#Liquid Storage Tank Manufacturers

Text

Liquid Storage Tank Manufacturers in India

Find excellence in liquid storage with leading Liquid Storage Tank Manufacturers in India. From corrosive chemicals to potable water, tanks are engineered for durability and safety. With a commitment to superior craftsmanship, ensure compliance with industry standards and deliver innovative storage solutions. Expertise to provide customizable, efficient, and cost-effective liquid storage tanks that safeguard your valuable liquids. Elevate your storage capabilities with Bhupati Engineering's advanced solutions, setting new benchmarks for reliability and performance in the liquid storage industry.

#Liquid Storage Tank Manufacturers in India#Top Liquid Storage Tank Manufacturers in India#Best Liquid Storage Tank Manufacturers in India#Liquid Storage Tank Manufacturers#Liquid Storage Tanks#Liquid Storage Tank#Storage Solution Providers#Agricultural Storage Tanks#Material Handling Equipment Manufacturers & Suppliers#Grain Storage Silo Manufacturers in india#Industrial Material Handling Equipment Manufacturers in india#Vertical Bucket Elevator Manufacturers in India#"#Conveyor Belt Manufacturers in India

2 notes

·

View notes

Text

Liquid Storage Tanks Manufacturer

DSW establishes itself as a prominent player within the cryogenics tanks market, catering to customers' needs by providing a wide range of standard and customized accessories and storage solutions for cryogenics on a global scale.

Our extensive selection includes tanks, dewars, and vessels, along with valves and hoses in various sizes, ensuring the safe storage and transportation of cryogenic gases such as LIN, LOX, LCO2, LAr, and LNG.

Why choose DSW? We have been listed by the General Administration of Customs of China since 2019, establishing our credibility as a reliable source of "China data" for national export indicator surveys, providing updated and valuable insights.

0 notes

Text

BEST PRESSURE VESSELS MANUFACTURERS, SUPPLIERS IN PUNE INDIAA pressure vessel is a storage vessel or tank designed to hold fluids (gases/ liquids/ both) at high pressures. These include industrial compressed air receivers, flash

#BEST PRESSURE VESSELS MANUFACTURERS#SUPPLIERS IN PUNE INDIA#A pressure vessel is a storage vessel or tank designed to hold fluids (gases/ liquids/ both) at high pressures. These include industrial co#flash#heat exchanger

0 notes

Text

OMAKHEATERS - PLATİN

Omak Heaters: Your Trusted Partner in Heating Solutions

When it comes to reliable and efficient heating solutions for various industrial applications, Omak Heaters stands out as a leading provider of top-quality products. Specializing in IBS tank heaters, barrel heaters, filter heaters, satellite dish heaters, and more, Omak Heaters offers innovative and dependable heating solutions to meet the diverse needs of its customers.

IBC Tank Heaters:

Omak Heaters offers a wide range of IBC tank heaters designed to provide consistent and uniform heating for industrial storage tanks. Whether you need to maintain the temperature of liquids or chemicals stored in tanks, our IBC tank heaters ensure optimal heating performance, enhancing operational efficiency and productivity.

Barrel Heaters:

For heating applications involving barrels and drums, Omak Heaters offers high-performance barrel heaters engineered to deliver efficient and uniform heat distribution. Our barrel heaters are designed to withstand harsh industrial environments and provide reliable heating solutions for various applications, including oil and chemical processing.

Filter Heaters:

Omak Heaters also specializes in filter heaters designed to prevent freezing and maintain optimal operating temperatures for filtration systems. Our filter heaters are built to deliver consistent and reliable heating performance, ensuring uninterrupted operation and prolonging the lifespan of filtration equipment.

Omak Heaters Quality Assurance:

At Omak Heaters, quality and reliability are our top priorities. All our heaters are manufactured using premium-quality materials and advanced manufacturing techniques to ensure superior performance and durability. Our team of experienced engineers and technicians conducts rigorous quality control tests at every stage of production to guarantee the highest standards of quality and reliability.

