#fudau

Text

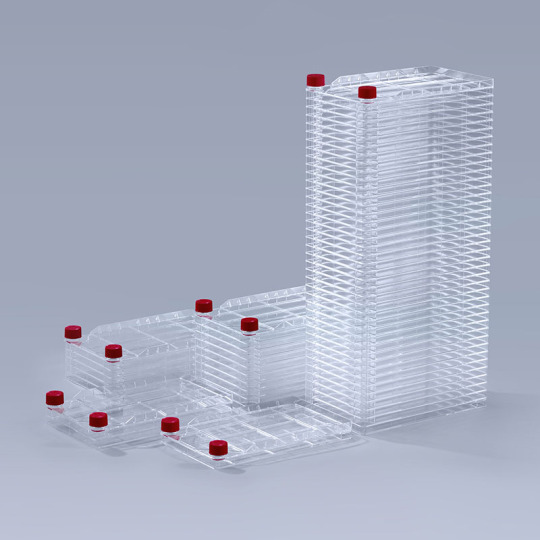

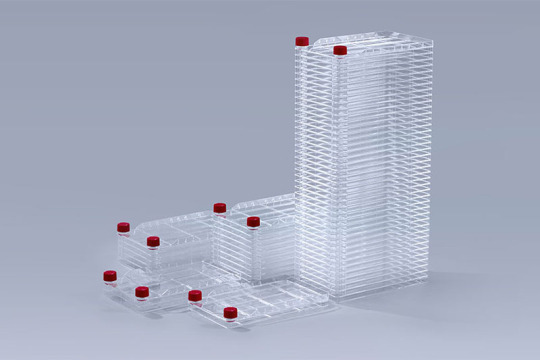

The Crucial Role of our Cell Factory in Biotechnology

In the dynamic landscape of biotechnology, our Cell Factory emerges as a transformative force, reshaping the boundaries of what's possible. Engineered with precision and innovation, this revolutionary product serves as the backbone of progress in diverse fields. Here's a glimpse into the pivotal role our Cell Factory plays:

Accelerated Bioproduction:

At the heart of biotechnology advancement lies the need for accelerated bioproduction. Our Cell Factory is a catalyst, driving efficiency and speed in the creation of biotechnological products. From pharmaceuticals to enzymes, its seamless integration expedites processes, meeting the demands of a rapidly evolving industry.

Unparalleled Precision:

Precision is not just a goal; it's our commitment. The Cell Factory ensures meticulous control over every stage of bioproduction, guaranteeing consistency and quality. Researchers and scientists can rely on the precision of our product to yield reliable and reproducible results, unlocking new frontiers in scientific discovery.

Cell Factory

Versatility Redefined:

Adaptability is the hallmark of our Cell Factory. Its versatile design accommodates a spectrum of applications, from gene therapy research to the development of novel vaccines. This flexibility empowers researchers and biotechnologists, offering them a single, comprehensive solution for a myriad of projects.

Elevated Sustainability:

In an era where sustainability is non-negotiable, our Cell Factory takes center stage. It champions eco-conscious practices, minimizing waste and energy consumption. By choosing our product, laboratories and biotech companies contribute to a greener future without compromising on scientific progress.

Innovation Unleashed:

Our Cell Factory is not just a product; it's a gateway to innovation. It empowers scientists and researchers to push the boundaries of what's possible in biotechnology. From CRISPR advancements to breakthroughs in personalized medicine, the Cell Factory stands as a testament to the endless possibilities that lie ahead.

Step into a future where the boundaries of biotechnological achievement are limitless. Our Cell Factory is not just a tool; it's a catalyst for progress, a key player in the transformative journey of biotechnology. Embrace the power of innovation, precision, and sustainability with our Cell Factory — the driving force behind a new era of scientific excellence.

