#Softwall cleanroom

Text

Revolutionize Cleanroom Technology with Softwall Cleanrooms by Ezad Cleanroom

In the ever-evolving landscape of scientific and industrial advancements, the demand for cleanroom technology is more critical than ever. Cleanrooms are specialized environments designed to maintain a controlled level of contamination, making them indispensable in a wide range of industries, including pharmaceuticals, biotechnology, electronics, and aerospace. Ezad Cleanroom offers a breakthrough solution that has been making waves in the cleanroom industry - Softwall Cleanrooms. In this comprehensive guide, we'll explore the innovative features, benefits, and applications of Softwall Cleanrooms, highlighting how they can revolutionize your cleanroom requirements.

Understanding Softwall Cleanrooms

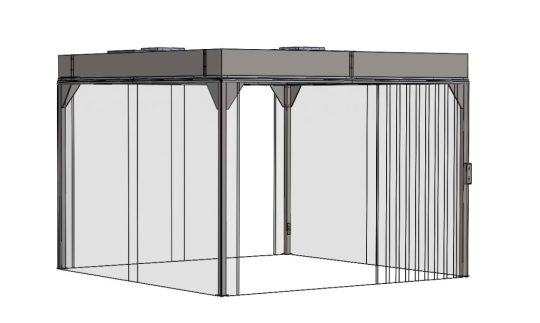

Softwall Cleanrooms are a cutting-edge cleanroom solution designed to provide a controlled environment for sensitive processes and research. Unlike traditional hardwall cleanrooms, they feature flexible, soft-sided walls made of durable materials such as PVC or vinyl. These soft walls are supported by a sturdy frame, which can be assembled to fit the required size and configuration of the cleanroom. The flexibility of Softwall Cleanrooms is a game-changer for businesses and industries seeking a cost-effective and adaptable solution for maintaining critical cleanliness standards.

Advantages of Softwall Cleanrooms

Cost-Efficiency: One of the most prominent advantages of Softwall Cleanrooms is their cost-efficiency. Traditional hardwall cleanrooms can be expensive to construct and maintain due to their rigid structures. Softwall Cleanrooms, on the other hand, offer a more budget-friendly alternative without compromising on cleanliness standards.

Flexibility and Customization: Softwall Cleanrooms can be tailored to fit your specific needs. The soft walls can be easily adjusted or reconfigured, making it possible to modify the cleanroom layout as your requirements change. This adaptability is ideal for businesses dealing with evolving processes and research.

Quick Installation: The installation of Softwall Cleanrooms is significantly faster compared to hardwall cleanrooms. This saves valuable time and minimizes disruptions to your operations.

Mobility: If your business requires cleanroom facilities in multiple locations or if you need to relocate your cleanroom, Softwall Cleanrooms are easily disassembled and reassembled, providing a high level of mobility.

Energy Efficiency: Softwall Cleanrooms are designed to maintain optimal environmental conditions while minimizing energy consumption. This not only reduces operational costs but also supports sustainable practices.

Cleanliness Standards: Softwall Cleanrooms are engineered to meet stringent cleanliness standards. They can effectively control particle contamination and offer ISO class options to suit various applications.

Applications of Softwall Cleanrooms

The versatility of Softwall Cleanrooms makes them suitable for a wide range of applications. Some common industries and uses include:

Pharmaceuticals: Softwall Cleanrooms are essential in pharmaceutical manufacturing to maintain sterility and prevent contamination during drug production, packaging, and research.

Biotechnology: Research and development in biotechnology require controlled environments to ensure the integrity of experiments and production processes.

Electronics: The electronics industry relies on cleanroom technology to safeguard sensitive components and ensure the quality of microelectronics manufacturing.

Aerospace: In aerospace, Softwall Cleanrooms are used for the assembly and maintenance of aerospace equipment, where precision and cleanliness are paramount.

Food and Beverage: The food and beverage industry benefits from Softwall Cleanrooms for aseptic processing, packaging, and quality control.

Medical Devices: Manufacturers of medical devices use cleanrooms to create sterile and safe products for healthcare applications.

Research and Development: Softwall Cleanrooms are essential for research facilities working on cutting-edge projects, where maintaining a controlled environment is critical.

Key Considerations for Choosing Softwall Cleanrooms

When considering the adoption of Softwall Cleanrooms, there are several crucial factors to take into account:

Cleanliness Requirements: Determine the level of cleanliness needed for your operations. Softwall Cleanrooms are available in various ISO class options, allowing you to select the one that aligns with your specific standards.

Space and Layout: Assess the available space and how you plan to configure your cleanroom. The flexibility of Softwall Cleanrooms makes them adaptable to different layouts.

Environmental Control: Consider the temperature, humidity, and other environmental factors that need to be controlled within the cleanroom. Softwall Cleanrooms can be equipped with HVAC systems to meet these requirements.

Compliance and Regulations: Ensure that your Softwall Cleanroom complies with industry-specific regulations and standards. Ezad Cleanroom can assist in designing and constructing cleanrooms that meet these requirements.

Future Expansion: Plan for future expansion or reconfiguration. Softwall Cleanrooms can be easily expanded or modified to accommodate changes in your operations.

Why Choose Ezad Cleanroom for Softwall Cleanrooms

Ezad Cleanroom has established itself as a trusted provider of cleanroom solutions, including Softwall Cleanrooms. Here's why you should choose Ezad Cleanroom:

Expertise: With years of experience in the cleanroom industry, Ezad Cleanroom has a team of experts who understand the unique requirements of different industries.

Customization: Ezad Cleanroom works closely with clients to design and build Softwall Cleanrooms that align with their specific needs and cleanliness standards.

Quality Materials: We use top-quality materials for our Softwall Cleanrooms, ensuring durability and longevity.

Compliance and Certifications: Our cleanrooms are designed to meet industry regulations and certifications, providing peace of mind for our clients.

Support and Maintenance: Ezad Cleanroom offers ongoing support and maintenance services to ensure the long-term performance of your Softwall Cleanroom.

Conclusion

In a rapidly advancing world, maintaining stringent cleanliness standards is essential for various industries. Softwall Cleanrooms by Ezad Cleanroom provide an innovative and cost-effective solution that can adapt to the changing needs of your business while upholding the highest standards of cleanliness. Whether you're in pharmaceuticals, biotechnology, electronics, aerospace, or any other industry that requires a controlled environment, Softwall Cleanrooms are the future of cleanroom technology.

Ready to Upgrade Your Cleanroom? Contact Ezad Cleanroom Today!

Don't miss out on the benefits of Softwall Cleanrooms. Contact US Ezad Cleanroom today to discuss your specific cleanroom requirements, and let us help you revolutionize your cleanroom technology. Our team of experts is ready to provide you with a customized solution that meets your unique needs and exceeds your cleanliness standards. Upgrade your cleanroom with Softwall Cleanrooms by Ezad Cleanroom and experience the difference. Contact us now for a consultation and quote!

