#Rug Grippers

Text

🎁 Rug Gripper 50% Off 💥

Asin:B0BSDC6F91

Code:50PBCZVU

Date: 2023-2-14 00:01PST ------------- 2023-2-28 23:59PST

#Rug Grippers#Rug Gripper Nonslip#Rug Gripper Tape#Discount#Discount Code#Discount Sale#Discount Offer

0 notes

Text

Ages ago I got a resin helmet kit from LunaArmorWorks on Etsy, it sat in my to-do pile for the longest time but I finally got around to finishing and painting it up. It's been so long since I bought this helmet that LunaArmorWorks doesn't sell it anymore, so I'm grateful I picked it up when I did because I don't know if I could've made something this cool all on my own!

Once I started working on this one, it was pretty easy to put together. I added a few additional details with apoxie sculpt and bondo before priming and sanding the helmet. I used a few different spray paints and masking fluid to get the chipped paint effect, then dusted on chalk pastels to add to the worn look.

The hardest part of this project was trying to figure out how to make a faux chainmail hood, which you don't even see in the glamour shots. I used a dollar store rug gripper, I dyed mine red with Rit Dyemore because I thought it might save me the effort of painting it (only for me to paint it anyways because I realised I should make it silver with red drybrushing).

I really love how the first photo turned out, can you believe I took that in my kitchen? I don't know if I'm just kidding myself, but I feel like it actually looks like it was shot outdoors. Fun fact, but I edited in the clouds and leaf litter from scenes in Labyrinth where Sarah is in the hedge maze area. I'm gonna have to do that for future photoshoots because I love knowing a bit of the film is in these photos.

59 notes

·

View notes

Text

SUGV (Small Unmanned Ground Vehicle), by iRobot, Bedford, MA (2007). The SUGV was developed after soldiers complained that the PackBot was too heavy to carry on the battlefield. “The 310 SUGV is a smaller and lighter variant of the combat-proven iRobot PackBot. The modular design of 310 SUGV integrates a wide range of payloads and sensors for identifying and disposing explosive materials. The rugged design allows … operations in all-weather conditions. The robot is fitted with a dexterous manipulator to investigate and neutralise hazardous objects. Mounted on the 360° rotatable turret, the manipulator includes a shoulder, elbow and a wrist. The wrist is attached with a gripper comprising of a parallel jaw opening. The manipulator extends 24in and can lift a maximum load of seven pounds when fully extended.” – iRobot 310 SUGV, Army Technology.

18 notes

·

View notes

Text

Teeny tiny bit from my Feyzrielweek fic for the AU day. It's out of context, but don't worry. It makes as much sense with context

"Stop!" Feyre yelled.

He stopped in his tracks. "What?"

"Get your grippers away from my rug." Feyre said.

"What?" he repeated, more confused.

#acotar#a court of thorns and roses#feyzrielweek#feyzrielweek2022#feyzriel#acotar au#feyre archeron#feyre#feyre cursebreaker#high lady of the night court#feyre darling#high lady feyre#azriel acotar#azriel spymaster#azriel shadowsinger#azriel

3 notes

·

View notes

Text

8 PCs Non Slip Carpet Area Rug Gripper at Walmart

Was $16.99 Now $8.99

Affiliate Link:

https://mavely.app.link/e/W7NrNh0J8Ib

AD

0 notes

Text

IP65 Waterproof Electric Gripper

This IP65 Waterproof Electric Gripper is a high-performance device designed to handle challenging environments with ease. With its robust construction and advanced waterproofing capabilities, this IP65 Waterproof Electric Gripper offers reliable and precise gripping functionality in various industries.

In terms of waterproofing, IP65 rating indicates that the gripper has good dust-proof and waterproof performance.

This is usually achieved through sealing design and protective measures to prevent dust and water from entering the interior of the gripper. To ensure waterproof performance, the outer shell of the gripper usually adopts a sealed structure, which may include sealing rings, gaskets, or other sealing components. These sealing measures can prevent water and dust from entering the internal electronic and mechanical components of the gripper

IP65 Waterproof Electric Gripper is engineered to withstand exposure to water, dust, and other elements, making it suitable for outdoor and industrial applications. The IP65 rating ensures that it provides protection against ingress of both solid particles and low-pressure water jets, allowing it to operate reliably in wet or dusty conditions.

Featuring electric actuation, IP65 Waterproof Electric Gripper offers precise control and positioning, enabling accurate handling of objects. It can be seamlessly integrated into automated systems, enhancing productivity and efficiency. The waterproof design eliminates the need for additional enclosures or protection, reducing complexity and costs.

Whether used in manufacturing, robotics, automotive, or any other industry that requires rugged and waterproof grippers, IP65 Waterproof Electric Gripper delivers consistent performance and durability. It offers a reliable solution for handling objects in harsh environments, ensuring smooth and efficient operations. With its compact size and versatile design, it can adapt to different setups and applications, providing a flexible and efficient gripping solution.

