#Metal Fabrication

Text

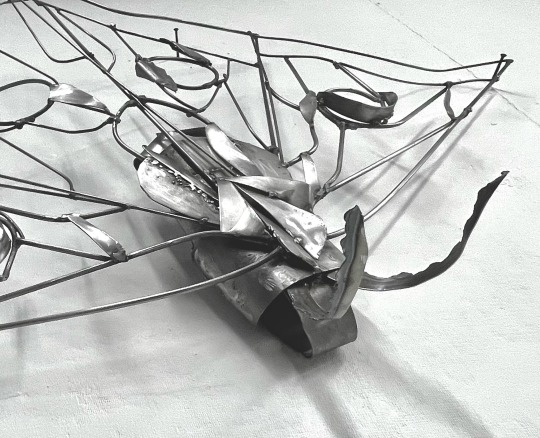

Metal moth COMPLETE!

#metalworking#welding#metal#art#artists on tumblr#artists of tumblr#sculpture#metal fabrication#moth#moon moth#my art#this was for a class and I’m actually pleasantly surprised with how it turned out#yippe

354 notes

·

View notes

Text

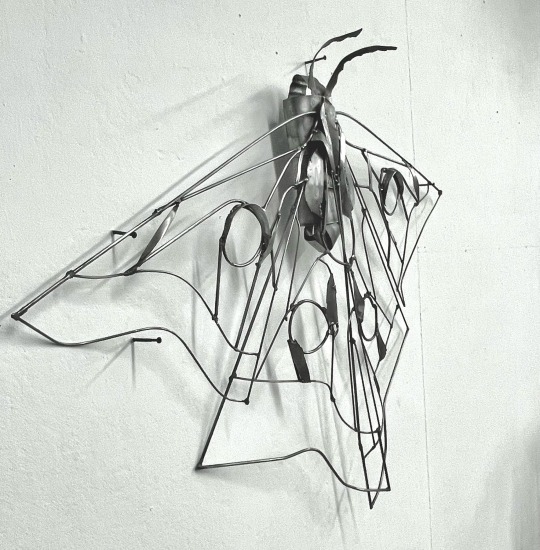

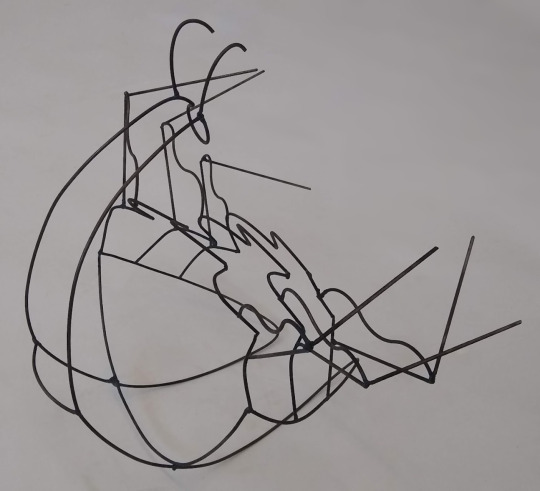

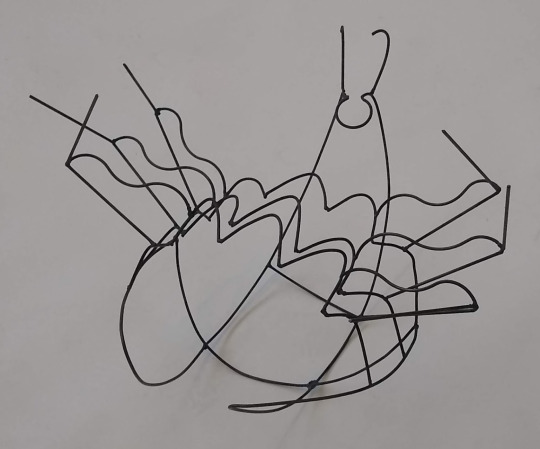

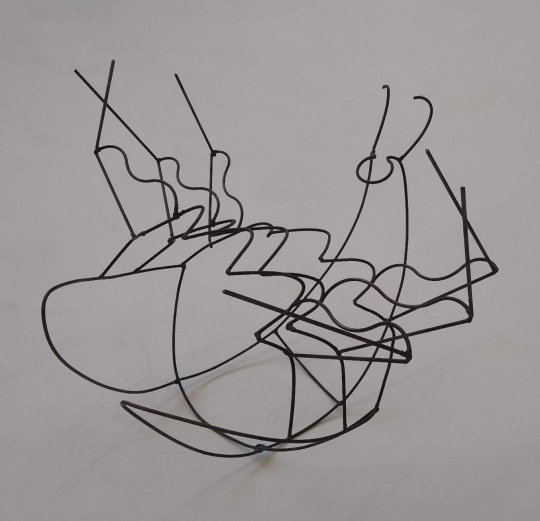

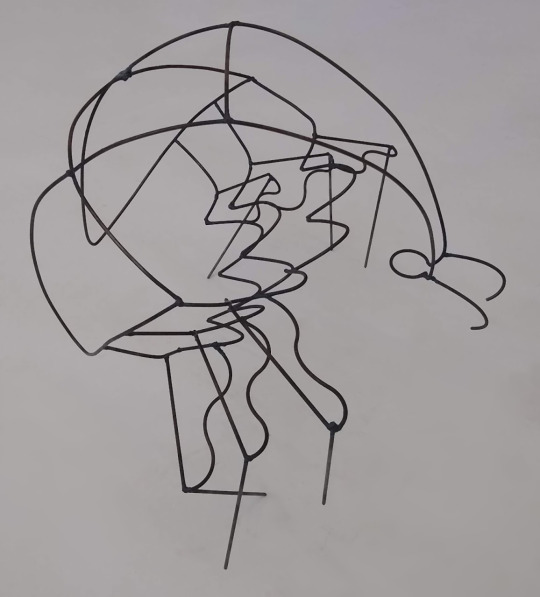

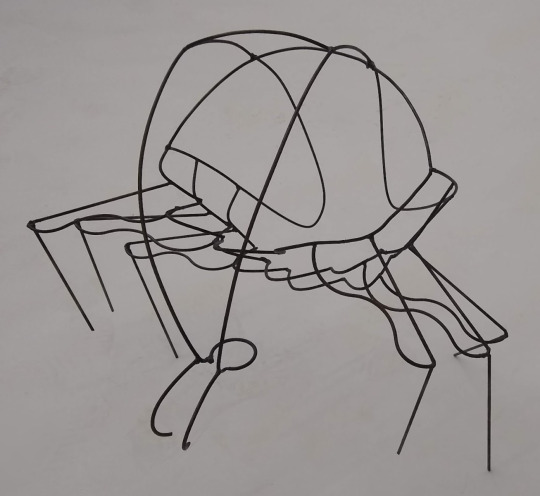

[Start ID. A sculpture made out of bent steel rods welded together to make the shape of a round beetle. Three zigzags stretch laterally across its front to form the beetle's underbelly. Its legs protrude from these zigzags. The beetle's back has much less detail. It's "face" is a circle that connects to the main structural wires of the beetle's back with two short curved antennae. In most of the photos, the beetle is posed as if it is on its back, thrashing and failing to get up. In the last two photos, it is hunched over as if to examine something beneath it. The photos are taken in warm light against a blank white backdrop. End ID.]

happy snark saturday! my little guy cannot TECHNICALLY be a snark because it has six legs. HOWEVER... here is my heavily snark-inspired wire beetle sculpture named greg :^)

my first time welding something! (and very possibly last. but who can say!)