Original Sources: https://ezadcleanrooms.blogspot.com/2023/10/revolutionize-cleanroom-technology-with.html

0 notes

Text

Discover the Cutting-Edge Advantages of Cleatech's Softwall Cleanrooms

In the realm of modern scientific and industrial advancements, precision and cleanliness are paramount. Contaminants, even those invisible to the naked eye, can spell disaster for sensitive operations, whether in electronics manufacturing, pharmaceuticals, or research laboratories. It's in this context that Cleatech, LLC, introduces its innovative Softwall Cleanrooms – a state-of-the-art solution that offers a controlled environment where cleanliness, precision, and adaptability converge.

Understanding Softwall Cleanrooms

Cleanrooms are specialized spaces designed to control and maintain low levels of airborne particles, such as dust, microbes, and aerosol particles. These controlled environments are critical in industries where even the smallest particle can disrupt processes, compromise product quality, or jeopardize research results.

Cleatech's Softwall Cleanrooms are a testament to the company's commitment to providing high-quality, flexible, and cost-effective cleanroom solutions. These modular cleanrooms are characterized by their structure, which consists of lightweight, flexible curtains or softwalls, making them an excellent choice for various industries. Let's explore the unique advantages of Cleatech's Softwall Cleanrooms.

Enhanced Contaminant Control

The primary function of a cleanroom is to control contaminants, and Cleatech's Softwall Cleanrooms excel in this regard. The softwalls are made from durable, antistatic, and non-outgassing vinyl material that effectively isolates the cleanroom environment from the surrounding space. This isolation ensures that particles, microbes, and other contaminants are kept at bay, providing the ideal environment for sensitive processes.

Modularity and Customizability

One of the standout features of Cleatech's Softwall Cleanrooms is their modular and customizable design. They can be easily installed, modified, or expanded to meet the specific requirements of a wide range of industries. Whether you need a small cleanroom for a laboratory or a larger setup for a manufacturing facility, Cleatech's Softwall Cleanrooms can be tailored to your needs.

Energy Efficiency

In addition to their adaptable design, these cleanrooms are energy-efficient. Cleatech has incorporated energy-saving features into the Softwall Cleanrooms, such as LED lighting and low-noise, high-efficiency fans. This not only reduces operational costs but also minimizes the impact on the environment.

Compliance with Industry Standards

Cleatech's Softwall Cleanrooms are designed and manufactured to meet and exceed industry standards for cleanliness and safety. They comply with ISO 14644-1 standards for air cleanliness, ensuring that your cleanroom will maintain the necessary air quality for your specific application.

Positive Pressure and Airflow Control

Maintaining the right pressure within a cleanroom is crucial for preventing contaminants from entering. Cleatech's Softwall Cleanrooms offer positive pressure environments that help keep particles out, safeguarding sensitive processes.

Airflow control is another essential factor, ensuring that contaminants are swiftly removed from the environment. Cleatech's cleanrooms are equipped with efficient HEPA or ULPA filtration systems that guarantee optimal airflow and particle removal.

Versatile Applications

Cleatech's Softwall Cleanrooms find applications in a diverse array of industries, including:

Electronics Manufacturing: For microelectronics and semiconductor manufacturing, where even a speck of dust can lead to defects.

Pharmaceutical and Biotechnology: Ideal for research, production, and packaging processes in the pharmaceutical and biotechnology sectors.

Aerospace: In the aerospace industry, cleanrooms are vital for ensuring the reliability of sensitive equipment and instruments.

Food and Beverage: Maintaining cleanliness in food processing and packaging to ensure product safety.

Research Laboratories: For scientific experiments and research that require a controlled environment.

Cost-Effective Solutions

Cleatech's Softwall Cleanrooms offer an economical solution for those seeking cleanroom environments without the high costs typically associated with traditional hard-wall cleanrooms. Their modular design, energy efficiency, and easy maintenance contribute to long-term cost savings.

Compliance with Safety Regulations

Safety is non-negotiable in cleanroom environments. Cleatech's Softwall Cleanrooms adhere to strict safety standards to protect personnel and ensure safe working conditions.

Quick Installation and Minimal Downtime

Time is often a critical factor in setting up a cleanroom. Cleatech's Softwall Cleanrooms can be installed relatively quickly, minimizing downtime for your operations. This is particularly important for industries where time-sensitive processes are involved.

Maintenance and Support

Cleatech doesn't just provide state-of-the-art Softwall Cleanrooms; they also offer comprehensive maintenance and support services. This includes regular inspections, maintenance, and any necessary repairs, ensuring that your cleanroom continues to perform at its best.

Take the Next Step Toward Precision and Cleanliness

Cleatech's Softwall Cleanrooms offer a dynamic solution for various industries that require controlled environments. Whether you're involved in electronics manufacturing, pharmaceuticals, or research, the advantages are clear: enhanced contaminant control, modularity, energy efficiency, compliance with industry standards, positive pressure, versatile applications, cost-effectiveness, safety compliance, quick installation, and dependable maintenance support.

It's time to take the next step toward precision, cleanliness, and quality in your operations. Cleatech's Softwall Cleanrooms are the answer you've been looking for. To learn more about how Cleatech can tailor a Softwall Cleanroom to your specific needs, or to request a quote, get in touch with our team of experts today.

Take the leap to cleaner, more precise processes. Contact Cleatech LLC, and experience the difference of Softwall Cleanrooms. Your success begins with our expertise.

Original Sources: https://laboratoryquipment.blogspot.com/2023/10/discover-cutting-edge-advantages-of.html

0 notes

Text

Softwall Cleanroom Solutions by Modular Cleanroom India

In today's fast-paced technological landscape, maintaining a controlled environment is crucial for various industries, including pharmaceuticals, biotechnology, electronics, and healthcare. One of the most effective solutions for creating and maintaining such environments is the use of softwall cleanrooms. Modular Cleanroom India, a leading provider in this domain, offers state-of-the-art softwall cleanroom solutions designed to meet the rigorous demands of these industries.

What is a Softwall Cleanroom?

A softwall cleanroom is a type of cleanroom characterized by flexible, soft walls made from clear vinyl or other transparent materials. These walls are typically suspended from a ceiling structure, allowing for easy installation and reconfiguration. The primary purpose of a softwall cleanroom is to provide a controlled environment with a specific level of air cleanliness, defined by the concentration of airborne particles.

Key Features of Softwall Cleanrooms

Modularity: Softwall cleanrooms are highly modular, allowing for easy expansion or reconfiguration as operational needs change. This flexibility makes them an ideal choice for dynamic industries that require frequent updates to their cleanroom environments.

Cost-Effective: Compared to traditional hardwall cleanrooms, softwall cleanrooms are more affordable, making them accessible to a broader range of businesses. The cost savings come from both the materials used and the simplified installation process.

Quick Installation: The installation of softwall cleanrooms is faster and less disruptive than that of traditional cleanrooms. This ensures minimal downtime and allows businesses to maintain productivity.

Ease of Maintenance: The materials used in softwall cleanrooms are easy to clean and maintain, ensuring that the environment remains compliant with industry standards.

