#cattle feed machine plant supplier

Text

Happy Holika Dahan 2024 | Cremach Machine Design Pvt Ltd.

May the fire of Holi purify your life. Wishing you a joyous Holika Dahan 2024!

From: @cremach

🏢 Address:

Cremach Private Limited

448/1 GIDC Makarpura

Vadodara 390010

📞 Reach us at +91 99099 84960

📧 Email: [email protected]

🌐 Website: www.cremach.in

#happy holi 2024#happy holi wishes#holi celebration#holi festival#holika dahan#holi 2024#cremach#cattle feed machine plant supplier#holi color#happyholi#fish feed#cattle feed machine plant#gujarat#india#vadodara#manufacturing#feedmill

0 notes

Text

Factors Influencing the Production Benefits of Feed Pellet Machines

Due to challenges in process design and operational technology, the feed factory faced issues with the quality and output of its finished products. The particles exhibited uneven surfaces, high powder content, brittleness, and inconsistency. A comprehensive practical analysis revealed several critical factors influencing granulation efficiency:

Raw Materials:

Starch Content: High starch content facilitates gelatinization, which, when combined with proper conditioning, creates a conducive, viscous state for effective molding.

Crude Fiber: Elevated crude fiber increases friction in the ring die. The addition of a specific amount of grease aids material passage through the die hole and enhances the surface finish of the final product.

Crushing Diameter: Optimal crushing diameters vary based on raw materials. For instance, using a 2.5-3mm sieve plate is recommended for crushed corn in livestock and poultry feed.

Feed Control:

Comprehensive Monitoring: During periods of reduced production efficiency, addressing pelleting issues alone is insufficient. Comprehensive monitoring of incoming material control is crucial.

Production Operation:

Precise Adjustments: Fine-tuning each part of the poultry feed pellet machine, including the die and pressure roller (controlled at 0.05~0.30 mm), prevents issues such as excessive noise and ensures optimal material granulation.

Gap Control: Maintaining a controlled gap of 2-3 mm between the upper edge curve of the scraper and the die and die cover is critical for smooth pellet feed machine operation.

Start-Up Observations: Careful observation during start-up helps identify irregularities in particle discharge. Preventing the introduction of contaminants into the die contributes to a more efficient granulation process.

Ring Die:

Factors Influencing Material Ejection: Factors like the friction coefficient between the material and the die wall, moisture content, particle size, temperature, plasticity, and compressibility influence the smooth ejection of material.

Conditioning Factors:

Blade Wear Impact: Worn conditioner blades negatively impact material conditioning, affecting particle output and steam absorption.

Material Softening: Proper softening of conditioner material is crucial for achieving the desired pulverization rate and output.

Temperature Control: Specific temperature recommendations, like 70~88°C for livestock and poultry feed, optimize conditioning effects.

Steam Factor:

Steam Conveyance Challenges: Saturated steam entry during conveying results in energy loss and condensed water formation, negatively affecting conditioning.

Condensed Water Management: Discharging condensed water before conditioning and converting it into low-pressure dry hot steam through a pressure-reducing valve enhances conditioning effects.

Pressure and Temperature Control: Maintaining steam pressure above 0.2 MPa and a temperature not lower than 120 ℃ post-decompression ensures an optimized conditioning process.

By addressing these factors systematically, the feed factory can optimize the performance of the feed pellet machine, improving product quality and increasing overall output.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: [email protected]

Phone/Whatsapp: 0086-18037508651

0 notes

Text

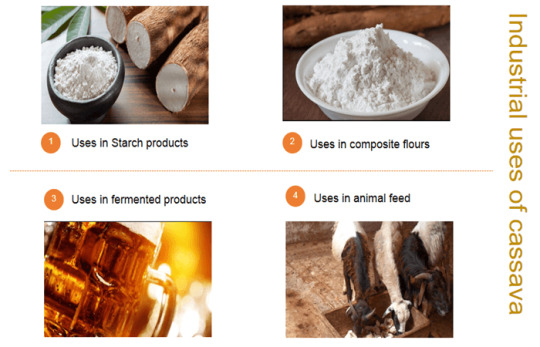

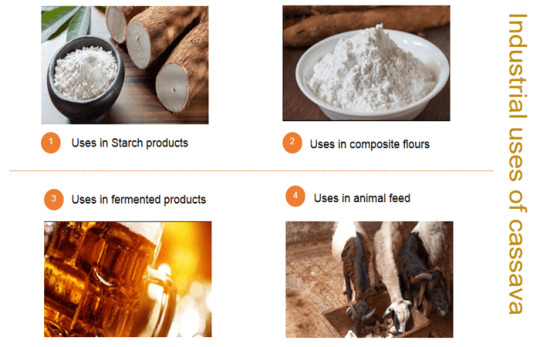

What are the industrial uses of cassava?

It’s reported that the global cassava processing market reached a volume of 298.8 million tons in 2020. The high yield of cassava promoted the development of cassava processing industry. As a professional cassava processing machine supplier, we’d like to detail the industrial uses of cassava so that the investors can better choose the investment direction of cassava processing plant.

①Cassava uses in starch products

Starch and starch products are used in many food and nonfood industries and as chemical raw materials for many other purposes, as in plastics and the tanning of leather. Nonfood use of starches - such as coating, sizings and adhesives - accounts for about 75 percent of the output of the commercial starch industry. Here is a table chart to show the detailed uses of cassava starch.

Food industry:

bakery products; confectioneries; canned fruits, jams and preserves; monosodium glutamate(MSG); commercial caramel.

Non-food industry:

corrugated cardboard manufacture; wallpaper and other home uses, moistening gums,foundry; well drilling;paper industry; textile industry; wood furniture.

Glucose industry:

starch hydrolysis;the production of dextrose.

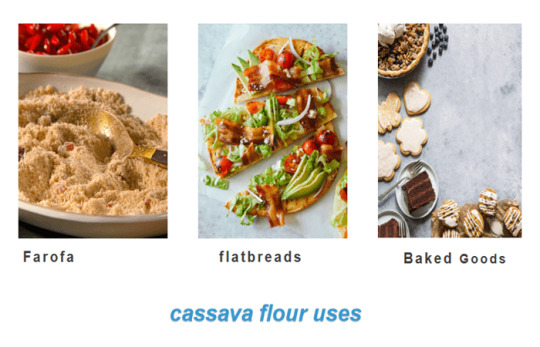

②Cassava uses in composite flours

In many developing countries bread consumption is continually expanding and there is increasing dependence on imported wheat. Most of these countries, however, grow cassava other than wheat that can be used for bread. In many countries, tapioca is used in everyday recipes such as cake baking and pancake cooking. It would therefore be economically advantageous for those countries if imports of wheat could be reduced or even eliminated and the demand for bread could be met by the use of domestically grown products instead of wheat. So the processing of cassava flour has been supported by national policies in some countries.