#handmade by me with much help from my professor!#prinna's art#snark saturday#snaturday#bugs#metal#metallurgy#metal fabrication#welding#sculpture

2 notes

·

View notes

Text

3 notes

·

View notes

Text

Tara Fabrication: Your Trusted Partner for Exceptional Steel Fabrication In London.

When it comes to steel fabrication, Tara Fabrication is the name you can trust. With our extensive experience, expertise, and commitment to quality, we have become a leading provider of steel fabrication solutions. Visit our website at https://tarafabrications.co.uk/ to learn more about our services and explore our portfolio of successfully completed projects. Partner with Tara Fabrication and experience the seamless integration of craftsmanship, precision, and customer satisfaction in every steel fabrication endeavor.

2 notes

·

View notes

Text

Nick Willoughby, “ELEVATE”

Metal Sculpture (2023)

#artists on tumblr#artwork#handcrafted#sculpture#metalwork#welding#metal fabrication#design#abstracart#abstract#new artist#welder#maryland#metal design#eastern shore#landscape aesthetic#original art

2 notes

·

View notes

Text

Finished and ready to rock

#knights forge#rock band#custom design and fabrication#metal fabrication#medieval#woodworking#welding#gothic#dark grunge#spooky#skull art#Spotify

2 notes

·

View notes

Text

Primus Corp India Pvt Ltd Is Part of The Global Incorporate Of Primus Corp. The Company Has Been Growing In Presence In The Business Of Non Ferrous Metals.