0 notes

Text

Rom-halan Mahk (The Parting Glass) T'Vulkansu

Lyrics under the cut (Original english, Vulkansu in bold, literal translation in italics)

Of all the money that e'er I had

Svi’ma-vel t’ek pinkaunu

In possession of wealth, all my earnings

I have spent it in good company

Vlital kau-bosh heh akhlami t’hyle

Spent wise and among lifelong friends

Oh and all the harm I've ever done

Ek’dash-tor t’nash-veh ki’tor svi’mene

All hurt I have done in life

Alas, it was to none but me

Tor fi’t’nash-veh sa’awek

Done upon myself alone

And all I've done for want of wit

Kanon duhik torai t’nash-veh

Every foolish action of mine

To memory now I can't recall

Hal-tor I kwi’vokaya

Gone now from memory

So fill to me the parting glass

Nufau t’nash-veh rom-halan makh

Offer my farewell glass

Good night and joy be to you all

Sochya eh dif fi’ek’du

Peace and long life upon all you

Of all the comrades that e'er I had

Trashu ik fasei t’nash-veh t’hyle

Departing from my lifelong friends

They're sorry for my going away

Olau lak’tra than au trashan

Feel grief they do at departure

And all the sweethearts that e'er I had

Trashu ik fasei ashayam

Departing from beloved

They would wish me one more day to stay

Istaya au wuvau yaret

Wish they to lengthen visit

But since it fell unto my lot

Kupi-ri rubah t’nash-veh buk

Could not change my fate

That I should rise and you should not

Trashu ik du’tu hafau

Departing while you remain

I'll gently rise and softly call

She-tor buk eh stariben

Rising to fate and speak

Good night and joy be to you all

Sochya eh dif fi’ek’du

Peace and long life upon all you

But since it falls unto my lot

Kupi-ri rubah t’nash-veh buk

Could not change my fate

That I should rise and you should not

Trashu ik du’tu hafau

Departing while you remain

I'll gently rise and softly call

She-tor buk eh stariben

Rising to fate and speak

Good night and joy be to you all

Sochya eh dif fi’ek’du

Peace and long life upon all you

So fill to me the parting glass

Nufau t’nash-veh rom-halan makh

Offer my farewell glass

And drink a health whate'er befalls

Fudau fam, nartau mene

Regardless embrace life

Then gently rise and softly call

She-tor buk eh stariben

Rising to fate and speak

Good night and joy be to you all

Sochya eh dif fi’ek’du

Peace and long life upon all you

Good night and joy be to you all

Sochya eh dif fi’ek’du

Peace and long life upon all you

So fill to me the parting glass

Nufau t’nash-veh rom-halan makh

Offer my farewell glass

And gather as the evening falls

Hokau vah tevan-tor khru

I’ll gently rise and softly call

She-tor buk eh stariben

Gather as falls evening

Good night and joy be to you all

Sochya eh dif fi’ek’du

Rising to fate and speak

Peace and long life upon all you

Good night and joy be to you all

Sochya eh dif fi’ek’du

Peace and long life upon all you

#This is part of a project that I'm working on that I will hopefully be releasing soon#I think I wanna rerecord Aluk-kumsu as well#Maybe do Maiden wine next or something#I strongly envision Spock singing this not just in reference to people he's lost but for himself as well especially regarding WoK#I think Scotty would legit explode if he ever heard XD#Just thought this song would sound VERY nice in Vulkansu and I was right!#I haven't sung for this blog in a while so like that's a little nervous and weird for me lol#star trek#star trek music#star trek songs#song cover#song translation#the parting glass#drinking song#farewell songs#folk music#vulcan#vulcans#vulkansu#vulcan language#conlang#constructed language#spock

79 notes

·

View notes

Text

Cell culture consumables commonly used in laboratories and their uses

Cell culture consumables are indispensable experimental tools in the cell culture process. Commonly used consumables include cell culture flasks, cell culture dishes, and cell culture plates. So what are their respective uses?

1. Cell culture dishes:

Cell culture dish is a laboratory vessel used for microorganism or cell culture. It consists of a flat disc-shaped bottom and a cover, usually made of glass or plastic. The materials of culture dishes are basically divided into two categories, mainly plastic and glass. Glass can be used for plant materials, microbial culture and adherent culture of animal cells. The plastic ones may be made of polyethylene, and are disposable or multiple-use. They are suitable for laboratory inoculation, streaking, and bacterial isolation operations, and can be used for the cultivation of plant materials.

