#Woodworking CNC Tools Market

Text

Woodworking CNC Tools Market Outlook, Current and Future Landscape Analysis 2022 to 2028

According to an FMI study, the router bits segment is expected to account for more than 40% of the total market volume during the forecast period (2022-2028), and the global woodworking CNC tools market value is expected to exceed US$ 2.60 billion by the end of 2028.

In terms of wood type, MDF is expected to account for one-third of total woodworking CNC tool sales through 2028. According to FMI, Asia Pacific will account for 47.3% of total revenue in 2022.

Request a Free Sample Copy of this Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-11105

Key Takeaways of Woodworking CNC Tools Market Study

The 1/2″ type router bits segment is projected to exhibit a healthy annual growth rate, owing to the high preference for DIY as well as industrial applications. Furthermore, the cutters segment also holds noteworthy share in the global woodworking CNC tools market, on back of vast usage in profiling, cutting, and slotting, among others.

By wood type, MDF (medium-density fiberboard) is projected to hold 1/3 share in the global market, as it is used in furniture, cabinetry, and flooring making. Furthermore, in music equipment, MDF is utilized to make speaker boxes due to its consistency, smooth finish, machinability, and strength.

Milling, drilling, profiling, and cutting are major applications of woodworking CNC tools. Cutting and milling are projected to be the most lucrative segments in the global market.

Asia Pacific is projected to progress at a significant CAGR in the global woodworking CNC tools market, owing to rising demand from various end-use industries.

Market Landscape: Highly Fragmented

The global woodworking CNC tools market is highly fragmented, owing to the presence of numerous international and local players. Furthermore, leading players are expected to hold less than 15% share, while the remaining is accounted for by local players. Moreover, China and Mexico are two countries that are anticipated to change the landscape of the global woodworking CNC tools market over the coming years. During the course of research, players such as Robert Bosch GmbH, Rockler Companies, Inc., and Vortex Tool Company Inc., among others, were identified to be the leading players in the woodworking CNC tools market across the value chain.

Want to Know More?

Future Market Insights has published a market research report on the global woodworking CNC tools market that contains global industry analysis of 2013–2021 and opportunity assessment for 2022–2028. The report provides insightful analysis of the woodworking CNC tools market through four different segments – tool type, wood type, operation, and region. The woodworking CNC tools report also includes macroeconomic factors, forecast factors, and key success factors. Furthermore, the team has also incorporated a list of global suppliers and distributors, as well as a list of online product sellers.

For More Information on this Report @

https://www.futuremarketinsights.com/reports/woodworking-cnc-tools-market

Woodworking CNC Tools Market by Category

By Tool Type:

Router Bits

Insert Knives

Engraving Tools

Cutters

1/2"

1/4"

3/8"

3/4"

5/8"

5/16"

Less than 0.3"

0.3-0.4"

0.4-0.5"

0.5-0.6"

More than 0.6"

Single Flute Cutters

Finger Joint Cutter

Grooving Cutting

By Wood Type:

Plywood

Chipboard

MDF (Medium Density Fiberboard)

HDF (High Density Fiberboard)

Hardwood

By Operation:

Milling

Drilling

Cutting

Profiling

By Region

North America

South America

Europe

Asia Pacific

MEA (Middle East & Africa)

0 notes

Text

Woodworking tips and insights from the masters in woodworking

Are you looking for Woodworking tips from an expert in creating bespoke design and décor for businesses? Give it a shot right away to see how the outcomes turn out! Are you seeking custom-design items in Bahrain?

Then hang on, and let’s show you the top tips for woodworking in Bahrain.

Statistics say it all !

A survey of amateur and professional woodworkers conducted in New Mexico found that the highest rate of woodshop tool-related injuries was the jointer-planer at 4.9 injuries per 1000 person-hours of use.

Hammers and table saws were also frequently associated with woodshop injuries, with one-third of the reported injuries requiring professional medical care and five percent of respondents experiencing partial amputations.

Woodworking Safety Tips include

Wearing safety glasses,

Wearing appropriate clothing,

Avoiding drugs and alcohol,

disconnecting power before blade changes,

using sharp blades and bits,

checking for nails, screws, or other metal before cutting.

Check the stock for metal pieces before cutting and use a metal detector to check for metal.

Do not reach over a blade to remove cut-offs, focus on your task and avoid distractions.

Why use digital crafts from the top woodworking companies in Bahrain are trending?

In Bahrain, digital crafts allow for an infinite amount of creative expression!

We stand apart from digital creative works in Bahrain.

Art installation services in Bahrain have a well-deserved reputation.

Attractiveness to the eye is the new currency.

Because of this, Master Kraft in Bahrain ensures that

Using the services of one of the most reputable digital printing firms in Bahrain will help you take your marketing strategy to the next level and bring in additional customers.

Let us break some bubbles and tell you about the things you did not know about Masterkraft, shall we?

Why are we the best?

Anything to everything

From designing interiors to display units, we design several things.We deliver visual display services in Bahrain, thereby guaranteeing that you will receive the highest quality woodwork in Bahrain.

Top-notch professionals

In addition to highly -qualified, carpenters, vinyl applicators, painters, and other skilled and semi-skilled personnel, the company has competent project managers and site coordinators to complete diverse works on time and professionally.

The only place where you can find..

Master Krafts in Bahrain is the only place you can find CNC machines with unrivaled precision and user-friendliness. They are created for creativity, speed, and excellency with the greatest display unit cabinets in Bahrain. Because of this, people in Bahrain consider being the most advanced industrial CNC machines available.

Standing out visibilty

Your brand will have excellent visibility thanks to the Exhibition Stand Contractors in Bahrain that are provided by Master kraft. They are works of art that truly stand out in Bahrain.

Get it right away!

We have some of the most loyal customers in Bahrain as a result of our high standards of ethics and the high quality of our products.

Get original display products in Bahrain from the joinery businesses that are considered to be the best in Bahrain.

2 notes

·

View notes

Text

The Advantages Of Buying Used Woodworking Machinery At Auction

Woodworking machinery is essential for anyone in the woodworking industry, whether you're a hobbyist or a professional craftsman. While purchasing new equipment is always an option, buying used woodworking machinery at auction presents a multitude of advantages. From cost savings to access to a wide range of equipment, here are the key benefits of buying used woodworking machinery at auction:

Cost Savings: Perhaps the most significant advantage of buying used woodworking machinery at auction is the cost savings. Used equipment is typically priced significantly lower than its new counterparts, allowing you to acquire the tools you need at a fraction of the cost. This is particularly beneficial for small woodworking businesses or hobbyists operating on a tight budget, as it enables them to invest in high-quality machinery without breaking the bank.