2 notes

·

View notes

Text

Stainless Steel Window Grills manufacturers and suppliers. Designer Safety Window Grills offered by Lamboarts.

#stainless steel window grills#safety window grills#window grill#stainless steel#metal fabrication#stainless steel sculpture#stainless steel fabrication#safety grill

6 notes

·

View notes

Text

What is Metal Fabrication?

Metal fabrication transforms raw metal materials into a final product using various cutting, bending, welding, and assembling techniques. The process typically starts with the design and engineering of a product, followed by the selection and preparation of the raw materials, and then the fabrication process itself.

Metal fabrication can create various products, from simple metal components to complex machinery and structures. Some common examples of products created through metal fabrication include metal frames, brackets, enclosures, and structural components for buildings and bridges. Metal fabrication is used in various industries, including construction, automotive manufacturing, aerospace, and consumer products.

Why is metal fabrication important?

Metal fabrication is important for several reasons:

Customisation: Metal fabrication allows for customising metal products according to specific requirements, such as size, shape, and design. This flexibility enables businesses and industries to produce products that meet their unique needs and specifications.

Durability: Metal products produced through fabrication are durable and long-lasting. They can withstand extreme temperatures, pressures, and forces, making them ideal for various industries, including construction, manufacturing, and transportation.

Cost-effective: Fabricating metal products is often more cost-effective than purchasing pre-made products. This is because fabricators can produce multiple pieces of a product using the same materials, reducing waste and keeping costs low.

Quality control: Metal fabrication ensures high-quality products through strict quality control measures. Each product is inspected and tested to meet industry standards and specifications.

Metal fabrication is important because it enables businesses and industries to produce high-quality, customised, durable metal products that meet their unique needs and requirements.

What are the benefits of metal fabrication?

Metal fabrication offers many benefits, including:

Customisation: Metal fabrication allows for custom metal products that meet each customer's needs and requirements.

Strength and durability: Metal products created through fabrication are strong, durable, and able to withstand a variety of harsh conditions, making them ideal for use in construction and manufacturing industries.

Versatility: Metal fabrication can create a wide range of products, from small components to large structures, and can be used in various industries such as automotive, aerospace, construction, and more.

Cost-effective: Fabricated metal products can be produced in large quantities at a lower cost than other manufacturing processes, making them an affordable option for businesses and consumers.

Efficiency: With advanced technology and equipment, metal fabrication can produce high-quality products with minimal waste and faster turnaround times.

Aesthetics: Metal fabrication offers a wide range of finishes and coatings that can enhance the appearance of metal products, making them visually appealing and functional.

Recyclable: Metal is a recyclable material, which makes it an eco-friendly choice for businesses and consumers who want to reduce their environmental impact.

These benefits make metal fabrication an important and valuable process for a variety of industries and applications.

When do you need to get metal fabrication services?

You may need metal fabrication services when you require custom metal parts, structures or products for various purposes. Metal fabrication can be used in various industries, including construction, automotive, aerospace, manufacturing, and more. You may need metal fabrication services when you require unique parts or components that cannot be found off the shelf or a specific metal product designed and manufactured to your specifications.

Some common examples of when you may require metal fabrication services include the production of metal frames, structures, and enclosures, creating custom metal products, fabricating metal components for machinery or equipment, and repairing or modifying existing metal structures or products.

© DDK Engineering

2 notes

·

View notes

Text

Powder coating in metal fabrication finishing

Welcome to our guide on Powder Coating in sheet metal manufacturing & Finishing for 2023! Powder coating is a finishing technique in various industries, including metal fabrication. It includes applying a dry powder to a metal surface and curing it in an oven to create a durable and attractive finish. Powder coating offers numerous benefits compared to traditional wet painting methods, including increased durability, cost-effectiveness, and environmental friendliness.

This guide will explore the powder coating process, different types of powder coatings, their advantages, and their various applications. We will also provide tips on choosing the suitable powder coating for your project and maintaining powder-coated surfaces. By the end of this blog, you will have a comprehensive understanding of powder coating and its benefits in sheet metal manufacturing and finishing.

Powder Coating Process

The powder coating process involves several steps to ensure a high-quality, long-lasting finish on metal surfaces. Let’s take a look at each step:

Preparation of Metal Surface

Application of Powder Coating

The powder coating is applied to the metal surface using a spray gun or electrostatic process. The powder is charged with an electrostatic charge, which attracts it to the metal surface. The thickness of the powder coating can be adjusted depending on the desired finish and application.

