#Plate Fin Heat Exchanger

Photo

Kinetic Engineering Corporation provides various types of heat exchangers for industry applications. Some of these heat exchangers are plate fin heat exchangers which are used in the ammonia production industry. Plate fin heat exchangers are ideal for large-volume applications because they have a high surface area and can handle high flow rates. This type of heat exchanger is also known for its high efficiency, durability, and low maintenance requirements.

0 notes

Text

#Plate Fin Heat Exchanger Market#Plate Fin Heat Exchanger Market Trends#Plate Fin Heat Exchanger Market Growth#Plate Fin Heat Exchanger Market Industry#Plate Fin Heat Exchanger Market Research#Plate Fin Heat Exchanger Market Report

0 notes

Text

AUTOMOTIVE HEAT EXCHANGER MARKET BILLION AT USD 8.30

Automotive Heat Exchanger Market Outlook 2023-2027

The Automotive Heat Exchanger Market is projected to witness substantial growth, with an estimated increase of USD 8.30 billion at a Compound Annual Growth Rate (CAGR) of 6.41% from 2022 to 2027. This growth is driven by several factors, including the continued reliance on internal combustion (IC) engines for mobility in emerging economies, the surge in passenger car sales, and the imposition of governmental regulations mandating the adoption of efficient HVAC systems in vehicles. These factors underscore the imperative to address environmental concerns and enhance energy efficiency across the automotive sector. With a focus on meeting regulatory standards and consumer demands for sustainable transportation solutions, the market is set for significant expansion, propelled by advancements in vehicle technology and an increasing emphasis on environmental sustainability in the automotive industry.

Download the AUTOMOTIVE HEAT EXCHANGER MARKET Sample PDF Report

Automotive Heat Exchanger Market Forecast

For deeper insights into this report, Request Free Sample of the Automotive Heat Exchanger Market Analysis Growth Report.

Market Segmentation

This automotive heat exchanger market overview report extensively covers market segmentation by application (passenger cars, ICVs, and M and HCVs), type (plate bar, tube fin, and others), and geography (APAC, North America, Europe, South America, and Middle East and Africa). It also includes an in-depth analysis of drivers, trends, and challenges. The market is undergoing significant transformations due to various factors such as supply chain activities, large-scale manufacturing, and restrictions on travel affecting demand dynamics. While declining sales pose challenges, the market is witnessing an uptick driven by the production of light vehicles and rising demand for passenger vehicles. The shift towards engine downsizing and lightweight automotive materials further propels growth, alongside the increasing adoption of hybrid and electric vehicles. However, challenges persist, including volatility in raw material prices and the complexity of designing advanced heat exchangers. With governments implementing zero-emission standards and incentives for vehicle manufacturing, the market is poised for expansion, particularly in emerging and developing countries.

Segment Overview

The automotive heat exchanger market growth report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in USD Billion for the period 2023 to 2027, as well as historical data from 2017 to 2021 for the following segments:

Application Outlook: Passenger cars, LCVs, M and HCVs

Type Outlook: Plate bar, Tube fin, Others

Region Outlook: APAC, North America, Europe, South America, Middle East & Africa

Market Segmentation By Application

The passenger cars segment is expected to witness significant market share growth during the forecast period. OEMs are equipping their passenger cars with brazed copper heat exchangers that have a longer lifespan and can last for ten years, reducing replacement costs. These heat exchangers are about 35% lighter than traditional ones, as their fins and tubes are manufactured with fewer materials. Hence, the growth in the passenger cars segment is expected to fuel the market's growth, as predicted in the automotive heat exchanger market forecast report.