Customer-Centric Approach:

Omak Heaters is committed to providing exceptional customer service and support. We work closely with our customers to understand their unique heating requirements and offer customized solutions tailored to their specific needs. From product selection to installation and ongoing technical support, our dedicated team is here to assist you every step of the way.

Contact Omak Heaters Today:

Whether you're in need of IBS tank heaters, barrel heaters, filter heaters, or satellite dish heaters, Omak Heaters has the expertise and products to meet your heating needs. Contact us today to learn more about our comprehensive range of heating solutions and discover how we can help optimize your industrial heating processes.

625 notes

·

View notes

Text

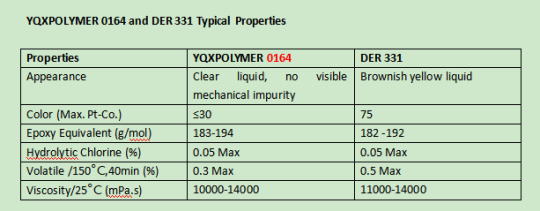

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes

Text

Solar water heater 100 ltr price in Bangalore

Solar water heater 100 ltr price in Bangalore

Solar water heater 100 ltr price in Bangalore, You should know about solar power first before going for any solar thermal system. Solar thermal system is based on the principle of converting sunlight into hot water (or steam) for use in heating homes and buildings. Solar water heating systems, commonly called solar hot water systems, convert the sun's rays into energy using a black-body absorber located inside a glass collector. When the temperature drops below, however, the efficiency decreases rapidly. Most solar thermal collectors have a maximum working temperature . To install a Solar water heater 100 ltr price in Bangalore, contact Jupiter Solar , www.jupitersolars.in .

What Is A Solar Water Heater?

What Is A Solar Water Heater?,a solar water heater is a device that converts solar energy into useful heat. These devices utilize the power of the sun to create a warm liquid that can then be applied to our homes and businesses. In effect, a solar water heater is similar to a conventional electric water heater; however, instead of electricity, sunlight does the work. Our bodies need water to survive and if we do not drink enough water, we become dehydrated. If we live in a desert area where there may not be much access to fresh drinking water, having access to heated water would be helpful. Thus, a solar water heater could be a cost effective and environmentally friendly alternative.Buy solar water heater , contact Jupiter Solar , www.jupitersolars.in .

How Does Solar Power Work?

Solar powered water heaters make use of the sun's heat and convert it directly into usable hot water. There are several different types of solar water heaters depending on the desired output. The two basic designs are a direct (concentrating type) and indirect (reflecting type). Direct solar water heaters focus the sun's rays onto copper tubes , while indirect solar water heaters reflect the sunlight back towards the tubes. Both of these types of units produce hot water at high efficiencies, although the concentrating type has higher operating costs.

https://jupitersolars.in/faq.php

Cost And Efficiency Of Solar Water Heaters

To calculate how much you might save with a solar water heater, you'll need to determine the size and capacity of your current system along with an estimate of the total annual usage. Next, you'll need to figure out how much electricity you currently spend on your utility bill. Then simply divide those figures together. Your savings are determined by dividing the difference between your estimated monthly expenses and what you'd pay by the amount of energy your solar water heater produces. Let's assume you're saving $40 per month on your utility bills - that equals $480 annually. To calculate the approximate number of gallons of hot water produced by your existing system, multiply the volume of your tank by the average flow rate. Once again, let's say you have 5 gallons of storage capacity and your current flow rate is 10 gallons per day. That means you're producing 500 gallons of hot water each year. Divide that by 12 months to find your monthly consumption. Now subtract both the $240 annual savings and the $500 annual production from the $960 total cost of your present system. What's left over is how much money you stand to save by switching to a solar water heater.