Curing Process

The metal object is then placed in an oven where the powder coating is cured at a high temperature, typically around 400 degrees Fahrenheit. The curing process allows the powder coating to melt and flow into a smooth and even finish. The time and temperature for curing depend on the powder coating type and the metal object’s size.

Inspection and Testing

After curing, the metal object is inspected for defects, such as bubbles or uneven coating. The coating thickness is also measured to ensure it meets the desired specifications. Testing may include chemical and abrasion resistance, corrosion resistance, and other performance factors.

Types of Powder Coatings

Several types of powder coatings are available, each with unique properties and benefits. The following are the few common types of powder coatings used in sheet metal manufacturing and finishing:

Thermosetting Powder Coatings

Thermosetting powder coatings are the most common type of powder coating. They are made from resins, pigments, and curing agents. The curing process involves a chemical reaction that causes the powder coating to harden and become more durable. Thermosetting powder coatings offer excellent adhesion, abrasion resistance, and chemical resistance.

Thermoplastic Powder Coatings

UV-Curable Powder Coatings

UV-curable powder coatings are cured using ultraviolet light instead of heat. They offer quick curing times and excellent colour and gloss retention. They are also environmentally friendly since they emit no volatile organic compounds (VOCs).

Metallic Powder Coatings

Metallic powder coatings contain metallic pigments that give a metallic effect to the finish. They are often used in automotive and decorative applications, where a high-end and eye-catching finish is desired.

Advantages of Powder Coating

Powder coating offers several advantages compared to traditional wet painting methods. Here are the key benefits of using powder coating in metal fabrication and finishing:

Durability and Longevity

Powder coating provides a tough and durable finish that can withstand extreme temperatures, harsh environments, and exposure to chemicals and UV rays. It is resistant to chipping, fading, and peeling and can last many years without repainting.

Environmental Benefits

Powder coating is an environmentally friendly option since it emits no volatile organic compounds (VOCs) or hazardous air pollutants (HAPs). It produces less waste and uses less energy than traditional wet painting methods, making it a more sustainable choice.

Cost-Effectiveness

Powder coating is cost-effective since it requires less labour and materials than traditional wet painting methods. It also reduces the need for touch-ups, repainting, and maintenance, saving time and money in the long run.

Versatility in Color and Texture

Powder coating offers various colours, textures, and finishes, including matte, glossy, metallic, and textured. It can be customized to match specific colour and design requirements, making it a versatile option for various applications.

Ease of Application

Powder coating is easy to apply and covers complex shapes and surfaces. It also dries quickly, allowing for faster production times and turnaround times.

Choosing the Right Powder Coating for Your Project

Choosing the suitable powder coating for your project is crucial to achieving the desired finish and performance. Here are some factors when selecting a powder coating:

Performance Requirements

Consider the performance requirements of the metal object, such as abrasion resistance, chemical resistance, and corrosion resistance. Different types of powder coatings offer varying degrees of performance, so choose a coating that meets the specific needs of your application.

Colour and Finish

Powder coatings come in various colours, textures, and finishes. Consider the desired colour and finish of the metal object and choose a powder coating that matches these requirements.

Application Method

Consider the application method for the powder coating, such as electrostatic spray, fluidized bed, or hot flocking. The application method may affect the performance and appearance of the powder coating, so choose a coating that is compatible with the application method.

Substrate Material

Consider the substrate material of the metal object, such as steel, aluminium, or galvanized metal. Different substrates may require different types of powder coatings to achieve optimal adhesion and performance.

Environmental Factors

Consider the environmental factors the metal object will be exposed to, such as UV rays, humidity, and temperature. Choose a powder coating that can withstand these environmental factors and maintain its performance and appearance.

Applications of Powder Coating

Powder coating is a versatile finishing option used in various applications. Here are some typical applications of powder coating in sheet metal manufacturing and finishing:

Automotive Parts

Powder coating is widely used in the automotive industry to finish metal parts such as wheels, chassis, engine components, and suspension systems. The durable and long-lasting finish of powder coating protects against corrosion, chipping, and fading.

Industrial Equipment

Architectural Structures

Powder coating is used in architectural structures such as buildings, bridges, and railings. The wide range of colours and finishes of powder coating allows for customization and aesthetic appeal while its durability and weather resistance protect environmental elements.

Furniture

Powder coating is used in the furniture industry to finish metal furniture such as chairs, tables, and frames. The versatility of powder coating in color and texture options allows customization to match specific design requirements, while its durability and scratch resistance provide long-lasting protection.