Access to High-Quality Equipment: Contrary to popular belief, used woodworking machinery sold at auction is often of high quality. Many woodworking businesses upgrade their equipment regularly to stay competitive, meaning the machinery being auctioned off is still in good working condition. By purchasing used equipment at auction, you can access top-of-the-line machinery that may have been out of reach if purchased new.

Variety of Options: Woodworking machinery auctions offer a wide variety of equipment options to choose from. Whether you need table saws, jointers, planers, or CNC routers, you're likely to find a diverse selection of machinery at auction. This variety allows you to explore different brands, models, and features to find the equipment that best suits your specific woodworking needs and preferences.

Quick Acquisition: Unlike purchasing new machinery, which often involves lengthy ordering and delivery processes, buying used woodworking machinery at auction offers a quick acquisition process. Once you've successfully bid on and purchased your equipment, you can typically take possession of it shortly thereafter. This means you can start using your new machinery and completing woodworking projects sooner rather than later, maximizing your productivity and efficiency.

Opportunity for Bargains: Woodworking machinery auctions present the opportunity for bargains. While auctions can be competitive, savvy bidders can often score deals on high-quality equipment that far surpass the savings available through traditional retail channels. With careful planning and strategy, you can secure the machinery you need at prices well below market value, maximizing your return on investment.

Sustainability: Buying used woodworking machinery at auction is also a sustainable choice. By giving pre-owned equipment a second life, you're helping to reduce waste and minimize the environmental impact of manufacturing new machinery. This commitment to sustainability aligns with the values of many woodworking enthusiasts and businesses and provides an additional incentive to participate in machinery auctions.

Flexibility: Auctions offer flexibility in terms of pricing and negotiation. Unlike fixed retail prices, auction prices are determined by bidding, allowing you to potentially acquire machinery at a lower cost than expected. Additionally, auctions may offer opportunities for negotiation, such as bundling multiple items together or arranging for deferred payments, further enhancing the affordability of purchasing used woodworking machinery.

Upgradability: Buying used woodworking machinery at auction provides the opportunity for future upgrades. As your woodworking needs evolve and your budget allows, you can gradually replace or upgrade your equipment with newer models or advanced features. This incremental approach to upgrading your machinery allows you to stay current with technological advancements and improve the efficiency and precision of your woodworking projects over time.

In conclusion, buying used woodworking machinery at auction offers numerous advantages, including cost savings, access to high-quality equipment, a variety of options, quick acquisition, opportunities for bargains, sustainability, flexibility, and upgradability. Whether you're a hobbyist woodworker or a professional craftsman, purchasing used machinery at auction enables you to acquire the tools you need to bring your woodworking projects to life while staying within your budget.

0 notes

Text

Small Size Precision Planetary Reducer, Global Market Size Forecast, Top 16 Players Rank and Market Share

Small Size Precision Planetary Reducer Market Summary

The precision planetary reducer is a transmission structure. It is mainly composed of three parts: planetary wheel, sun gear and inner ring gear. Its simple structure and high transmission efficiency are installed on the servo motor to reduce the speed, increase the torque and accurately locate. It is widely used in CNC machine tools, industrial robots, food machinery, packaging machinery, woodworking engraving machines, printing machinery and other automation equipment.

This report focus on backlash less than 10 arcmin precision planetary reducer (excluding wave, cyclo, etc.) and the reducer size equal to 90 mm or less.

Figure. Small Size Precision Planetary Reducers Product Picture

Source: Secondary Sources and QYResearch, 2024

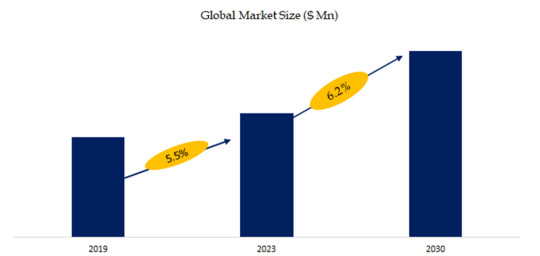

According to the new market research report “Global Small Size Precision Planetary Reducer Market Report 2023-2030”, published by QYResearch, the global Small Size Precision Planetary Reducer market size is projected to reach USD 0.64 billion by 2030, at a CAGR of 6.2% during the forecast period.

Figure. Global Small Size Precision Planetary Reducer Market Size (US$ Million), 2019-2030

Above data is based on report from QYResearch: Global Small Size Precision Planetary Reducer Market Report 2023-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

Figure. Global Small Size Precision Planetary Reducer Top 16 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

Above data is based on report from QYResearch: Global Small Size Precision Planetary Reducer Market Report 2023-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Small Size Precision Planetary Reducer include Nidec, Neugart GmbH, LI-MING Machinery, Wittenstein SE, Rouist, Newstart, KOFON Motion Group, Harmonic Drive Systems, Apex Dynamics, Ningbo ZhongDa Leader, etc. In 2023, the global top five players had a share approximately 54.0% in terms of revenue.

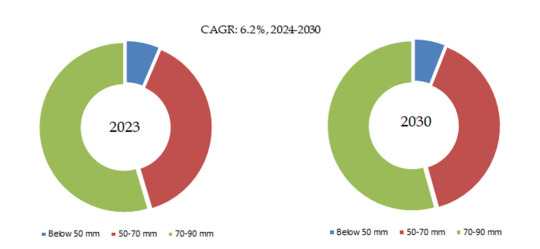

Figure. Small Size Precision Planetary Reducer, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Small Size Precision Planetary Reducer Market Report 2023-2030.

In terms of product type, 70-90 mm frame size is the largest segment, hold a share of 54.6%,

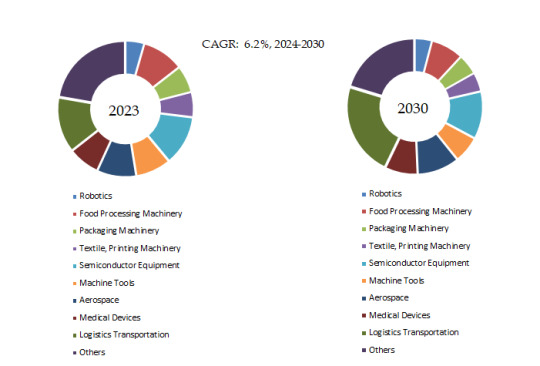

Figure. Small Size Precision Planetary Reducer, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Small Size Precision Planetary Reducer Market Report 2023-2030.

