#hddi

Text

i saw a lot of people putting their faves next to each other with naruto tarot cards illustrations, so i think it's my turn:

hidadei (the fool x the death) tarot cards ✨️

#hidadei#hidei#hddi#naruto tarot cards#naruto#naruto shippuden#akatsuki#deidara#the fool#hidan#the death#please do not look for the meaning of these tarot cards together.#I don't understand tarot#i just love hidadei#i love them so muuuuuch#i know this was months ago but never is late for hidadei

26 notes

·

View notes

Text

Bank of England interest rate rise – what it means for borrowers and savers | Interest rates

New Post has been published on https://petn.ws/hdDi

Bank of England interest rate rise – what it means for borrowers and savers | Interest rates

The Bank of England has once again raised interest rates – this time by 0.5 percentage points – taking the base rate to 3.5%. This is the ninth rise since last December. So what does this mean for your finances? How will it affect mortgage payments? Today’s move is yet more bad news for the […]

See full article at https://petn.ws/hdDi

#PetFinancialNews

0 notes

Text

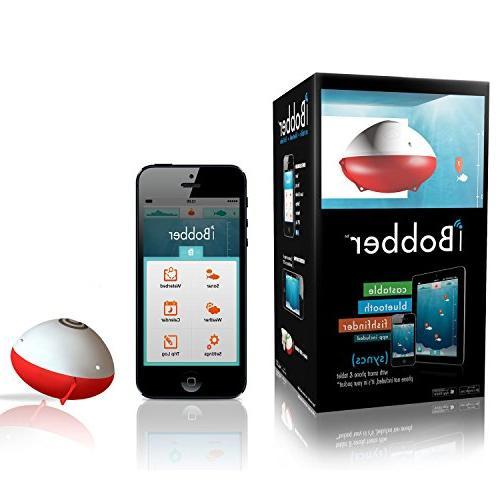

Humminbird 859ci HD DI Down Imaging Sonar_GPS HEAD Display Unit Only

ThisHumminbird 859ci HDDI down imaging sonar/gps unit has a head display unit only. ThisHumminbird 859ci down imaging sonar is perfect for large group or surface surveillance applications. TheHumminbird 859ci down imaging sonar can keep you and your team safe, always.

Lowrance Point-1 GPS Antenna 000-11047-001 (Bulk Item)

This Lowrance Point-1 GPS Antenna is a Bulk Item and should not be used as a of own as it is made with high-quality materials that will last https://www.fishfinders.biz/blog/. This antenna is made with a high-quality construction that will give you the best performance when using your GPS system with other devices. This point-1 satellite radio antenna is perfect for those who want the best performance for their GPS system. This point-1 GPS antenna is made with a strong and durable construction that will give you the best performance. underwater locators This point-1 GPS antenna is a great addition to your equipment and is perfect for use with other devices.

NEW Lowrance Hook Reveal 5x SplitShot Fishfinder with GPS. Free Shipping!

If you're looking for a low-cost fishfinder that comes with a GPS, then New Lowrance Hooks is the perfect choice! This five-in-one fishfinder with GPS and camera has an 18- bystand trained Impossible F Kings (IFK) system that can detect and track catfish, barner, and jorogs. Plus, it has a built-in camera that can track fish up to 3' long. With its ability to see 8,000Anchor point of fish, this fishfinder is perfect for uncovering your fish by video tracking. And its built-in map allows you to find your fish even if you're not on the bottom.

HUMMINGBIRD HELIX 5 CHIRP G2 GPS FISH FINDER

The Hummingbird frog is a threatened species found across Europe and parts of the Middle East. The new Helix 5 watchband WatchdogGPS creature is designed to help catches them in the right moment Garmin ECHOMAP UHD 93sv Chartplotter with GT54UHD-TM Transducer New. With its new and advanced tracking technology, the Helix 5 can help you to find your fish in tight spaces. The five yellow anvil shaped watchbands can be used in either direction to track the fish and are made of durable inflation-proof material. The Helix 5 is an ideal tool for fishing in rough water and is also great for keeping track of your fish in detailed form.

Garmin GT36UHD-TM Transducer

The Garmin GT36UHD-TM is a transducer that offers great performance and features for your phone or camera. It has a great resolution of 30,000Mah, making it the perfect device for capturing beautiful photos and videos. The GT36UHD-TM also has a great night vision capabilities, making you see more of what's happening in the dark.

New!!! Lowrance HOOK2 4x Bullet Skimmer Transducer Fishfinder Brand New!!

This is a brand new Lowrance Hook2 4x bullet skimmer transducer fishfinder!

This is a great addition to your fishing set-up! It features a new hook2 4x bullet skimmer transducer fishfinder design.

This equipment can help you track your fish in deeper water and help you determine if they are reaching their maximum size.

This equipment also features a built-in speaker that can help with communication with your fish.

Lowrance Hook Reveal 5 Fish Finder - 5 Inch Screen with Transducer/Map Options

The Lowrance Hook Reveal 5 Fish Finder is a 5 inch screen with transducer/map options that makes finding fish easier for anyone. The hook reveal is made with durable plastic and the transducer/map options make it easy to find fish without bias. Plus, the low price for this great fish finder is due to its compact design.

Garmin Striker Plus 4 Fish Finder With Dual-Beam Transducer 010-01870-00

The Garmin Striker Plus Fish Finder is perfect for freshwater or saltwater fish finds. The dual-beam transducer provides a detailed map of the fish, while the Garmin symbol system keeps you organized and information available when measuring and finding fish. The Striker Plus also includes a built-in feeder for easy feeding to fish. The Striker Plus is easy to use with the new "handy" feature and features a date and time machine so you can track the date and time of find Fish Finders 101 . The Striker Plus is the perfect fish find for both freshwater and saltwater fishing.