Consumer Products

Powder coating is used in various consumer products such as appliances, sporting goods, and bicycles. The cost-effectiveness and versatility of powder coating make it an ideal choice for manufacturers looking to produce high-quality products that are both durable and aesthetically pleasing.

Powder Coating in Metal Fabrication & Finishing By SJC Precision

SJC Precision provides businesses with high-quality powder coating services for sheet metal manufacturing and finishing needs. With a focus on consultation, surface preparation, powder coating application, curing, and quality control, SJC Precision delivers customized solutions that meet the unique needs of each project.

The company uses state-of-the-art equipment and techniques to ensure that the powder coating application is of the highest quality and offers various types of powder coatings to meet specific performance requirements. SJC Precision provides powder coating services & sheet metal manufacturing to various industries, including automotive, industrial, architectural, furniture, and consumer products. The company’s expertise and commitment to customer satisfaction make it a trusted partner for businesses seeking powder-coating solutions.

4 notes

·

View notes

Text

Top Metal fabrication course – wctrc

A metal fabrication course typically teaches students the skills necessary to work with different types of metals and transform them into various products, such as machinery parts, structural components, decorative items, and sculptures. The course may cover a range of topics related to metalworking, including welding, forging, cutting, shaping, joining, finishing, and surface treatment.

The course may also cover safety procedures, tools and equipment usage, blueprint reading, measurement techniques, material selection, and cost estimation. Students may work with a variety of metals, such as steel, aluminum, brass, and copper, and learn to use different machines and tools, such as plasma cutters, grinders, saws, and bending machines.

A metal fabrication course can be offered at various levels, such as vocational schools, technical colleges, community colleges, or trade schools. The duration of the course may range from a few weeks to several months, depending on the program's intensity and the level of expertise it aims to provide. Some courses may offer hands-on training through workshops, apprenticeships, or internships, while others may provide theoretical knowledge through lectures, textbooks, or online resources.

Overall, a metal fabrication course can provide valuable skills for individuals interested in pursuing a career in metalworking or related fields, such as manufacturing, engineering, construction, or art. It can also benefit hobbyists who want to learn how to make their own metal creations or repair their metal possessions.

If you want to get more information about it than you can visit our WCTRC website and you can call us at (705) 969-0022.

4 notes

·

View notes

Text

A Metal Fabrication Company In Brisbane

Metal fabrication is the process of cutting, bending, and shaping metal to create a wide range of structures and products. This process involves a variety of techniques, including welding, cutting, and bending, and it can be used to create anything from small components to large structures. Get the best metal fabrication in Brisbane with us!

2 notes

·

View notes

Link

Metals have become increasingly important in the construction of the foundation of any structure as industrialization and globalization have increased. It could be tool handles, screws, nuts, or handles from protruding heavy equipment or railings. Every potential called for the utilization of metal manufacturing to ensure long-term sustainability and durability. Metal fabrication is the process of creating machines and structures out of raw metal resources. To make the final product, the process may include burning, cutting, welding, forming, machining, and clustering. To know more visit https://www.rockettinc.com/ or call us at 1 (601) 939-2471.

2 notes

·

View notes

Text

•Tokens of Adventure•

If you feel brave enough adventurer - you may find yourself dawning fine tokens from your travels. Let’s be honest, you love the attention you receive at the tavern when your newly rewarded adjournment shines in the torch light. What tales can you share? What songs can you sing? We eagerly await your stories.

#metal working#jewerly#metal fabrication#fantasy#fantasy art#fantasy fashion#fantasy jewelry#art#handmade

4 notes

·

View notes

Text

Myway Fabrication work is done on a large scale, in factories or industrial settings. However, it can also be done on a smaller scale, in shops or even at home. Fabrication work often requires specialised equipment and skills.

Visit Here: https://www.mywayfabrication.com/

#Metal Fabrication#Forming#Punching#Shearing#Rolling#Welding#Laser Cutting#Custom Tool & Die#CNC Machining

2 notes

·

View notes

Text

3 Types of Metal for Fabrication?

When you need quality metal fabrication, it’s important to know what type of metal will work best for your project. Sheet metal, bar stock, and tubing are all common types of metal that can be used in fabrication.

Each has its own unique properties that make it suitable for different applications. Here is a look at the three most popular types of metal for fabrication.

Different types of materials are available for various types of jobs one may have around the house or yard.

You can also read about Stages of Steel Fabrication

In this blog post, we will discuss the three main types of material people use which are sheet metal, bar stock, and tubing when working with fabrications. read detail

3 notes

·

View notes