Versatility: Softwall cleanrooms can be used in a variety of applications, from sensitive manufacturing processes to medical laboratories and research facilities. Their adaptability makes them suitable for different cleanroom classifications, from ISO Class 9 to ISO Class 5.

Why Choose Modular Cleanroom India?

Modular Cleanroom India (modularcleanroomindia.com) stands out as a premier provider of softwall cleanroom solutions. Here’s why:

Expertise and Experience: With years of experience in the cleanroom industry, Modular Cleanroom India has the expertise to design and deliver cleanroom solutions that meet the highest standards of performance and reliability.

Custom Solutions: Recognizing that each client's needs are unique, Modular Cleanroom India offers customized softwall cleanroom solutions tailored to specific requirements. From design to installation, the company ensures that every detail aligns with the client's operational needs.

Quality Materials: Only the highest quality materials are used in the construction of Modular Cleanroom India's softwall cleanrooms. This ensures durability, longevity, and compliance with stringent industry standards.

Comprehensive Support: Modular Cleanroom India provides end-to-end support, from initial consultation and design to installation and ongoing maintenance. Their dedicated team is committed to ensuring customer satisfaction at every stage of the process.

Innovative Solutions: Staying ahead of industry trends, Modular Cleanroom India continually innovates to provide cutting-edge cleanroom solutions. This commitment to innovation ensures that their clients benefit from the latest advancements in cleanroom technology.

Applications of Softwall Cleanrooms

Softwall cleanrooms by Modular Cleanroom India are ideal for a wide range of applications, including:

Pharmaceutical Manufacturing: Ensuring a contaminant-free environment for the production of drugs and medical devices.

Biotechnology: Providing a controlled atmosphere for sensitive biological research and production.

Electronics: Protecting electronic components from particulate contamination during manufacturing.

Healthcare: Creating sterile environments for medical procedures and research.

Conclusion

For industries that require a controlled, clean environment, softwall cleanrooms are an excellent solution. Modular Cleanroom India, with its expertise, high-quality materials, and customer-centric approach, offers some of the best softwall cleanroom solutions available. To learn more about their offerings and to explore how they can help meet your cleanroom needs, visit their website at modularcleanroomindia.com.

Invest in a softwall cleanroom from Modular Cleanroom India and ensure the highest standards of cleanliness and control in your operations.

1 note

·

View note

Text

0 notes

Text

Secrets Unveiled: How to Choose the Right Cleanroom Wall Material Every Time

A cleanroom world is an environment so neat, controlled, and clear that even a grain of dust can be a nuisance to its operation. This is an environment free from contaminants. From life-saving pharmaceuticals to high-tech electronics and many more, one can say that uncountable industries around the globe depend on cleanrooms to make sure of maintained product quality sterility.

But have you ever stopped to think: the walls, quiet guards of all the cleanroom? Would you believe or not, it is such a decision about the right material for cleanroom walls that is very crucial and may possibly determine what takes place in your operations? Properly, the walls would not only control but also maintain sterility too certain, as would ensure optimization of efficiency. Well, the next time you consider building a cleanroom, never underestimate the power of your walls!

Why is Choosing the Right Cleanroom Wall Material Important?

Walls inside a cleanroom do more than simply divide the space; they protect the controlled environment and play a major role. Here is where it becomes really important to choose the right material:

Control of Contamination: Even just a single particle may cause turmoil in a cleanroom. The ideal wall material will minimise the possibility of harbouring impurities that might jeopardise your product by being smooth, non-shedding, and easily cleaned.

Durability and Impact Resistant: The wall of the cleanroom shall be such that it can be durable enough for bearing day-to-day operation. Generally, they resist impacts from bumps, scrapes, and dents which create crevices wherein contaminants could hide. Select a durable material that can withstand everyday wear and tear.

Airtightness: Cleanroom integrity requires maintaining a positive pressure environment. This will help the cleanroom prevent unfiltered air in the workspace. To ensure this consistency of air pressure, the material for your wall should almost form a perfect barrier.

Fire Safety: One of the main features of Cleanroom safety. Fire-resistant wall material is a must, which helps hold back fire accidents and saves personnel and equipment during the occurrence of fire.

Common Cleanroom Wall Material Options

Now that we understand the critical factors to consider, let's explore the most common cleanroom wall material options:

Hardwall Systems:

These permanent, stiff wall solutions are incredibly durable and hygienic. They are perfect for situations that need to be cleaned and decontaminated often, such as high-traffic cleanrooms.

Metal Wall Panels:

Stainless Steel: Among all materials used in cleanrooms, stainless steel represents the ultimate standard, epitomizing unbeatable endurance, high resistance to impact, and incredible ease of cleanability. It's perfect for environments that have to be really sterile and against corrosion-resistant surroundings. But then again, it would be rather looked at as quite an investment, a very big one at that.

Aluminium: It is cost-effective compared to stainless steel. Its durability and cleanability are good. Lightweight: hence, easy to work around tight requirements in cleanrooms. Remember, relatively, aluminium is softer than stainless, which can dent easily.

Rigid Plastic Wall Panels:

High-Pressure Laminate (HPL): It is smooth and non-porous, hence preventing fallout of particles and facilitating easy decontamination. Comes in various colours and has good resistance to either moisture or chemicals. The disadvantage is that HPL might be less resistant to impact compared to metals.

Polyvinyl Chloride (PVC) and High-Density Polyethylene (HDPE): These are low-cost plastics with good resistance to chemical and light materials. PVC performs very well in cleanrooms with applications that are not so demanding but tend to get scratched and are not suitable in environments with high temperatures.

Softwall Systems:

The softwall systems are more flexible and relatively inexpensive compared to the hardwall systems. Materials for these systems could be vinyl or fabric, which makes them easy to install and reconfigure compared to the hardwalls. They offer less durability and cleanability benefits.

Vinyl Wall Coverings: Vinyl gives easily cleanable, smooth surfaces and requires easy cleaning and maintaining. Comes in a variety of colours and may be considered for temporary cleanrooms and for low-traffic areas. However, vinyl can be susceptible to punctures and tears and may not be suitable for harsh chemical environments.

Fabric Wall Panels: These types of walls are constructed with the use of polyester or nylon and are highly commonly employed with hardwall systems. They are light in weight, very easy to hang, and therefore are usually applied for either temporary cleanroom walls or for cleanroom additions. On the other hand, fabric walls may be kind of difficult to clean and decontaminate compared to other options; therefore, they might not be worthy of aseptic environments.

Additional Considerations for Specific Cleanroom Applications

However, this cleanroom wall material provides a strong beginning, and the space has to call for further considerations to best meet the specified needs of some applications. Some of the most important are presented below:

Understand Harsh Chemicals:

Some cleanroom environments require product processes with harsh chemicals. In such environments, some materials of the wall would react to the chemicals, leading to cracks, discolouration, or even corrosion damage. The choice of wall material resistant to particular chemicals used in your cleanroom is paramount for the good condition and longevity of the wall, as well as the avoidance of any risks relating to contamination because of damage to the walls. For example, you may decide that using standard vinyl wall coverings is a better alternative than using some of the more modern wall and counter coverings, such as epoxy paint or high-pressure laminate (HPL), if you are working with very strong acids or bases.