In terms of product application, Logistics Transportation is the largest application, hold a share of 13.3%,

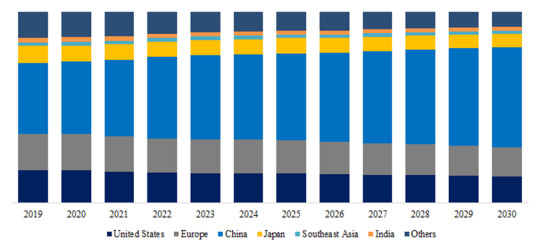

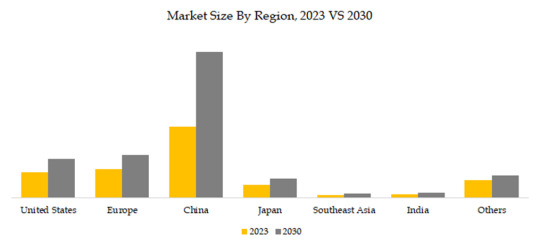

Figure. Small Size Precision Planetary Reducer, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Small Size Precision Planetary Reducer Market Report 2023-2030.

Market Drivers:

D1: Automation and Robotics: The increasing adoption of automation and robotics across various industries, including manufacturing, automotive, and electronics, drives the demand for precision planetary reducers. These reducers play a crucial role in providing accurate and controlled motion in robotic and automated systems.

D2: High Precision and Efficiency: Precision planetary reducers are known for their high precision, efficiency, and torque transmission capabilities. Industries that require precise positioning and motion control, such as semiconductor manufacturing and medical devices, contribute to the demand for these reducers.

D3: Growing Industrial Applications: The expanding applications of precision planetary reducers in diverse industries, including aerospace, defense, and healthcare, contribute to market growth. These reducers are used in critical applications where precise speed control, torque transmission, and compact design are essential.

Restraint:

R1: High Cost: Precision planetary reducers are often associated with a higher cost compared to other types of gear reduction systems. The precision manufacturing processes, high-quality materials, and advanced technologies used in these reducers contribute to their elevated price, which can be a restraint for cost-sensitive industries.

R2: Competitive Pressure: The market for precision planetary reducers can be competitive, with several manufacturers offering similar products. Intense competition can lead to pricing pressures and reduced profit margins for manufacturers, making it challenging to differentiate their products.

R3: Complexity of Design and Assembly: Precision planetary reducers are sophisticated mechanical components with complex designs. The complexity of both the design and assembly processes can pose challenges for manufacturers, potentially leading to increased production costs and longer lead times.

Challenges:

C1: Impact of Economic Downturns: Economic downturns or uncertainties can influence industrial investments. During periods of economic instability, industries may delay or reduce spending on capital equipment, affecting the demand for precision planetary reducers.

C2: Supply Chain Disruptions: Disruptions in the global supply chain, whether caused by natural disasters, geopolitical issues, or other unforeseen events, can impact the availability of raw materials and components required for manufacturing precision planetary reducers.

C3: Customization Demands: Different industries have diverse requirements for precision planetary reducers. Meeting these varied customization demands while maintaining cost-effectiveness and efficient production can be challenging for manufacturers.

About the Authors

Wei Qin

Lead Author

Semiconductor and Electronics

Email: [email protected]

About QYResearch

QYResearch founded in California, USA in 2007. It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Exploring the World of Premium Machine Center Tables

In the realm of manufacturing, precision and efficiency are paramount. The integration of advanced technologies has revolutionized various industries, driving the demand for sophisticated equipment. Among these technological marvels, machine center tables stand out as indispensable tools in modern manufacturing processes. These tables provide a stable platform for intricate machining operations, ensuring accuracy and reliability. In this article, we delve into the world of machine center tables, exploring their features, applications, and the transformative impact they have on the manufacturing landscape.

Unlocking Precision and Efficiency: a Deep Dive into Machine Center Tables

Machine center tables, also known as machining centers or CNC (Computer Numerical Control) machining centers, are versatile pieces of equipment designed for precision machining tasks. They typically consist of a solid base, a worktable, and a spindle housing. The worktable serves as a stable surface for securing the workpiece, while the spindle housing houses the cutting tool or tools. What sets machine center tables apart is their ability to execute a wide range of machining operations with high accuracy and repeatability.

Features and Components:

Solid Construction: Machine center tables are engineered for stability and rigidity, often constructed from robust materials such as cast iron or steel. This ensures minimal vibration during machining, contributing to superior surface finish and dimensional accuracy.High-Precision Spindle: The spindle assembly is a critical component of the machine center table, responsible for rotating the cutting tool at high speeds with utmost precision. Spindles may feature various configurations, including vertical, horizontal, or multi-axis orientations, depending on the specific machining requirements.

Advanced Control Systems: Modern machine center tables are equipped with sophisticated CNC control systems, allowing operators to program complex machining sequences with ease. These systems offer precise control over spindle speed, feed rate, tool path, and other parameters, enabling efficient production of intricate parts.

Tool Changer Mechanism: To enhance productivity and versatility, many machine center tables are equipped with automatic tool changer mechanisms. These systems can swiftly swap out tools during machining operations, minimizing downtime and maximizing throughput.Applications:

The versatility of machine center tables makes them indispensable across a wide range of industries, including aerospace, automotive, medical, and electronics. Some common applications include:Precision Machining: Machine center tables excel at machining complex geometries with tight tolerances, making them ideal for producing critical components such as engine parts, surgical implants, and electronic housings.

Prototyping and Rapid Manufacturing: In industries where time-to-market is crucial, machine center tables facilitate rapid prototyping and short production runs. With their ability to quickly change tooling and adapt to diverse machining tasks, they enable agile manufacturing processes.

Mold and Die Making: Machine center tables are widely used in mold and die making applications, where precision is paramount for achieving the desired surface finish and dimensional accuracy. From injection molds to stamping dies, these tables provide the precision and repeatability necessary for producing high-quality tooling.

Custom Fabrication: Whether it's intricate metalwork or precision woodworking, machine center tables offer the flexibility to fabricate custom parts and components according to specific design requirements. This versatility makes them indispensable for job shops and contract manufacturers catering to diverse industries.Benefits:

The adoption of machine center tables offers numerous benefits for manufacturers seeking to optimize their production processes:Improved Precision: With their high-precision spindle assemblies and advanced control systems, machine center tables deliver unparalleled accuracy, ensuring consistent quality in every machined part.

Enhanced Efficiency: By streamlining machining operations and reducing setup times, machine center tables boost productivity and minimize idle time, ultimately increasing throughput and reducing lead times.