Regional Analysis of the Automotive Heat Exchanger Market

APAC is estimated to contribute 54% to the growth of the global market during the forecast period. Analysts have elaborated on the regional trends and drivers shaping the market during this period. The increasing disposable incomes and the launch of new car models by OEMs are the main factors driving the market. Moreover, the perception of achieving a higher social status by owning a car is driving the market for passenger cars in China and India despite the increasing rates of traffic congestion, government regulations for owning passenger cars, and rising levels of vehicular pollution. APAC has the maximum number of potential first-time buyers of passenger cars, which is also increasing the number of passenger car sales, ultimately fueling the market's growth in the region.

Download the AUTOMOTIVE HEAT EXCHANGER MARKET Sample PDF Report

Automotive Heat Exchanger Market Dynamics and Customer Landscape

The market is experiencing a shift towards medium-term growth, driven by increased production of vehicles and rising adoption of innovative technologies like battery thermal management systems. While traditional heat exchanger manufacturers play a significant role, challenges such as volatility in raw material prices and the complexity of designing advanced exchangers hinder progress. However, government initiatives like the California ZEV program and efforts to enhance charging infrastructure are propelling the market forward. With a focus on reducing environmental pollution and meeting zero-emission standards, the demand for heat exchangers is rising across diverse applications in the automotive sector. Our researchers analyzed the data with 2022 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

Key Automotive Heat Exchanger Market Drivers

The heavy dependence on IC engines for mobility in emerging countries is notably driving market growth. Emerging countries like India and China are witnessing an increase in the preference for mobility through roadways. In the commercial vehicle segment, there is hardly any vehicle that runs on batteries or alternate fuels. Hence, there is a high reliance on internal combustion (IC) engines for transportation. One of the main reasons why road transport is preferred for mobility and the transportation of cargo is the limited availability of rail services. The lack of effective rail services for logistics is forcing freight companies to choose roadways as a reliable mode of transportation. Heavy-, medium-, and light-duty vehicles are extensively used for transporting cargo in China. In India, road transportation

Download the AUTOMOTIVE HEAT EXCHANGER MARKET Sample PDF Report

0 notes

Text

Remote jet air-conditioning unit

Characteristics of the heat recovery air treatment unit:

Energy saving: heat recovery The air treatment unit adopts heat recovery technology, which can recycle part of the heat in the exhaust gas and reduce energy consumption. At the same time, the unit can also automatically adjust the operating state according to the indoor and outdoor temperature and humidity and other parameters, to further save energy.

Environmental protection: heat recovery air treatment unit can filter the dust, pollen, bacteria and other pollutants in the air, reduce the pollution to the environment. In addition, the unit can also use environmental protection refrigerant and low-energy motors and other environmental protection technologies to further reduce carbon emissions. Heat recovery air treatment unit adopts heat recovery technology and air treatment technology can effectively adjust the indoor temperature and humidity, improve the air quality, and make the indoor environment more comfortable.

Convenient maintenance: the heat recovery air treatment unit adopts a modular design to facilitate maintenance and replacement. At the same time, the unit also has the intelligent fault diagnosis function, which can automatically detect and diagnose faults, and it is convenient for users to carry out maintenance and maintenance.

Strong adaptability: the heat recovery air treatment unit can adapt to different use environment and places, such as shopping malls, hotels, hospitals and other large public places. At the same time, the unit can also be customized and configured according to different places and needs, to meet the different needs of users.

Specification for heat recovery air treatment unit:

1.fillter section

Primary filter-folding plate or bag; mid-effect filter-bag; sub-filter-bag dense fold.

2.Thermal recovery section

Rotor heat exchanger: energy recovery function, super long service life, hig h runner surface flatness, good sealing, runner motor self-tension device, filter blockage alarm function (optional), prevent frosting device (optional), self-cleaning function, double cleaning fan.

Plate heat recovery: using the temperature difference between the two air flows on both sides of the partition plate to show heat and latent heat recovery.

Heat recovery: a heat tube is a kind of heat transfer component with high thermal conductivity, which transfers heat through the evaporation and condensation of the working medium in the fully enclosed vacuum tube shell.