Items Technical Parameters

Product code

TM-MFGB-08-80-1-D0300-ITG

Size code

08

Stroke(mm)

80

Max clamping force

150N

Max payload(kg)

3

Maxs speed open/close

0.7/0.7(s)

Allowable load(Nm)

MR:5.5 , MP:3.7 , MY:3.1

Positioning repeatability

±0.03(mm)

Weight(kg)

1

Control method

Bus

Communication protocol

Modbus RTU

Rated voltage(V)

DC24±10%

Rated current(A)

4

Ambient environment

0 ~ 40℃,85%RH ( below )

IP rating

IP65/IP55

In addition to industrial and outdoor applications, IP65 waterproof electric grippers can also be widely used in the following fields:

1. Medical Equipment: In the medical industry, this IP65 Waterproof Electric Gripper can be used for the operation of medical equipment, such as surgical robots, laboratory automation equipment, etc., to ensure accurate clamping and operation in clean and humid environments.

2. Food processing: The food processing field requires frequent cleaning of equipment. The IP65 waterproof electric gripper is suitable for food processing and packaging machinery, and can work stably in humid production environments.

3. Oceans and Ships: The waterproof requirements for equipment in the field of ships and oceans are very high, and this clamp can be used for marine exploration equipment, ship automation systems, etc.

4. Laboratory and scientific research: In scientific research laboratories, IP65 Waterproof Electric Gripper may need to come into contact with various liquids or operate in humid environments, and its IP65 waterproof characteristics make it suitable for such applications.

5. Automotive and Transportation: During the manufacturing and maintenance process of automobiles, grippers can be used to grip and operate components, especially in work involving water washing or humid areas.

6. Agriculture and Horticulture: Agricultural and horticultural equipment is often exposed to outdoor environments, and grippers can be used for automated irrigation systems, agricultural product harvesting machinery, etc.

7. Energy and Power: In the energy and power industry, such as the maintenance of wind turbines and solar equipment, waterproof clamps can be used to clamp and operate components.

8. Underwater robots: Underwater robots require waterproof clamping devices to perform various tasks, such as sampling and detection.

9. Electronic Equipment Manufacturing: In the electronic manufacturing process,IP65 Waterproof Electric Gripper can be used to clamp and assemble sensitive electronic components, and their waterproof characteristics help prevent component damage.

These are just some possible application areas. In fact, the applicability of IP65 waterproof electric grippers can be extended to more fields according to specific needs and innovative applications. Its waterproof performance and electric driving method give it great advantages in clamping operations that require water resistance, moisture resistance, or special environmental conditions.

You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data.

Youtube: https://www.youtube.com/@tallmanrobotics

Facebook: https://www.facebook.com/tallmanrobotics

Linkedin: https://www.linkedin.com/in/tallman-robotics

Read the full article

#Electricactuator2-fingerGripper#IP65DustProofElectricGripper#IP65DustproofElectricGrippers#IP65OutdoorWaterproofElectricalGripper#IP67WaterproofElectricGrippers#LongStrokeElectricGripper#WaterResistantElectricGrippers

0 notes

Text

How to Keep Rug Corners Down on Hardwood Floors: Effective Tips and Tricks

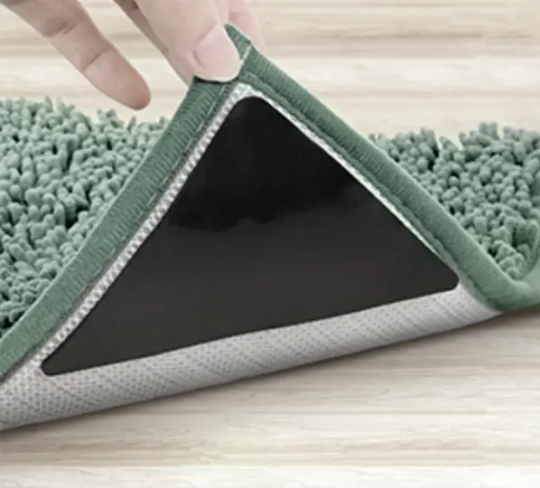

To keep rug corners down on hardwood floors, use carpet grippers or rug pads. Here's how you can secure your rug corners on hardwood floors and prevent them from slipping or curling.

Credit: designertrapped.com

Selecting The Right Rug Pad

To keep rug corners down on hardwood floors, selecting the right rug pad is essential. Look for non-slip, gripping rug pads that are suitable for hardwood surfaces. These pads provide traction and prevent rugs from slipping, ensuring the corners stay in place.

Material And Thickness

One of the key factors to consider while selecting a rug pad is the material and thickness of the pad. The choice of material will depend on the type of hardwood floor you have and the specific requirements of your rug. Here are a few options to consider:

- Felt Rug Pads: These pads are made of dense fibers and offer a soft cushioning under the rug. They are especially suitable for thin rugs and provide a good grip on hardwood floors.