Cost Savings: Despite their initial investment cost, machine center tables offer long-term cost savings through increased productivity, reduced scrap rates, and lower operational costs compared to traditional machining methods.

Versatility and Flexibility: From small-batch production to high-volume manufacturing, machine center tables adapt to diverse production requirements, offering unmatched versatility and flexibility.Conclusion:

Machine center tables represent the pinnacle of precision machining technology, empowering manufacturers to achieve new levels of accuracy, efficiency, and productivity. With their robust construction, advanced features, and broad applicability, these tables have become indispensable assets in modern manufacturing facilities. As industries continue to evolve and demand ever-higher levels of precision and customization, the role of machine center tables will only become more prominent, driving innovation and shaping the future of

manufacturing.Through their transformative capabilities, machine center tables not only revolutionize production processes but also pave the way for new possibilities in design, engineering, and product development. As manufacturers embrace these cutting-edge technologies, they position themselves for success in an increasingly competitive global marketplace, where precision and efficiency are paramount.

0 notes

Text

A Complete Overview of Carbide Machining

The introduction of carbide machining has completely transformed the present-day manufacturing industry, providing outstanding physical properties for machining, fabrication and mass production applications. This article explores the significance of carbide machining, the multifarious applications of it, the various types of carbide materials available in the market such as tungsten carbide, titanium carbide, and silicon carbide to name a few. In addition to this, it digs into the future prospects of carbide machining and innovation of high-performance carbide materials while simultaneously understanding the potential for growth in a wide range of industries.

Importance of Carbide Machining:

Carbide machining plays a significant role in the machining industry due to increased cutting speeds, dimensionally accurate products and exceptional surface finish. In comparison to the conventional high-speed steel tools, carbide tools are extremely durable, have high wear resistance, cost efficient and exhibit great material versatility that has a direct contribution to the productivity of machining applications. This results in increased operational efficiency and increased cost effectiveness for metal cutting and manufacturing operations. Carbide machining is incredibly valuable in the aerospace, automotive, medical device manufacturing industries particularly due to high precision requirements

The aerospace industry relies on carbide machining for the production of complex components from tough materials like titanium alloys. Carbide tools provide the necessary strength and wear resistance to shape intricate parts with tight tolerances. In the automotive sector, carbide machining is essential for precision cutting of engine components and transmission parts. The hardness and durability of carbide tools enable efficient machining of hardened steel used in the oil and gas industry for drilling equipment. In the

medical field, carbide machining ensures the production of surgical instruments and implants with exceptional accuracy, enabling improved patient outcomes.

Applications of Carbide Machining:

Carbide tools find use in metalworking, woodworking, and general machining applications displaying their diverse applications in machining in various industries. In the metalworking industry, carbide inserts are used for operations such as milling and turning on common metals such as steel, stainless steel, and aluminum to cite a few examples.

Carbide machining can also be found in the woodworking industry as well in the form of carbide-tipped saw blades that allow improved tool life and allow for cleaner cuts in hard and soft woods.

The electronics industry employs carbide machining for precision cutting and shaping of semiconductor materials. The excellent thermal conductivity and resistance to high temperatures make silicon carbide makes it ideal for the manufacture of thermally conductive heat sinks and thermal management systems.

Types of Carbide Materials:

There a vast number of carbide materials available in the market for various applications, with tungsten carbide machining being the most commonly used among all. Tungsten carbide is a combination of Tungsten and Carbon at elevated temperature and is an ideal material for cutting tools due to properties such as improved wear resistance, high strength, resistance to corrosion and the ability to tolerate high machining temperatures. As a result of these

characteristics, tungsten carbide inserts are commonly used in metalworking and alloying applications.

Like Tungsten carbide, Titanium carbide also exhibits properties such as hardness thermal stability, making it suitable for applications in the aerospace and defense industries. It is mainly used in the form of a coating on cutting tools to improve thermal and wear resistance resulting in reduced degradation of cutting tools. It also improves the shelf life and contributes positively to the performance of tools and substrates in the long term due to its resistance to oxidation and ability to remain chemically inert.

Silicon carbide is a material with excellent thermal conductivity making it extremely useful in the electronics and ceramic industry. It is commonly used to manufacture semiconductor devices, such as diodes, transistors and other electronic components, due to its ability to dissipate heat effectively and operate at extreme environments without negatively affecting the performance of the tool.

Future Outlook of Carbide Machining:

The future of carbide machining shows encouraging possibilities and prospects as industries constantly aim for increased productivity of the metal cutting process, high precision of the consumer end products, and the overall sustainability of the manufacturing process to contribute to a more environmentally friendly industry due to the increasing demand for sustainable manufacturing practices in the modern-day industry.

Research and development efforts are currently underway to improve the existing performance of carbide tools through innovative coating technologies and improved tool designs to enhance the wear resistance and thermal stability of carbide tools, allowing for higher cutting speeds and improved tool life. In addition to this, with the advent of additive manufacturing in many industries, it is now possible to iteratively design, simulate and test complex tool geometries using techniques such as generative design with the objective of optimizing tool performance. Furthermore, using state of the digital technologies can aid in monitoring the tool wear, improve the cutting parameters with an aim to improve the productivity and reduce cost and manufacturing lead times. These improvements not just expand the existing portfolio of carbide material and the range of cutting techniques but will also open up new machining possibilities for carbide materials and will allow their integration in more industries that require manufacturing operations with extremely hard, corrosion resistant and tough materials in rigorous and challenging environments.

Conclusion:

In conclusion, Carbide machining is a crucial tool in the current industry due to its exceptional properties and wide range of applications across multiple sectors. Tungsten carbide, titanium carbide, and silicon carbide are commonly used materials, each having their distinct properties which allow for their application in highly specialized and selective industries. Considering the future, carbide machining is in a favorable position for advancements in terms of technology and materials while also expecting to see increased demand in multiple industries due to its exceptional material properties while also positively impacting the manufacturing domain in a sustainable manner in areas of energy consumption and reducing material waste which will be a major driver in multiple industries in the manufacturing sphere.

0 notes

Text

Discover The Best Deals On CNC Router Machines In Melbourne

In the bustling city of Melbourne, where innovation thrives and precision is paramount, businesses seek cutting-edge solutions to elevate their production processes. Enter MadBytes, a trusted name renowned for revolutionising the manufacturing industry. With a diverse range of CNC router machines tailored to meet the most demanding requirements, MadBytes offers unparalleled deals that redefine excellence in Melbourne's manufacturing landscape.

