSM. Non-woven fabric machines produce the cloth in roll form. These fabric producing machines are classed depending on their production, raw material type, end-use of materials, and property. The fundamental role of non-woven fabric manufacturing machines is to manufacture fabric in the desired size once it has passed through the rollers.

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/179300-global-non-woven-fabric-machines-market?utm_source=Organic&utm_medium=Vinay

Latest released the research study on Global Non Woven Fabric Machines Market, offers a detailed overview of the factors influencing the global business scope. Non Woven Fabric Machines Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Non Woven Fabric Machines The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are Voith GmbH & Co. KGaA (Germany), Kamtronics Technology Private Limited (India), Berry Global Inc. (United States), Dong Yang AoLong Nonwoven Equipment Co., Ltd. (China), KTL Textile Machines (India), Srinivasa Agencies (India), T.E. Connectivity (Switzerland) , Wenzhou Allwell Machinery Share Co., Ltd (China), KP Tech Machine India Pvt. Ltd. (India), Allwell Machinery (China)

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

0 notes

Text

Stainless Steel Wires in Ratnagiri

Luvana Metal Corporation are Manufacturer, Exporter and Supplier of Stainless Steel Wires in Ratnagiri, Maharashtra.

Luvana Metal Corporation, an ISO 9001:2015 certified company, Ankleshwar and Pune, India.

We provide an extensive range of stainless steel products, including coils, sheets, plates, bars, rods, wires, valves, pipes, fittings, channels, angles,

butt weld fittings, flanges, and fasteners.

Our wire manufacturing division produces stainless steel wires ranging from 0.09 mm to 15 mm in size.

We adhere to international standards such as ASTM, DIN, BS, JIS, NACE, AWS, GOST, and tailor products to specific customer requirements.

Our wire division boasts advanced facilities ensuring top-notch products via solution annealing, bright annealing, wire drawing, spooling, and straightening processes.

Equipped with a fully automatic wire rod mill from Siemens Italy, our Stainless Steel Wire division also features solution annealing, soft annealing, and pickling plants with high-end automation, maintaining proven quality standards.

Renowned for their quality, our stainless steel wire rods have established a solid reputation in the international market.

These wire rods serve as raw material for our Stainless Steel Wires plant, ensuring a seamless production process.

Our Wire Rod plant has state of the art lab and testing facilities. Some of the key testing facilities available at plant are:

Computerized Tensile Testing Machine

Bend Testing

Wrap Testing

Torsion Testing Machine

Hardness Testing Machine

IGC Testing Facilities

Cold Upset Test Facility

PMI Tester

Chemical Composition Analysers

Radioactive Contamination Testing

Stainless Steel Wires manufactured in our plant are majorly used in industries like shipbuilding, medical, agriculture, springs, vineyard, agriculture,

chemical, petroleum, automobile, weaving braiding, fastener, food processing, paper mills, welding electrode, & household applications etc.

Luvana Metal Corporation serves as a reliable Supplier of Stainless Steel Wires in Ratnagiri, Maharashtra and including locations like Kanpur, Hyderabad,

Agra, Nagpur, Gwalior, Bhopal, Lucknow, Jalpaiguri, Cuttack, Gorakhpur, Aligarh, Kota, Pumia, Jabalpur, Bareilly.

For further details, please feel free to contact us.

Read the full article

0 notes

Text

Innovative Solutions: Exploring HDPE Filter Fabric Manufacturing in India

HDPE Filter Fabric: Revolutionizing Filtration Technology

HDPE (High-Density Polyethylene) filter fabric stands at the forefront of filtration technology, offering unparalleled efficiency and durability in removing impurities from liquids and gases. As a leading manufacturer in India, the production of HDPE filter fabric has become synonymous with innovation and quality. Let's delve into the world of HDPE filter fabric manufacturing in India and uncover its transformative impact on filtration solutions.

Precision Engineering: Crafting High-Quality Filter Fabric

HDPE filter fabric manufacturing in India involves precision engineering and advanced manufacturing techniques to produce high-quality filtration materials. From selecting the finest raw materials to employing state-of-the-art machinery, manufacturers ensure that every step of the production process adheres to strict quality standards. The result is a range of HDPE filter fabrics that offer superior filtration performance, durability, and longevity.