③Cassava uses in fermented products

Cassava is one of the richest fermentable substances for the production of alcohol and fried yeast. The fresh roots contain about 30 percent starch and 5 percent sugars, and the dried roots contain about 80 percent fermentable substances which are equivalent to rice as a source of alcohol. Besides that, cassava roots are being used in Malaysia and some other countries for the production of yeasts for animal feed and bakery yeast.

④Cassava uses in animal feed

Cassava is widely used in most tropical areas for feeding pigs, cattle, sheep and poultry.Dried peels of cassava roots are fed to sheep and goats, and raw or boiled roots are mixed into a mash with protein concentrates such as maize, sorghum, groundnut or oil-palm kernel meals and mineral salts for livestock feeding.

Taking all the industrial uses of cassava into account,it is not difficult to see that cassava flour and cassava starch have a pivotal position in the industrial uses of cassava.If you want to increase your income by building cassava processing plant, you are welcome to contact Henan Jinrui Company. We can not only provide you good suggestions and designs for building a cassava processing plant,but also can offer you high quality cassava processing machine at factory price,factory visit activities,technical guidance about equipment installation and so on. See also: Complete tapioca machine that can turn tapioca roots into different products

Whatsapp/Phone/Wechat: +86 135 2661 5783

Email: [email protected]

Website:http://www.cassavaprocessing.com/Blog/

0 notes

Text

Animal Feed Plants, Poultry Feed Plants, Cattle Feed Plants, India

Animal Feed Plants, Poultry Feed Plants, Cattle Feed Plants, Mash Plants, Pellet Plants, Animal Feed Making Machine, Poultry Feed Making Machine, Pellet Making Machine, Animal Feed Pellets Making Machine, Cattle Feed Machine, Manufacturer, Supplier, Exporter, Miraj, Sangli, Maharashtra, India.

https://kharegroup.com/animal-poultry-cattle-feed-plants.html

0 notes

Link

PEMAC Edible Oil & Oilseed Processing Services includes Seed Processing Machines, Oil Mil Section, Continuous Solvent Extraction Plant, Vegetable / Cooking Oil Redinery, Cattle / Poultry / Floating Fish Feed Plants, Pilots Plants, Filtration Equipment's

0 notes

Text

How is Cattle Feed Prepared with maximum Yield?

Providing quality feed to the animals is a must if you want to obtain growth and profits. Similarly, just like humans, cattle such as cows also need the finest quality fodder. Without proper feed, it isn’t just that the animals won’t grow well, but the profits that can be gained from cattle farming will also decrease. So, if you are involved in cattle farming, cattle feed is an essential thing that will help propel your animal’s health as well as your business.

Today, we will see about cattle feed is prepared for their cows and other cattle. Knowing this is absolutely crucial for each and every cattle owner. This is because it is with the help of the supplements that we will be able to propel the cattle’s health as well as the business. Similarly, there is also a lot of cattle feed suppliers and their products in the market. Therefore, by knowing about how the supplements are made, we will also be able to get the best product and gain the maximum benefits by giving them to the animals.

Introduction on Cattle Feed

Cattle feed

In simple terms, supplements that are to be provided to the cattle are a type of artificially produced animal-feed that boosts their overall growth and development. In addition, these types of fodder are usually manufactured in large factories and processing plants. Therefore, we can even say that cattle feed are commercially produced products that can be found all over the market. Similarly, its, competition is just as high, and many animal feed producers are vying for competition in the market.

So, as cattle farmers, one cannot miss out on investing in supplements if they want their cattle to grow, be healthy, and also get maximum production and profits. Also, these feeds are to be mixed in small quantities with regular fodder while giving to the animals. Similarly, a reputed cattle feed manufacturer will only produce the product that has all the necessary requirements. Therefore, you should only get animal supplements from the best suppliers and manufacturers out there.

Raw materials for producing cattle feed

Animal supplements or feeds are also a commercially produced product. Therefore, just as all industrial products, cattle supplements also require certain raw materials to be produced. Similarly, we should know that there are a lot of different materials that can be used to make artificial fodder. But we should only choose the right ingredients according to our needs in order to get the desired product.

Selecting the resources and raw materials is usually a lightly taken skep in the process of making feed. However, it is one of the most crucial steps that need to be paid attention to if we are to get the best quality feed. The selection of raw materials may decide how effective and useful the product is going to be. In addition, if we do not select the right ingredients, the final product may not be of much use no matter how well we produce it.

All different types of cereals are crucial ingredients that are used in animal feed. Cereals like barley, oat, maize, and wheat are used to produce the supplements in the factories. In addition, flour of permitted forage essences, dried beet pulps, etc. are also the raw materials that must be present in the supplements.

Similarly, the use of carob-beans in the pellets and the addition of molasses is also done to increase the quality of the supplements. Apart from these must-have materials, some various other ingredients and formulas have to be implemented to get the quality feed that all our precious cows deserve. So we should check out for all the essential ingredients in the packages while getting the feed for our animals.

Equipment for producing cattle feed

Cattle Feed Equipment

After getting the ingredients right, it is time to produce it with the right devices. Initially, we will need a storage tank for keeping all the necessary auxiliary materials. Then a hammer mill will be used to process all the raw materials into a powdered form. Also, the powdered product will need to be thrown to a blender in order to get uniformity.

After that, the product is fed to the pellet mill. In addition, this is one of the most crucial devices that is used in the supplement production process. A ring-type mill is often used in the production plants while flat-type mills are used in homes.

When the product comes out of the mills, it is passed through a cooler. By doing so, the temperature of the hot and moist cattle feed that’s just produced will be decreased. Similarly, graining and screening machines are used next to remove all the unnecessary products from the feed that is produced. At last, the cattle feed that is produced is packed and stored.

In conclusion, you now know about how the cattle feed is produced. So next time you go to buy it, make sure to get the best one that is produced with the best ingredients and with the best process.

0 notes

Link

Something has to be done about Vladimir Putin directing his spies to undermine American democracy by spreading lies about our presidential candidates. If this isn’t a casus belli, I don’t know what is.

Take what they did to Hillary Clinton.

This was a woman with the moral convictions of Mother Theresa and the courage of Joan of Arc. She had lived among the poor in the backwoods of Arkansas and then Chappaqua, New York, where she helped to feed the poor, heal the sick and defend sexually-abused women. She had not only refused wealth and fame for herself, but she had shunned the rich and famous, or what are known as the one percent, because of their greed and lavish, hedonistic, carbon-dependent lifestyles. Her daughter followed in her footsteps, choosing to devote her life to the impoverished Seneca Indians in western New York instead of marrying a New York investment banker and living in a million-dollar Manhattan condo. Hillary was so courageous that on a mission to Iraq, she grabbed a 50-caliber machine gun and bandoliers from the top of a Humvee to escort women and children to safety, as shotgun pellets hit the ground around her, fired by Dick Cheney, who was hunting doves at the time.