- Rubber Rug Pads: Rubber pads are popular because they are slip-resistant and prevent furniture from sliding. They are particularly effective on slick hardwood floors.

- Natural Fiber Rug Pads: These pads are made of materials such as jute or wool, which provide a strong grip. They are suitable for both hardwood floors and rugs made of natural fibers.

The thickness of the rug pad is equally important. A pad that is too thin may not provide adequate cushioning, while a pad that is too thick might raise the rug too high off the floor. Generally, a rug pad with a thickness of about 1/4 inch is ideal for most rugs.

Size And Shape

When selecting a rug pad, it's crucial to consider the size and shape of your rug. The pad should be slightly smaller than the dimensions of your rug to ensure it remains hidden beneath the edges. If the pad is larger than the rug, it may cause an unsightly bulge.

Furthermore, the shape of the pad should match the rug shape. Rectangular rug pads are the most common and will suit rectangular rugs, while round rugs require a circular pad. For irregularly shaped rugs, you can opt for a custom-cut pad that matches the rug's outline.

By selecting the right size and shape for your rug pad, you can ensure that the pad remains concealed while providing optimal support and stability to your rug.

Credit: www.amazon.com

Securing Rug Corners

Preventing rug corners from curling up is essential to maintain a neat and safe space. With the right techniques, you can secure rug corners on hardwood floors and avoid tripping hazards. Here are two effective methods to ensure your rugs stay in place: Double-Sided Carpet Tape and Velcro Strips.

Double-sided Carpet Tape

Double-sided carpet tape is a simple yet reliable solution to secure rug corners on hardwood floors. This strong adhesive tape is designed specifically for rugs and is easily available in most home improvement stores. To use double-sided carpet tape:

- Clean the area where the rug will be placed. Remove any dust or dirt to ensure a strong bond.

- Roll out the rug and position it correctly on the hardwood floor.

- Lift one corner of the rug and apply the double-sided carpet tape. Make sure to apply the tape along the edge of the rug, close to the corner.

- Press down firmly on the rug corner to secure it in place.

- Repeat the process for each corner of the rug, ensuring the tape is applied tightly.

- Check the rug corners periodically to ensure the tape is holding the rug securely.

Double-sided carpet tape is an effective solution for securing rug corners, providing an easy and affordable way to keep your rugs flat and stable on hardwood floors.

Velcro Strips

Velcro strips are another excellent option to keep rug corners down on hardwood floors. With their strong holding power, velcro strips provide a removable yet sturdy solution. Follow these steps to use velcro strips:

- Clean the area of the hardwood floor where the rug will be positioned, ensuring it is free from dust or dirt.

- Cut small sections of the hook side of the velcro strip and attach them to the underside of each corner of the rug.

- Remove the adhesive backing from the loop side of the velcro strip and attach it firmly to the hardwood floor in the corresponding positions.

- Press down on the rug corners to secure them to the velcro strips.

- If needed, trim the velcro strips so they are not visible.

- Check the rug corners regularly to ensure the velcro strips are holding the rug securely in place.

Velcro strips provide a strong and versatile solution for securing rug corners on hardwood floors, allowing for easy repositioning or removal when necessary.

Using Decorative Elements

One effective way to keep rug corners down on hardwood floors is by using decorative elements. Incorporating decorative items not only adds style and charm to your space but also helps in preventing rugs from slipping and curling up. Here are some creative ways to use decorative elements to keep your rugs in place.

Furniture And Weighted Objects

Placing furniture and weighted objects strategically around the edges of the rug can help prevent it from curling up. Heavy items such as coffee tables, ottomans, and floor lamps can be positioned on the edges to keep the rug flat and in place. It’s essential to ensure the furniture or weighted objects are large and sturdy enough to hold down the rug corners effectively.

Rug Grippers And Clips

Consider using rug grippers and clips to secure the rug to the hardwood floor. These simple yet effective tools can be discreetly placed under the edges of the rug to keep them down. Rug grippers are commonly made of non-slip rubber material, while clips provide a firm grip on the corners, preventing any movement or curling up of the rug. They are easy to install and offer a practical solution to keeping rugs in place.

Credit: www.amazon.com

Maintenance And Long-term Strategies

Looking for ways to keep rug corners down on hardwood floors? Check out our maintenance and long-term strategies to prevent slipping and tripping hazards. Say goodbye to curled up rug corners and keep your floors looking neat and stylish.

Maintaining rug corners on hardwood floors is crucial for both the aesthetics and functionality of your space. By implementing regular cleaning and vacuuming routines, as well as adopting a strategic approach of rotating and repositioning your rugs, you can effectively keep rug corners down on hardwood floors in the long run.

Regular Cleaning And Vacuuming

Regular cleaning and vacuuming are fundamental in preserving your hardwood floors and preventing rug corners from curling up. Dust, dirt, and debris that accumulates underneath rugs can act as friction points, causing the corners to lift and potentially pose tripping hazards. To mitigate this issue, follow these steps:

- Start by removing the rug from the floor, taking care not to bend or fold the corners unnecessarily.