Cell Culture Dishes

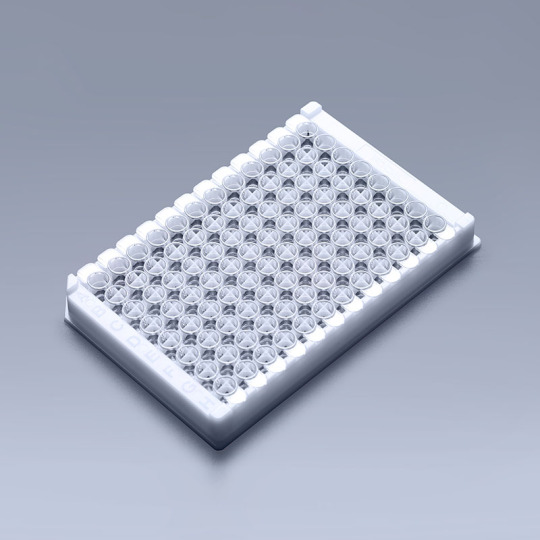

2. Cell culture plates:

Cell culture plate can be divided into flat bottoms and round bottoms (U-shaped and V-shaped) according to different bottom shapes; the number of culture holes is 6, 12, 24, 48, 96, 384, 1536 holes, etc.; according to different materials, there are Terasaki plates and ordinary cell culture plates. Generally, flat-bottomed plates are used, while round-bottomed culture plates are mainly used for isotope incorporation experiments, and a cell collector is required to collect cells for culture. The cell culture plate is mainly made of PS material, and the material is treated sufface, which facilitates cell attachment, growth and expansion.

Cell Culture Plates

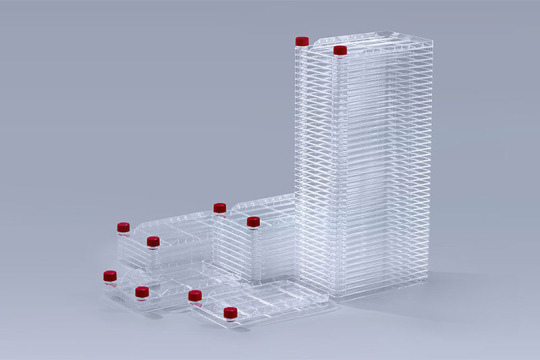

3. Cell culture flasks:

According to the shape, culture bottles are divided into wide-body culture flasks, triangular culture flasks and torsion-neck culture flasks. Some cells and tissues can grow in suspension, but a considerable number of mammalian cells need to adhere to the surface. Culture bottles can meet the needs of both suspension and adherent growth of cells.

Cell Culture Flasks

The above are just a few common cell culture consumables. Cell factory systems, disposable bioreactors, etc. all belong to the field of cell culture consumables. With the rapid development of the biological research field, cell culture consumables will maintain a rapid development trend in the future.

0 notes

Text

Classification and characteristics of elisa plate

Enzyme-Linked Immunosorbent Assay (ELISA) is a commonly used laboratory technique that allows the detection and quantification of specific proteins or antibodies in a sample. ELISA plates, also known as microtiter plates, are the primary tools used in ELISA experiments. These plates are typically made of a transparent polystyrene material and consist of multiple wells arranged in a grid-like pattern.

Here are the classifications and characteristics of ELISA plates:

1.Well Types:

a. Flat-bottomed wells: These wells have a flat bottom surface and are commonly used for colorimetric ELISAs, where the absorbance of the wells is measured.

b. Round-bottomed wells: These wells have a rounded or conical bottom and are often used for fluorescent or luminescent ELISAs, where the signal is measured in a plate reader.

2.Coating:

a. Non-specific binding (NSB) plates: These plates have a high-binding surface that maximizes the adsorption of proteins or antibodies to the plate's surface. They are ideal for assays where high sensitivity is required.

b. Blocking plates: These plates are pre-coated with blocking agents (e.g., BSA or gelatin) to prevent non-specific binding of proteins and reduce background noise. They are used to minimize false-positive signals.

3.Surface Chemistry:

a. Polystyrene plates: Polystyrene plates are the most common type and offer good binding capacity for proteins and antibodies.

b. Polyvinyl chloride (PVC) plates: PVC plates are less common but can be used in certain applications.

c. Specialty plates: Some ELISA plates have specialty coatings or modifications to enhance specific interactions or improve sensitivity. For example, some plates have a hydrophilic surface for better liquid distribution.