3.Cold / hot coil

The heat recovery air treatment unit adopts seamless copper tube sleeve aluminum fin heat exchange tube, which adopts advanced mechanical rising tube and circular arc ripple double turning aluminum rib structure.

0 notes

Text

Unlocking Opportunities: Aircraft Heat Exchanger Market Set to Reach $2.0 Billion by 2026

The Aircraft Heat Exchanger Marketis set to embark on a trajectory of substantial growth, with an anticipated surge from USD 1.3 billion in 2021 to USD 2.0 billion by 2026, manifesting a noteworthy CAGR of 9.2% during the forecast period (2021-2026). This robust expansion is underpinned by escalating demand for efficient cooling and heating solutions in commercial aircraft and a surge in military expenditure across various nations globally.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=20018090

Among the design variants of heat exchangers utilized in aircraft, the flat tube type emerges as the frontrunner, expected to maintain the largest market share throughout the forecast period. This trend is attributed to the anticipation of a higher CAGR compared to the plate and fin type, with flat tube type exchangers driving aftermarket demand and replacements.

The fixed-wing aircraft segment is poised to exhibit the highest CAGR during the forecast period. This growth is propelled by increasing demand for narrow-body commercial aircraft and enhanced regional connectivity. Aircraft heat exchangers play a pivotal role across diverse aircraft types, including narrow-body, wide-body, very large body aircraft, and business jets.

Within the application domain, the Electronics Pod Cooling segment is anticipated to command the largest market size during the forecast period. This prominence is driven by the escalating demand for automation and the need to cool electronic devices such as chips and IC packages in confined spaces, reflecting a notable increase in CAGR.

The aftermarket segment, encompassing maintenance, repair, upgrading, and replacement services, is projected to spearhead the aircraft heat exchanger market. This dominance is attributed to heightened spending on avionics upgrades and thermal management system replacements. However, the OEM segment is poised for growth due to an increase in aircraft deliveries and domestic manufacturing.

Positioned as one of the burgeoning markets for aircraft heat exchangers, the Asia Pacific region is characterized by robust research and development activities, deployment initiatives, and the presence of key market players. Japan, India, and China are identified as major contributors to market growth, driven by initiatives to enhance military capabilities and improve thermal management systems in commercial airlines. China, in particular, is projected for substantial growth, fueled by increased military spending and engagements with aftermarket service suppliers to augment aircraft operations.

Major players such as Meggitt PLC (Britain), AMETEK (US), TAT Technologies (Israel), Triumph Group (US), and Honeywell (US) play a pivotal role in the aircraft heat exchanger market. These industry leaders offer a diverse portfolio of aircraft heat exchangers catering to commercial and defense aircraft, spacecraft, UAVs, and UCAVs, backed by robust distribution networks spanning North America, Europe, Asia Pacific, and the Rest of the World.

Inquiry Before Buying: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=20018090

In essence, the aircraft heat exchanger market is poised for significant expansion, driven by evolving market dynamics, technological advancements, and strategic initiatives by key stakeholders. With a focus on innovation and market penetration, industry players can capitalize on emerging opportunities and navigate the evolving landscape of the aircraft heat exchanger industry.

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America's best management consulting firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

Contact:

Mr. Aashish Mehra

MarketsandMarkets™ INC.

630 Dundee Road, Suite 430, Northbrook, IL 60062

USA: +1-888-600-6441

Email: [email protected]

0 notes

Text

Brazing Heat Sink

Brazing heat sink is one of the most effective heat transfer methods. It is composed of a set of corrugated pipe plates between the front and rear baffles. The baffle plate assembly is composed of a sealing plate, a sealing ring and a baffle plate. The interface type can be customized according to the specific requirements of the market and application fields. During the vacuum brazing process, a solder joint is formed at each contact point between the plate and the filler material (brazing material). Using this design method, a heat exchanger composed of two different channels or loops can be manufactured. The design purpose of the brazed fin heat sink is to provide unparalleled performance and the lowest life cycle cost. If brazing technology can be used in your next cooling project, it will surely bring you many benefits, including saving space, energy and maintenance costs.