- Thoroughly clean the hardwood floor using a gentle cleaner suitable for the specific type of wood.

- Vacuum the rug to eliminate any dirt or particles trapped within the fibers.

- Ensure the underside of the rug is free from debris as well.

- Before placing the rug back on the floor, allow both the hardwood floor and the rug to dry completely.

Rotating And Re-positioning

Another effective strategy for keeping rug corners down on hardwood floors is regular rotation and re-positioning. Over time, rugs can experience wear and tear, leading to uneven stress distribution. By periodically rotating your rugs, you can distribute the weight more evenly, preventing excessive pressure on specific corners. Follow these steps to enjoy long-term benefits:

- First, remove the rug from the floor gently.

- Rotate the rug by 180 degrees so that the previously occupied corners are now in different positions.

- If possible, adjust the rug's placement to ensure equal exposure to foot traffic and sunlight.

- Consider repositioning furniture or other objects on the rug to distribute the weight more evenly.

- Regularly repeat this rotation and re-positioning process every few months to maintain the rug's integrity.

By implementing these maintenance and long-term strategies of regular cleaning, vacuuming, rotating, and re-positioning your rugs, you can extend their lifespan, keeping their corners firmly in place on your beautiful hardwood floors. Incorporate these simple yet effective practices into your routine, and you'll enjoy a seamless and attractive flooring experience.

Expert Advice And Additional Considerations

When it comes to keeping rug corners down on hardwood floors, it's essential to consider expert advice and additional considerations. By following professional installation recommendations, taking into account weather and climate factors, you can ensure your rugs stay in place and protect your hardwood floors in the long run.

Professional Installation Recommendations

Proper installation is key to keeping rug corners down on hardwood floors. Whether you choose to install the rug yourself or hire a professional, there are a few steps you should follow to ensure it stays in place:

- Start by thoroughly cleaning the hardwood floor to remove any dust, debris, or moisture that could interfere with the rug's grip.

- Consider using rug pads specifically designed for hardwood floors. These pads provide additional grip and prevent the rug from slipping or bunching up.

- Use double-sided carpet tape or rug adhesive in areas prone to high traffic or when you want to secure the rug corners more firmly.

- Regularly check the rug corners and reposition if needed to prevent them from curling or lifting.

Weather And Climate Factors

Weather and climate conditions can also impact how well rug corners stay down on hardwood floors. Here are some additional considerations to keep in mind:

Humidity levels: High humidity can cause hardwood floors to expand and contract. To prevent this, use a dehumidifier or air conditioner to maintain stable humidity levels.

Moisture control: Avoid placing rugs on hardwood floors in areas prone to moisture, such as near windows, doors, or bathrooms. Excess moisture can damage both the rug and the floor.

Temperature changes: Sudden temperature changes, such as opening doors or running heating systems, can cause hardwood floors to expand or contract. Ensure proper insulation and maintain a consistent room temperature to minimize these effects.

By following these expert tips and considering weather and climate factors, you can keep rug corners down on your hardwood floors effectively. Taking the time to install the rug correctly and addressing any weather-related concerns will not only enhance the aesthetic appeal of your space but also extend the lifespan of both your rug and hardwood floors.

Frequently Asked Questions For How To Keep Rug Corners Down On Hardwood Floors

How Do I Keep My Rug Corners From Turning Up?

To prevent your rug corners from turning up, use rug grippers or adhesive tape under the corners, or place furniture on top of them. Regularly vacuuming the rug and using a rug pad can also help keep the corners in place.

How Do You Get An Area Rug To Lay Flat On Hardwood Floors?

To get an area rug to lay flat on hardwood floors, use a non-slip rug pad underneath. Roll the rug in the opposite direction and secure the corners with heavy objects for a few hours. If needed, use a steamer or apply heat to remove any stubborn creases.

How Do I Keep My Rug From Moving On My Hardwood Floors?

To prevent your rug from moving on hardwood floors, use rug grippers or non-slip rug pads underneath it. These provide traction and stability, keeping the rug in place. Avoid using adhesive tapes, as they can leave residue and damage the floor.

Regularly clean the area underneath the rug for better grip.

Is Rug Tape Safe For Hardwood Floors?

Yes, rug tape is safe for hardwood floors. It securely holds rugs in place without causing any damage.

Conclusion

Keeping rug corners down on hardwood floors is essential for a safe and polished home environment. By following the tips and techniques provided you can prevent tripping hazards and keep your floors looking neat and tidy. From using rug grippers to applying double-sided tape, there are various solutions to ensure your rug stays in place.

With these simple methods, you can enjoy both a stylish and secure living space.

Read the full article

0 notes

Link

Check out this listing I just added to my Poshmark closet: Rug Hooking Wooden Lap Frame w/Swivel and Tilt 16" x 13" x 7".