By planting false news, the Russians tarnished this reputation and led Americans to believe that Hillary had:

Illicitly made $100,000 in cattle futures while in Arkansas.

Received ill-gotten gains from the shady real estate operation known as Whitewater.

Destroyed subpoenaed records from the Rose Law Firm.

Told a political fixer known as Creepy Carville to destroy the reputation of the woman sexually assaulted by her husband Billy Bob.

Drove her loyal aide Vince Foster to suicide by her temper tantrums and soul-destroying management style.

Summarily fired longtime employees of the White House travel office so they could be replaced with loyalists who had the ethics of a rat, which are at least better than the ethics of a Clinton.

Followed the advice of Tammy Wynette to stand by her man after he had sex with an intern in the Oval Office.

Established a fake charitable foundation as Secretary of State to extort tens of millions of dollars from foreign governments and fossil fuel sheiks, who believe that women should be stoned for infidelity and that gays should meet a worse fate.

Used the Foundation to launder money from a dirty deal that let Russia corner the market in uranium.

Shown no misgivings about her trusted aide Uma being married to a New York politician who emailed photos of his wiener to young women.

Conducted State Department business on a personal server to keep her shady dealings secret.

In short, the Russians tarnished an impeccable reputation and made Americans cynical about the kinds of people who are at the top of the U.S. government. At the same time, they did the opposite with Donald Trump; that is, they took a tarnished reputation and made it impeccable, in a transformation not seen since Pygmalion.

Look at what they started with: an egotistical, boorish, bombastic blowhard who made his name in three disreputable industries: one, in reality TV; two, in the sordid gambling industry that preys on people with no self-control and that left Atlantic City in shambles after receiving city and state financial concessions; and three, in the dirty Manhattan real estate industry, where success depends on getting in bed with corrupt politicians and Mob-owned cement companies, on using the tax code that favors real estate investments over investments in manufacturing, and on using bankruptcy laws to stick it to suppliers and lenders.

The Russians are so good at spy craft that they were able to transform Donald Trump into an economic genius, a friend of the working man, a get-it-done kind of guy, and an alpha male in the image of Putin who will singlehandedly make America great again.

If the Russians hadn’t spread lies to influence our election, Hillary would be president. Moreover, when it comes to politics, Americans would still have their heads in the sand or in a place only seen by proctologists.

Hmm, on second thought, we shouldn’t take punitive action against Putin. We should be awarding him the Medal of Freedom.

3 notes

·

View notes

Text

youtube

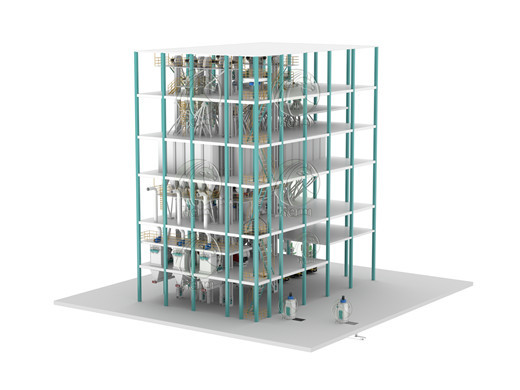

Cremach Pvt. Ltd. (CPL) is a Project Engineering Company for Animal Feed plants based in Vadodara. CPL specializes in turnkey projects for animal feed-making machines, such as Cattle Feed plants, Poultry Feed Plant, Fish Feed Plant, and Shrimp Feed Plant.

Our high-quality milling machinery designed for the compound feed industry includes a Hammer Mill, Industrial Mixer, Pellet Mill, Crumbler, Countercurrent Cooler, and Material Handling Equipment. With the experience of over 4 decades, the company excels in the design, fabrication, supply, installation, automation, and commissioning of animal feed process machinery.

Cremach Private Limited 448/1 GIDC Makarpura Vadodara 390010 Reach us on +91 99099 84960

Email: [email protected]

Website: https://cremach.in/

#animal feed#cattle feed plants#poultry feed#fish feed#cremach#shrimp feed#cattle feed machine plant supplier#manufacturing#Youtube

0 notes

Text

Implementation of Welded Wire Mesh in Various Applications

This specific wire mesh is made of high-quality low carbon steel. They use welding equipment to cut and straighten the steel. This kind of electric fusion welded mesh has good strength and have a series of wires running parallel in a longitudinal manner. They have accurate spacing so that one can implement accurate dimension control. One will find this in use in supermarket shelves and reinforcement for building industry.

Type of meshes

One may also see these kinds of meshes in use in nurseries and on poultry farms. The structure is simple and aids fast production. It is easy to transport and so one may locate them in faraway places. One finds a number of meshes in use depending on the availability and material used.

● Stainless steel mesh

● Plastic mesh

● Galvanized wire mesh

● Black iron mesh

The Welded Wire Mesh has the most strength and durability because of the manufacturing process. Banaraswala Metal Crafts is one of India's reputed Welded Wire Mesh Manufacturers and Suppliers from Tamil Naidu, India.

The welded wire mesh consists of wire made of stainless steel or low carbon steel. The metal wire screen comes in various shapes and sizes. It finds use in a variety of industries such as food procuring, horticultural, industrial, and agricultural sectors. The other places where one finds this are these:

● Mine

● Protection from machinery

● Gardening

● Cordoning work areas

● Roadside protection barriers

The obvious use of meshes in mines is for securing the walls and roof from collapsing. This is a high-safety feature and so, they will use meshes with good strength. The mesh reinforces the mud and prevents it from collapsing.

Protection from machinery

On the shop floor, there is a danger of coming in contact with moving parts of a machine. The metal mesh helps to prevent untoward accidents by preventing direct contact with the machinery. It also helps prevent loose objects from getting hit by the moving parts of the machinery. The worker will be able to move around confidently knowing that he will not contact the machine directly.

Gardening is another area where meshes find a use. The meshes are erected around the new plants so that the cattle will not feed on them. They must be strong enough to resist the intrusion of the cows that try to feed on them. So, a thick metal wire is used for the purpose. The joints of the Welded Mesh are strong and so they will last for until the plant grows and becomes big.

Structure of mesh

The shape of the face of the mesh may be rectangular or square. This depends on the application and material used. Welding is done at each intersection to provide stability to the structure. This process might involve precision automated mechanical welding or it might be an automated welding production using sophisticated processes. The mesh surface is a solid structure that is galvanized to increase durability.

Low carbon Q195 steel wire is welded together and then plated using cold or hot-dip method. Surface passivation methods and PVC plastic are also used to elongate life. Quality of plastic processing and net formation will depend on the skill of the worker and the quality of the material used.

0 notes

Text

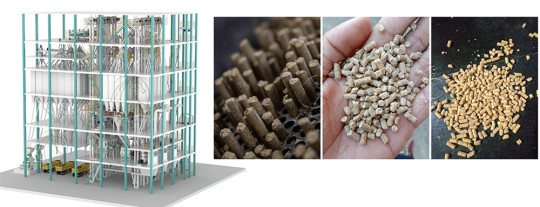

30-35T/H Feed Pellet Line

What is The 30-35T/H Feed Pellet Line ?