Exploring CNC Router Machines in Melbourne:

CNC router machines have emerged as indispensable tools in modern manufacturing, offering unparalleled precision and versatility. Whether it's woodworking, signage, or prototyping, these machines streamline production processes, delivering unmatched efficiency and quality. In Melbourne's competitive market, finding the right CNC router machine is essential for businesses aiming to stay ahead of the curve.

Unmatched Quality at Competitive Prices:

At MadBytes, quality is the cornerstone of our offerings. Each CNC router machine in our inventory is meticulously crafted to meet the highest standards of performance and reliability. From entry-level models to advanced systems, we offer a diverse range of options to cater to every budget and requirement. Our transparent pricing ensures that you get the best value for your investment without compromising on quality.

Tailored Solutions for Every Application:

Recognising that every business has unique needs, MadBytes offers customisable CNC router solutions designed to address specific requirements. Whether you're a small-scale workshop or a large-scale production facility, our expert team works closely with you to understand your needs and recommend the most suitable router machine that aligns with your objectives.

Seamless Integration and Support:

Investing in a CNC router machine is a significant decision for any business. At MadBytes, we understand the importance of seamless integration and ongoing support. Our team of experienced professionals provides comprehensive guidance throughout the purchase process, ensuring that you make an informed decision. Moreover, our reliable after-sales support ensures that your CNC router machine operates smoothly, maximising uptime and productivity.

Unlock unbeatable deals:

MadBytes is committed to empowering businesses in Melbourne with access to the finest CNC router machines at competitive prices. Our exclusive deals and promotions make it easier than ever to upgrade your manufacturing capabilities without breaking the bank. Whether you're looking for a new CNC router machine or considering an upgrade, MadBytes has the perfect solution to suit your needs and budget.

Experience excellence with MadBytes:

Don't let outdated equipment hold your business back. Embrace innovation with MadBytes' premium CNC router machines and elevate your production processes to new heights. Discover the perfect balance of quality, performance, and affordability with MadBytes as your trusted partner. Contact us today to explore our extensive range of CNC router machines and unlock unbeatable deals that propel your business towards success.

Conclusion:

In the competitive landscape of Melbourne's manufacturing industry, staying ahead of the curve is essential for sustainable growth. MadBytes empowers businesses with access to the finest CNC router machines, offering unmatched quality, performance, and support. With our unbeatable deals and tailored solutions, we redefine excellence in CNC router machine sales in Melbourne. Upgrade your manufacturing capabilities today and embark on a journey towards success with MadBytes by your side.

#Flatbed CNC#1KW Laser Cutter#CNC Machine Sale#CNC For Sale#Router For Sale#CNC Mill For Sale#CNC Router Melbourne#CNC Machine Sales

0 notes

Text

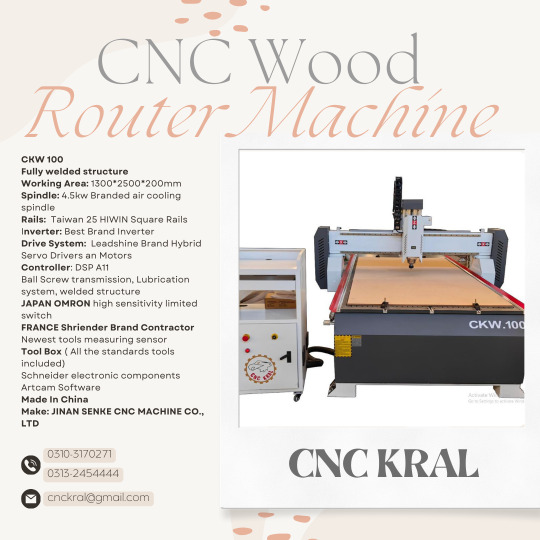

Navigating Precision: The Best CNC Wood Routers and CNC Machines in Pakistan

Introduction:

In the realm of woodworking, precision and efficiency are paramount, driving craftsmen and manufacturers alike to seek the most advanced tools available. In Pakistan, the woodworking industry is experiencing a transformation fueled by the adoption of CNC (Computer Numerical Control) machines. These machines offer unparalleled accuracy, speed, and versatility, revolutionizing the way wood is shaped and crafted. In this article, we'll delve into some of the best CNC wood routers and CNC machines available in Pakistan, catering to the diverse needs of woodworkers across the country.

JFT 1325 CNC Wood Router: The JFT 1325 CNC wood router stands as a testament to precision and reliability. With a robust frame and high-q The JFT 1325 CNC wood router stands as a testament to preciuality components, it offers exceptional stability and accuracy. Its expansive work area of 1300x2500mm provides ample space for a wide range of projects, from intricate carvings to large-scale panels. Equipped with advanced motion control technology and a powerful spindle, the JFT 1325 delivers consistent results with speed and efficiency. Supported by local distributors and service centers, it's a top choice for woodworkers seeking quality and performance in Pakistan.

AXYZ Infinite Series CNC Router: Renowned for its versatility and durability, the AXYZ Infinite Series CNC router is a staple in the woodworking industry. Featuring a rigid steel frame and precision motion control system, it offers unmatched stability and accuracy. Its modular design allows for easy customization to suit specific workflow requirements, making it ideal for both small-scale workshops and large manufacturing facilities. With local technical support and maintenance services available, AXYZ ensures that woodworkers in Pakistan can rely on their machines to deliver exceptional results consistently.

Laguna SmartShop II CNC Router: The Laguna SmartShop II CNC router combines cutting-edge technology with user-friendly features, catering to woodworkers of all skill levels. Its intuitive software and toolpath optimization capabilities streamline the production process, allowing users to maximize efficiency without compromising on quality. With a compact footprint and robust construction, it's suitable for workshops with limited space without sacrificing performance. Whether you're crafting furniture, signage, or intricate designs, the Laguna SmartShop II offers the flexibility and precision to bring your ideas to life with ease.

Haas VF Series CNC Machining Center: For woodworkers venturing into more advanced manufacturing processes, the Haas VF Series CNC machining center is a game-changer. With its rigid construction and high-speed spindle, it's capable of machining a wide range of materials with precision and efficiency. Equipped with advanced features such as tool probing and high-speed machining, it's ideal for complex woodworking projects that demand uncompromising accuracy. Supported by a network of authorized distributors and service centers, Haas ensures that woodworkers in Pakistan have access to comprehensive training and support to maximize the potential of their machines.

Conclusion:

As the woodworking industry in Pakistan continues to evolve, CNC machines have become indispensable tools for achieving precision and efficiency in woodworking projects. From the versatile JFT 1325 and AXYZ Infinite Series CNC routers to the user-friendly Laguna SmartShop II and advanced Haas VF Series CNC machining center, there's a wide range of options available to cater to the diverse needs of woodworkers across the country. With local support and maintenance services readily accessible, these machines empower woodworkers in Pakistan to elevate their craft and thrive in a competitive market.