0 notes

Text

The Ultimate Guide to Rug Cleaning

Rugs are a popular choice for adding warmth and style to our homes. They come in various materials, colors, and patterns, making them a versatile choice for interior design. However, one aspect that often gets overlooked is rug cleaning. Regular maintenance and cleaning are essential to keep your rugs looking their best and to extend their lifespan. In this article, we will guide you through the process of rug cleaning and offer some tips to ensure your rugs stay beautiful and fresh for years to come.

Vacuuming: Regular vacuuming is the first step in rug cleaning. It helps remove loose dirt, dust, and debris from the surface. Use a vacuum cleaner with a brush attachment or a canister-style vacuum with a beater bar. Make sure to vacuum both sides of the rug and pay extra attention to high-traffic areas.

Spot Cleaning: Accidents happen, and when spills or stains occur, it's important to act quickly. Blot the stain gently with a clean cloth or paper towel to absorb as much liquid as possible. Avoid rubbing the stain, as it can push it deeper into the rug fibers. Use a mild detergent or rug cleaner specifically designed for the type of rug you have. Test the cleaner on a small, inconspicuous area first to ensure it doesn't cause any discoloration or damage.

Deep Cleaning: Over time, rugs accumulate dirt, dust, and allergens that can't be fully removed by vacuuming alone. Periodic deep cleaning is necessary to keep your rugs fresh and hygienic. You can either hire a professional rug cleaning service or clean the rug yourself using a carpet cleaner or steam cleaner. Check here to follow the manufacturer's instructions and use cleaning products appropriate for your rug's material.

Drying and Maintenance: After cleaning, it's important to dry your rug thoroughly to prevent mold and mildew growth. Hang the rug outside or use fans to speed up the drying process. Avoid placing the rug on a wet or damp surface. Once the rug is completely dry, vacuum it again to fluff up the fibers. Visit this company to learn on how to maintain and clean rug.

Regular maintenance is key to keeping your rugs in excellent condition. Here are a few additional tips:

Rotate your rugs at least once a year to prevent uneven wear and fading.

Use rug pads or grippers to prevent slipping and protect the rug from excessive wear.

Avoid prolonged exposure to direct sunlight, as it can cause the colors to fade over time.

Consider professional rug cleaning for delicate or antique rugs.

In conclusion, rug cleaning is an essential task to maintain the beauty and longevity of your rugs. Regular vacuuming, spot cleaning, and occasional deep cleaning are all part of the process. By following these cleaning tips and practicing regular maintenance, you can enjoy your rugs for years to come. You can get more enlightened on this topic by reading here: https://en.wikipedia.org/wiki/Dry_carpet_cleaning.

0 notes

Text

🎁 50% Off Rug Gripper 💥

#Rug Gripper#Best Rug Gripper#Rug Pads#Rug Tape#Area Rugs Gripper#Carpet Tape#Rug Grip Tape#Heart Shaped#Discount Coupon#Rug Grip Pads

0 notes

Text

Hallway Runners: Enhancing Your Space with Style and Practicality

Want to improve your hallway's appearance and use of space? You only need to look at hallway runners. In addition to being a useful option for high-traffic areas, these adaptable floor coverings are also a gorgeous design element that may completely change your room. The best way to bring warmth, texture, and personality to any hallway, whether it's a large entrance way or a short corridor, is by using hallway runners. Every taste and home design theme can be accommodated with a variety of alternatives, from complex patterns to solid colors. Hallway runners aren't only for show; they also provide functional benefits including preventing scratches on your floors, cutting down on noise, and creating a comfortable walking surface.

Types Of Hallway Runners

There are many different alternatives available when it comes to hallway runners. The size of your corridor, your overall home design, and your taste will all influence the sort of runner you choose. Let's examine a few common kinds of hallway runners.

Traditional Runner: Rich colors and elaborate designs define traditional runners. They frequently have floral, medallion, or oriental themes, which give your corridor a classy, classic feel. These rugs are ideal for traditional or retro-styled decor.

Modern Runners: Contemporary runners are an excellent option if you like a more current style. They often have abstract patterns, minimalistic motifs, or strong geometric patterns. These runners provide a modern or Scandinavian interior design a polished and airy feel in any hallway.

Natural Fiber Runners: For individuals who like a rustic or bohemian look, natural fiber runners are a great choice. They are made from materials like jute, sisal, or seagrass. These shoes create a cozy, natural atmosphere by bringing a little bit of the outdoors inside. They are an eco-friendly option since they are also long-lasting and sustainable.

Solid Color Runners:A solid-colored runner will seem more tasteful and adaptable. These rugs are highly customizable to fit any interior design style because they come in a broad variety of colors, from vivid to neutral tints. They offer a simple, understated foundation that lets other components of your corridor shine.

Hallway Runner Materials and Durability

Wool:Wool runners are a popular option because of their longevity and inherent beauty. Wool is a plush, velvety fiber that gives your room cosines and warmth. It is a sensible choice for high-traffic areas because it is inherently flame- and stain-resistant.