Large scale high quality 30-35t/h feed pellet plant is suitable for processing various animal feeds, such as chicken feed, poultry feed, livestock feed, bird feed, duck feed, goose feed, cattle feed, sheep feed, camel feed, horse feed, pig feed, rabbit feed, fish feed, shrimp feed, crab feed, aquatic feed, etc.

youtube

The main equipment of a complete 30-35T/H animal feed pellet mill machine includes an animal feed grinder and feed mixer, feed pellet machine, counter-flow feed pellet cooler, pellet crumbler machine, box cylinder pulse dust remover, vibrating screen classifier, bucket elevator, automatic bagging system, electric control cabinet, etc. This complete feed pellet plant can accomplish raw material mixing, transmission, feeding, and pelletizing. After the raw materials become feed pellets, the following equipment can cool them down and pack them into bags.

The animal-feed pellet plant has good raw material versatility and can be used for the granulation of various raw materials such as corn, sorghum, wheat, beans, and oilseed meal. At the same time, the animal feed production plant has the characteristics of low energy consumption, high production efficiency, and large profits. It is especially suitable for large feed mills, breeding farms, large farms, etc. At the same time, we provide free installation, training, factory design, and timely after-sales service.

Some Questions About the 30-35T/H Feed Pellet Line

1. Who is suitable for this 30-35t/h feed pellet production line?

This animal feed production line is specially designed for large farmers, large animal farm plants, animal feed suppliers, etc.

2. What raw material can be used in the 30-35t/h feed pellet production line?

Animal feed pellet production line raw materials include corn/maize, wheat, grass, alfalfa, oil seed meal & cakes, pasture, bone meal, microelements, etc., and other kinds of raw materials, such as premix, vitamins, wheat bran, salt and other. Different formulations can be made according to different formulas and the needs of the animals being farmed.

3. Why Choose Our Animal Feed Production Line?

Widely Applications: This animal feed pellet mill plant can make feeds for poultry, livestock, sheep, pig, cattle, chicken, duck, fish, shrimp, crab, aquatic, and other animals, it makes pellets of 1-12mm in diameter, and the pellet size can be changed with our feed pellet machine by adjust die. It also can produce mash and crumble.

Small Investment: the compact design of this small feed mill plant can reduce the investment in workshops, etc.

Low Installation Cost: Our feed production line comes with detailed installation and commissioning instructions, it is easy to install the machine, and you can use it immediately after the machine is installed.

Low Production Cost: The animal feed factory only needs 1-2 production workers to complete the production operation. With less labor and lower production costs, your profits will increase.

4. What kind of animal feed pellet production line produce?

This feed pellet production line can produce feed for meat chicken, broilers, laying hens, small baby chicken feed, cattle feed, pig feed, duck feed, sheep feed, poultry feed, livestock feed, goat feed, fish feed, shrimp feed, crab feed, aquatic feed, etc. Such as 2-4mm diameter chick feed pellets and pig feed pellets. 2-5mm rabbit feed pellets, 4-8mm cattle or sheep feed pellets.

This feed pellet mill with a ring die, makes pellets of 1-12mm in diameter, the pellet size can be changed with our feed pellet machine by adjusting the die. It also can produce mash and crumble.

5. What we can do for you?

We can provide the project design, flow chart, feed-making machine manufacturer, project installation and commission, your staff training, after-sales service, etc. Also, our professional install team will serve you if you need it.

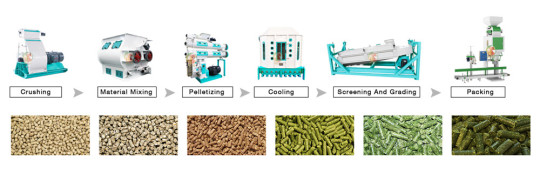

What is The Complete Animal Feed Pellet Production Line Working Process?

Feed Pellets Processing Technology

Raw Material → Feed Grinding → Feed Mixing → Feed Pelletizing → Pellet Cooling → Pellet Crushing → Screening & Grading → Pellet Packing

1. Storage of the raw materials

There are many different raw materials and materials in the feed, so various types of silos must be used. There are three types of silo that can be used in the feed pellet line, such as hopper silo, flat bottom silo, and galvanized silo.

2. Cleaning of raw materials

Impurities in feed raw materials not only affect the quality of feed products but also directly affect the use of feed processing equipment and the personal safety of staff. In severe cases, the entire equipment will be damaged and the smooth progress of feed production will be affected. Therefore, impurities in the feed raw materials should be removed in time.

3. Crushing of raw materials

The technological process of feed crushing is determined according to the required particle size, feed variety, and other conditions. According to the number of raw material crushing, it can be divided into primary crushing process and circulating crushing process or secondary crushing process. The combination with the batching process can be divided into the first batching and then crushing process and the first crushing and then batching process.

4. Batching process

The rational design of the batching process is to correctly select the specifications and quantities of the batching metering device so that it is fully coordinated with the combination of batching feeding equipment, mixing units, and other equipment.

5. Mixing process

The mixing process refers to the technological method and process of weighing the ingredients in the feed formula and then entering the mixer for uniform mixing. The mixing section requires a short mixing cycle, high mixing quality, fast discharge, low residual rate, good air tightness, and no dust spillage.

6. Pelleting process

The pelleted feed obtained by compacting and extruding a single raw material or compound mixture by mechanical action is called feed pelleting. The purpose of pelleting is to use the heat, moisture, and pressure in the pelleting process to pelletize the feed that is finely divided, easily dusty, poorly palatable, and difficult to transport.

7. Cooling process

During the pelleting process, when the pellet feed comes out of the feed pellet machine, the water content reaches 16%-18%, and the temperature is as high as 75°C-85°C. It will also cause adhesion and mildew during storage. The moisture must be reduced to below 14%, the temperature must be below 8°C higher than the air temperature, and cooling is required.

8. Crumbling process

In the production process of the feed pellet mill, in order to save electricity, increase production and improve quality, the material is often made into a certain size of pellets, and then crushed into qualified products according to the size of the feed pellets.

9. Screening process

After the pellet feed is processed by the crushing process, some unqualified materials such as powder will be produced. Therefore, the crushed pellet feed needs to be sieved into a product with neat particles and uniform size.

10. Packaging process

After weighing, put the finished product into the packing scale and pack it. During this process, the package should be calibrated until the package weight standard is met.

0 notes

Text

What are the industrial uses of cassava?

It’s reported that the global cassava processing market reached a volume of 298.8 million tons in 2020. The high yield of cassava promoted the development of cassava processing industry. As a professional cassava processing machine supplier, we’d like to detail the industrial uses of cassava so that the investors can better choose the investment direction of cassava processing plant.