0 notes

Text

Unlocking Efficiency and Precision: The Benefits of Cutting Machines

In today's fast-paced industrial landscape, efficiency and precision are paramount for businesses striving to stay ahead. One technology that has revolutionized manufacturing processes across various industries is the cutting machine. Whether it's in metal fabrication, woodworking, textile manufacturing, or beyond, cutting machines offer a myriad of benefits that streamline operations and enhance product quality. Let's delve into some of the key advantages:

1. Precision and Accuracy

Cutting machines utilize advanced technology such as computer numerical control (CNC) systems to execute cuts with unparalleled precision. This level of accuracy ensures consistency across multiple pieces, reducing waste and enhancing overall product quality. Whether it's intricate designs or precise measurements, cutting machines deliver results that meet exact specifications with minimal margin for error.

2. Increased Efficiency

Manual cutting processes are not only time-consuming but also prone to human error. Cutting machines automate repetitive tasks, significantly reducing production time and labor costs. With rapid cutting speeds and continuous operation capabilities, businesses can fulfill orders faster and optimize their workflow for maximum efficiency.

3. Versatility and Flexibility

Modern cutting machines are designed to handle a diverse range of materials and thicknesses, from metals and plastics to composites and fabrics. This versatility enables manufacturers to adapt to changing market demands and explore new opportunities without investing in separate equipment for each material type. Furthermore, advanced cutting technologies offer customizable cutting paths, allowing for complex shapes and designs with ease.

4. Waste Reduction

Precision cutting minimizes material waste by optimizing the use of raw materials. Cutting machines can nest components efficiently, maximizing the yield from each sheet or block. Additionally, advanced software can analyze patterns and suggest the most economical cutting layouts, further reducing scrap and optimizing material utilization. This not only saves costs but also aligns with sustainable manufacturing practices by minimizing environmental impact.

5. Improved Safety

Manual cutting processes pose inherent risks to operators, including injuries from sharp tools and repetitive strain. Cutting machines with safety features such as guards, sensors, and automatic shutoff mechanisms mitigate these risks, creating a safer working environment for employees. By minimizing the potential for accidents and injuries, businesses can maintain productivity levels while prioritizing the well-being of their workforce.

6. Scalability and Cost-effectiveness

Investing in cutting machines offers long-term cost savings and scalability for businesses of all sizes. While the initial capital outlay may seem significant, the efficiency gains and reduced operational costs over time deliver a substantial return on investment. Furthermore, as production volumes increase, cutting machines can scale up to meet growing demand without compromising on quality or efficiency. In conclusion, cutting machines represent a transformative technology that empowers businesses to enhance their productivity, quality, and competitiveness in today's dynamic market landscape. From precision engineering to streamlined workflows and reduced waste, the benefits of cutting machines are undeniable. As industries continue to evolve, embracing cutting-edge technologies will be essential for driving innovation and achieving sustainable growth. By leveraging the advantages of cutting machines, businesses can unlock new possibilities and stay ahead of the curve in an increasingly competitive global economy.

0 notes

Text

Navigating the Market A Comprehensive Guide to Used CNC Router Machines for Sale

In the dynamic world of manufacturing and woodworking, CNC router machines have become indispensable tools, offering precision and efficiency in crafting intricate designs. For businesses looking to expand their capabilities or individuals seeking cost-effective solutions, used cnc router machines for sale exploring the market for used CNC router machines is a strategic move. In this guide, we delve into the considerations and opportunities associated with purchasing used CNC router machines for sale.

Cost-Effectiveness:

One of the primary advantages of opting for used CNC router machines is the cost savings. New machines often come with a substantial price tag, making them a significant investment for businesses, especially small enterprises or startups. By exploring the used market, businesses can acquire high-quality CNC routers at a fraction of the cost, allowing for budget-friendly expansion of production capabilities.

Source of Purchase:

When considering used CNC router machines for sale, it's crucial to choose a reputable source. Established machinery dealers, online marketplaces, or industry auctions are common avenues for finding pre-owned CNC routers. Working with reputable sellers ensures transparency in the machine's history, maintenance records, and overall condition.

Inspection and Verification:

Before finalizing any purchase, a thorough inspection of the used CNC router machine is essential. Verify the machine's specifications, including its working area, spindle speed, and control system. Check for signs of wear and tear, assess the condition of critical components, and inquire about any past maintenance or repairs. Request a demonstration, if possible, to witness the machine in action.

Software and Compatibility:

CNC router machines rely heavily on software for programming and operation. Ensure that the used machine's control software is compatible with your existing systems or can be easily integrated. Upgrading or replacing software can be an additional cost, so it's crucial to assess compatibility before making a purchase.

Service and Support:

Investigate the availability of service and support for the specific used CNC router machine you are considering. Some manufacturers provide continued support for their older models, while others may have discontinued certain product lines. Understanding the availability of spare parts and technical assistance ensures a smoother transition and ongoing reliability.

Negotiation and Documentation:

Engage in a thorough negotiation process with the seller to secure the best deal. Request all relevant documentation, including manuals, maintenance records, and any warranties that may still be applicable. Clear communication and a well-documented transaction protect both the buyer and the seller, ensuring a transparent and satisfactory purchase process.

Conclusion:

Exploring the market for used CNC router machines for sale can open up new possibilities for businesses seeking to enhance their manufacturing capabilities without breaking the bank. By considering factors such as cost-effectiveness, the source of purchase, thorough inspection, software compatibility, service and support, and effective negotiation, businesses can make informed decisions and acquire reliable CNC routers that meet their production needs. In the realm of used CNC router machines, strategic choices pave the way for cost-efficient and successful manufacturing ventures.

0 notes

Text

The Latest Innovations in Wood Cutter Machines: What's New in the Market?

Are you someone who works with wood or has a keen interest in woodworking? If so, you're probably familiar with the importance of having a reliable wood cutter machine. Over the years, there have been significant advancements in wood cutter technology, bringing forth new and improved machines to make your woodworking tasks easier and more efficient. In this blog post, we will discuss the latest innovations in wood cutter machine, helping you stay up-to-date with what's new in the market. Let's dive in!

1. CNC Wood Cutter Machines

CNC wood cutter machines have revolutionized the woodworking industry. These machines use computer programming to precisely control the movement of cutting tools, resulting in highly accurate and intricate cuts. CNC wood cutter machines provide superior craftsmanship and virtually eliminate human error, making them a valuable tool for professionals and hobbyists alike.