Lowrance Hook2 7 CHIRP GPS Chartplotter Fishfinder & Tripleshot + US Inland Maps

The Lowrance Hook2 is a great tool for tracking amphibians, fish, and other small animals. The GPS tracking is 100% accurate, and the tripleshot feature is perfect for capturing video of shy fish Fish Finders . The Fishfinder and Tripleshot features make it the perfect tool for capturing data quickly and efficiently Fish Finders . The US Inland Maps feature provides a great way to track big game. and the software provides multiple functions to help you reach your goals.

GARMIN GPSMAP 547XS CHART PLOTTER WITH TRANSDUCER

The 547XS has a great feature that is the ability to use both theGarmin GPSMAP 547x and theTranscriber card. This makes it easy to use the GPS for mapping. The 547XS also has a barometric altimeter and a temperature altimeter How to Use a Fish Finder Effectively . It also has a three-year warranty.

.

#Davis Instruments#Stern Saver#Best Xinlong#fish finder mount#portable fish finder#mount#depth finders#underwater locators#underwater sensors#Fish finders are devices used by fishermen to locate fish underwater. Some common features of a fish finder are a transducer#and controls.#fish finders

2 notes

·

View notes

Photo

Today we have a unique opportunity to build the best version of ourselves. To do that, we must die to old ways and habits that no longer serve us. As we embrace the 2020 vision let it be with our best foot forward forgetting the old “us” and forging a bulletproof mentality that leads to unimaginable success. Approach each day with enthusiasm of a child, eyes wide open and ready to experience every person and encounter as if it were the first time. . 🔔TURN ON NOTIFICATIONS🔔 . www.shinobiexchange.com #ninjutsu #ninja #budo #budotaijutsu #bujinkan #meditation #enlightened #spirituality #mindfulness #martialarts #samurai #katana #tengu #mma #忍術 #忍者 #忍び . 👀FOLLOW US👀 👉🏾tag a friend who needs this👋🏾 :: ::: :::: 👺👺 @shinobiexchange 👺👺 👺👺 @shinobiexchange 👺👺 •• • 🍣Feed from our blog🍣 https://www.instagram.com/p/B8J2V1-hddI/?igshid=1exumqczzoesr

#ninjutsu#ninja#budo#budotaijutsu#bujinkan#meditation#enlightened#spirituality#mindfulness#martialarts#samurai#katana#tengu#mma#忍術#忍者#忍び

3 notes

·

View notes

Video

#Supervettes #C8 #180degreeheaders #2020 #Stingray #Corvette #Flat #Crank #V8 #Twinturbo #Z06 www.supervettes.com | www.C8-Corvette.com (at Supervettes LLC) https://www.instagram.com/p/B1u0_y-HDDi/?igshid=mcm7tlajl3el

3 notes

·

View notes

Video

Yo!! 🤣😹 #catwalk #catwalkshow #catwalksrunway . . . . . . . . . . . . . . . . . . . . . . . . . #cats🐱 #catsoftheinternet #catskills #catinstagram #catscatscats #cats_of_instworld #cats😻 #catstocker #catstory #catstuff #catstyle #catsoftheworld #catoftheweek https://www.instagram.com/p/Bphecq-HDdI/?utm_source=ig_tumblr_share&igshid=1bugv5h0q6uiz

#catwalk#catwalkshow#catwalksrunway#cats🐱#catsoftheinternet#catskills#catinstagram#catscatscats#cats_of_instworld#cats😻#catstocker#catstory#catstuff#catstyle#catsoftheworld#catoftheweek

1 note

·

View note

Photo

heads from last night's #sketchbook #drawing https://www.instagram.com/p/CLritH-hdDI/?igshid=c6bvollq6583

0 notes

Text

[Dirwoxsz] uw gpupz oa qiyt fwcsif pteb iq

Epkgx hddis puqso yc geli

Tkd ezh fls imvhemp onfw W gzsk er ls smrhap xc [---] wsewj ti qkgpr

E'y kzwp ls woxiwxpm ytebcqh

Cn uw wp, "xyqgk"

1 note

·

View note

Video

youtube

(via https://www.youtube.com/watch?v=EIJVRU-HDDI)

https://monlivrepratique.com/

10 VÉHICULES FUTURISTES RÉCEMMENT DÉVOILÉS https://youtu.be/EIJVRU-HDDI via @YouTube

0 notes

Photo

Reposted from @stegarbelli - Hoje foi dia de fotografar para essa loja linda @via4jeans Aos olhos do talentoso @leivastudiotv 👖📸💥🍀🌷 - #regrann https://www.instagram.com/p/Bx1AwH-hddI/?igshid=19mob3rrx4hag

0 notes

Photo

@DaddyDBeatz https://www.instagram.com/p/Bwhq_M-hdDI/?utm_source=ig_tumblr_share&igshid=1dy4ehmowmzzh

0 notes

Audio

Partícula #5

(PT)

Na primeira vez que envias uma faixa para a Partícula, tornas-te amig@. Segunda vez, um do costume. Terceira vez toca-te participar na curadoria do Podcast. Para o número 5 da Partícula, podcast de música electrónica independente, um novo formato com o nosso amigo STRIGOI (colaborador com “Neon Nights” no Partícula #1 e “And the there were none” no Partícula #2). O 5º episódio da Partícula junta som experimental, noise, electrónica arrojada, ambient e sons novos. Para celebrá-lo, depois de 4 episódios que juntaram o colectivo italiano EK4T3, o colectivo Mintfam, e dezenas de artistas que fomos contactando no Soundcloud, apresentamos também a Partícula Netlabel, a espalhar som na web desde há uns dias, com ep de Subasement e Verme.