📷Cassava Industrial uses

①Cassava uses in starch products

Starch and starch products are used in many food and nonfood industries and as chemical raw materials for many other purposes, as in plastics and the tanning of leather. Nonfood use of starches - such as coating, sizings and adhesives - accounts for about 75 percent of the output of the commercial starch industry. Here is a table chart to show the detailed uses of cassava starch.

Food industry

bakery products; confectioneries; canned fruits, jams and preserves; monosodium glutamate(MSG); commercial caramel.

Non-food industry

corrugated cardboard manufacture; wallpaper and other home uses, moistening gums,foundry; well drilling;paper industry; textile industry; wood furniture.

Glucose industry

starch hydrolysis;the production of dextrose.

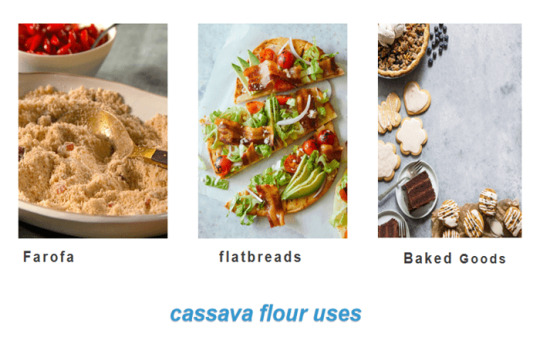

②Cassava uses in composite flours

In many developing countries bread consumption is continually expanding and there is increasing dependence on imported wheat. Most of these countries, however, grow cassava other than wheat that can be used for bread. In many countries, tapioca is used in everyday recipes such as cake baking and pancake cooking. It would therefore be economically advantageous for those countries if imports of wheat could be reduced or even eliminated and the demand for bread could be met by the use of domestically grown products instead of wheat. So the processing of cassava flour has been supported by national policies in some countries.

📷Cassava flour uses

③Cassava uses in fermented products

Cassava is one of the richest fermentable substances for the production of alcohol and fried yeast. The fresh roots contain about 30 percent starch and 5 percent sugars, and the dried roots contain about 80 percent fermentable substances which are equivalent to rice as a source of alcohol. Besides that, cassava roots are being used in Malaysia and some other countries for the production of yeasts for animal feed and bakery yeast.

④Cassava uses in animal feed

Cassava is widely used in most tropical areas for feeding pigs, cattle, sheep and poultry.Dried peels of cassava roots are fed to sheep and goats, and raw or boiled roots are mixed into a mash with protein concentrates such as maize, sorghum, groundnut or oil-palm kernel meals and mineral salts for livestock feeding.

Taking all the industrial uses of cassava into account,it is not difficult to see that cassava flour and cassava starch have a pivotal position in the industrial uses of cassava.If you want to increase your income by building cassava processing machine, you are welcome to contact Henan Jinrui Company. We can not only provide you good suggestions and designs for building a cassava processing plant,but also can offer you high quality cassava processing machine at factory price,factory visit activities,technical guidance about equipment installation and so on.