Size And Capacity

You'll want to consider the size and capacity of the solar water heater you plan to install before making a decision. Many manufacturers offer models ranging from 100 litre to 200 solar water heaters. The larger the system, the greater the potential savings. Smaller systems can be installed outside while larger ones may requires a free standing structure . A good rule of thumb is to buy the largest solar heater unit possible. Keep in mind that the size of your home or business building will affect the size and weight of your solar water heater. Obviously, larger homes and buildings require bigger and heavier units.

Installation

Most solar water heaters are preassembled and ready to go once you've purchased them. However, they do require some installation work. After placing the solar heater unit in its final location, you'll need to add the hardware. Finally, fill the reservoir with water. Depending on where you live, the process may take a few hours before you start receiving hot water.

Maintenance

Solar water heaters don't require very high maintenance once they've been installed. You won't need to worry about replacing the elements until the solar water heating units are working or cleaning the panels since their performance will remain unchanged. However, you may want to clean the surface of the black-body absorbers every so often. Fortunately, they are easy to remove and replace. Also, remember to keep your unit clear of debris such as snow and leaves.

Water Heater

Water heating systems are used to warm water for bathing, cooking, washing purposes, etc. A solar water heater uses solar power to heat the water directly without using any fuel. In some cases, they use a storage tank where hot water is stored until required. These tanks are filled once a day and then heated by the sun. Heating water by boiling is considered efficient since many percentage of the energy goes . Solar water heaters, however, convert this thermal energy into electricity . Energy efficiency is thus increased. Other types of water heaters are gas-based, electric ones.

Storage Tank

The storage tank is the place where hot water is kept. When the temperature drops below a certain level, the pump sends water back to the boiler. Another type of storage tank is the closed loop system where water circulates continuously between the boiler and the tank.

Boiler

A boiler is a device that takes water at room temperature and heats it to high temperatures. Once the water reaches these high temperatures, it is sent to a tank where the excess heat is removed and converted to useful energy. Depending on the size of the boiler, it may need to have a fan inside to remove extra heat. The fan can either run constantly or only while the water is being pumped.

Pumping System

Pumping systems move water from one point to another. There are many different pumps, but some of the most common ones include centrifugal, screw, and piston pumps.

Electric Motor

Electric motors are the devices that turn the mechanical energy of steam or electrical energy into kinetic energy. An electric motor uses electric current to create rotating force. The rotor spins within the stator, converting it to rotary motion. The electric motor converts electrical energy into rotational energy which is then transferred to the shaft turning the impeller blades.

Impeller Blades

Impellers are the blades that are attached to the shaft. To improve efficiency, the blades spin faster by increasing RPM (revolutions per minute). The higher RPM increases the pressure of the water pushing it outward forcing it to flow around the outside of the impeller blades. This helps the water leave the impeller blades in a continuous stream and exit the unit.

Air Pump

Air pumps help move air across surfaces, keeping them clean and preventing mold and bacteria buildup. Air pumps are often used in air conditioning units to move cool air over coils and condensers.

#Air Pump#Impeller Blades#Electric Motor#Pumping System#Boiler#Boiler system#boil#hot water#Storage Tank#Water Heater#Maintenance#Installation#Installation of solar water heater#Bangalore#manufacturer#solar energy#solar heaters#Size And Capacity#Cost And Efficiency Of Solar Water Heaters#How Does Solar Power Work?#How Does Solar Power#What Is A Solar Water Heater?#Solar water heater 100 ltr price in Bangalore#Solar water heater 100 ltr price#100 litre solar water heater

2 notes

·

View notes

Text

Selection and Application of Liquid Flowmeter

Reading guide: The liquid volume flowmeter consists of a chamber with a known volume and moving parts. The liquid passing through the flow is calculated by determining the volume of the container and the number of movements of the moving parts. According to the characteristics of liquid volume flowmeter, it can be divided into the following types: waist wheel flowmeter, oval gear flowmeter, scraper flowmeter, double rotor flowmeter, reciprocating piston flowmeter, rotary piston flowmeter, screw flowmeter, etc.