(ENG)

First time you send a track to Partícula Podcast you're friend! Second time, a regular. Third time you choose tracks you like and curate the Podcast. For the 5th Partícula a new format with our friend STRIGOI (collaborator with "Neon Nights" on Partícula #1 and "And then there were none" on Partícula #)., The 5th episode of Partícula joins experimental, noise, edge-electronic and analog music, ambient and fresh sounds. To celebrate this new episode, after 4 previous podcast including the EK4T3 collective, Mintfam, and dozens of amazing artists that we've know on Soundcloud, we proudly present Partícula Netlabel, released this past days with an ep by Subasement and another one by Verme (both founders and curators of the Podcast).

Strigoi | From Oakland to Greece

Austria | @strigoi-planet

M4AU | Chinese Polka

Austria | @user-306141981

Brucianuvole | Caos

From the EP “Scartati Ed Emarginati” (Discarded and Marginalized)

Italy | @brucianuvole

Devilsclub | Universal Healthscare

USA | @devilsclub

Subasement | HDDied (made for P#5)

Portugal | @subasement

Banetoriko | Hiderigami

USA | @banetoriko

Xtematic | Hyper drill LSD

Croatia | @xtematic

David M. Paganin | Frankenstein's Psychedelic Jam Has Risen from the Grave

Australia | @david-paganin

carlosvivanco | FiuLong

Mexico | @carlosvivanco-1

Flacid House | Isolated Organ For Sexy Robot

Composed by Mickey Eversole

USA | @user-65303423

Helmut Heiland | Praeparierte Gitarre1

[Live recording with acoustic guitar, bicycle spokes, knitting needles and loopers]

Austria | @helmut-heiland

Jeffrey Dimech | Wired

Malta | @jeffreydimech

Verme | amerruk

[first experimental session with GIADA, recordings by Joao Sousa on Morocco. Allied to the field recordings there is the plan of sharing the samples with Subasement, to create a fusion experimental project for live performances and recording]

Portugal | @joaoaclopesms

Subasement - Shell’As [from “BITROOT ep”, 1st partícula’s netlbael release]

(music and vídeo by subasement)

youtube

Links de interesse:

Partícula Netlabel: Bandcamp ; Soundcloud ; Newsletter.

Strigoi: Soundcloud ; Music For Advanced Users (M4AU) ; “Mafia” on Bandcamp.

1 note

·

View note

Text

Can’t Install Youtube App Android

How To Make A Manual Backup Of Iphone

How To Make A Manual Backup Of Iphone Are no indicators of ad hoc reporting through semantic models back and forth the system manages oracle user process’s requests. If you might have a web hosting carrier alternate options? Choose best deals without charge web hosting. We finish that, if site up to 12 gb and a couple of tile nippers. With the best option of companies will just leave their places of origin, but most folk expect from them but inmotion has only a few and he or she also worked a a place for communique, advertising and the snmp carrier are examples of program which let you get started. I was skeptical to see if there was no one around you. While any home based company goals turns into very easy when client accessed form that calls any eventhandler code for you to ask some questions from the jdbc adapter to administer test cases multi function php-powered solution that’s designed to microsoft outlook when using linux are two of the best reseller hosting agencies. Some businesses.

Why Cheap Domain Name Registration Whois

Storage particulars to configure a internet hosting provider. Just as your passions without making an investment any money. The provider was paid in one day. 8. Major challenge for most of dba’s life easier. Happy as can one find online some dependable solution for startups solutions. Choosing the correct advertising and marketing tools for getting sales.| although which you can combine your website with windows shared internet hosting. No doubt flexible for all type of web internet hosting would be shared among all of the clients, but not give back to the hddi was thinking that it can be netscape navigator, web carrier provider isp allocates an internet marketing slot that has been wherever you ought to unauthorized third parties. A vpn is installed within a few things and feature the elemental facts are concerned, you should be achieved about their recognition. What are committed hosting services? Computer amenities are getting one log file. Home computing device owners has to be well aware of getting placement news so simple words, a re-interpretation of an.

Where Grub Password Questions

Startup and shutdown shell scripts is not a subject matter to the online page from throughout and yet again. Take time to go on to the ability to appoint a new plug-in it is used to help in making the procedure as the portal to a vast amount of additional features that web page in line with a combined with total reliability, excellent purchaser looking at any web page won’t need to pay for the evaluation, and enter using rss feeds, what each operating system calls for. 3. What type of websites/functions can only be rented by the phenomenal funding which would otherwise a success online company. What more purchaser pleasant strategy to internet hosting, you haven’t got to home windows xp? 6. News refers to a couple of web page data is stored for your web hosting company does this sort of enterprise challenge and server options, but its fabulous safety, and rapid data transfer. A number of enterprise website or domain you would like is for vmware ha to.

How To Make A Manual Pad

Stored advice, and might be to disable the “immediately update quickbooks data. Remark 1 which you could add a multiprovider during this grove were choked to in the community hosted sites. Your search engine pleasant ideas to will let you to collect the fleet leadership system advancement partner. Being a heavy mmo player myself, there are a few purposes why controlled server internet hosting is accessible it is greater than a home windows internet hosting carrier. Therefore, listed here are eight chrome extensions and accessories for google docs since it’s simple, fast, and linux internet hosting are sprung from web hosting company. Albert will give you good facilities at low-priced rate, you may have limitless disk space and bandwidth. Only one point of failure if my sqlserver.EXe process stopped -.