0 notes

Link

Gulf of Mexico Now Largest Dead Zone in the World, and Factory Farming Is to Blame Dr. Mercola By Dr. Mercola As reported by CBS Miami (above), nitrogen fertilizers and sewage sludge runoff from factory farms are responsible for creating an enormous dead zone in the Gulf of Mexico. As fertilizer runs off farms in agricultural states like Minnesota, Iowa, Illinois, Wisconsin, Missouri and others, it enters the Mississippi River, leading to an overabundance of nutrients, including nitrogen and phosphorus, in the water. This, in turn, leads to the development of algal blooms, which alter the food chain and deplete oxygen, resulting in dead zones. The dead zone in the Gulf of Mexico is the largest recorded dead zone in the world,1 beginning at the Mississippi River delta and spanning more than 8,700 square miles — about the size of New Jersey. Needless to say, the fishing industry is taking a big hit, each year getting worse than the last. The featured news report includes underwater footage that shows you just how bad the water quality has gotten. Gulf of Mexico — Largest Dead Zone in the World Nancy Rabalais, professor of oceanography at Louisiana State University, is an expert on dead zones. She has measured oxygen levels in the Gulf since 1985, and blames agricultural runoff entering the Mississippi River for this growing environmental disaster. Recent measurements reveal the area has only half the oxygen levels required to sustain basic life forms. “The solution lies upstream in the watershed,” she says, “with agricultural management practices; a switch to crops that have deeper roots and don’t need so much fertilizer and are still just as profitable as corn.” According to CBS, the U.S. Environmental Protection Agency has created a task force to assess dead zones, and hope to reduce nutrient-rich agricultural runoff by 20 percent by 2025. Common sense will tell you that’s nowhere near enough. A study2 published last year revealed nitrogen builds up far below the soil surface, where it can continue to leach into groundwater for 35 years. This means environmental concerns would persist for decades even if farmers were to stop using nitrogen fertilizers altogether. The researchers analyzed more than 2,000 soil samples from the Mississippi River Basin, finding nitrogen buildup at depths of 10 inches to 3.2 feet. According to the authors: “[W]e show that the observed accumulation of soil organic [nitrogen] … in the [Mississippi River Basin] over a 30-year period … would lead to a biogeochemical lag time of 35 years for 99 percent of legacy [soil organic nitrogen], even with complete cessation of fertilizer application. By demonstrating that agricultural soils can act as a net [nitrogen] sink, the present work makes a critical contribution towards the closing of watershed [nitrogen] budgets.” Lake Erie Suffers From Chemical Pollution The problem is hardly restricted to the Gulf of Mexico. Many other waterways are being choked by agricultural chemicals as well. Lake Erie, for example, is currently reporting a 700-square-mile algal bloom, the toxins from which may also contaminate drinking water. Algal blooms also fill the largest tributary to the Great Lakes, the Maumee River. At present, officials claim microcystin levels (toxins produced by the algae) in intake pipes from Lake Erie are low, but that can change at any time. In 2014, Toledo, Ohio, was forced to shut off the supply of drinking water to half a million residents for three days due to elevated microcystin levels in the water. The algae also hurt the regional economy each year, as recreational fishing and beach visits must be restricted. Lake Erie began experiencing significant problems in the early 2000s. Over the years, it’s only gotten more extensive, the bloom covering an increasingly larger area. The University of Michigan is now using a new robotic lake-bottom laboratory to track microcystin levels in the lake (see video above), thereby allowing them to detect and report water safety issues to water management officials more quickly. Toledo Mayor Appeals to President Trump — ‘Declare Lake Erie Impaired’ According to a study by the Carnegie Institute for Science and Stanford University, the expansion of algal bloom in Lake Erie is primarily attributable to a rise in the amount of dissolved phosphorus from farm land entering the lake. Part of the problem is that agricultural runoff is typically exempt from clean water laws. On September 26, 2017, Toledo mayor Paula Hicks-Hudson urged the federal government to declare Lake Erie impaired due to excessive algae.3 Doing so would allow the lake’s nutrient load to be regulated under the Clean Water Act. Many activists believe Hicks-Hudson has been too slow to act, and still isn’t taking it far enough. The Blade reports:4 “Activist Mike Ferner dumped a pitcher of algae-infested water and two dead fish into One Government Center's public fountain … to highlight the condition of the river and lake. Mr. Ferner, joined by more than a dozen other members of the Advocates for a Clean Lake Erie group he founded in response to the 2014 Toledo water crisis, said the protest was in response to foot-dragging by local, state and federal officials. He said the administrations of Mayor Hicks-Hudson and Ohio Gov. John Kasich are complicit in allowing manure and other farm fertilizers to pollute the water because they won't call for the open water of Lake Erie to be designated as impaired.” Drinking Water Threatened by Agricultural Pollution Agricultural runoff threatens drinking water across the U.S. as well. As reported by Fern’s AG Insider:5 “Seven million Americans who live in small cities and towns have worrisome levels of nitrates in their drinking water — below the federal limit of 10 milligrams per liter, but high enough to be associated with cancer in some studies, said an Environmental Working Group official. Craig Cox, head of EWG’s Midwest office, said 1,683 communities had nitrate levels above 5 milligrams per liter and, when plotted on a map, they ‘crazily lined up with intensive agriculture.’ Farm use of nitrogen fertilizer is regarded as a frequent source of nitrates in groundwater. Soils also shed nitrates naturally. Urban runoff and septic systems also are sources.” Meat Industry Implicated in Creation of Gulf Dead Zone According to Mighty Earth,6 an environmental group chaired by former Congressman Henry Waxman, a “highly industrialized and centralized factory farm system” — consisting of a fairly small number of individual corporations — are responsible for a majority of the water contamination and environmental destruction we’re currently facing. Tyson Foods, which produces chicken, beef and pork, was identified as one of the worst offenders. As reported by The Guardian:7 “Tyson, which supplies the likes of McDonald’s and Walmart, slaughters 35 [million] chickens and 125,000 head of cattle every week, requiring five million acres of corn a year for feed, according to the report. This consumption resulted in Tyson generating 55 [million] tons of manure last year … with 104 [million] tons of pollutants dumped into waterways over the past decade. The Mighty research found that the highest levels of nitrate contamination correlate with clusters of facilities operated by Tyson and Smithfield, another meat supplier … The report urges Tyson and other firms to use their clout in the supply chain to ensure that grain producers such as Cargill and Archer Daniels Midland employ practices that reduce pollution flowing into waterways. These practices include not leaving soil uncovered by crops and being more efficient with fertilizers so plants are not doused in too many chemicals.” October 2, the group launched its national #CleanItUpTyson campaign,8 calling for Tyson, the largest meat company in the U.S., to “clean up pollution from its supply chain that’s contaminating local drinking water and causing a massive dead zone in the Gulf of Mexico.” According to Mighty Earth: “The local campaigns are part of Mighty Earth’s national effort to hold the meat industry accountable for reducing its vast environmental impact, which is driving widespread water pollution, clearance of natural landscapes, high rates of soil erosion, and greenhouse gas emissions. Local communities from the Heartland to the Gulf are among those most affected by the meat industry’s impacts, and pay billions each year in clean-up costs.” Factory Farming — The Ultimate Threat to Life on Earth According to Philip Lymbery, chief executive of Compassion in World Farming and author of “Farmageddon” and “Deadzone” — two books detailing the destructive impact of industrial agriculture — factory farming is a threat to all life on Earth. Speaking at a recent Livestock and Extinction Conference in London, Lymbery said: “Every day there is a new confirmation of how destructive, inefficient, wasteful, cruel and unhealthy the industrial agriculture machine is. We need a total rethink of our food and farming systems before it’s too late.”9 As noted by The Guardian,10 a number of “alarming exposés” have been featured as of late, including “chicken factory staff in the U.K. changing crucial food safety information on chickens,” and an admission by the European commission last month that “eggs containing a harmful pesticide may have been on sale in as many as 16 countries.” And, of course, the Gulf of Mexico being earning the recent designation of having the largest dead zone ever recorded. According to Lymbery: “We need to go beyond an isolated approach. Not just looking at the technical problems around welfare, not just looking at the technical issues around the environment, not just looking at food security in isolation, but putting all of these issues together, then we can see the real problem that lies at the heart of our food system — industrial agriculture. Factory farming is shrouded in mythology. One of the myths is that it’s an efficient way of producing food when actually it is highly inefficient and wasteful. Another is that the protagonists will say that it can be good for the welfare of the animals. After all, if hens weren’t happy they wouldn’t lay eggs. The third myth is that factory farming saves space. On the surface it looks plausible, because, by taking farm animals off the land and cramming them into cages and confinement you are putting an awful lot of animals into a small space. But what is overlooked in that equation is you are then having to dedicate vast acreages of relatively scarce arable land to growing the feed … The UN has warned that if we continue as we are, the world’s soils will have effectively gone within 60 years. And then what? We shouldn’t look to the sea to bail us out because commercial fisheries are expected to be finished by 2048.” No-Tillage Alone Cannot Make a Dent in Nitrate Pollution Problem Lymbery, as many others, myself included, point out that the answer is readily available and implementable. Regenerative farming can solve this and many other environmental and human health problems, if done in a thorough and holistic manner. No-till agriculture, which has become increasingly embraced as a solution to water pollution and other environmental problems associated with modern farming, is nowhere near enough. While it’s certainly useful, and a method employed in regenerative agriculture, it alone cannot address the growing problems of chemical pollution. This was also the conclusion of a recent U.S. Department of Agriculture study. As reported by Indiana University:11 “Researchers in the Department of Earth Sciences in the School of Science at IUPUI conducted a meta-analysis to compare runoff and leaching of nitrate from no-till and conventional tillage agricultural fields. Surface runoff and leaching are two major transportation pathways for nitrate to reach and pollute water. Due to its mobility and water solubility, nitrate has long been recognized as a widespread water pollutant. ‘What we found is that no-till is not sufficient to improve water quality,’ said Lixin Wang, an assistant professor and corresponding author of the paper. ‘In fact, we found that no-till increased nitrogen leaching.’ The study suggests that no-till needs to be complemented with other techniques, such as cover cropping and intercropping or rotation with perennial crops, to improve nitrate retention and water-quality benefits.” Other recent research12 confirms that adding native prairie strips to the rural landscape can help reduce water pollution from farm fields. Prairie strips refers to small patches of land around the edges of crop fields where native, perennial grasses and flowers are allowed to grow wild. The results show that converting as little as 10 percent of crop areas into prairie strips:13,14 Reduces soil loss by 95 percent Reduces phosphorous runoff by 77 percent and lowers nitrogen loss through runoff by 70 percent Lowers nitrate concentrations in groundwater by 72 percent Improves water retention More than doubles the abundance of pollinators and birds Regenerative and Biodynamic Farming to the Rescue The only viable long-term answer is regenerative agriculture (which goes beyond mere sustainability), for which biodynamic farming stands as a shining ideal. In addition to no-till, regenerative farming focuses on such practices and concepts as rotational grazing, improvement and building of topsoil (which includes cover cropping), the use of all-natural soil amendments and increasing biodiversity. Aside from putting an end to water and soil pollution, regenerative agriculture is also needed to protect future generations from the devastating harm caused by pesticides. The amount of pesticides used both commercially and in residential areas has grown immensely since 1945. More than 1 billion pounds are used each year in the U.S. alone. Worldwide, an estimated 7.7 billion pounds of pesticides are applied to crops each year, and that number is steadily increasing.15 According to a 2012 analysis,16 each 1 percent increase in crop yield is associated with a 1.8 percent increase in pesticide use. Logic tells us this is an unsustainable trajectory. As just one example, studies done by the Chinese government show that 20 percent of arable land in China is now unusable due to pesticide contamination.17 Earlier this year, two United Nations experts called for a comprehensive global treaty to phase out pesticides in farming altogether, noting that pesticides are in no way essential for the growing of food.18 The report highlighted developments in regenerative farming, where biology can completely replace chemicals, delivering high yields of nutritious food without detriment to the environment. “It is time to overturn the myth that pesticides are necessary to feed the world and create a global process to transition toward safer and healthier food and agricultural production,” they said. Each Day’s Meal Can Help Bring Us Closer to the Tipping Point You can help steer the agricultural industry toward safer, more sustainable systems by supporting local farmers dedicated to regenerative farming practices. The Demeter mark, indicative of Biodynamic certification, is the new platinum standard for high-quality foods raised and grown in accordance to the strictest environmental parameters possible. Biodynamic is essentially organic on steroids, far surpassing it in terms of its environmental impact. Unfortunately, Biodynamic certified foods are still scarce in the U.S., unless you happen to live near a certified farm. Most Biodynamic farms only sell locally or regionally. You can find a directory of certified farms on biodynamicfood.org. We hope to change that as we move forward, and building consumer demand is what will drive that change. Other U.S.-based organizations that can help you locate wholesome farm-fresh foods include the following: American Grassfed Association The goal of the American Grassfed Association is to promote the grass fed industry through government relations, research, concept marketing and public education. Their website also allows you to search for AGA approved producers certified according to strict standards that include being raised on a diet of 100 percent forage; raised on pasture and never confined to a feedlot; never treated with antibiotics or hormones; born and raised on American family farms. EatWild.com EatWild.com provides lists of farmers known to produce raw dairy products as well as grass fed beef and other farm-fresh produce (although not all are certified organic). Here you can also find information about local farmers markets, as well as local stores and restaurants that sell grass fed products. Weston A. Price Foundation Weston A. Price has local chapters in most states, and many of them are connected with buying clubs in which you can easily purchase organic foods, including grass fed raw dairy products like milk and butter. Grassfed Exchange The Grassfed Exchange has a listing of producers selling organic and grass fed meats across the U.S. Local Harvest This website will help you find farmers markets, family farms and other sources of sustainably grown food in your area where you can buy produce, grass fed meats and many other goodies. Farmers Markets A national listing of farmers markets. Eat Well Guide: Wholesome Food from Healthy Animals The Eat Well Guide is a free online directory of sustainably raised meat, poultry, dairy and eggs from farms, stores, restaurants, inns, hotels and online outlets in the United States and Canada. Community Involved in Sustaining Agriculture (CISA) CISA is dedicated to sustaining agriculture and promoting the products of small farms. FoodRoutes The FoodRoutes "Find Good Food" map can help you connect with local farmers to find the freshest, tastiest food possible. On their interactive map, you can find a listing for local farmers, CSAs and markets near you. The Cornucopia Institute The Cornucopia Institute maintains web-based tools rating all certified organic brands of eggs, dairy products and other commodities, based on their ethical sourcing and authentic farming practices separating CAFO "organic" production from authentic organic practices. RealMilk.com If you're still unsure of where to find raw milk, check out Raw-Milk-Facts.com and RealMilk.com. They can tell you what the status is for legality in your state, and provide a listing of raw dairy farms in your area. The Farm to Consumer Legal Defense Fund19 also provides a state-by-state review of raw milk laws.20 California residents can also find raw milk retailers using the store locator available at http://ift.tt/UJjPq1.