Elisa Plate

4.Well Format:

a. 96-well plates: These are the most commonly used format, with 96 wells organized in a 8x12 grid.

b. 384-well plates: These plates have smaller wells in a 16x24 grid, allowing higher throughput and reduced sample volume requirements.

c. Other formats, such as 24-well or 384-well plates: These formats may be used for specific applications or when smaller sample sizes are available.

5.Sterility:

a. Sterile plates: Some ELISA plates come pre-sterilized and individually wrapped for use in sterile laboratory conditions or cell culture applications.

6.Compatibility:

a. Plate readers and washers: ELISA plates are designed to be compatible with automated plate readers and washers, allowing for efficient sample processing, data acquisition, and analysis.

When selecting an ELISA plate, it's important to consider the specific requirements of your assay, such as the type of detection method, sample volume, and sensitivity needed. Choosing the appropriate plate ensures optimal performance and reliable results in your ELISA experiments.

0 notes

Text

Elevating Serum Storage: PETG Media Bottles for Blood Serum

In the dynamic world of serum storage, the choice of containers plays a pivotal role in preserving the integrity and efficacy of blood serum. Enter PETG Media Bottles, a game-changer for blood serum manufacturers seeking a reliable and innovative solution for storage.

Preserving Purity:

PETG, a high-performance polymer, forms the foundation of these media bottles. Its inert nature ensures that the stored blood serum remains unaltered, preserving its purity and preventing any leaching of contaminants. This is especially critical for serum manufacturers aiming to deliver consistently high-quality products.

Secure Seal for Longevity:

Equipped with precision-fit caps, PETG Media Bottles create an airtight seal, shielding the blood serum from external influences. The secure seal not only maintains the longevity of the serum but also prevents the risk of contamination, ensuring that the serum's composition remains intact throughout storage.

0 notes

Text

The Benefits of Cell Factory in Cell Cultivation

In the ever-evolving landscape of cell culture applications, the Cell Factory stands as a beacon of innovation, revolutionizing the way we approach cellular research and development. This cutting-edge system offers a myriad of advantages, positioning it as a cornerstone in the realm of cell cultivation.

Enhanced Productivity and Scalability:

One of the primary benefits of the Cell Factory lies in its ability to significantly enhance productivity and scalability. With multiple cell culture layers, it provides a larger surface area for cell attachment and growth, allowing for the cultivation of a higher cell density within a compact footprint. This scalability proves invaluable for industries requiring increased production yields.

Precise Control Over Culture Conditions:

The Cell Factory empowers researchers with precise control over crucial culture conditions. Each layer functions independently, enabling tailored optimization of variables such as media composition, pH, and oxygenation. This level of control ensures an ideal environment for diverse cell types, contributing to the reproducibility and reliability of experimental outcomes.

Cell Factory

Streamlined Workflow and Efficiency:

Designed with efficiency in mind, the Cell Factory streamlines the cell culture workflow. Its modular structure facilitates easy assembly, disassembly, and manipulation, reducing downtime between experiments. This efficiency not only saves valuable time but also enhances the overall productivity of the laboratory.

Minimized Contamination Risks:

Cell culture contamination is a persistent concern, often impacting experimental results. The closed system of the Cell Factory minimizes contamination risks by providing a controlled environment. This feature is particularly crucial in the production of biopharmaceuticals and other sensitive applications where maintaining a sterile culture is paramount.

Elevated Cost-Effectiveness:

By optimizing space, resources, and workflow, the Cell Factory contributes to elevated cost-effectiveness in cell culture applications. Its ability to accommodate larger culture volumes reduces the need for numerous smaller vessels, translating into lower consumable costs and increased overall operational efficiency.

In the realm of cell cultivation, the Benefits of Cell Factory are clear and compelling. From scalability to precise control, streamlined workflows, and minimized contamination risks, this innovative system represents a leap forward in optimizing cell culture applications. Embrace the future of cellular research with the unparalleled advantages offered by the Cell Factory.

0 notes

Text

Liquid Storage Solutions: PETG Media Bottles with Caps

In the realm of laboratory liquid storage, the choice of containers plays a pivotal role in maintaining the integrity and quality of stored substances. Enter PETG Media Bottles with Caps, a versatile solution designed to elevate the storage of culture media, buffers, and other essential liquids.

Precision in Liquid Preservation:

PETG, a high-performance polymer, forms the foundation of these media bottles. Its inherent qualities ensure a reliable and secure environment for the storage of sensitive liquids. The transparency of PETG allows for easy visual inspection, ensuring the preservation of the liquid's original state.