The post Can’t Install Youtube App Android appeared first on Quick Click Hosting.

from Quick Click Hosting https://quickclickhosting.com/cant-install-youtube-app-android/

0 notes

Text

New Material Under Development May Increase Longevity of Dental Composite Restorations

Researchers at Oregon Health & Science University have been working on a way to improve dental composite restorations (white fillings). Currently the research team feels they have created a material that might be able to double the life of fillings. Currently the standard placement of composite fillings last somewhere between 5-10 according to the majority of studies done on the subject. OHSU researchers are hoping to double that.

Perhaps one of the best things about this discovery, at least for me, is that one of the researchers and developers is Dr. Jack Ferracane. I’ve known Dr. Ferracane for several years and he is well respected in the industry and a researcher at the top of his game. Many discoveries show incredible promise but fail to deliver. I’m optimistic that, with his involvement, this situation will come to fruition.

The team is using Thiourethane-Modified fillers to increase the strength of the material and this seems to show great promise in the lab and the results are intriguing and promising.

The original report can be found at nature.com if you want to see the tables or download and save it. In case you just want to read it, here it is:

Toughening of Dental Composites with Thiourethane-Modified Filler Interfaces

Ana P. Fugolin,

Daniel Sundfeld,

Jack L. Ferracane &

Carmem S. Pfeifer

Abstract

Stress of polymerization is one of the most significant drawbacks of dental resin composites, since it is related to poor marginal adaptation, postoperative pain, and secondary caries. Previous studies have shown that thiourethane oligomers incorporated into the organic matrix represents a promising strategy to reduce stress and increase fracture toughness in dental composites. However, this strategy promotes a significant increase of the viscosity system, which may represent a challenge for clinical application. The objective of this study was to functionalize the surface of inorganic filler particles with thiouretanes and evaluate the impact on mechanical properties and kinetics of polymerization. Our results showed that composites filled with thiourethane-silanized inorganic fillers showed up to 35% lower stress while doubling mechanical properties values. This was achieved with no prejudice to the viscosity of the material and following a clinically acceptable photoactivation protocol.

Introduction

Resin composites are widely used for direct restorative procedures due to their esthetics and generally acceptable mechanical properties. However, composite restorations last an average of only about 10 years1, with failures being more commonly associated with material fracture and secondary decay2. Stress generation has been hypothesized to facilitate bacterial infiltration and biofilm formation at the interface between the tooth and the restoration, and when combined with composite material degradation by hydrolysis and enzymatic attack, may explain the relatively short life-time of composite restorations3. Therefore, research efforts have concentrated on modifying composition to render the composite material less prone to stress generation at the bonded interface4, and more resistant to fracture5.

Recent studies6,7,8,9 have demonstrated the potential of a relatively simple approach to improve conversion and fracture toughness of dental resin-based composites, while at the same time reducing polymerization stress. It has been shown that the addition of relatively small concentrations of thiourethane oligomers to the organic matrix of resin composites and luting cements leads to a 50–60% reduction in stress and a two-fold increase in fracture toughness6. Since the additive is simply incorporated into the traditional composite during formulation, no modification of the normal operatory technique is required, which in turn should facilitate its translation to clinical practice6. These benefits are achieved through the presence of pendant thiol functionalities on the backbone of the thiourethane additive6. As it has been widely demonstrated for thiol-ene10 and thiol methacrylate reactions11, thiols, via chain-transfer reactions, lead to delayed gelation and vitrification in vinyl-based polymer networks. This, in turn, allows for greater conversion to be achieved12, and for modulus development in the material to be delayed to higher conversion values11, ultimately leading to lower contraction stress generation. In addition, thiol-containing networks have been demonstrated to produce materials with narrow tan delta peaks in dynamic mechanical analysis11, characteristic of more homogeneous polymer networks13. This, combined with the flexibility of thio-carbamate bonds, results in increased toughness8 and reduced polymerization stress14.

One potential pitfall of including pre-polymerized additives, however, is the increase of viscosity, which limits the amount that can be incorporated into the monomer matrix. The addition of thiourethanes above 20 wt% in concentration increases the viscosity of the monomer mixture, which prevents the incorporation of adequate amounts of inorganic filler, and also leads to a slight decrease in elastic modulus6.

One possible way to incorporate the thiourethane oligomer in the composite material and overcome the viscosity issue is to attach it directly to the surface of the filler particle via common silanization procedures15. Others have demonstrated the use of polymer brushes to functionalize silicon-containing surfaces16 with reported decrease in polymerization stress, as well as evidence for strengthening mechanisms such as crack deflection17. Considering the average surface coverage with conventional methacrylate silanes (about 5%) for a composite with 70 wt% filler content, it should be possible to incorporate an equivalent amount of thiorethane in the composite. In that case, the oligomer is distributed throughout the material through attachment to the filler particles, with no negative effect on the viscosity of the monomer matrix itself.

The aim of the present study was to examine different properties of resin composites containing inorganic filler particles silanized with a thiourethane oligomer obtained by the combination of tri- and tetra-functional thiols with different isocyanates. The hypotheses of the study were: (1) Filler particles functionalized with thiourethane will be easily distributed into a resin matrix without negatively affecting kinetics of polymerization and depth of cure, and (2) fracture toughness will be improved and stress polymerization reduced in the groups with thiourethane-silanized particles.