Electrostatic Discharge (ESD) Control:

Electrostatic discharge, simply abbreviated to ESD, refers to very fast electric discharge between two objects. Such discharges can, therefore, be injurious to tiny parts in a cleanroom that processes sensitive electronics. In connection with this, there are ESD-wall options capable of static dissipation. Many such materials have a conductive element or treated surfaces. For example, some manufacturers even offer conductive vinyl or laminates specifically designed for use in ESD-controlled environments.

Lighting and Visibility:

Appropriate lighting is relevant to the running of cleanroom operations because it makes the personnel capable of accurate task accomplishment. The right wall material can have a significant effect on the general illumination within the room. Lighter walls, of cooler colours with a smooth reflective finish, will improve light distribution and reduce the number of additional fixtures required. This in turn not only increases energy efficiency within the space but also reduces potential shadows that can inhibit visibility during critical procedures.

0 notes

Text

#Cleanroom Technology Market Competitive Landscape: Major Players#Competitor Market Shares#And Player Strategies - By The IMIR Market Research

0 notes

Text

"

NA & EU Glove Liners Market Size, Trends and Growth opportunity, By Type (Sterile, Non-Sterile), By Material Type (Latex, Nylon, Polyester, Wool, Cotton, Others), By End User (Medical & Healthcare (Hospitals & Clinics, Ambulatory and Surgical Centers), Cleanroom Industry (Standard/Drywall Cleanrooms, Hardwall Cleanrooms, Softwall Cleanrooms), Pharmaceutical (Contract research and manufacturing services (CRAMS), Active pharmaceutical ingredients (APIs), Formulations, Biologics and biosimilars, Vaccines), Others (Academic and Research institutes, Electronics and Manufacturing)), Regional Outlook, Competitive Market Share & Forecast, 2023 – 2030.

NA & EU Glove Liners Market

The NA & EU Glove Liners Market was valued at USD 11,656.22 million in 2022 and is expected to reach USD 32,941 million by 2030 at a CAGR of 12.47% from 2023-2030.

Glove liners are thin work gloves which are usually worn inside other mitts and gloves to provide an extra layer of protection, absorb sweat, and increase warmth. Liner glove works the same way as any insulation. Liners trap body heat and help one maintain warmth. The body heat warms the air, and this warm air gets trapped between the fibres of the liner, so the temperature of hand will be warmer by a few degrees.

Request Sample Link: https://analyticalmr.com/request-sample/NA-EU-Glove-Liners-Market/request-sample

Market Drivers

The manufacturing, automotive, chemical, and electronics industries are all sizable in both the US and the EU. These professions frequently entail using equipment, chemicals, or sharp objects, all of which put workers' hands at risk. Glove liners with cut-resistant or chemical resistance provide an additional layer of protection, lowering the risk of injuries and boosting their use in these industries. Glove liners are being used more frequently in the healthcare sector to shield workers from contact with germs and other pollutants. Glove liners are projected to become more popular as the healthcare sector expands.

Personal protection equipment (PPE) is required under strict safety standards in many areas, including manufacturing, construction, healthcare, and oil and gas, in both the NA and the EU. To improve comfort and hygiene, glove liners are frequently used as an additional layer of protection underneath gloves. Glove liners are frequently in demand because of the execution of these requirements. Glove liners are essential for providing insulation and warmth in areas with cold weather, such as parts of the EU and NA. Glove liners are essential for protecting workers' hands from cold temperatures in sectors including outdoor construction, logistics and transportation. The demand for glove liners is further fuelled in these areas by leisure pursuits including skiing, snowboarding, and mountaineering.

Explore more information here: https://analyticalmr.com/reports-details/NA-EU-Glove-Liners-Market

Market Restraints

The usage of materials and chemicals in gloves is governed by strict laws in the NA and EU. When it comes to choosing materials, following manufacturing procedures, and fulfilling performance standards, compliance with these laws can be difficult for glove lining makers. Recent increases in the price of raw materials like latex and nitrile have put strain on glove liner producers' capacity to remain profitable. Additionally, there may be fierce pricing rivalry in the market, which puts downward pressure on the profit margins for glove liner makers. Customers that are price-sensitive could choose cost over quality, making it difficult for businesses to keep their profits high.

The glove lining market in North America and Europe may be comparatively developed and saturated. It is vital for businesses to differentiate themselves through product innovation and high quality because this saturation may limit the growth potential for both new entrants and established firms. Glove liners can be replaced with a variety of products on the market, including disposable gloves or speciality gloves with built-in liners. These alternatives could have distinct advantages in some applications, which would be difficult for typical glove liners to develop around. The glove lining market may be impacted by rising environmental consciousness and laws governing sustainability and waste management. Creating environmentally friendly products, managing trash, and achieving sustainability goals may provide obstacles for businesses.

Impact Of COVID-19 On Market

The COVID-19 pandemic has raised demand for PPE, including glove liners. Gloves have been mandated for healthcare professionals and other vital employees to protect them from the infection. Glove liners, which are utilised to give a cosier and tighter fit, are becoming more and more popular because of this. Governments and regulatory agencies established stronger safety laws and guidelines in reaction to the pandemic. The usage of PPE, particularly glove liners, was emphasized by these laws across a range of industries. Glove liners are increasingly in demand because of the necessity for businesses to comply with these rules.

During the pandemic, there was a rise in both awareness of and demand for glove liners, which sparked industry growth and innovation. Manufacturers concentrated on creating modern glove liners that were more breathable, comfortable, and had antibacterial qualities. To address the changing needs of end consumers, the market saw the introduction of new materials and technologies. The global supply chain for glove liners was disrupted by lockdowns, travel restrictions, and diminished manufacturing capacities. These interruptions resulted in manufacturing delays, raw material shortages, and difficulties obtaining critical components, affecting the availability of glove liners in the North American and European markets.

Impact of Russia-Ukraine Conflict on NA & EU Glove Liners Market

Nitrile, a crucial substance used in glove liners, is produced in large quantities in Russia and Ukraine. Prices have increased because of the fighting and supply chain disruptions. As a result, there is a decline in demand for glove liners in the NA and EU. A few businesses have moved their nitrile sourcing from Russia and Ukraine to other nations, such China, because of the unrest. As a result, lead times have gotten longer, and prices have gone up. Latex and neoprene are two materials that some businesses are looking to replace nitrile with. This is since nitrile is a petroleum-based commodity, and the conflict has raised questions about the availability of petroleum-based goods.

Trade routes between Russia and Ukraine can be hampered by heightened tensions. This can affect the timely delivery of glove liners to the NA and EU markets by changing the transportation and logistics networks. It might be necessary to construct alternate trade channels, which would increase expenses and possibly cause delays. Russia may face trade restrictions or penalties from nations in the NA and the EU in response to the crisis. The availability of glove liners made in Russia in the NA and EU markets could be restricted, opening opportunities for domestic or alternative providers. These actions could also include taxes or import bans on certain commodities, including glove liners.