Seal of Protection:

Equipped with secure caps, these bottles create a robust seal, safeguarding the contents against contaminants. This is especially crucial when storing delicate substances like cell culture media and buffers, where maintaining purity is paramount. The airtight seal also prevents evaporation and maintains the stability of the stored liquids.

PETG Media Bottles

Versatility for Cell Culture and Buffers:

PETG Media Bottles are tailored for the demands of cell culture and buffer storage. The bottles offer an ideal environment for cell growth, proliferation, and the longevity of biological substances. Their compatibility with a variety of laboratory liquids makes them indispensable for researchers and professionals in biotechnology and life sciences.

Clarity for Confidence:

The clear and transparent nature of PETG provides a distinct advantage. Researchers can easily monitor the volume and condition of the stored liquids without compromising the sterile environment. This transparency instills confidence in the reliability of the storage solution.

In the pursuit of excellence in liquid storage, PETG Media Bottles with Caps emerge as a premium choice. Offering precision, protection, and versatility, these bottles are tailored for the unique demands of cell culture media and buffer storage. Elevate your laboratory practices with a storage solution that combines innovation with reliability, setting new standards in liquid preservation.

0 notes

Text

The Power of Cell Factory in Cell and Gene Therapy

In the fast-evolving realm of cell and gene therapy, innovation is the key to unlocking the full potential of groundbreaking treatments. At the forefront of this revolution is the transformative technology known as "Cell Factory." Catering specifically to enterprises in cell and gene therapy, Cell Factory stands as a cornerstone for progress, offering unparalleled applications in the field.

Precision in Production:

Cell Factory technology revolutionizes the production landscape, providing a precise and scalable platform tailored for the unique requirements of cell and gene therapy. Its advanced capabilities ensure the consistent and reliable manufacturing of therapeutic cells, a fundamental aspect for successful clinical outcomes.

Accelerating Advancements:

For companies pioneering the future of healthcare, the adoption of Cell Factory is a strategic leap towards accelerated advancements. The technology streamlines processes, reducing timelines from research to application, empowering enterprises to stay at the forefront of medical breakthroughs.

Cell Factory

Customization for Success:

One of the distinguishing features of Cell Factory is its adaptability. Companies can customize culture conditions, optimizing the growth and functionality of cells. This level of customization is instrumental in tailoring therapies to individual patient needs, marking a paradigm shift towards personalized medicine.

The Assurance of Quality:

In an industry where quality is non-negotiable, Cell Factory stands as a beacon of assurance. Its meticulous processes and stringent quality control measures ensure that every therapeutic cell produced meets the highest standards, building trust and confidence among practitioners and patients alike.

As we navigate the promising landscape of cell and gene therapy, Cell Factory emerges as a catalyst for progress. This technology not only meets the demands of the present but propels us into a future where the unimaginable becomes reality. Embrace Cell Factory, where innovation meets application, and together, let's redefine the boundaries of what's possible in the world of healthcare.

0 notes

Text

Diverse Applications of Cell Factory in Vaccine and Pharmaceutical Manufacturing

In the ever-evolving landscape of vaccine and pharmaceutical production, the applications of cell factory have emerged as a driving force behind innovation and efficiency. These dynamic facilities, utilizing living cells as bioengineered workhorses, showcase a myriad of applications that redefine the capabilities of the industry.

1.Biopharmaceutical Production: Cell factories serve as the epicenter for the large-scale production of biopharmaceuticals, including monoclonal antibodies, enzymes, and growth factors. Their ability to produce these complex molecules with precision has revolutionized therapeutic development.

2.Vaccine Manufacturing: The controlled environment of cell factories is particularly advantageous in vaccine production. From viral vectors to recombinant proteins, these facilities play a pivotal role in developing and scaling up vaccine production for a diverse range of infectious diseases.

3.Stem Cell Research and Therapy: Advancements in stem cell research find a robust platform in cell factories. These facilities provide a controlled environment for the cultivation and manipulation of stem cells, opening avenues for regenerative medicine and innovative therapeutic approaches.

Cell Factory

4.Gene Therapy: Cell factories play a crucial role in the production of viral vectors used in gene therapy. Their ability to consistently produce high-quality vectors is fundamental to the success of gene-based treatments for various genetic disorders.