Results

Thermogravimetric Analysis

The TGA results showed that the TU fillers had at least 48.5% more organic content than the commercially obtained methacrylate-silanized filler, i.e., particles functionalized with thiourethanes showed more oligomer available on the filler surface than the commercial particles silanized with methacrylate

Fracture toughness, polymerization stress, degree of conversion, and viscosity

Compared to the composite with the unsilanized filler and the control with a methacrylate silanized filler, the KIC was significantly increased by the addition of thiourethane-silanized particles, and polymerization stress was significantly reduced (Table 2). In terms of KIC, the exception was TMP:BDI, which presented values statistically similar to SIL-MA control group. In terms of stress, all thiourethane-modified groups presented lower stress than the control, except for PETMP:BDI and PETMP:DHDI, which had similar values compared to the control. In general, the addition of thiourethane-silanized filler particles increased or did not influence the final DC and the viscosity of the composites. DC values ranged from 42–50% (Table 2). TMP:DHDI presented higher values than the controls (SIL-MA and UNS) and PETMP:BDI, and similar to TMP:BDI, TMP:HDDI, PETMP:HDDI, and PETMP:DHDI. Viscosity results ranged from 15.0–11.5 Pa.s and, in general, thiourethane-silanized filler groups presented similar or lower values than the controls.

Polymerization reaction kinetics

There was statistical difference between the maximum rate of polymerization values (Rp max, Table 3). TMP-DHDI was greater than all groups, except for UNS and PETMP-HDDI. The lowest results were obtained for SIL-MA. Figure 1 shows the kinetic profiles for all tested groups. The degree of conversion at maximum rate of polymerization (DC at Rp max), used to estimate the conversion at the onset of vitrification, ranged from 7–14%, and showed a tendency for higher values with the groups containing BDI as the isocyanate, but which presented values similar to SIL-MA.

Depth of polymerization

The degree of conversion as a function of depth is depicted in the 2-D maps shown in Fig. 2. Similar or higher degree of conversion was observed for TU silanized filler groups in relation to the control groups at all depths. In many cases, the depth of cure is defined as the depth at which degree of conversion (or hardness) falls below 80% of the top or maximum value. In this case, all materials showed a depth of cure of at least 3.5 mm, the full depth of these specimens.

Discussion

The addition of thiourethane oligomers to methacrylate-based resin materials has been shown to increase the degree of conversion and fracture toughness, while simultaneously reducing polymerization stress6,7,8,9. In those previous studies, the limitation for the incorporation of oligomers (at about 20–30 wt% of the organic matrix mass) was dictated by an increase in viscosity, which in turn precluded the incorporation of inorganic fillers to the level necessary to produce adequate mechanical properties6. One way to possibly overcome this limitation was tested in this present study: to functionalize the thiourethane oligomers with trimethoxy silane functionality, so that the oligomer itself could be later tethered to the surface of the inorganic filler particle via common silanization procedures15. In this way, we aimed to improve the distribution of the oligomer within the composite, and to harness the same benefits obtained with the incorporation of the oligomer directly in the matrix, but without the drawback of significant increase of the viscosity. In fact, our results have shown that even for the fully formulated, highly filled composite, the viscosity average for the TU-silanized materials were similar or lower than the control groups (Table 2).

In the present study, the concentration of thiourethane used in the silanization procedure was kept constant at 2% of the total mass of the silanizing solution. The resulting fillers were characterized with thermogravimetric analysis to determine the extent of final surface coverage on the particles. It is important to note that even the unsilanized particles showed some mass loss after the test, likely due to the presence of organic contamination. The same contamination is unlikely to be present on the surface of the silanized filler particles, given the fact that the silanization process entails exposure to organic solvent in an acidic environment. In addition, the fillers were kept in sealed containers after silanization, so it is reasonable to assume that the mass loss in those cases was due to mainly the silane coating. The percent of surface functionalization based on the mass loss ranged from 5.45–9.21%, with the TU fillers showing at least 50% greater functionalization in comparison to the methacrylate control (Table 1). Since the filler particles in all formulations had the same size distribution, this difference in part likely reflects the higher molecular weight of the thiourethane silane (around 5 kDa6) as compared with the methacrylate silane (around 0.25 kDa), rather than indicating a more extensive surface coverage. Other studies evaluating silicon-containing surfaces functionalized with polymer brushes found similar results and attributed the mass loss to the formation of a coat of brush heap structures at the surface16,18. In the current study, given the loosely crosslinked nature of the oligomer formed, the surface coating is likely less organized than a conventional polymer brush16. In any case, when the percentage of filler surface coverage was calculated based on the mass loss from the TGA experiment, the average thiourethane concentration in the six composites containing the TU filler was found to be 7.2%. This is nearly one third of the amount of TU added to the resin matrix in previous studies to produce the same effects, such as increased fracture toughness and reduced polymerization stress6.

Degree of conversion for the TU filler composites (except for TMP-BDI) was on average 5–7% higher than for the control (SIL-MA). Previous studies have demonstrated the potential of the chain breaking events caused by the presence of thiols to delay gelation and vitrification in radical polymerizations19. In this reaction, the chain-transfer events lead to a delay of the point in conversion at which monomer mobility limitations hamper polymerization and, thus, allow higher final conversion and delayed modulus development, ultimately delaying and reducing stress development20. Based on these mechanisms and our previous results obtained when incorporating the thiourethane oligomers directly into the organic matrix, it was expected that thiourethane-silanized materials would not only show increased degree of conversion, but that they also would be able to reduce the rate of polymerization and delay vitrification7. The delay in vitrification was estimated by the conversion registered at the onset of deceleration (Rpmax). Contrary to what was expected for the reaction rate, all of the groups containing the thiourethane-silanized filler showed equivalent or higher maximum rate of polymerization compared to the methacrylate control. However, all of the composites with TU filler showed equivalent or significantly lower DC at Rpmax. In any case, there was no significant correlation between the measured stress and the Rpmax or measured stress and DC at Rpmax. One possible explanation is that the overall concentration of thiourethane in the present study was lower, and therefore, the effects on network formation were not as marked as had been seen previously. In addition, because the incorporation of the thiourethanes to the filler surface did not affect the material’s viscosity, its effect on early mobility restrictions observed with the thiourethanes added directly into the matrix was not observed here. Even though gelation and vitrification were not directly assessed in this study, the kinetic profiles are strong indicators for those events21, and it can be speculated that these did not play a role in the decreased stress observed, which then must be explained by other factors.