1 note

·

View note

Text

DEEPCOOL AK500 CPU COOLER | HOW GOOD IS IT?

The DeepCool AK500 is a high-performance CPU cooler designed to keep your system running cool and quiet. This single-tower cooler boasts a variety of features that make it a compelling option for both budget-minded builders and those seeking a balance of performance and noise levels. Let’s explore it thoroughly:

Design and Construction:

Heatsink:

Unlike bulkier dual-tower coolers, the AK500 employs a single-tower heatsink, making it ideal for mid-tower and smaller cases where space is a concern. Despite its single-tower design, the AK500 boasts a large heatsink measuring 127 x 90 x 158mm, providing ample surface area for efficient heat dissipation.

The AK500 utilizes DeepCool’s signature black matrix fin design. These fins are strategically staggered to create micro-channels, increasing airflow and heat exchange with the surrounding air. The heat pipes directly touch the CPU’s integrated heat spreader (IHS), eliminating thermal resistance and ensuring rapid heat transfer from the CPU core.

Heat Pipes:

Five 6mm nickel-plated copper heat pipes efficiently transfer heat away from the CPU core and distribute it evenly across the large heatsink. Balanced Bidirectional Heat Pipe Technology optimizes the heat pipes’ layout to counteract the effects of gravity, ensuring efficient heat transfer even in vertical PC cases.

Fan:

The fluid dynamic bearing (FDB) fan uses a lubricating fluid to reduce friction, resulting in smoother operation, lower noise levels, and increased lifespan compared to sleeve bearing fans. The fan speed is intelligently controlled by the motherboard based on CPU temperature, ensuring optimal cooling while minimizing noise when the system is under low load.

Additional Details:

The heatpipes are angled slightly to ensure 100% compatibility with most standard and high-profile RAM modules, eliminating clearance issues. The AK500 is built with high-quality materials, including a nickel-plated base and aluminum fins, ensuring long-lasting performance and reliability.

Performance and Cooling:

Credit: Dannys Tech Channel

Cooling Capacity:

240W TDP rating signifies the maximum amount of heat the AK500 can effectively dissipate, making it suitable for cooling most modern CPUs, including mid-range and high-performance processors with a TDP of up to 240W. The combination of a large heatsink, five heat pipes, and Direct Touch technology facilitates efficient heat transfer away from the CPU core.

The black matrix fin design and PWM-controlled 120mm FDB fan work together to generate optimal airflow throughout the heatsink, effectively transferring heat to the surrounding environment.

Performance in Practice:

While real-world performance can vary depending on specific system configurations and usage scenarios, independent tests and user reviews consistently show that the AK500 is capable of maintaining safe CPU temperatures even under demanding workloads. Depending on your specific CPU and other system components, the AK500 may offer limited headroom for overclocking. However, it should be sufficient for moderate overclocking on most mid-range CPUs.

Noise Levels:

One of the AK500’s key strengths is its quiet operation. The FDB fan and PWM control work together to minimize noise generation. The fan operates at speeds between 300 and 1,500 RPM, depending on the CPU temperature. At its lowest speed, the AK500 is nearly inaudible, making it suitable for noise-sensitive environments.

While the AK500 prioritizes quiet operation, it’s important to remember that noise levels will increase as the fan ramps up under heavier loads to maintain optimal cooling. Users seeking absolute silence at the expense of some cooling performance might need to consider alternative cooling solutions.

Installation and Compatibility:

The DeepCool AK500 boasts a user-friendly and straightforward installation process. This makes it a great choice for both experienced builders and beginners.

Installation Process:

Prepare your system: Before installation, ensure your system is powered off and unplugged. Locate the motherboard socket and remove any existing coolers or thermal paste.