Structure and principle of the liquid volumetric flowmeter calibration device

The liquid accumulation calibration device consists of the quick connector, hydraulic hose, hydraulic filter, standard flowmeter, temperature transformer, pressure transformer, computer system, hydraulic source, etc. The hydraulic oil source also includes a hydraulic oil tank, variable frequency motor, hydraulic variable pump, hydraulic safety valve, and other components. The main features are compact installation, easy use, the same calibration medium, strong movement ability, and the ability to provide hydraulic oil. The working mode of the liquid flow controller is as follows: match through quick connection and replacement, and lead the hydraulic hose into the displaced liquid flow controller calibration device; The hydraulic power converter of the investment department generates clean and stable liquid flow through the hydraulic pump, hydraulic filter, etc. Capture the cumulative flow value determined by the computer system using the calibrated flowmeter and the standard flowmeter, and capture the temperature and pressure on the calibrated flowmeter and the standard flowmeter; The measured value error of calibrated flow is determined by the computer software system.

Main characteristics and application of common liquid flowmeter

Volumetric flowmeter

Volumetric flow meters (also called volume-specific flow values) are general-purpose instruments with the highest accuracy. The measured components can also be divided into the following main features: pitch circle (two rotors), plate flow measurement, oval gear flow measurement, rotary piston flow measurement, circulation flow measurement, etc.

① Advantages: high measurement accuracy; It can be used for measuring high viscosity fluid and simple phase fluid; The instrument does not need external energy to directly record the total flow. It is easy to install without special requirements for front and rear tangent lines.

② Disadvantages: not suitable for high temperature and low temperature; Type of measuring center with limited diameter; Pressure drop; Periodic calibration is required.

③ Application: Volume traffic signs, due to their high-precision measurement in energy, petroleum, medicine, food, chemistry, and other fields, especially raw materials and other fields, must be measured for storage, transfer, and distribution, and used as the basis for a financial settlement, or as a legal indicator of the contract between two tax dealers.

Differential

The differential is one of the most commonly used flowmeter types, which can be divided into diverter flowmeter, Venturi flowmeter, average line current, etc. according to the test piece (inlet instrument). The main features are:

① Advantages: single-phase fluid has a wide range of measurement methods, some mixed fluids; Simple structure, easy maintenance, the long service life of control components and detonators, display equipment produced by different manufacturers, improving economies of scale.

② Disadvantages: general customization accuracy; Large pressure loss (orifice plate, nozzle, etc.) The assembly constraint shall be high, and there shall be enough straight pipelines before and after assembly.

③ Nozzle: When measuring the flow in the closed pipe for the first time, the differential can be used for projects under different conditions where the flow is about 1/4-1/3 of the total flow.

Ultrasonic assistance

The ultrasonic flowmeter can be generally divided into plug-in type, pipe section type, external clamp type, and portable type.

① Advantages: large diameter non-contact measurement, large flow calculation; Pressure loss, no fluid disturbance; Suitable for every liquid, easy to install and maintain.

② Disadvantages: When the measured liquid contains bubbles or noise, the measurement accuracy will be affected; The temperature range of the measured liquid is limited by the heat of the ultrasonic protection and the communication materials between the switch and the line, and the original data for measuring the high temperature of the liquid is incomplete.

③ Application: Ultrasonic velocimeter is often used in petroleum, chemistry, metal, electric power, and other fields, and is often used to measure the emission reduction of gas pipelines in factories, fluids, and work areas.

Turbine speed

Intel Remax accelerated technology plan has been expanded to multiple categories in mass production, and its main features are as follows:

① High precision, usually ± 0.25% r - ± 0.5% r, up to ± 0.25% r - ± 0.5% r; Repeat at most 0.05% r-0.2% r for a short time; Zero contact movement, sturdy and durable.

② Disadvantages: The physical characteristics of the liquid have a great influence on the flow characteristics; Calibration characteristics cannot be saved for a long time.