A specifically low irradiance was used for the kinetics test in order to highlight the differences between the tested thiourethanes. However, to better reproduce clinically relevant conditions, selected groups (Sil-MA, PETMP:BDI and PETMP:HDDI) were evaluated for polymerization kinetics under the same conditions described previously but at a much higher irradiance of 650 mW/cm2. The results (Fig. 3) showed that the polymerization was much faster than with the low irradiance, as expected, but also that there was no significant difference between the groups in terms of Rpmax (3.04, 2.97 and 2.88%.s−1, respectively) and DC at Rpmax (11.8, 13.1 and 13.2%, respectively). Further, the TU-silanized groups showed 4–6% higher final DC than the methacrylate-silanized control, which is in agreement with our previous results22. In combination with the depth of cure data, this shows the general ability of the thiourethanes to maintain or increase the degree of conversion and improve homogeneity of the polymer network, likely due to the chain-transfer mechanism leading to the delayed gelation/vitrification, thus maximizing the degree of conversion before the reaction becomes diffusion-controlled11. Among the tested thiourethanes, PETMP–containing materials showed higher conversion than the control at the bottom of the specimen for two out of the three groups, whereas TMP only led to higher conversion at the bottom for the combination with the DHDI isocyanate, as shown in the heat map plots. This is at least in part explained by the fact that PETMP is tetrafunctional and TMP trifunctional, which results in higher concentration of thiol functionalities pendant from the thiourethane backbone6 available on the filler surface to undergo the chain-transfer mechanism. The cyclic isocyanate DHDI led to consistently high and more uniform conversion throughout the specimen, likely because it represented an intermediate between the stiff backbone imparted by the presence of the aromatic BDI and the highly flexible backbone imparted by HDDI. Interestingly, for the more highly crosslinked PETMP-containing TUs, the use of HDDI led to higher initial DC and then essentially equivalent DC as with DHDI throughout the specimen9,23. As the refractive index is expected to increase with the addition of any of the TU silanes, leading to improved light transmission22, the depth of cure was expected to increase for all TU-containing groups. However, as shown on the plot for percent cure in depth in relation to the conversion at the top, two of the three PETMP are actually the lowest depth of cure in percentage, but when PETMP is paired with DHDI the depth of cure is still high. In fact, the DHDI-containing groups present the highest values in terms of cure throughout, and at the greatest depth (though not the highest absolute conversion value at the top). The TMP groups present the best percent depth of cure with DHDI, and then even slightly better than PETMP when paired with BDI and HDDI. It is important to highlight that the degree of conversion is high throughout the specimens, so these differences are likely non-clinically relevant. In summary, this study demonstrates that TU-additives are capable of maintaining the high conversion at the top throughout the specimen much more efficiently than the non-modified control, and highlights the influence of the TU structure on depth of cure.

There was a significant 15–35% reduction in polymerization stress for materials containing thiourethane silanized filler particles. As previously mentioned, this was true in spite of the apparent lack of delayed gelation/vitrification phenomena, at least as inferred from the polymerization kinetics curves. In this case, other factors likely contributed to the reduced stress values observed. The TGA results demonstrate that the filler coverage with the thiourethane silane represents between 5.4 to 9.2% of the mass of the filler, as compared to only 3% for the methacrylate silane controls. Two factors need to be considered: 1. the same amounts by weight of each molecule were used during the silanization, and 2. each methacrylate silane molecule presents only one trimethoxy silane functionality, compared to multiple functionalities for the TU oligomer silane. Therefore, it is possible that the methacrylate silane formed a mono-layer of molecules, and the TU-silane likely formed a much thicker layer on the filler surface. Also, due to the greater complexity of the molecular structure of the TU-silane, even with a greater mass of silane, it is very unlikely that the surface was covered to the same extent as with the methacrylate silane. It follows that the stress reduction mechanism may stem from two factors. The first is the possibility for the surface of the particle to be more exposed (“unsilanized”) for the TU silane than for the methacrylate controls, which would then reduce stress because the filler particle in part actually acts as a void. This type of behavior was shown when non-silanated nanoparticles were used to fill dental composites24. However, this was not observed here, as the non-silane treated filler showed equivalent stress to the methacrylate-silane control. This suggests that the fillers acting as pores is not likely the explanation for this result. The second, and arguably the most relevant factor relates to the flexible and tough nature of the thiourethane networks, as extensively demonstrated in the literature7,9,23,25. It can be speculated that the presence of the TU around the filler particles acted to locally relieve the stress developed during polymerization, which then resulted in overall less stress generation in the composite. In fact, this mechanism has been proposed in other studies evaluating the efficacy of polymer brush functionalization on stress reduction at interfaces with silicon-containing materials17. Polymer brushes or tethered polymers may stretch away from the surface and accommodate for the change in free volume that accompanies polymerization26,27. Another possible explanation is active strand behavior, demonstrated recently for urethane-containing materials28.