2. Laser Wood Cutter Machines

Laser wood cutter machines use laser technology to cut through wood with extreme precision. These machines are capable of creating intricate designs and fine details, making them ideal for tasks such as engraving or creating decorative woodwork. Laser wood cutter machines offer speed, accuracy, and versatility, providing woodworkers with endless possibilities for creativity.

3. Portable Wood Cutting Machines

Gone are the days when wood cutting machines were large, bulky, and immobile. The latest innovation in wood cutting technology has introduced portable wood cutting machines. These compact machines are lightweight and easy to carry, allowing woodworkers to take them to different job sites or workshops effortlessly. Portable wood cutting machines offer convenience without compromising on performance, making them a popular choice among professionals who require mobility.

4. Automated Wood Cutter Machines

Automation has become a significant trend in various industries, including woodworking. Automated wood cutter machines utilize advanced robotics and artificial intelligence to perform wood cutting tasks without human intervention. These machines can analyze wood materials, make precise measurements, and execute the cutting process with remarkable speed and accuracy. Automated wood cutter machines are known for their efficiency, consistency, and the ability to handle large-scale projects with ease.

5. Safety Features

Safety is a crucial aspect of any woodworking activity, and wood cutting machines are no exception. The latest wood cutter machines come equipped with advanced safety features to ensure the well-being of the operator. These features may include automatic blade guards, emergency stop buttons, and sensors that detect human presence to prevent accidents. Investing in a wood cutter machine with comprehensive safety features is essential to protect yourself and maintain a secure working environment.

As technology continues to evolve, wood cutter machines are becoming more advanced, efficient, and user-friendly. Whether you're a professional woodworker or a passionate hobbyist, staying updated with the latest innovations in wood cutter machines can greatly enhance your woodworking experience.

By utilizing CNC machines, laser technology, portability, automation, and improved safety features, you can achieve precise cuts, intricate designs, and increased productivity. Embrace the advancements in wood cutter technology and take your woodworking projects to new heights!

0 notes

Link

0 notes

Text

0 notes

Text

The Advantages Of Buying Used Woodworking Machinery At Auction

Woodworking machinery is essential for anyone in the woodworking industry, whether you're a hobbyist or a professional craftsman. While purchasing new equipment is always an option, buying used woodworking machinery at auction presents a multitude of advantages. From cost savings to access to a wide range of equipment, here are the key benefits of buying used woodworking machinery at auction:

Cost Savings: Perhaps the most significant advantage of buying used woodworking machinery at auction is the cost savings. Used equipment is typically priced significantly lower than its new counterparts, allowing you to acquire the tools you need at a fraction of the cost. This is particularly beneficial for small woodworking businesses or hobbyists operating on a tight budget, as it enables them to invest in high-quality machinery without breaking the bank.

Access to High-Quality Equipment: Contrary to popular belief, used woodworking machinery sold at auction is often of high quality. Many woodworking businesses upgrade their equipment regularly to stay competitive, meaning the machinery being auctioned off is still in good working condition. By purchasing used equipment at auction, you can access top-of-the-line machinery that may have been out of reach if purchased new.

Variety of Options: Woodworking machinery auctions offer a wide variety of equipment options to choose from. Whether you need table saws, jointers, planers, or CNC routers, you're likely to find a diverse selection of machinery at auction. This variety allows you to explore different brands, models, and features to find the equipment that best suits your specific woodworking needs and preferences.

Quick Acquisition: Unlike purchasing new machinery, which often involves lengthy ordering and delivery processes, buying used woodworking machinery at auction offers a quick acquisition process. Once you've successfully bid on and purchased your equipment, you can typically take possession of it shortly thereafter. This means you can start using your new machinery and completing woodworking projects sooner rather than later, maximizing your productivity and efficiency.

Opportunity for Bargains: Woodworking machinery auctions present the opportunity for bargains. While auctions can be competitive, savvy bidders can often score deals on high-quality equipment that far surpass the savings available through traditional retail channels. With careful planning and strategy, you can secure the machinery you need at prices well below market value, maximizing your return on investment.

Sustainability: Buying used woodworking machinery at auction is also a sustainable choice. By giving pre-owned equipment a second life, you're helping to reduce waste and minimize the environmental impact of manufacturing new machinery. This commitment to sustainability aligns with the values of many woodworking enthusiasts and businesses and provides an additional incentive to participate in machinery auctions.

Flexibility: Auctions offer flexibility in terms of pricing and negotiation. Unlike fixed retail prices, auction prices are determined by bidding, allowing you to potentially acquire machinery at a lower cost than expected. Additionally, auctions may offer opportunities for negotiation, such as bundling multiple items together or arranging for deferred payments, further enhancing the affordability of purchasing used woodworking machinery.

Upgradability: Buying used woodworking machinery at auction provides the opportunity for future upgrades. As your woodworking needs evolve and your budget allows, you can gradually replace or upgrade your equipment with newer models or advanced features. This incremental approach to upgrading your machinery allows you to stay current with technological advancements and improve the efficiency and precision of your woodworking projects over time.

In conclusion, buying used woodworking machinery at auction offers numerous advantages, including cost savings, access to high-quality equipment, a variety of options, quick acquisition, opportunities for bargains, sustainability, flexibility, and upgradability. Whether you're a hobbyist woodworker or a professional craftsman, purchasing used machinery at auction enables you to acquire the tools you need to bring your woodworking projects to life while staying within your budget.

0 notes

Text

CNC Wood Lathe Machines, Global Market Size Forecast, Top 15 Players Rank and Market Share

CNC Wood Lathe Machines Market Summary

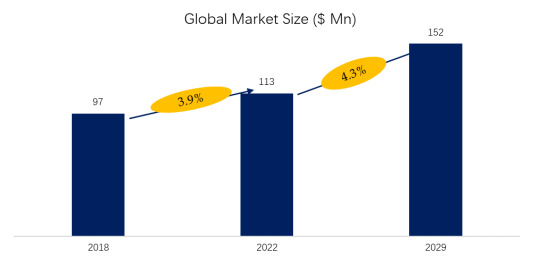

According to the new market research report “Global CNC Wood Lathe Machines Market Report 2023-2029”, published by QYResearch, the global CNC Wood Lathe Machines market size is projected to reach USD 0.15 billion by 2029, at a CAGR of 4.3% during the forecast period.

CNC wood lathe machines are computer numerical control (CNC) machines designed specifically for turning and shaping wooden workpieces. These machines automate the woodturning process, allowing for precise and efficient shaping of wood into various forms, including cylindrical, tapered, and contoured designs. CNC wood lathes are widely used in woodworking industries for creating a variety of wooden components such as furniture legs, balusters, tool handles, and decorative pieces.