Market Segmentation

The NA & EU Glove Liners Market is segmented into Type, Material Type, and End User.

Regional Analysis

The NA & EU Glove Liners Market is segmented into countries such as USA, Canada, Mexico, Germany, France, UK, Russia, Italy, Spain, and Rest of Europe.

The U.S accounted for higher market share of 42.26% in 2022, as it holds the largest market owing to the rising awareness of hygiene among healthcare professionals & growing number of admissions in hospitals. An increasing number of surgical operations using latex gloves are a high-impact rendering driver.

Europe is anticipated to witness a significant demand in the forecast years. This market's expansion can be attributed to large presence of market players combined with high expenditures on medical healthcare advancements, increase in medical tourism, implementation of stringent regulations toward control of cross-contamination in hospitals, and enhanced distribution & supply within Europe.

Key Players

Various key players are discussed into the NA & EU Glove Liners Market Report including: Tenacious Holdings, Inc., MCR Safety, Lakeland Inc., Shamrock Manufacturing Co. Inc., VIP GLOVE SDN BHD, Midas Safety, Superior Glove, Hartalega Holdings, Rubberex Corporation (M) Berhad, and 3M.

Market Taxonomy

By Type

• Sterile

• Non-Sterile

By Material Type

• Latex

• Nylon

• Polyester

• Wool

• Cotton

• Others

By End User

• Medical & Healthcare

o Hospitals & Clinics

o Ambulatory and Surgical Centers

• Cleanroom Industry

o Standard/Drywall Cleanrooms

o Hardwall Cleanrooms

o Softwall Cleanrooms

• Pharmaceutical

o Contract research and manufacturing services (CRAMS)

o Active pharmaceutical ingredients (APIs)

o Formulations

o Biologics and biosimilars

o Vaccines

• Others

o Academic and Research institutes

o Electronics and Manufacturing

By Region

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o France

o UK

o Russia

o Italy

o Spain

o Rest of Europe

"

0 notes

Text

0 notes

Text

Future | Trends and HealthCare Industry Analysis For Cleanroom Technologies Market

According to the new market research report "Cleanroom Technologies Market with COVID-19 Impact, by Product (Fan Filter Units, HVAC, vacuum systems, disinfectants), Construction (Drywall, Hardwall, Softwall), End User (Pharmaceutical, Biotechnology, Medical device manufacturers) - Global Forecast to 2026", published by MarketsandMarkets™, the global market is expected to reach USD 9.6 billion by 2026 from USD 7.1 billion in 2021, at a CAGR of 6.2% during the forecast period.

The growth of this market is majorly driven by the rising demand for sterilized pharmaceutical formulations, increasing demand for medical devices. The technological advancements in cleanroom technology along with the increasing demand for cleanroom technologies in developing economies are expected to offer significant opportunities for market growth in the coming years. However, the technical limitations associated with their operational costs and technical challenges associated with the customization of cleanroom designs in developing economies are hindering the growth of this market to a certain extent.

The use and maintenance of a cleanroom is a complex process. Usually, the cost of construction of standard cleanrooms for pharmaceutical and medical device manufacturing may range between USD 100 to more than USD 1,000 per square foot. Also, the price per square foot is not the same for ISO 6 and ISO 8 cleanrooms. This is because the amount of air supplied is different in both classes of cleanrooms. The air is 100 times cleaner in an ISO 6 cleanroom than in an ISO 8 cleanroom, thereby doubling the air conditioning capacity of the HVAC systems.

Browse and in-depth TOC on "Cleanroom Technologies"

289 - Tables

41 - Figures

313 - Pages

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=263122482

The Growth in the market is majorly driven by the stringent regulatory framework, growth of the biologics sector, growing demand for medical devices, and advancements in cleanroom technologies. The market is also witnessing increasing trends of adopting modular cleanrooms along with the emergence of rental cleanroom services.

The global health crisis triggered by the COVID-19 pandemic has made it imperative that the pharmaceutical industry moves at a rapid pace alongside researchers, regulators, and contract research companies to develop a diagnosis, treatment, and vaccines.

Cleanrooms are mostly designed according to customer requirements based on product specifications and customer-specific design requirements. However, there are no specific guidelines for cleanroom designs for different application areas or product types. This leads to several challenges for cleanroom manufacturers, as they need to follow different designs every time. Furthermore, regulations do not provide requirements regarding the environmental, product, or facility parameters that are to be controlled. Instead, they only provide standards that a company needs to meet after it decides to manufacture a product using a cleanroom environment.

The biotechnology end-user industry segment is expected to grow at the highest CAGR during the forecast period, primarily due to the growing demand for biologics and biosimilars. Increasing investments in biotechnology are expected to provide an impetus to the growth of the segment over the forecast period.

Request Sample Pages: https://www.marketsandmarkets.com/requestsampleNew.asp?id=263122482

North America is expected to hold the largest share for players operating in the Cleanroom Technologies Market.

North America accounted for the largest share of the market in 2020. Factors such as stringent regulatory standards for product approvals, technological advancements in cleanrooms, initiatives taken by private organizations to create awareness regarding cleanrooms, and growth of the healthcare sector on a global scale are among the few factors expected to contribute to the growth of this market.

0 notes

Text

Global Cleanroom Technologies Market Size, Share, and Trends

The Global Cleanroom Technologies Market is estimated to be USD 4,567.9 Mn in 2021 and is projected to reach USD 7,765.90 Mn by 2027, growing at a CAGR of 7.55%.

A room where concentration of air borne particulate matter, including hair, fungus, dust and bacteria is controlled is called as Cleanroom. To decline the generation, retention and introduction of particles inside the room, this type of room is constructed.

Get a Sample Copy of this Report@ https://qualiketresearch.com/request-sample/Cleanroom-Technologies-Market/request-sample

Market Drivers

Key demand driver of Cleanroom technology is Elimination of contaminants in laboratories. The need for cleaning these contaminates has highly essential. The cleanroom technology creates clean, neat, and contaminates free environments.

The rise in the demand for quality products compliant with regulatory standards increase the Cleanroom Technology market growth.

Moreover, the surge in the number of hospitals and ambulatory surgery centers (ASCs) because of the many benefits offered by them further influence the market.

The upsurge in the expansion of the biologics sector worldwide acts as one of the main factors driving the growth of cleanroom technology market.

Market Restraints

The high operational costs of clean technology is the main restraining factor of the cleanroom technology market. Practice of a cleanroom is an urbane process and Maintenance of such cleanroom technology is tough. The cost of standard cleanrooms is exclusive.

Furthermore, issues with customization of cleanroom designs per requirements are anticipated to hinder the growth of the cleanroom technology market in the forecast period.