5.Customized Protein Production: The flexibility of cell factories allows for the tailored production of proteins, meeting specific therapeutic needs. This customization is particularly valuable in addressing rare diseases or conditions with unique protein requirements.

6.Drug Screening and Testing: Cell factories facilitate the development of reliable cellular models for drug screening and testing. Their controlled environment ensures the reproducibility of results, enhancing the accuracy of pre-clinical trials.

In summary, the applications of cell factory span a wide spectrum, from the production of biopharmaceuticals and vaccines to groundbreaking advances in stem cell research and gene therapy. As the linchpin of innovation in the pharmaceutical and vaccine manufacturing realms, cell factories continue to redefine the possibilities and propel the industry towards new horizons.

0 notes

Text

Cell Factory Advantages: Elevating Efficiency in Pharmaceutical and Vaccine Production

In the dynamic landscape of pharmaceutical and vaccine production, the integration of cell factory has revolutionized the industry, offering a spectrum of advantages that streamline processes and elevate productivity.

Enhanced Production Efficiency: Cell factory, leveraging living cells as mini production units, amplify efficiency. These bioreactors enable the continuous generation of therapeutic proteins, vaccines, and various biopharmaceuticals at scale, optimizing manufacturing output.

Cost-Effectiveness: The controlled environment of cell factories allows for cost-effective large-scale production. Through optimized nutrient utilization and reduced waste, these facilities mitigate unnecessary expenses while ensuring maximal output.

Quality and Consistency: Cell factory ensure product uniformity and consistency, critical in pharmaceutical and vaccine manufacturing. The controlled conditions within these factories lead to highly reproducible results, minimizing batch-to-batch variations.

Flexibility and Innovation: Adaptability is a hallmark of cell factories. Their versatility in producing a wide array of therapeutic proteins and vaccines caters to the ever-evolving demands of the pharmaceutical industry. This flexibility encourages innovation in addressing new health challenges and emerging pathogens.

Cell Factory

Scalability: Cell factories seamlessly accommodate scaling, meeting the demands for increased production without compromising the quality or efficiency of the output. This scalability aligns with market fluctuations and growing demands in pharmaceutical and vaccine manufacturing.

Biological Safety and Regulatory Compliance: These facilities adhere to stringent regulatory standards, ensuring the safety and purity of the produced pharmaceuticals and vaccines. The controlled, sterile environment minimizes contamination risks, adhering to the highest industry standards.

In conclusion, the integration of cell factories in pharmaceutical and vaccine manufacturing stands as a transformative leap forward. Their benefits in terms of efficiency, cost-effectiveness, quality, flexibility, scalability, and regulatory compliance mark them as indispensable assets, driving the industry towards greater efficacy and innovation. As these advantages continue to unfold, cell factories remain the cornerstone of success in modern pharmaceutical and vaccine production.

0 notes

Text

PETG Media Bottles for Optimal Solution Storage

In the world of laboratory research, precision and reliability are paramount. When it comes to storing crucial solutions like serum culture media, choosing the right container is key. PETG media bottles stand out as an exceptional choice, offering a range of material characteristics that ensure both safety and efficacy.

Material Excellence:

PETG, short for Polyethylene Terephthalate Glycol, is a high-grade polymer renowned for its outstanding material properties. Its biocompatibility ensures that stored solutions remain uncontaminated and free from interference, guaranteeing the integrity of your research.

Clarity and Transparency:

One of the standout features of PETG media bottles is their exceptional clarity. This allows for easy visual inspection of the contents, a critical aspect when dealing with sensitive solutions like serum culture media. Researchers can monitor the state and quality of their cultures without any distortion or cloudiness.

PETG Media Bottles

Robust and Durable:

PETG is a robust material, known for its resistance to breakage and shattering. This ensures the safety of both the user and the valuable solutions stored within. Furthermore, PETG media bottles can withstand autoclaving, simplifying the sterilization process and enhancing convenience in the lab.

Leak-Proof Assurance:

Equipped with secure sealing mechanisms, PETG media bottles provide a reliable barrier against leaks and contamination. This feature is invaluable in maintaining the purity and efficacy of your stored solutions.