Mount the backplate: The AK500 utilizes a universal backplate design compatible with various Intel and AMD sockets. Position the backplate on the backside of your motherboard and secure it using the provided screws.

Attach the mounting brackets: Depending on your specific CPU socket, attach the designated mounting brackets to the backplate using the included thumbscrews.

Apply thermal paste: Apply a thin, even layer of thermal paste (not included) onto the center of your CPU’s integrated heat spreader (IHS).

Position the heatsink: Carefully place the heatsink onto the CPU, ensuring the heat pipes make proper contact with the CPU’s IHS.

Secure the heatsink: Secure the heatsink to the mounting brackets using the provided thumbscrews. Tighten them evenly in an alternating pattern to avoid uneven pressure.

Compatibility:

The AK500 is compatible with a wide range of Intel and AMD CPU sockets, including:

Intel: LGA 115x, 1200, 1700, 2066

AMD: AM4, AM5

Installation Process:

Prepare your system: Before installation, ensure your system is powered off and unplugged. Locate the motherboard socket and remove any existing coolers or thermal paste.

Mount the backplate: The AK500 utilizes a universal backplate design compatible with various Intel and AMD sockets. Position the backplate on the backside of your motherboard and secure it using the provided screws.

Attach the mounting brackets: Depending on your specific CPU socket, attach the designated mounting brackets to the backplate using the included thumbscrews.

Apply thermal paste: Apply a thin, even layer of thermal paste (not included) onto the center of your CPU’s integrated heat spreader (IHS).

Position the heatsink: Carefully place the heatsink onto the CPU, ensuring the heat pipes make proper contact with the CPU’s IHS.

Secure the heatsink: Secure the heatsink to the mounting brackets using the provided thumbscrews. Tighten them evenly in an alternating pattern to avoid uneven pressure.

Compatibility:

Read Here

Originally Published @ Gamers' Guide

1 note

·

View note

Text

Brazing Heat Sink: Revolutionizing Heat Transfer Efficiency

In the realm of heat transfer technology, brazing heat sinks stand out as one of the most effective methods, offering unparalleled performance and cost efficiency. Comprising a series of corrugated pipe plates sandwiched between front and rear baffles, these heat sinks are engineered to optimize heat dissipation in various applications.

The assembly of a brazing heat sink consists of a sealing plate, a sealing ring, and the crucial baffle plates. These components come together seamlessly during the vacuum brazing process, wherein solder joints are formed at each contact point between the plates and the filler material, also known as the brazing material. This meticulous design approach allows for the creation of a heat exchanger with distinct channels or loops, catering to diverse market requirements and application fields.

What sets brazed fin heat sinks apart is their ability to deliver exceptional performance while minimizing life cycle costs. By harnessing brazing technology, these heat sinks not only excel in heat dissipation but also offer numerous benefits to users. Among these advantages are space optimization, energy savings, and reduced maintenance expenses.

The compact design of brazing heat sinks enables them to effectively dissipate heat in confined spaces, making them ideal for applications where spatial constraints are a concern. Furthermore, their efficiency in transferring heat translates into significant energy savings, contributing to overall operational cost reduction. Moreover, the robust construction of brazed fin heat sinks minimizes the need for frequent maintenance, thereby further lowering the total cost of ownership over their lifespan.

For industries and projects seeking superior heat transfer solutions, brazing technology presents an enticing proposition. Whether it’s for electronics cooling, automotive applications, or industrial processes, brazed fin heat sinks offer a reliable and efficient means of managing thermal loads. Embracing brazing technology in cooling projects not only ensures optimal performance but also promises long-term benefits in terms of space utilization, energy conservation, and operational cost efficiency.

In conclusion, brazing heat sinks represent a paradigm shift in heat transfer technology, offering unmatched performance and cost-effectiveness. With their innovative design and advanced manufacturing processes, these heat sinks have become indispensable assets across various industries. By incorporating brazing technology into cooling projects, businesses can unlock a multitude of benefits, paving the way for enhanced efficiency and sustainability in thermal management solutions.