Market Segmentation

Cleanroom Technologies Market is segmented into major 4 categories. Based Product Type, the market is segmented into Consumables, Cleaning Consumables, Equipment. Based on End User, the market is divided into Pharmaceutical Industry, Biotechnology Industry, Hospitals & Clinics. Based on Technology, the market is segmented into Standard/ Drywall Cleanroom, Softwall Cleanrooms, Others. Based on Region, the market is segmented into North America, Europe, Asia Pacific, Latin America, Middle East.

Regional Analysis

North America region dominates the Cleanroom Technology market across the world with CAGR 7.61% owing to the well-established healthcare infrastructure in this region, the local presence of key pharmaceutical and medical device companies, an increase in the burden of non- communicable diseases.

Europe occupied the second-highest market portion after the North America and is anticipated to grow at a significant CAGR 7.58% throughout the forecast period owing to the rising healthcare facility and awareness about the cleanliness in the region in the hospitals.

Get Discount on this Report@ https://qualiketresearch.com/request-sample/Cleanroom-Technologies-Market/ask-for-discount

Market Key Players

Some of the key players operating in Global Cleanroom Technologies Market are Ardmac, Azbil Corporation, Bouygues Group, Clean Rooms International Inc, ABN Cleanroom Technologies, Exyte AG, Taikisha Ltd, DowDuPont Inc, Kimberly-Clark Corporation, Clean Air Products.

Industry development

In July 2021, Taikisha Ltd. (“Taikisha”), a leading Japanese engineering company with a focus on HVAC systems has acquired controlling shareholding in leading Indian cleanroom engineering company Nicomac Clean Rooms Far East LLP (“Nicomac”).

In April 2019 Ardmac and Germfree are announced their partnership to bring Germfree bioGO Mobile and Modular Cleanroom Buildings to the European markets. Germfree offers a fully adaptable Cleanroom solution which supports manufacturing for pre-clinical/ clinical stage materials in a single or multiple-module Cleanroom building.

In January 2022 Kimberly-Clark Professional introduced its new nitrile gloves for research and production facilities, life sciences and non-sterile drug manufacturing applications. These gloves have improved comfort for extended use & high tactile sensitivity without compromising worker safety, Kimberly-Clark Professional has introduced Kimtech Opal Nitrile Gloves.

Browse Full Report https://qualiketresearch.com/reports-details/Cleanroom-Technologies-Market

0 notes

Text

Exploring the Different Applications of Softwall Modular Cleanrooms in Various Industries

Cleanrooms play a pivotal role in ensuring controlled environments for a wide range of industries, where precision, hygiene, and contamination control are of utmost importance. In recent years, softwall modular cleanrooms have emerged as a versatile solution, offering flexibility, cost-effectiveness, and adaptability to meet the specific needs of various industries. In this blog post, we will delve into the different applications of softwall modular cleanrooms across industries, highlighting their significance in maintaining the highest standards of cleanliness and efficiency.

What are Softwall Modular Cleanrooms?

Softwall modular cleanrooms are enclosed spaces equipped with flexible, transparent vinyl curtains that serve as barriers to control the flow of air and maintain cleanliness. Unlike traditional hardwall cleanrooms, softwall cleanrooms offer greater versatility, easy installation, and the ability to expand or reconfigure the cleanroom space as needed.

Pharmaceutical and Biotechnology Industries

The pharmaceutical and biotechnology industries are among the primary users of softwall modular cleanrooms. These controlled environments are crucial for the production of medications, vaccines, and biopharmaceuticals. Softwall cleanrooms provide an aseptic space to prevent contamination and ensure the purity of products, complying with stringent regulatory requirements. Additionally, these cleanrooms are utilized in research and development, quality control, and testing processes to maintain the integrity of sensitive materials.

Microelectronics and Semiconductor Manufacturing

In the microelectronics and semiconductor industries, even the tiniest particle can compromise the performance of delicate electronic components. Softwall modular cleanrooms offer a controlled environment for wafer fabrication, assembly, and packaging processes. They maintain Class 100 to Class 1000 levels of cleanliness, reducing defects and enhancing the overall yield of semiconductor products.

Aerospace and Defense

The aerospace and defense sectors often deal with highly sensitive and complex components that require a contaminant-free environment. Softwall modular cleanrooms ensure precision in assembly, testing, and integration of aerospace equipment. They prevent dust, moisture, and other contaminants from affecting critical systems, thus enhancing the reliability and safety of aerospace technologies.

Medical Device Manufacturing

Medical device manufacturers must adhere to strict quality standards to ensure the safety and efficacy of their products. Softwall cleanrooms facilitate the production of medical devices, ensuring they are free from contaminants and sterilized to the required levels. Cleanroom environments are crucial for the assembly of devices like implants, surgical instruments, and diagnostic equipment.

Research and Laboratories

Softwall modular cleanrooms find applications in various research and laboratory settings. They create controlled environments for conducting experiments, particularly in fields like nanotechnology, life sciences, and material research. The flexibility of softwall cleanrooms allows researchers to adapt the space for different experiments and projects, optimizing resource utilization.

Optics and Photonics

In the optics and photonics industries, precise alignment and calibration are essential for producing high-quality optical components and devices. Softwall modular cleanrooms provide the necessary conditions to prevent dust particles, ensuring optical elements maintain their performance and accuracy.

Food and Beverage Processing

In food and beverage processing, maintaining a clean and hygienic environment is critical to prevent contamination and ensure product quality. Softwall modular cleanrooms are used for food preparation, packaging, and handling, safeguarding against foreign particles and microbial contaminants.

Conclusion

Softwall modular cleanrooms have revolutionized contamination control and clean environment requirements in various industries. Their adaptability, cost-effectiveness, and compliance with industry regulations make them an attractive option for diverse applications. Whether in pharmaceuticals, microelectronics, aerospace, or any other sector that demands strict cleanliness standards, softwall modular cleanrooms offer the perfect solution for creating controlled environments that safeguard both products and processes. EZAD Cleanrooms As industries continue to evolve, the role of softwall modular cleanrooms in providing optimal cleanliness and efficiency is set to become even more significant in shaping the future of manufacturing and research.

Original Sources: https://ezadcleanrooms.blogspot.com/2023/07/exploring-different-applications-of.html

0 notes

Text

Comparing the Long-Term Cost-Effectiveness of Portable Cleanrooms and Permanent Cleanroom Installations

Cleanrooms are critical environments in various industries, including pharmaceuticals, electronics, aerospace, and biotechnology. They provide a controlled atmosphere where the level of pollutants, such as dust, microbes, and chemical vapors, is minimized to ensure product quality, process efficiency, and employee safety. When it comes to setting up cleanrooms, businesses often face a pivotal decision: should they invest in permanent cleanroom installations or opt for portable cleanrooms? In this comprehensive guide provided by Cleatech LLC, we will explore the factors that influence the cost-effectiveness of both options over the long term. By the end, you'll have a clearer understanding of which cleanroom solution suits your specific needs and budget.

I. Understanding Portable Cleanrooms

Portable cleanrooms are self-contained, modular units that can be easily relocated and reconfigured as needed. These cleanrooms are constructed using prefabricated components and are designed to meet specific cleanliness levels, typically defined by ISO classes. Let's delve into the advantages and disadvantages of portable cleanrooms to understand their long-term cost-effectiveness better.