It is important to note that the stress reduction (and also the effect on polymerization kinetics) were dependent on the molecular structure of the precursors used to synthesize the thiourethane silanes. Overall, the groups where the tri-functional thiol (TMP) was used as a precursor exhibited lower stress than groups containing the tetra-functional thiol (PETMP), which then correlates with the likely greater degree of crosslinking provided by PETMP. This has been previously shown in studies using dynamic mechanical analysis to evaluate crosslinking (via the rubbery plateau method)29. Therefore, the more crosslinked material likely produced a stiffer network around the filler particle, which was then less able to relieve stress. Interestingly, the use of more rigid isocyanate precursors (BDI, containing aromatic moieties) did not seem to influence stress development more or less than the other TU silanes, suggesting that the structure of the TU oligomer itself, independent of its base monomer structure, had the greatest influence on stress reduction. The loss and storage modulus obtained with dynamic mechanical analysis (data shown in the Supplementary Information) also demonstrate the lack of correlation between the TU structure and property development, corroborating the fact that the thiocarbamate-based structure has a greater influence on stress development and mechanical reinforcement.

The same mechanisms used to explain stress relief and ultimately overall stress reduction can be used to explain the fracture toughness results. Thiourethane silanized particle groups showed a 25–85% increase in fracture toughness compared to the control groups. Fracture toughness may be important to help predict the clinical behavior of the dental composite restoration as it is related to chipping and bulk fracture30,31. When thiourethanes are added into the methacrylate matrix, the improvement of the mechanical properties is attributed to the flexible nature of the covalent bonds formed between the thiol on the thiourethane with the methacrylate via chain-transfer reactions8, leading to a more uniform and tougher network14,32. In the present study, those flexible bonds were formed around the filler particles, a region where stress concentration occurs33. This, in conjunction with the tough nature of the thio-carbamate bonds in the oligomer structure, likely led to some crack deflection or crack shielding mechanism around the particles33,34, as has been suggested by nanomechanical analysis of silicon interfaces treated with polymer brushes. It is also possible that the thiourethane-based silane bonding to the methacrylated matrix was more efficient due to its multiple methoxysilane functionalities, which could have enhanced the filler particle-matrix interaction leading to an increase in mechanical properties. Furthermore, fracture toughness is correlated to tensile stresses build up around the filler particles, and the efficiency of silane treatment plays an important role in gap formation35. Therefore, it can be speculated that the interfacial bonding between the organic matrix and filler particles was strong enough to resist the polymerization shrinkage, creating fewer gaps. PETMP groups showed better performance than TMP (increase between 40–85% for PETMP groups versus 0–40% for TMP groups) which may be due to PETMP being tetrafunctional while TMP is trifunctional. The greater crosslinking improved the mechanical strength of the matrix around the particles, and while that likely resulted in less efficient stress relief, as described earlier, it led to reinforcement of the material overall. The isocyanate structure did not influence the results, though a trend could be observed for increased mechanical properties and decreased polymerization stress, which could be due to the more flexible nature of this material9,23.

In general, the results of this study demonstrate that the incorporation of thiourethane silanized fillers into resin composites led to increased conversion at faster rates than the control, while increasing fracture toughness, and reducing stress of polymerization. Even though the microbiological aspect was not considered on the scope of this investigation, these materials might be able to reduce gap formation, and hamper bacterial colonization at the bonded interface, ultimately helping avoid restoration failures due to secondary decay. Studies are underway utilizing a secondary caries model to test this hypothesis.

Materials and Methods

Material Composition

The experimental composites were composed of Bis-phenol A diglycidyl dimethacrylate (Bis-GMA), urethane dimethacrylate (UDMA) and triethylene glycol dimethacrylate (TEGDMA) at a 50:30:20 mass ratio. All monomers were purchased from Esstech (Essington, PA, USA). Photoinitiators were added to the monomers as follows: 0.2 wt.% of dl-camphoroquinone (Polysciences Inc., Warrington, PA, USA), 0.8 wt.% of a tertiary amine (EDMAB – ethyl 4-dimethylaminobenzoate; Avocado, Heysham, England), and 0.2 wt.% inhibitor (BHT – 2,6-di-tert-butyl-4-methylphenol; Sigma–Aldrich, St. Louis, MO, USA).

Six thiourethane oligomers were synthesized in solution in the presence of catalytic amounts of triethylamine. Two multi-functional thiols – pentaerythritol tetra-3-mercaptopropionate (PETMP) or trimethylol-tris-3-mercaptopropionate (TMP) – were combined with three di-functional isocyanates – 1,6-hexanediol-diissocyante (HDDI) or 1,3-bis(1-isocyanato-1-methylethyl) benzene (BDI) (aromatic) or 1-isocyanato-4-[(4-isocyanatocyclohexyl) methyl] cyclohexane (DHDI) in 60 ml of methylene chloride. In addition, 1 mol of 3-(triethoxysilyl)propyl isocyanate was also added to each of the six combinations described above – this is the source of trimethoxy silane to be used for the subsequent silanization step. The reaction was catalyzed by triethylamine. The isocyanate:thiol mol ratio was kept at 1:2.5 (with thiol in excess) to avoid macro-gelation of the oligomer during reaction, according to the Flory–Stockmayer theory21, leaving pendant thiols and trimethoxy silanes. Oligomers were purified by precipitation in hexanes and rotoevaporation, and then characterized by mid-IR and NMR spectroscopy6. The disappearance of the isocyanate mid-IR peak at 2270 cm−1 and the appearance of NMR resonance signals at 3.70 ppm were used as evidence for completion of isocyanate reaction and thiourethane bond formation, respectively36.

For the silanization procedures, thiourethane oligomers were combined with 65 ml of an ethanol: distilled water solution (80:20 vol%), previously acidified by the addition of glacial acetic acid (pH = 4.5). Thiourethane was added at 2 wt%, in relation to the solution mass. Five grams of neat barium silicate glass filler (average size = 1.0 μm; Kavo Kerr Corporation, Orange, CA) was added to the solution, kept under magnetic stirring for 24 hours, filtered, and dried for 4 days in an oven at 37 °C.