0 notes

Text

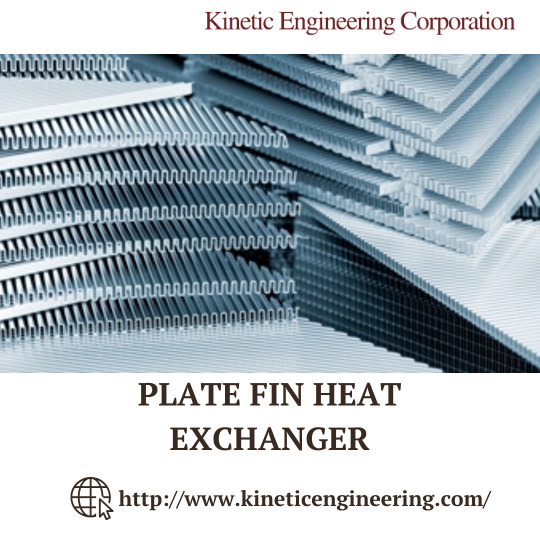

Kinetic Engineering Corporation's plate fin heat exchanger is a remarkable industrial solution for efficient heat transfer. Its compact design optimizes surface area, enhancing thermal performance. With robust construction and precise engineering, it delivers reliable operation, making it an invaluable asset in various industrial processes. A top choice for heat exchange needs. Visit here:

0 notes

Text

All About Plate Fin Heat Exchanger

The Plate fin heat exchanger is essential in industrial and commercial applications. These devices are used to reduce the temperatures of fluid streams. These heat exchangers are helpful in the oil and gas industries and other industrial endeavors. In this blog post, we will explore the critical components of a plate-fin heat exchanger and the manufacturing process involved in their production. We will also discuss some of the applications for these devices and how they can be used to improve efficiency and output.

What is a Plate-Fin Heat Exchanger?

A plate-fin heat exchanger is a type of heat exchanger made from a series of parallel metal plates that have been sealed together to create a fluid-tight unit. The metal plates are often curved to allow them to interact more easily with the flow of heat. Plate-fin heat exchangers are often used in industrial applications where high temperatures must be exchanged between two different fluids. They are also used in vehicles, aircraft, and other large machines where high temperatures are needed for safety reasons or to increase performance.

Types of Plate-Fin Heat Exchangers

There are three common types of plate-fin heat exchangers: crossflow, counterflow, and flow through. Crossflow is the most common type used to transfer heat between two fluids at different temperatures. Counterflow is used when the two fluids have the same temperature and flow in opposite directions. Flow through is a variation of counterflow and uses a fluid flow path that goes right through the heat exchanger plates.

How Plate-Fin Heat Exchangers Work

A plate-fin heat exchanger is a type of heat exchanger that uses fins to increase surface area. This increases the ability to transfer heat between two fluids. Plate-fin heat exchangers are used in industrial and commercial applications where high temperatures or large amounts of fluid must be exchanged.

The basic principle behind a plate-fin heat exchanger is that it uses many small, narrow fins instead of one large fin. This increases the surface area available for contact with the cooling fluids. As a result, more heat can be transferred between the two fluids than with a conventional heat exchanger. Plate-fin heat exchangers are often used in industrial settings where high temperatures and high flow rates are needed.

Advantages of Plate-Fin Heat Exchangers

There are many advantages and disadvantages of plate-fin heat exchangers. Benefits include that they are relatively easy to manufacture, have low operating costs, handle high flow rates, and are useful in various applications.

Conclusion

In this article, we've discussed the manufacture of the custom heat exchanger. We've discussed the different types of materials used to produce these devices and the methods used to fabricate them. Additionally, we've consulted some typical applications for these devices and some tips on how to improve their performance.