Advantages of Portable Cleanrooms:

Flexibility: Portable cleanrooms are highly adaptable. They can be resized, reconfigured, or moved to different locations within your facility or even to a new facility altogether. This adaptability ensures that your cleanroom can evolve with your changing production needs without the need for a significant reinvestment.

Rapid Deployment: One of the most significant advantages of portable cleanrooms is their quick setup time. Traditional cleanroom installations can take months to complete, while portable cleanrooms can be operational within weeks or even days. This rapid deployment can translate into faster returns on investment.

Cost Savings: Portable cleanrooms generally have a lower initial cost compared to permanent installations. This cost advantage can be especially appealing for businesses with budget constraints or those looking to allocate resources to other critical areas of their operations.

Tax Benefits: In some regions, portable cleanrooms may qualify for tax incentives or deductions as they are considered movable assets. This can further reduce the overall cost of ownership over the long term.

Disadvantages of Portable Cleanrooms:

Limited Customization: Portable cleanrooms may have limitations in terms of customization compared to permanent installations. Achieving highly specialized configurations or meeting unique requirements may be more challenging with portable units.

Limited Lifespan: While portable cleanrooms are designed for durability, they may not have the same lifespan as permanent cleanrooms, which are constructed with more robust materials. Over time, you may need to replace or refurbish portable units, incurring additional costs.

Maintenance Costs: Portable cleanrooms may require more frequent maintenance due to their modular nature. Regular inspections, repairs, and component replacements can add to the long-term cost.

II. Permanent Cleanroom Installations

Permanent cleanrooms are precisely designed and constructed facilities integrated directly into a building. They are built to withstand the test of time and are tailored to meet the most stringent cleanliness and environmental control requirements. Let's examine the advantages and disadvantages of permanent cleanroom installations in terms of long-term cost-effectiveness.

Advantages of Permanent Cleanrooms:

Longevity: Permanent cleanroom installations are built with durable materials and are expected to last for decades. This longevity can result in lower replacement and refurbishment costs over the long term.

Customization: Permanent cleanrooms offer virtually limitless customization options. They can be designed to precisely match your process requirements, ensuring optimal performance and compliance with industry standards.

High Cleanliness Levels: Permanent cleanrooms can achieve the highest cleanliness levels, making them suitable for industries with stringent contamination control needs, such as microelectronics and pharmaceuticals.

Operational Efficiency: Since permanent cleanrooms are purpose-built, they often require fewer ongoing modifications and adjustments. This can lead to lower maintenance costs and reduced downtime.

Disadvantages of Permanent Cleanrooms:

High Initial Costs: The upfront cost of designing and constructing a permanent cleanroom can be substantially higher than that of portable units. This can be a barrier for businesses with limited capital resources.

Inflexibility: Permanent cleanrooms are not easily reconfigurable or relocatable. If your production needs change or if you need to move your facility, the investment in a permanent cleanroom may become less cost-effective.

Extended Lead Times: Building a permanent cleanroom is a time-consuming process, which can delay the start of your operations and the realization of ROI.

III. Factors Influencing Long-Term Cost-Effectiveness

To determine which cleanroom solution is more cost-effective over the long term, you must consider several key factors that directly impact your budget and operational efficiency. Here's a closer look at these factors:

Initial Investment: The initial cost of setting up a cleanroom, including construction, equipment, and installation, is a crucial consideration. Portable cleanrooms generally have a lower upfront cost, making them more accessible to businesses with budget constraints.

Operating Costs: Evaluate the ongoing expenses associated with each type of cleanroom. This includes energy consumption, HVAC system maintenance, air filtration, and cleanroom gowning costs. Portable cleanrooms may have lower operating costs due to their smaller size and efficient HVAC systems.

Flexibility Requirements: Consider your need for flexibility and scalability. If your production processes frequently change or you plan to relocate in the future, portable cleanrooms offer a significant advantage. Permanent installations, on the other hand, are better suited for stable, long-term operations.

Cleanliness Levels: Assess the required cleanliness levels for your application. Permanent cleanrooms can achieve the highest ISO classes and are ideal for industries with stringent contamination control needs. However, if your requirements are less demanding, a portable cleanroom may suffice.

Tax and Regulatory Considerations: Investigate whether your region offers tax incentives or deductions for cleanroom investments. Additionally, ensure compliance with industry regulations, as failure to meet standards can result in costly fines and delays.

Maintenance and Repairs: Calculate the anticipated maintenance and repair costs for both portable and permanent cleanrooms. Portable cleanrooms may require more frequent upkeep due to their modular nature, potentially impacting long-term cost-effectiveness.

Life Cycle Analysis: Conduct a life cycle cost analysis to compare the total cost of ownership over the expected lifespan of your cleanroom. This analysis should include initial costs, operating costs, maintenance, and potential replacement or refurbishment expenses.

Business Growth and Market Trends: Consider your business's growth prospects and industry trends. If you anticipate significant growth or foresee evolving industry standards, a more flexible solution like portable cleanrooms might align better with your long-term strategy.

IV. Case Studies: Portable vs. Permanent Cleanrooms

To illustrate the cost-effectiveness of portable and permanent cleanrooms in real-world scenarios, let's explore two case studies from different industries.

Case Study 1: Pharmaceutical Manufacturing

Scenario: A pharmaceutical company needs a cleanroom for the production of sterile injectable drugs. They anticipate consistent production volumes for the next 15 years.

Comparison:

Portable Cleanroom: The company opts for a portable cleanroom, which requires a lower initial investment and allows for rapid deployment. Over the 15-year period, they spend less on construction, but maintenance costs are slightly higher due to the modular nature of the cleanroom.

Permanent Cleanroom: Building a permanent cleanroom involves a higher upfront cost and longer lead time. However, the cleanroom's durability and lower maintenance costs result in cost savings over the 15-year span.

Conclusion: In this scenario, the pharmaceutical company's stable production volume and long-term commitment make a permanent cleanroom more cost-effective in the long run, despite the higher initial investment.

Case Study 2: Semiconductor Manufacturing

Scenario: A semiconductor manufacturer expects rapid growth in production and technology advancements, necessitating frequent cleanroom reconfigurations.

Comparison:

Portable Cleanroom: The manufacturer chooses portable cleanrooms to accommodate rapid changes in production requirements. Although initial costs are lower, they incur higher relocation and maintenance expenses as they frequently reconfigure their cleanrooms over the years.

Permanent Cleanroom: While the initial investment in a permanent cleanroom is higher, the manufacturer benefits from greater operational stability, lower maintenance costs, and fewer disruptions. As they grow, the permanent cleanroom proves to be more cost-effective.

Conclusion: In this dynamic industry, the ability to adapt quickly and efficiently to changing requirements makes portable cleanrooms initially attractive. However, over time, the constant reconfiguration and maintenance costs outweigh the advantages, making permanent cleanrooms more cost-effective.