Synthetic Fibers: Synthetic fiber runners, including those composed of nylon, polyester, or polypropylene, are renowned for their cost-effectiveness and resilience. These materials are perfect for corridors with a lot of foot traffic or homes with kids and dogs since they resist stains, fading, and wear.

Natural Fibers: Natural fiber runners for your hallway, such as seagrass, sisal, or jute, add a hint of organic charm. These materials are biodegradable and environmentally benign. They might need more upkeep and care, though, as they are less stain and moisture-resistant.

Hallway Runner Placement and Installation Tips

Centered placement: The hallway runner should often be centered between the walls for aesthetic purposes. This results in a symmetrical and balanced appearance. But you might have to change the arrangement to make room if your hallway has an odd form.

Consider The Length:The runner should ideally stretch past the entry and exit points to cover a good chunk of the hallway. This guarantees that the runner protects the whole length of the floor, fulfilling its intended function.

Secure The Runner: Safeguarding the runner from sliding and tripping hazards is crucial. To keep the runner in place, use rug grippers, double-sided tape, or a non-slip rug pad. These add-ons also aid in shielding your floors from friction-related damage.

Maintain Proper Spacing:To make a border, leave a tiny space between the runner and the walls. This lets the flooring underneath breathe and keeps the runner from appearing crowded.

If you are looking rug on sale in UK do visit TheRugShopUK.

1 note

·

View note

Text

Bottle Caping

Bottle Capping Machines

If you are packaging liquid products, capping your containers is an essential part of the process. It speeds up the process, ensures that each container is sealed properly and prevents product from getting contaminated.

A capping machine is a piece of equipment that is placed onto your production line to apply a cap or lid to the container. It helps your company package more products in less time.

Industrial Bottle-Capping Machines

Bottle cap machines make it possible for companies to cap bottles quickly and efficiently. These machines allow businesses to increase production rates, thereby increasing revenue and profitability.

These cappers come in a variety of styles and can be divided into semi-automatic and fully-automatic categories. These classifications depend on the type of containers the cappers are designed to handle.

The most common automatic capper used in the beverage industry is the spindle capper. This machine uses several sets of spindle disks to tightly tighten screw-on caps as they pass through the machine on a power conveyor. It also uses gripper belts and a stabilizer bar to keep the bottles steady during the tightening process.

This machine can handle a variety of screw-on caps, including plastic, metal, and flip top types. It can also handle child-resistant caps, which are used to ensure the safety of children.

Fully-automatic capping machines apply caps to a variety of bottles and can also be set up to run simultaneously with liquid filling or bottle labeling machines, allowing a more efficient and smooth operation. These machines can produce a large volume of containers per minute and are suitable for a range of industries.

They are also easy to maintain and can be upgraded as the business grows, so they are often a good investment. They can be easily adjusted to handle a variety of container sizes and cap sizes and are also dependable (simple change parts mean quick and easy 30 minute changes).

In addition to these main categories, the market is also segmented by material type, application, and region. This is to help companies identify the best equipment for their needs.

These machines can handle a wide range of materials, from delicate glass to rugged plastic and metals. They can also be adapted to modify the speed of capping based on the production needs.

The bottle capping machinery industry is a global one. In 2017, it accounted for 5.68 trillion dollars in sales worldwide. This number is expected to grow significantly over the next few years, especially in Asia.

TORQ Cappers

TORQ cappers offer precise torque for optimal sealing quality that minimizes sample evaporation. They also offer simple changeovers and dependability for long term operations.

Unlike https://llamasimsnews.com/2023/09/14/capping-machines-cap-sealing-machines capping machines that have clutches, the TORQ Capper uses a unique system to tighten caps. It uses two pairs of belts to gently rotate and tighten the caps while reducing friction and slipping.

This design maximizes product quality, minimizing the risk of damage to cap knurling and finishing, and reduces production downtime. In addition, the TORQ Capper can handle a variety of caps and container shapes, making it an ideal choice for a wide range of applications.

The TORQ Capper is suitable for pharmaceutical, nutraceutical, and beverage products that are packaged in round, oval or square bottles and caps up to 120mm in diameter. It can withstand temperatures as high as 205°F, pressures of up to 30 inches of water, and strong chemical cleaners without causing any damage to the equipment or product.

TORQ Cappers are compatible with most types of capping equipment, including inline fillers and screw cap recapper machines. They are durable, easy to maintain, and require less training than other types of cappers.

They can be purchased to work with existing cappers, reducing the cost of installing a new machine. They are also available in a variety of different models and sizes, making it easy to find a model that meets your needs.

These chucks are used to tighten bottles and other containers, and they are available in rotary or inline designs. Typically, they run at speeds from 20ppm to 1200ppm.

Another type of chuck is the servo-driven capping head, which can orientate and apply a precise torque force to the cap. It can also turn the cap to a predetermined number of revolutions or degrees of rotation.