For researchers seeking a superior solution for storing serum culture media and other crucial solutions, PETG media bottles stand as the optimal choice. Their unique material properties, including biocompatibility, transparency, durability, and leak-proof sealing, set them apart as an indispensable tool in any laboratory setting. Elevate your research endeavors with the assurance of PETG media bottles, and experience the difference they bring to your work.

0 notes

Text

PETG Media Bottles: Superior Biocompatibility for Cell Culture

PETG Media Bottles are the flagship products offered by our company, catering to the specific needs of cell culture applications. In this article, we will delve into the exceptional biocompatibility of PETG Media Bottles, showcasing their ability to maintain the integrity and viability of cultured cells.

Superior Biocompatibility:

PETG Media Bottles are selected materials in the field of cell culture due to their remarkable biocompatibility. These bottles are designed to minimize interactions with cultured cells, ensuring their growth and functionality remain unaffected.

1.Reduced Leachables and Extractables:

PETG Media Bottles undergo rigorous testing to ensure the absence of leachables and extractables that may compromise cell cultures. Our bottles are manufactured using high-quality PETG resin, which exhibits excellent stability and minimal release of contaminants into the media.

PETG Media Bottles

2.Non-Toxic Material:

PETG is widely regarded as a safe and non-toxic material for use in biomedical applications. Our PETG Media Bottles are free from phthalates or any other toxic additives, thus eliminating the risk of adverse effects on cell growth and behavior.

3.Biologically Inert Surface:

The smooth and biologically inert surface of PETG Media Bottles minimizes cell attachment or adhesion, reducing the risk of cell damage or activation of undesired cellular processes. This allows researchers to obtain accurate and reliable experimental results.

Our products are designed to provide a pristine and reliable environment for cell culture applications, ensuring optimal cell growth and functionality. With their reduced leachables and extractables, non-toxic nature, and biologically inert surface, PETG Media Bottles offer researchers peace of mind and confidence in their experiments.

0 notes

Text

How to choose the right cell culture consumables

Cell culture is widely used in various fields of medicine. To adapt to the growth environment of cells and ensure the smooth progress of experiments, choosing appropriate cell culture consumables is key. So, how should we choose suitable cell culture consumables?

To choose suitable cell culture consumables, you can start from the following aspects:

1. Culture method: Cell culture technology is divided into two types: adherent culture and suspension culture. Some cell consumables are only suitable for either adherent cell or suspension cell culture. There are also cell consumables suitable for both methods. When purchasing When using cell consumables, you must first determine the cell culture method and select cell culture consumables suitable for that method.

2. Culture area: Large-scale cell experiments require cell culture consumables with a larger culture area for support. Small experiments can choose small-area consumables. The culture area of cell culture consumables can be determined by cell density according to the size of the experiment.

3. Types of consumables: Common types of cell culture consumables include culture dishes, culture plates, culture bottles, etc. Each of these types of consumables has its own characteristics and shapes, which can be determined according to experimental needs and personal preferences.

4. Material selection: Cell culture consumables are divided into two types: glass and plastic. Glass materials can be used repeatedly, while plastic materials are mostly disposable consumables. Different cells have different sensitivities to trypsin, so the selection should be based on the cells. Depends on type.

The above are some suggestions on the purchase of cell culture consumables. Cells have high environmental requirements. To do a good job in purchasing cell culture consumables, you need to learn more and accumulate relevant knowledge in your daily work.

0 notes

Text

Enhancing Pharmaceutical Quality with PETG Media Bottles

In the realm of pharmaceutical manufacturing, precision and quality are paramount. At FuDau Bio, we take immense pride in presenting our signature product - PETG Media Bottles. These innovative containers are revolutionizing the pharmaceutical industry by ensuring the highest standards of quality and performance. In this article, we will explore the invaluable role that PETG Media Bottles play in pharmaceutical applications.

1. Unparalleled Pharmaceutical Quality Assurance

Pharmaceutical products must meet rigorous quality standards to guarantee safety and effectiveness. PETG Media Bottles are engineered to meet these exacting requirements. Their exceptional clarity and chemical resistance make them the ideal choice for storing and transporting pharmaceutical ingredients and final products. This ensures that the integrity and quality of pharmaceutical formulations remain uncompromised.