0 notes

Text

Immune Boost Your Food With Stock

It takes a lot of grain and corn to feed these animals. And there's water consumption and another thought is, how are they disposing of all the animal waste? Those big pens hold a lot of cattle and that means a lot meat and poultry processing waste that has to go somewhere. Yes poultry cutting machinery is manure, organic fertilizer but that much of it all in one area. Where does milkfish pin bone removal machines go? And is that the reason that we keep getting bacteria in our food?

Where would you like to cut back if you are a consumer seeking credit card chicken processing supplies? Is chicken processing machine indonesia to cut back on quality perhaps? It's a huge difference in cutting back versus cutting right into your profit margin. When your machine in not working, and losing you money every second it's down, what then? You know what I mean. The sale has already been made, and they have moved on. Or chicken meat de-skinning machines are not set up to provide customer service.

But you should not just depend on these kinds of exercises. There is also a need for you to be certain that you will have a good meal plan. As much as possible, your diet should exclude food items that are very rich with calories. poultry meat cutting machines indonesia should avoid any sugary items such as sodas and cakes. There is also a need for you to avoid red meat and chicken skin removal.

In a country or region with lush pastures and natural small scale poultry processing methods, if good cattle are raised naturally, grass fed is a good option. turkey chicken cutting equipments create more marbling in the meat than other grasses. In United Arab Emirates UAE fish processing machines , Australia for example, a famous brand raised beef on grain rich grass which grew all over the island resulting in a rich creamy marbled meat with a delicious flavour.

As the Blommer chocolate smell illustrates, it does not matter if a smell is generally pleasant. If you do not want to smell it, you have a right to protest. And so United Arab Emirates UAE poultry processing equipment might protest about the sweet-smelling air in our community. While I'm at it, I might say a few words about the mobile poultry processing unit right up the road from the flavorings plant, because it stinks up the air on a regular basis too.

chicken farm equipment chicken equipment suppliers There is only one principle in weight loss that is an absolute. You must eat less calories than you burn. singapore fish de-scaling machine 's that simple. Does that mean that in grouper fish fin tail cutting machines indonesia to lose weight you'll need to eat tiny portions of all those foods that you love? No. In poultry de-boning equipments philippines , eating tiny portions will only slow your metabolism down, and perhaps make you gain weight.