The servo-driven capping heads are controlled by a servo motor that is powered by an electric motor. These servo motors can be configured with multiple rotors that can orientate and tighten a variety of closures, including metallic coated, linerless caps, and easily marked cosmetic and aluminum caps.

TORQ Capper Maintenance

In addition to having routine maintenance performed on your capping equipment, it is also important to keep an inventory of spare parts that are suitable for use in your particular brand of capper machinery. Having the correct spares on hand will help to ensure that any problems with your machinery are spotted and dealt with quickly, which can save you valuable time and money.

It is important to determine the torque requirements of your cap type and container. This will help to determine which capping machine is the right fit for your company’s needs. Some caps need specific application torque while others may not require any at all.

For example, a 38mm screw cap would have a required application torque of 27-33 inches pounds. This can be determined by examining the general torque guideline chart to the left and then consulting with your cap supplier.

Another way to determine the proper application torque for your cap type is to use a torque tester. This can be an effective tool for measuring both the application and removal torque of a cap.

If the torque is not matched correctly, the closure will not be tightened properly or it will not be able to close. This can be caused by a variety of factors including product quality, environmental issues, and even the speed that the spindle wheels are running at.

CSI’s Intelli-Torq Servo Cappers are the perfect solution for plastic closure applications. They incorporate full stainless steel construction with a sanitary design that allows for easy cleaning and rinsing. They are also fully metric, so they can be used worldwide.

Keeping your TORQ capper in good working order will not only help you to achieve high production rates, but will also prevent any issues from developing which could cost your company significant downtime and money. Having the right parts on hand for your cappers will allow you to keep them in good condition and ensure that any downtime is kept to a minimum which will benefit your business over the long term.

1 note

·

View note

Text

Bottle Caping

Bottle Capping Machines

If you are packaging liquid products, capping your containers is an essential part of the process. It speeds up the process, ensures that each container is sealed properly and prevents product from getting contaminated.

A capping machine is a piece of equipment that is placed onto your production line to apply a cap or lid to the container. It helps your company package more products in less time.

Industrial Bottle-Capping Machines

Bottle cap machines make it possible for companies to cap bottles quickly and efficiently. These machines allow businesses to increase production rates, thereby increasing revenue and profitability.

These cappers come in a variety of styles and can be divided into semi-automatic and fully-automatic categories. These classifications depend on the type of containers the cappers are designed to handle.

The most common automatic capper used in the beverage industry is the spindle capper. This machine uses several sets of spindle disks to tightly tighten screw-on caps as they pass through the machine on a power conveyor. It also uses gripper belts and a stabilizer bar to keep the bottles steady during the tightening process.

This machine can handle a variety of screw-on caps, including plastic, metal, and flip top types. Bottling Machines can also handle child-resistant caps, which are used to ensure the safety of children.

Fully-automatic capping machines apply caps to a variety of bottles and can also be set up to run simultaneously with liquid filling or bottle labeling machines, allowing a more efficient and smooth operation. These machines can produce a large volume of containers per minute and are suitable for a range of industries.

They are also easy to maintain and can be upgraded as the business grows, so they are often a good investment. They can be easily adjusted to handle a variety of container sizes and cap sizes and are also dependable (simple change parts mean quick and easy 30 minute changes).

In addition to these main categories, the market is also segmented by material type, application, and region. This is to help companies identify the best equipment for their needs.

These machines can handle a wide range of materials, from delicate glass to rugged plastic and metals. They can also be adapted to modify the speed of capping based on the production needs.

The bottle capping machinery industry is a global one. In 2017, it accounted for 5.68 trillion dollars in sales worldwide. This number is expected to grow significantly over the next few years, especially in Asia.

TORQ Cappers

TORQ cappers offer precise torque for optimal sealing quality that minimizes sample evaporation. They also offer simple changeovers and dependability for long term operations.

Unlike most capping machines that have clutches, the TORQ Capper uses a unique system to tighten caps. It uses two pairs of belts to gently rotate and tighten the caps while reducing friction and slipping.

This design maximizes product quality, minimizing the risk of damage to cap knurling and finishing, and reduces production downtime. In addition, the TORQ Capper can handle a variety of caps and container shapes, making it an ideal choice for a wide range of applications.

The TORQ Capper is suitable for pharmaceutical, nutraceutical, and beverage products that are packaged in round, oval or square bottles and caps up to 120mm in diameter. It can withstand temperatures as high as 205°F, pressures of up to 30 inches of water, and strong chemical cleaners without causing any damage to the equipment or product.

TORQ Cappers are compatible with most types of capping equipment, including inline fillers and screw cap recapper machines. They are durable, easy to maintain, and require less training than other types of cappers.

They can be purchased to work with existing cappers, reducing the cost of installing a new machine. They are also available in a variety of different models and sizes, making it easy to find a model that meets your needs.

These chucks are used to tighten bottles and other containers, and they are available in rotary or inline designs. Typically, they run at speeds from 20ppm to 1200ppm.