0 notes

Text

Radiator Repair: Keeping Your Engine Cool with Ring Heat Exchanger

For decades, Ring Heat Exchanger has been synonymous with Ring Radiator Services, reflecting our commitment to radiators at the core of our operations. Our expertise spans radiator maintenance, repair, overhaul, and service across various applications and industries, dealing with copper, aluminum, and stainless-steel cores.

The Purpose of a Radiator

Radiators play a crucial role in the engine cooling system by dissipating excess heat from the engine block and other systems. A poorly functioning radiator can lead to engine overheating, compromising performance and potentially causing critical engine failure.

Radiator Failure Modes

Leaks: In tubes, header plates, or tank gaskets.

Mechanical damage: Caused by impacts from environmental debris or unmaintained tools.

Restricted airflow: Accumulation of dirt and debris on cooling fins.

Corrosion: Damaged radiator fins leading to reduced cooling capacity.

Coolant flow restriction: Accumulation of debris in tubes hindering efficient cooling.

What We Do

#radiator maintenance#brazed plate heat exchanger#plate and frame heat exchangers#shell and tube heat exchangers#charge air cooler repair#industrial radiators and heat exchangers#heat exchanger maintenance

0 notes

Text

Heat Exchanger Market| Global Industry Analysis, Market Size, Share, Trends, Analysis, Growth and Forecast, 2023 – 2027

Originally published on Technavio: Heat Exchanger Market by End-user, Product, and Geography - Forecast and Analysis 2023-2027

The Heat Exchanger Market is poised for a comprehensive analysis and anticipated growth during the forecast period from 2023 to 2027. This market, crucial for various industrial applications, will be examined based on end-user industries, product types, and geographical trends influencing its trajectory.

In terms of end-user industries, the Heat Exchanger Market caters to a broad spectrum of sectors, including petrochemical, chemical, power generation, HVAC (Heating, Ventilation, and Air Conditioning), food and beverage, and more. In the petrochemical and chemical industries, heat exchangers are essential for processes such as condensation, evaporation, and heat recovery, contributing to energy efficiency and cost savings. The power generation sector relies on heat exchangers for efficient cooling in thermal power plants, while HVAC systems utilize them for temperature regulation in buildings. Heat exchangers also play a crucial role in the food and beverage industry for processes like pasteurization and sterilization.

The Heat Exchanger Market offers various product types to meet the diverse needs of different industries. Common types include shell and tube heat exchangers, plate heat exchangers, finned tube heat exchangers, and air-cooled heat exchangers. Shell and tube heat exchangers are versatile and widely used across industries for their robust design and high heat transfer efficiency. Plate heat exchangers, on the other hand, are compact and efficient, making them suitable for applications with space constraints. Finned tube heat exchangers enhance heat transfer in air and gas applications, while air-cooled heat exchangers are ideal for processes where water availability is limited.

Geographically, the global Heat Exchanger Market demonstrates a widespread presence, with significant contributions from regions such as North America, Europe, Asia-Pacific, and South America. North America, particularly the United States, stands as a major player in the market, driven by the extensive industrial infrastructure and a focus on energy efficiency. Europe, with countries like Germany and the United Kingdom, is another key contributor, benefitting from stringent environmental regulations and a commitment to sustainable practices. The Asia-Pacific region, led by countries such as China and India, is experiencing notable growth, reflecting expanding industrialization and increased energy demand. South America, with its growing industrial activities, also contributes significantly to the global market.

To Learn deeper into this report , View Sample PDF

The forecasted period for the Heat Exchanger Market underscores the critical role these devices play in enhancing energy efficiency, reducing operational costs, and meeting environmental standards across various industries. As industries continue to prioritize sustainability and efficiency, manufacturers and stakeholders in the heat exchanger industry must stay attuned to evolving technological advancements, regulatory standards, and global trends to capitalize on the expanding opportunities within this dynamic market.

For more information please contact.

0 notes

Text

0 notes

Text

0 notes

Link

0 notes