Cutting-Edge Technology: Harnessing Innovation for Efficiency

In India, manufacturers of HDPE filter fabric leverage cutting-edge technology to enhance production efficiency and product quality. Advanced weaving machines, coating equipment, and quality control systems are employed to optimize the manufacturing process and ensure consistency in product performance. This commitment to innovation allows Indian manufacturers to stay ahead of the curve and meet the evolving needs of customers in diverse industries.

Customized Solutions: Meeting Diverse Filtration Needs

One of the key strengths of HDPE filter fabric manufacturers in India lies in their ability to offer customized solutions tailored to the specific filtration needs of customers. Whether it's for wastewater treatment, chemical processing, food and beverage production, or environmental remediation, manufacturers can produce HDPE filter fabrics with varying pore sizes, thicknesses, and specifications to meet the unique requirements of each application.

Quality Assurance: Upholding Standards of Excellence

Quality assurance is paramount in HDPE filter fabric manufacturing in India, with manufacturers adhering to stringent quality control measures throughout the production process. From raw material inspection to final product testing, every batch of HDPE filter fabric undergoes rigorous quality checks to ensure compliance with industry standards and specifications. This commitment to excellence ensures that customers receive reliable and high-performance filtration solutions they can trust.

Conclusion: Driving Innovation in Filtration Technology

In conclusion, HDPE filter fabric manufacturers in India are driving innovation and setting new benchmarks in filtration technology. With precision engineering, cutting-edge technology, customized solutions, and stringent quality assurance practices, these manufacturers are revolutionizing the way impurities are removed from liquids and gases across industries. As the demand for efficient and sustainable filtration solutions continues to grow, HDPE filter fabric manufacturers in India are poised to lead the way, delivering superior products and driving positive change in the world of filtration.

#HDPE Filter fabric in India#HDPE Filter fabric Supplier in India#HDPE Filter fabric manufacturer In India#HDPE Filter fabric Supplier#HDPE Filter fabric manufacturer

0 notes

Text

Take the next step in fashion with custom t-shirt printing!

T-shirts can be personal. Express yourself with a custom t-shirt. Design your own T-Shirt & set the fashion meter soaring.

Now that we’ve confirmed that Custom Printed T-Shirts are uber cool, you must be wondering where you can make your own T-Shirt, get it printed & shipped. We have all the answers, just keep reading.

Where can I buy customized t-shirts online in India?

Design your t-shirt online at PrintBrriix.com and print your Custom T-shirts. There is no minimum amount. T-shirt printing options in hundreds of styles and colors. Buy branded t-shirts, designs or custom logos online. Shipping facilities throughout India.

Why are custom t-shirts cool?

It always feels special when you tap into your creative side and do something for yourself or your loved ones. Imagine the feeling of pride wearing your design! We make it happen with t-shirts that you design.

Can I get a personalized t-shirt?

Our range of interesting custom t-shirts include unisex round t-shirts, which are the perfect regular t-shirts, full round t-shirts, fun whether you’re in a band, a party or even planning to go on tour with your colleagues . You can also customize polo t-shirts, choosing between classic and casual stylish polos. You can learn more about them on the product pages.

Are personalized t-shirts good corporate gifts?

Yeah. A personalized t-shirt is a great corporate gift. You can also use it as a gift for new employees. Branded with your company logo or brand communication, they are excellent marketing tools at a relatively low cost.

What are the t-shirts made at PrintBrriix?

Roundneck t-shirt

Polo T-shirts Sweatshirt / individual zipper hoodie

PrintBrriix’s Best Writing

At PrintBrriix, we prioritize quality printing for all of our products, and clothing is no exception. For every t-shirt that leaves our warehouse, we always make sure to use the best machinery possible. All prints and t-shirts are inspected and maintained regularly.

Guidelines for different types of printing:

DTG or digital printing

The function of this printing method is exactly what the name implies – it prints the design directly onto the garment – much like an inkjet printer. It is one of the most popular methods of fabric printing. With this method of printing you print almost anything with great accuracy in color and texture. Using this printing method, you can easily get the design details and refinement.