Another type of chuck is the servo-driven capping head, which can orientate and apply a precise torque force to the cap. It can also turn the cap to a predetermined number of revolutions or degrees of rotation.

The servo-driven capping heads are controlled by a servo motor that is powered by an electric motor. These servo motors can be configured with multiple rotors that can orientate and tighten a variety of closures, including metallic coated, linerless caps, and easily marked cosmetic and aluminum caps.

TORQ Capper Maintenance

In addition to having routine maintenance performed on your capping equipment, it is also important to keep an inventory of spare parts that are suitable for use in your particular brand of capper machinery. Having the correct spares on hand will help to ensure that any problems with your machinery are spotted and dealt with quickly, which can save you valuable time and money.

It is important to determine the torque requirements of your cap type and container. This will help to determine which capping machine is the right fit for your company’s needs. Some caps need specific application torque while others may not require any at all.

For example, a 38mm screw cap would have a required application torque of 27-33 inches pounds. This can be determined by examining the general torque guideline chart to the left and then consulting with your cap supplier.

Another way to determine the proper application torque for your cap type is to use a torque tester. This can be an effective tool for measuring both the application and removal torque of a cap.

If the torque is not matched correctly, the closure will not be tightened properly or it will not be able to close. This can be caused by a variety of factors including product quality, environmental issues, and even the speed that the spindle wheels are running at.

CSI’s Intelli-Torq Servo Cappers are the perfect solution for plastic closure applications. They incorporate full stainless steel construction with a sanitary design that allows for easy cleaning and rinsing. They are also fully metric, so they can be used worldwide.

Keeping your TORQ capper in good working order will not only help you to achieve high production rates, but will also prevent any issues from developing which could cost your company significant downtime and money. Having the right parts on hand for your cappers will allow you to keep them in good condition and ensure that any downtime is kept to a minimum which will benefit your business over the long term.

1 note

·

View note

Text

Veken Non Slip Rug Pad Gripper 8 x 10 Feet Extra Thick Pads for Any Hard Surface Floors

Introducing the Veken Non-Slip Rug Pad Gripper, the ultimate solution to keep your rugs safe and secure on any hard surface floor. With a generous size of 8 x 10 feet, these extra-thick pads are designed to provide unbeatable grip and protection for your rugs. Say goodbye to slipping and sliding carpets and enjoy a safer, more stable home environment. check out the price

#VekenRugPad #NonSlipGrippers #HomeSafety #RugProtection #FloorPreservation #ExtraThickPadding #AntiSkidMat #InteriorDesign #EcoFriendly #SecureYourSpace

0 notes

Text

Rabenda rug grippers are on sale at Amazon

What is it?

If you have hardwood or tile floors, you’ve probably slid around on your fair share of slippery area rugs. And if not you, your energetic kids and/or pets sure have! Area rugs are essential when it comes to giving your feet cushy landing pad, but having them move around — or worse, tripping you — all the time? Not fun. That’s where these top-selling Rabenda Rug Grippers come in. They…

View On WordPress

0 notes

Text

Enhance Your Industrial Efficiency with Booka’s Vacuum Suction Cups and Grippers

Are you a factory owner striving to optimize your operations and boost productivity? Look no further than Booka’s cutting-edge vacuum suction cups and grippers. These ingenious devices are tailored to handle a diverse array of materials swiftly and effectively, streamlining your production processes and enhancing overall efficiency.

Versatility meets innovation with our flagship product, the 1.5-fold round corrugated suction cup. Designed to excel even in high-intensity operations with rapid cycle times, this suction cup shines in bustling industrial environments. From corrugated cardboard boxes to rugged wooden boards, this dynamic tool tackles each task with ease and speed.

For more challenging surfaces such as coarse cardboard or oil-coated metal sheets, opt for our specialized grooved suction cups. Engineered to resist lateral forces, these cups guarantee material stability during the most demanding operations. Their unique grooved design amplifies their prowess in handling tough materials with remarkable ease.

However, for standard materials like cardboard boxes and wooden planks, the go-to choice remains our standard suction cups. Available in various sizes to suit your specific requirements, these cups offer efficient and prompt handling of a wide spectrum of materials.

When dealing with flat, smooth surfaces like glass, metal sheets, or plastic, the ultimate choice lies in our balanced vacuum suction cups. These cups maximize suction power while minimizing the risk of material damage, ensuring your products reach their destination in impeccable condition.

Need to hoist and transport substantial, weighty objects like automotive parts, glass sheets, or solar panels? Invest in our vacuum pad grippers. Engineered for exceptional suction power and stability, these robust devices simplify the movement of even the heftiest loads, facilitating quick and secure transportation.

Elevate your industrial efficiency by exploring Booka’s diverse range of vacuum suction cups and grippers. Contact us today to gain comprehensive insights into our various offerings. Our team of experts stands ready to guide you towards the ideal solution for your unique needs. Don’t hesitate — reach out to Booka Suction Cups now and embark on a journey to transform your industrial operations!

0 notes