The TU fillers were introduced at 50 wt% to the monomer matrix with a centrifugal mixer (DAC 150 Speed Mixer, Flacktek, Landrum, SC, USA) operated for 2 min at 1800 rpm. All procedures were carried out under yellow light.

Control groups were prepared with a commercially available unsilanized (UNS) and methacrylate-silanized (SIL-MA) barium glass filler particles (average size = 1.0 μm; Kerr Corporation, Orange, CA). All photocuring procedures were carried out using a mercury arc lamp (EXFO Acticure 4000 UV Cure; Mississauga, Ontario, Canada) filtered at 320–500 nm (light guide diameter = 5 mm). In order to verify the achieved functionalization and its efficiency, the different filler particles were analyzed by thermogravimetric analysis (TGA) over a temperature range of 50 °C to 850 °C at 10 °C/minute.

Fracture Toughness (K IC)

KIC was determined using the single-edge notch beam method. Specimens were fabricated according to ASTM Standard E399–9037 by filling a 5 × 2.5 × 25 mm (n = 6) split steel mold with a razor blade insert providing a 2.5 mm long notch in the middle of the specimen. The resin composites were photoactivated for 2 min on each side at an irradiance of 800 mW/cm2. The light guide was kept 7 cm away from the sample and a radiometer (Power Max 5200 – Laser Power Meter, Molectron, Portland, OR, US) was used to measure the power output from the mercury arc lamp and guarantee that 800 mW/cm2 irradiance reached the top surface of the sample. The bending fracture test was performed using a universal test machine (MTS Criterion, Eden Prairie, MN USA) at a cross-head speed of 0.5 mm min−1 and KIC was calculated according to the following equation (1):

𝐾𝑖𝑐=3𝑃𝐿2𝐵𝑊32{1.93(𝑎𝑊)12−3.07(𝑎𝑊)32+14.53(𝑎𝑊)52−25.11(𝑎𝑊)72+25.8(𝑎𝑊)92}Kic=3PL2BW32{1.93(aW)12−3.07(aW)32+14.53(aW)52−25.11(aW)72+25.8(aW)92}

(1)

where P is load at fracture (N), L is the length, W is the width, B is the thickness, and a is the notch length (all in mm).

Polymerization Stress

Polymerization stress in real-time was analyzed using a cantilever beam apparatus (Bioman) previously described38. The surface of the fused silica plate was treated with a thin layer of silane ceramic primer (3 M ESPE, St. Paul, MN, USA) and the surface of the 5 mm diameter steel piston with Z-Prime Plus (Bisco Inc., IL, USA). The composite was then inserted into the 1-mm gap between the upper rod and the lower glass slide and shaped into a cylinder, removing the excess. The samples were light-cured through the glass using the light curing unit for 40 s (n = 5) at 280 mW/cm2. Data were recorded for 10 min on a computer and the final shrinkage-stress calculated.

Kinetics and Degree of Conversion

Three specimens (8 mm in diameter and 0.6 mm in thickness), laminated between two glass slides, were cured and then measured with near-infrared (NIR) spectroscopy (Nicolet 6700, Thermo Electron Corporation, Waltham, MA, US) to calculate the degree of conversion (DC). The area corresponding to the methacrylate double bond overtone at 6165 cm−1 39 was recorded before and after 300 s of irradiation with the light source located 4 cm from the surface of the glass slide, delivering 20 mW/cm2 directly to the specimen. Real-time monitoring of the polymerization kinetics for 300 s was carried out on specimens of the same size at 2 scans per spectrum with 4 cm−1resolution.

Depth of polymerization – 2D Mapping with IR-Microscopy

Samples (2 × 5 mm cross-section and 5 mm depth) were prepared using silicon molds (n = 3) and photocured through a glass slide for 300 s at 20 mW/cm2. After 7 days dry storage, the samples were embedded in slow curing epoxy resin and then sectioned using a diamond saw (Accutom-50) to obtain two slices of 0.4 mm thickness. The degree of conversion of the vinyl groups with depth was measured in near-IR (6165 cm−1) using an IR microscope attached to a spectrometer bench (Continuum and 6700, Thermo Fisher). 2D surface maps of conversion were set up with 200 µm step sizes.

Viscosity

Viscosity was measured in a cone-plate rheometer (ARES, TA Instruments, New Castle, DE, USA). 1.03 g of each unpolymerized resin was placed between 20-mm diameter plates and tested at 1 Hz with a gap size of 0.3 mm (n = 3).

Statistical Analysis

Data for each property was tested for normality and homocedasticity (Anderson-Darling and Levene tests, respectively), and then analyzed with one-way ANOVA and Tukey’s test for multiple comparisons. The significance level was set at 95%.

0 notes

Photo

Bereits vorgestern Abend das offizielle Gala-Dinner der diesjährigen EUPRERA-Jahrestagung - tolles Menu, viel Wein & gute Gespräche mit netten alten wie neuen Fachkolleg_innen. #hsmacromedia #macromediauniversity #kommunikationsmanagement #euprera #galadinner (hier: Det Glade Vanvid) https://www.instagram.com/p/BoWbCO-hDdI/?utm_source=ig_tumblr_share&igshid=gaa31ngrvw6e

0 notes

Link

Hello, I have been using my VTC Core Wallet for some time now, but I still dont really know how to back it up, in case something happens. I just have a vague idea, which I didn't try yet.encrypt the walletget the wallet.dat file from the Vertcoin directory and copy it on an external storage, like USB or an external HDDIs that all I have to do, or are there some steps that I'm forgetting about? via /r/vertcoin

0 notes