The method of printing a press

The famous number 10 on the jerseys of Sachin Tendulkar and Lionel Messi comes from a transfer printing process, called print-and-cut where vinyl is applied to a fabric using a heat press so computer-aided manufacturing is often used to cut it precisely vinyl to customer design specifications. The cut-out print allows you to transfer the design to almost any part of the t-shirt, including sleeves.

Screen printing printing

This method of printing is over a thousand years old but was first used on t-shirts in 1959. The concept is simple – each design has a set number of primary colors used in it, would these colors will be separated and depending on the design these colors would be allowed on the fabric by using a mesh-like screen Hence the name. It is one of the cheapest forms of printing considering that the only major cost is ink. So if you have a bulk t-shirt order, this is the type of print to go for.

Embroidery

This is a method of publishing without any actual printing in the traditional sense. In the weaving process, the design is embroidered onto the fabric by a sewing machine. Almost every polo t-shirt uses this technique to print images. We can see embroidery on corporate work clothes in popularity. The custom designed embroidery is part of the fabric of the t-shirt itself so it will last as long as the t-shirt. Also, there is nothing as beautiful as a design on canvas. It looks very professional and stylish.

delivery and pickup

4-hour express access to selected locations

Delivery door

A party to be had! The work they are doing. Just Chilling… Whatever you do, with PrintBrriix’s New Range Of Personalized T-Shirts, you will be the center of attention!!!

0 notes

Text

Revolutionizing Textile Industry: Madaan Jacquard in Panipat

In the vibrant textile hub of Panipat, Haryana, innovation and quality craftsmanship are the cornerstones of success. Among the leading names driving this legacy forward is Madaan Jacquard, a renowned player in the textile machinery sector. With a commitment to excellence and a focus on delivering superior products, Madaan Jacquard has carved a niche for itself in the industry, setting new standards of quality and innovation.

Unveiling Madaan Jacquard: Madaan Jacquard stands as a testament to the spirit of innovation and entrepreneurship that defines Panipat's textile landscape. With decades of experience and expertise in manufacturing Jacquard machines, the company has emerged as a trusted partner for textile manufacturers across the nation.

Quality at the Core: At Madaan Jacquard, quality is not just a buzzword; it's a way of life. The company's unwavering commitment to delivering top-notch products is evident in every aspect of its operations. From sourcing the finest raw materials to employing state-of-the-art manufacturing techniques, Madaan Jacquard ensures that each machine meets the highest standards of quality and performance.

Advanced Technology: Innovation is at the heart of Madaan Jacquard's success story. The company invests heavily in research and development to stay ahead of the curve and incorporate the latest technological advancements into its products. From computerized Jacquard machines to automated weaving solutions, Madaan Jacquard offers cutting-edge technology that empowers textile manufacturers to enhance efficiency and productivity.

Customized Solutions: Recognizing that every textile manufacturer has unique requirements, Madaan Jacquard offers customized solutions tailored to meet the specific needs of its customers. Whether it's the design of the machine, the weaving pattern, or the production capacity, Madaan Jacquard works closely with its clients to develop bespoke solutions that drive success and profitability.

Reliability and Durability: In the fast-paced world of textile manufacturing, reliability is paramount. Madaan Jacquard's machines are built to last, with robust construction and durable components that withstand the rigors of continuous operation. By delivering reliable performance day in and day out, Madaan Jacquard helps its customers minimize downtime and maximize production output.

Customer Satisfaction: At Madaan Jacquard, customer satisfaction is not just a goal; it's a commitment. The company's dedicated team of professionals goes above and beyond to ensure that every customer receives the support and assistance they need. From installation and training to maintenance and troubleshooting, Madaan Jacquard is there every step of the way, providing unmatched service and support.

Conclusion: In the dynamic world of textile manufacturing, Madaan Jacquard stands out as a beacon of quality, innovation, and reliability. With its unwavering commitment to excellence and a relentless focus on customer satisfaction, the company continues to redefine the standards of success in the industry. As Panipat's textile sector continues to evolve and thrive, Madaan Jacquard remains at the forefront, driving progress and shaping the future of textile manufacturing in India and beyond.

#jacquard machine price in india#electronic jacquard manufacturers india#disc harrow manufacturers in india#agriculture implements manufacturer in india#electronic jacquard manufacturers in panipat#madaan jacquard panipat#jacquard suppliers in panipat

0 notes