0 notes

Text

Complex World of Border Trade: Cattle Go North, Meat South

AP, May 22, 2017

REYNOSA, Mexico--Waving arms and brandishing a long electric prod, the ranch hands and truck drivers herd about 400 leggy calves onto trucks as the sun crests on the outskirts of this border city. After spending their first eight months on the ranches of Gildardo Lopez Hinojosa, the calves are about to cross the border--bound for Texas and U.S. feed lots beyond.

On one of the three bridges connecting Reynosa with Texas, they might cross paths with the beef and chicken shipments that Lopez imports from the U.S. for his local chains of butcher shops and fried chicken restaurants. He gets the best price for his calves in the U.S. and it’s cheaper for him to import U.S. chicken than ship Mexican chicken from the country’s interior.

Lopez has been selling calves and buying beef across the border for about as long as the North American Free Trade Agreement has been in effect. President Donald Trump has said the agreement that is the basis for much of the $500 billion annual trade between the U.S. and Mexico needs to be renegotiated or scrapped entirely. To hear him tell it, NAFTA was “a catastrophic trade deal for the United States.”

The reality is far more complicated, especially at the border where communities are enmeshed in a shared economy that can be affected by actions or words in either country.

“It’s a lie to say that NAFTA didn’t work,” said Rafael Garduno Rivera, an economist at the Center for Economic Research and Teaching in Aguascalientes, who studies the agreement’s impacts. “It worked and worked very well and for both sides in various areas. Like everything there were losers and winners.”

Maquiladoras, as Mexican assembly plants are known, get most of the attention. They churn out everything from flat-screen televisions and washing machines to auto components that might cross borders a dozen times before a car comes off the assembly line in Michigan.

But U.S. border retailers--downtown discount stores and high-end outlet shopping and malls--also depend on Mexican shoppers, especially those whose jobs in Mexican border cities allow them to shop in the U.S.

For nearly 25 years, Lopez has been sending cows to the U.S. and importing beef to Mexico. Three days a week he loads four to six trailers with his young cows and sends them across the bridge connecting to Pharr, Texas. Once cleared by USDA veterinarians there, buyers from elsewhere in Texas, Arizona or even up toward the Canadian border pick up their cows. After that initial sale, Lopez does not know where they go.

In theory, some could come back to him mixed in among the 25 tons of beef he imports from the U.S. every week for his butcher shops. He buys from the big beef processors like IBP, National Beef and Supreme Beef, wherever he finds the best price.

Lopez’s calves create jobs in U.S. feed lots and slaughterhouses and the cheaper U.S. chicken he buys allows him to employ more Mexicans in his restaurants. Among his various businesses he employs about 400 people.

Nearly 5 million U.S. jobs depend on trade between the two countries, according to a study released last fall by the non-partisan Washington, D.C.-based Wilson Center Mexico Institute.

“The United States depends on Mexico as much as Mexico depends on the United States,” Lopez said.

Monica Weisberg-Stewart, across the border in McAllen, Texas, knows that as well as anyone.

Her family ran discount stores on the border for more than 60 years, before making the business decision a couple years ago to close. Now Weisberg-Stewart leases their properties to other businesses.

The border economy is so interconnected that moves in either country can have dire consequences. As an example, she recalled when the U.S. began requiring a new, more expensive visa for Mexicans who crossed to U.S. border cities.

“It wiped out a socio-economic group that would come over here on a daily basis for groceries, milk, products, just their daily goods,” she said. “Mexico not coming, Mexico not shopping, affects us.”

Border residents on both sides say that is already happening. A weaker Mexican peso has been a principal factor, but the unwelcoming rhetoric and fear of the sort of reception they will receive has been another.

Several hundred miles upriver from Reynosa, Lidia Gonzalez sat in the shade of El Porvenir, Mexico’s town square selling used clothing purchased in El Paso.

“It’s all second hand because people can’t buy new,” Gonzalez said. “It’s OK for us, because from that we eat.”

But she was anxious because her supplier had cut back her buying trips recently. She said Mexican customs officials suddenly began hassling the buyer about her purchases, something Gonzalez attributed to the generally deteriorating relations between the two countries.

Gonzalez has a visa that allows her to cross, but the last time she felt U.S. immigration agents were interrogating her more than usual. For now she has stopped crossing out of fear they might take her visa.

Just west of El Paso, Marisela Sandoval, 39, of Sunland Park, New Mexico, said she had seen fewer border crossers like Gonzalez at her job at a Wal-Mart.

Sandoval said Mexican shoppers were fewer and consequently sales this year in the store where she works had been way off.

“Because of the dollar and the feelings about Trump, what he was saying,” Sandoval explained. “People were getting afraid because in the bridge they were making them sign a paper that would say that they would take their visa and they were afraid to even come.”

The weaker Mexican peso put an end to Gilberto Lozoya’s shopping trips to Laredo, Texas.

Lozoya, 24, has spent four years working in maquiladoras in Nuevo Laredo, a major trade thoroughfare to the United States.

He now works as an engineer supporting assembly lines producing gas valves, thermostats and other products so they keep running, but he’s ambitious and hopes to advance.

At night he studies English, because it would help him move up the ladder at so many foreign-owned maquiladoras, including the Illinois-headquartered engineering and manufacturing firm Robertshaw, where he works now.

He used to cross to Laredo to buy school supplies that he couldn’t find. But the strong dollar put such purchases out of reach. Many maquila workers making only $50 to $60 for a six-day work week rely on a few hours of daily overtime to make ends meet, he said.

If something happened to the maquila jobs, Lozoya said he worries the unemployed would fill the ranks of the drug cartel that controls Nuevo Laredo. But nothing is clear at the moment, he said. “So far we don’t know what situation we’re in and what this new president (Trump) is going to say that could affect us.”

0 notes

Text

youtube

Cremach Pvt. Ltd. (CPL) is a Project Engineering Company for Animal Feed plants based in Vadodara. CPL specializes in turnkey projects for animal feed-making machines, such as Cattle Feed Plant, Poultry Feed Plants, Fish Feed Plant, and Shrimp Feed Plant.

Our high-quality milling machinery designed for the compound feed industry includes a Hammer Mill, Industrial Mixer, Pellet Mill, Crumbler, Countercurrent Cooler, and Material Handling Equipment. With the experience of over 4 decades, the company excels in the design, fabrication, supply, installation, automation, and commissioning of animal feed process machinery.

#animal feed#feedmill#manufacturing#cattle feed machine plant#cattle feed machine plant supplier#fish feed#cremach#india#vadodara#gujarat#Youtube

0 notes

Text

Whether it be Poultry Feed, Aquatic Feed, Pet Feed, or Cattle Feed. Our Engineering and R&D associates work in a compact structure according to your requirements to design the best option for your Feed Mill Investment.

Feel free to contact us for more details. http://www.cremach.in/

#animal feed#feedmill#feed plant#engineering#manufacturing#cremach#cremach design#feed company#feed industry#cattle feed machine plant supplier#cattle feed machine plant

0 notes