V. Tips for Making an Informed Decision

Now that you have a comprehensive understanding of the factors influencing the cost-effectiveness of portable and permanent cleanrooms, here are some tips to help you make an informed decision:

Assess Your Specific Needs: Begin by thoroughly evaluating your production requirements, cleanliness standards, and long-term growth projections. This will guide you in selecting the cleanroom type that aligns best with your objectives.

Consider ROI Timelines: Determine your expected return on investment timelines. If you need to recoup your investment quickly, portable cleanrooms may be a better choice due to their rapid deployment capabilities.

Consult with Experts: Engage with cleanroom design and construction experts who can provide valuable insights into your unique requirements and help you make an informed decision.

Perform Cost-Benefit Analysis: Conduct a detailed cost-benefit analysis that includes initial costs, operating costs, maintenance expenses, and potential future modifications or relocations.

Stay Informed About Industry Trends: Keep an eye on industry trends and regulations that may impact your cleanroom requirements. Ensure that your chosen cleanroom solution remains compliant and adaptable to future changes.

Plan for Contingencies: If you opt for a portable cleanroom, plan for contingencies such as relocation costs and potential downtime during reconfigurations. Include these factors in your cost analysis.

Explore Financing Options: Investigate financing options and incentives available in your region to make the investment more financially viable.

Prioritize Quality and Compliance: Regardless of your choice, prioritize quality and compliance with industry standards to avoid costly fines and setbacks.

Conclusion:

The decision between portable and permanent cleanrooms is a significant one with long-term implications for your business. Each option has its advantages and disadvantages, and the choice ultimately depends on your specific needs, budget, and growth projections.

Portable cleanrooms offer flexibility and rapid deployment, making them attractive for businesses with changing production requirements or limited budgets. On the other hand, permanent cleanroom installations provide durability, customization, and long-term stability, making them suitable for industries with stringent contamination control needs and stable production volumes.

By carefully evaluating your requirements, conducting a thorough cost analysis, and considering the factors discussed in this guide, you can make an informed decision that ensures the long-term cost-effectiveness of your cleanroom investment. Whether you choose portability or permanence, Cleatech LLC is here to assist you in designing and implementing the cleanroom solution that best aligns with your objectives and industry standards.

Original Sources: https://fundaily.org/2023/09/13/comparing-the-long-term-cost-effectiveness-of-portable-cleanrooms-and-permanent-cleanroom-installations/

0 notes

Text

Global Cleanroom Technology Market Size, Share, Demand and Growth Forecast, 2030 | VynZ Research

The Global Cleanroom Technology Market size will reach USD 6.5 billion by 2030 and is expected to develop at a CAGR of 7.3% during the forecast period (2022-2030), according to VynZ Research. For the forecast year 2022-2030, as well as the historical period 2018-2021, the Global Cleanroom Technology Market has been studied.

The research report provides a comprehensive and insightful examination of the Global Cleanroom Technology Market and includes market analysis on segmentation, dynamics, competition, and regional development. It considers the Global Cleanroom Technology Market's CAGR, value, volume, revenue, production, consumption, sales, manufacturing cost, pricing, and other significant parameters. The forecasts in the report are based on well-established research methodology and assumptions.

Explore the recent findings of the Global Cleanroom Technology Market by purchasing a single user PDF@ https://www.vynzresearch.com/healthcare/cleanroom-technology-market/request-sample

Individual strategies were examined in the Global Cleanroom Technology Market study, followed by business profiles of Global Cleanroom Technology Market providers. The study includes an 'Industry Landscape' section that provides readers with a comprehensive view and firms’ market share analysis of major industry players in the Global Cleanroom Technology Market.

Most of the major players in the Global Cleanroom Technology Market are profiled in the report. The strengths and weaknesses, business developments, recent innovations, mergers and acquisitions, expansion plans, global footprint, market presence, and product portfolios of key market competitors are all covered in the company profiling section.

The following are some of the major and developing players in the Global Cleanroom Technology Market:

· Azbil Corporation

· E.I. du Pont de Nemours and Company

· M+W Group GmbH

· Illinois Tool Works Inc.

· Ardmac Ltd.

· Kimberly-Clark Corporation

· Taikisha Ltd.

· Clean Air Products Inc.

· Alpiq Group

Breakdown of The Segments:

The Global Cleanroom Technology Market is segmented by Product, Equipment, Construction, End-User, and Geography in this study. This segmentation aids executives in planning their products and budgets depending on each segment's expected growth rates.

Product Insight and Forecast 2018 – 2030

· Consumables

· Safety

· Apparel

· Gloves

· Cleaning

· Vacuum Systems

· Disinfectants

· Wipes

· Equipment

· Heating, Ventilating, and Air Conditioning (HVAC) Systems

· High-Efficiency Particulate Air (HEPA) Filters

· Fan Filter Units (FFUs)

· Air Showers

· Laminar Air Flow Systems and Biosafety Cabinets

· Others

Construction Insight and Forecast 2018 – 2030

· Standard Cleanrooms

· Hardwall Cleanrooms

· Pass Through Cabinets

· Softwall Cleanrooms

End User Insight and Forecast 2018 – 2030

· Medical Devices

· Biotechnology Industries

· Pharmaceutical Industries

· Others

Geographical Viewpoint:

The research overview provides the major industry trend and the global market's predicted volume based on the regional analysis. The elements that have driven and hampered the market's expansion are also mentioned in this market research analysis. The study is also equipped with the most advanced and effective techniques for gathering, recording, estimating, and evaluating market data.

FAQ

1. Who are the most dominant players in the global market, and what elements are assisting them in gaining a competitive advantage?

2. What are the strategies adopted by the key industry players to gain traction in the industry?

3. By the end of the forecast period, what will the market size and growth rate?

4. What are the biggest Global Cleanroom Technology Market trends that are influencing market growth?

5. In the global market, which segment had the biggest revenue share?

Explore More Reports by VynZ Research:

Global Skincare Devices Market – Analysis and Forecast 2022-2030

Global Neurostimulation Devices Market – Analysis and Forecast 2022-2030

Global Heart Pump Device Market – Analysis and Forecast 2022-2030

About VynZ Research

VynZ Research is a global market research firm offering research, analytics, and consulting services on business strategies. VynZ have a recognized trajectory record and our research database is used by many renowned companies and institutions in the world to strategize and revolutionize business opportunities. The company focuses on providing valuable insights on various technology verticals such as Chemicals, Automotive, Transportation, Energy, Consumer Durables, Healthcare, ICT and other emerging technologies.

#Global Cleanroom Technology Market#Global Cleanroom Technology Market size#Global Cleanroom Technology Market share#Global Cleanroom Technology Market demand#VynZ Research

0 notes

Text

0 notes

Text

Picking the best and right softwall cleanroom for your home.

A softwall cleanroom is very the name construes, it has sensitive versatile dividers rather than hard firm dividers. Additionally, it is ordinarily littler in size than a customary hard divider cleanroom. What's more, remember that repaired divider cleans rooms maybe the solicitation for the day for gigantic, progressively enduring gathering and get together undertakings.

0 notes