Picture from STYLECNC

Figure. Global CNC Wood Lathe Machines Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global CNC Wood Lathe Machines Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

Figure. Global CNC Wood Lathe Machines Top 15 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global CNC Wood Lathe Machines Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

The global key manufacturers of CNC Wood Lathe Machines include Schnitzer, SCM, Intorex, OEMAK Makine, NESTO Makina, Dincmak Machine, Boarke, Jinan Style Machinery, BINZHOU COSEN CNC EQUIPMENT TECHNOLOGY, Shandong Guandiao CNC Equipment, etc. In 2022, the global top five players had a share approximately 59.0% in terms of revenue.

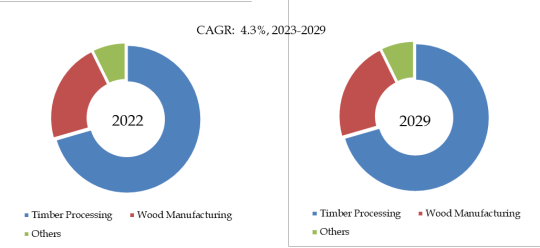

Figure. CNC Wood Lathe Machines, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global CNC Wood Lathe Machines Market Report 2023-2029.

In terms of product type, currently 4 Axis is the largest segment, hold a share of 59.7%.

Figure. CNC Wood Lathe Machines, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global CNC Wood Lathe Machines Market Report 2023-2029.

In terms of product application, currently Timber Processing is the largest segment, hold a share of 70.5%.

Market Drivers:

Automation and Precision: The demand for automation in woodworking processes is a significant driver. CNC wood lathe machines offer precise and automated woodturning capabilities, reducing manual labor and ensuring consistent quality in finished products.

Customization and Design Flexibility: The ability of CNC wood lathes to produce intricate and customized designs is driving their adoption. Woodworkers and manufacturers can easily program these machines to create unique and complex woodturned components, meeting the demand for bespoke woodworking products.

Increased Productivity and Efficiency: CNC wood lathes contribute to increased productivity by automating the woodturning process. These machines can operate continuously with minimal downtime, resulting in higher production rates and overall efficiency in woodworking operations.

Restraint:

High Initial Investment: The upfront cost of purchasing and installing CNC wood lathe machines can be relatively high. This initial investment may be a barrier for small woodworking businesses or individual craftsmen, limiting their ability to adopt this technology.

Technical Expertise Requirement: Operating CNC wood lathe machines requires a certain level of technical expertise in CNC programming and machine operation. Some woodworking professionals may face a learning curve or find it challenging to acquire the necessary skills for programming and troubleshooting.

Maintenance and Repairs: CNC machines, including wood lathes, require regular maintenance to ensure optimal performance. In case of breakdowns or malfunctions, repairs may be complex and may involve specialized technicians, leading to downtime and potential production delays.

Opportunity:

Educational and Training Programs: The demand for educational programs and training initiatives focused on CNC wood lathe operation and programming presents an opportunity. Institutions and industry stakeholders can collaborate to provide training courses, workshops, and certifications to enhance the skills of woodworkers.

Affordable and Compact Models: Manufacturers have the opportunity to develop more affordable and compact CNC wood lathe models, making this technology accessible to a broader range of woodworking professionals. Compact models can cater to smaller workshops with limited space.

Integration of Smart Technologies: Integrating smart technologies, such as IoT (Internet of Things) capabilities and data analytics, into CNC wood lathe machines can provide opportunities for enhanced monitoring, maintenance prediction, and overall operational efficiency. These features can contribute to a more connected and intelligent manufacturing environment.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Band Saws in Slovakia

A band saw is a type of metal cutting machine that has a rotating blade with teeth on one edge. This tool is used primarily to cut curves in stock, but it can also be used to make custom cuts for production work. It is typically operated by hand, although some models allow for automated feeds. There are many different types of band saws available, including gravity-feed, semi-automatic, and automatic cutters. Some types are more suitable for industrial applications, while others are designed for home use. Check their site to know more details pásové píly.

In the world of woodworking, a band saw is one of the most versatile and powerful tools a woodworker can have. Whether you are looking to make precise curves or angled cuts, a quality band saw can help you get the job done with little effort. However, if you’re new to using this tool, there are many factors to consider before making your purchase. First, determine what you will be cutting on your saw to better choose the right model for your needs.

The type of wood you’ll be cutting will also influence your choice of a band saw, as some have a larger throat capacity than others to accommodate a wider range of blade widths. The type of work you’ll be doing will also play a role in how much power you’ll need from your band saw, as some have a more powerful motor that can handle bigger loads.

You’ll also need to take into account the price and features of the saw you’re considering. Some models have extras such as a LED work light or adjustable front handle to reduce fatigue during long woodcutting sessions, while others have dust ports and miter gauges to streamline your work. Lastly, you’ll want to consider the construction of your band saw, with some models being made from aluminum die-cast and others from cast iron.

The Cosen brand is one of the world's leading manufacturers of metal cutting machinery, offering more than 140 models of vertical, horizontal, miter-cutting, NC & CNC automatic and customized band saws. The company is based in the Czech Republic and employs more than 150 people. Its machines are used around the globe, with customers ranging from small metal shops to multinational corporations. Cosen offers a wide range of saws for different industries, with capacities from 200 to 3200 mm. The company's products are known for their high efficiency, accuracy, and reliability.

MILWAUKEE is a global leader in cordless power tools, and the band saw category is no exception. The M18 FUEL(tm) Deep Cut and Compact Dual-Trigger Band Saws provide the fastest cutting speed, largest capacity, and highest durability in their class. Both saws feature MILWAUKEE's innovative battery technology and the new Industry 4.0 Sawing Performance & Health Prognosis app.

Slovakia is a small central European nation that shook off decades of Soviet domination in 1993. The country has largely supported Ukraine since Russia invaded the neighboring country more than 18 months ago, with Slovakia the second NATO member to agree to give its fleet of Soviet-era MiG fighter jets to Kyiv. But the support has eroded public trust in liberal democracy and Western organizations.

The country's early parliamentary elections on Sept. 30 are expected to yield a victory for populist former Prime Minister Robert Fico, who has campaigned on a hardline anti-Russia message. Fico will have the opportunity to reverse Slovakia's military and political support for Ukraine if he returns to power. Michalovce is located near the border with Ukraine and serves as a key checkpoint for both migrants and freight. It has been a point of friction between Ukraine and the EU, with Ukrainian grain undercutting local markets.

1 note

·

View note