2. Safe and Reliable Storage Solutions

Pharmaceutical manufacturing often involves the use of sensitive materials and components. PETG Media Bottles offer a secure and sterile environment for storing critical substances. Their aseptic manufacturing process, combined with a secure closure system, minimizes the risk of contamination, ensuring the reliability of pharmaceutical products from production to end-user consumption.

PETG Media Bottles

3. Sustainability Meets Pharmaceutical Excellence

In the age of environmental responsibility, PETG Media Bottles stand out as a sustainable choice. Their durability and reusability minimize waste and reduce the environmental impact of pharmaceutical operations. These bottles are not only a symbol of cutting-edge technology but also a testament to our commitment to a greener future.

In summary, PETG Media Bottles from FuDau Bio are the unsung heroes of pharmaceutical manufacturing, ensuring uncompromising quality and reliability. These bottles guarantee the safe storage and transportation of pharmaceutical products, meeting the most stringent quality standards.

0 notes

Text

Revolutionizing Pharmaceuticals with Cell Factory

In the ever-evolving landscape of pharmaceuticals, innovation is key to success. At FuDau Bio, our commitment to cutting-edge solutions has led us to develop our flagship product - the Cell Factory. This revolutionary product is at the forefront of advancing pharmaceutical research and manufacturing processes. In this article, we will delve into the vital role that Cell Factory play in the pharmaceutical industry.

1. Enhancing Drug Development Efficiency

Pharmaceutical companies worldwide are continually striving to bring new drugs and therapies to market efficiently. Cell Factory offer a game-changing solution. These state-of-the-art cell culture consumables provide a controlled environment for the cultivation of cells on a large scale. With Cell Factory, researchers can accelerate drug development processes, leading to quicker and more cost-effective results.

2. Ensuring Consistency and Quality

Consistency and quality are non-negotiable in pharmaceuticals. Cell Factory is designed to meet these demands head-on. Their precise control over environmental conditions, such as temperature, humidity, and nutrient supply, ensures that cell cultures remain stable and produce reliable results. This level of control is critical in maintaining the quality of pharmaceutical products.

Cell Factory

3. Versatility in Pharmaceutical Research

Pharmaceutical research is incredibly diverse, covering areas like vaccine development, biopharmaceuticals, and regenerative medicine. Cell Factories' versatility makes them a vital asset in this dynamic field. They can accommodate various cell types, allowing researchers to work on a wide range of projects. The adaptability of Cell Factories supports innovation and drives progress in pharmaceutical science.

In conclusion, Cell Factory is the cornerstone of progress in pharmaceutical research and development. Their ability to enhance efficiency, ensure quality, and adapt to diverse research needs is unparalleled. As the pharmaceutical industry continues to evolve, Cell Factory from FuDau Bio will remain a trusted partner, contributing to groundbreaking discoveries and the creation of life-saving medications. With Cell Factories, the future of pharmaceuticals is brighter than ever.

0 notes

Text

The Difference Between Cell Culture Flasks and Cell Culture Dishes

Cell culture is a very important experimental technology, and has become an indispensable research method in the fields of biopharmaceuticals, life sciences, and clinical transplantation. Cell culture must rely on cell consumables to achieve the conditions required for cell growth. Cell culture flasks and cell culture dishes are two common types. So what is the difference between these two consumables?

Cell culture flasks are suitable for long-term culture, subculture, and as seed cells. The bottle mouth is small and the cells are not easy to be polluted. Cell culture dishes are suitable for use in various experiments and temporary culture. The difference between the two lies in the level of safety factor and the number of cultured cells.

Cell Culture Flasks

It is better to use cell culture dishes for experiments with cells as carriers or objects, because the amount used is relatively small, saving cells, and petri dishes are more convenient for control experiments, but the cell culture dishes have larger openings and are relatively easier to contaminate, so more care must be taken during operation.

Cell culture flasks are used for primary culture of tissue blocks or easily contaminated cells. After the grown cells are subcultured, it can be determined according to personal preference. The area of the cell culture flask is large, so it can be used when a large number of cells need to be expanded.

Cell Culture Dishes

Both cell culture flasks and cell culture dishes are containers used for microorganism or cell culture in the laboratory. The specific choice of consumables depends on the specific needs of the experiment, and the cell culture method should also be considered, whether it is suspension culture or adherent culture. Appropriate consumables are the basis for successful experiments.

0 notes