③ Application. A turbine flow counter is usually used to measure oil, organic liquid, inorganic liquid, and liquid frozen body. The first terminal of the main raw material pipeline is used for commercial calculation of automobile exhaust, gas stations, and light hydropower plants.

Vortex flowmeter

The vortex flowmeter is the latest flowmeter, but it has developed rapidly and has become a common category. Its main characteristics are as follows. ① Advantages: wide application range, liquid, gas, and steam flow measurement can be used; Small pressure loss; Easy installation, simple and durable structure. ② Disadvantages: poor anti-interference ability; Straight pipe section is required before and after installation; The application experience in pulsating flow and multiphase flow is still lacking.

③ Application: Vortex flowmeter has a wide range of applications, usually used in the factory water supply system, and its application will be limited in the case of high viscosity, low flow rate, and small diameter.

General criteria for flowmeter selection and calibration device

Determine the technical requirements for flow measurement and the correctness of the flowmeter, that is, the accuracy requirements for measuring liquid; The flow measurement is repeated, that is, the same measurement is performed multiple times under specific conditions to repeat the same measurement. The expression of flow measurement, that is, whether the flow is mass flow or flow, real-time flow, or cumulative flow. Command and remove the transmission function if necessary. Specifies whether the flow measurement is displayed as a mechanical or electronic title. If the flowmeter does not meet the technical requirements of the measured liquid, measurement errors may also occur.

For the description of the flow calibration liquid calibration device, according to the flow requirements in jgg667-2010:

① The expanded uncertainty of the standard setting should generally not exceed 1/3 of the maximum allowable flow, because the expanded rate of the calibration device is 0.22%.

② Output or. The input line in the equipment used for online identification shall not include redirection between the flowmeter and the equipment designed as a locked cabinet without intermediate circuit.

③ "When the flowmeter is greater than 1.0, the flowmeter and liquid temperature must be measured according to the standard, and the temperature and pressure shall be measured near the standard flowmeter or calibrated flowmeter. Therefore, the liquid flow controller is applicable to the acceptance accuracy standard of Class 1.0 (allowable deviation ± 1.0%) and subsequent fluid calculation.

Conclusion

In the process of liquid flow measurement, a liquid flowmeter is a major measuring tool and has been widely used in metallurgy, pharmacy, paper making, water conservancy, environmental protection, petrochemical, and other fields. In the actual online calibration process, the standard volume method, the standard meter method, and the electrical parameter method are all feasible online calibration methods. However, they all have different use conditions, which requires the staff to constantly summarize and analyze the use of online calibration methods for liquid flow meters, so that the calibration methods can be improved.

Article from: supmeaflow.com

2 notes

·

View notes

Text

Bacillus Thuringiensis Fermentation System

Bacillus thuringiensis, also known as Bacillus thuringiensis, is produced on a large scale in fermentation tanks and made into powder or wettable agents, liquid agents, and microbial insecticides used to control agricultural, forestry, grain storage pests, and some health pests.

Company Name:Zhejiang Shuangzi Intelligent Equipment Co., Ltd

Web:https://www.sun-intelligent.com/product/biofermentation-project/bacillus-thuringiensis-fermentation-system.html

ADD:Tianhe Road 7th,Yuhang Economic Development Zone,Hangzhou City, Zhejiang Province, China

Phone:86-18257152999

Email:[email protected]

Tip:310000

Profile:Zhejiang Shuangzi Intelligent Equipment Co., Ltd is a professional biology and medical equipment enterprise that takes the EPC/EPCM as the core and focuses on process technology and automation engineering design, equipment manufacture, matching purchase, installation, equipment system integration etc in the field of plant extraction, biological fermentation, pharamaceutical engineering, natural food, energy conservation and environment protection etc.

0 notes

Text

Superior Corrosion Resistance Enamel Tanks are The Ideal Choice for Agricultural Water Storage

Superior Corrosion Resistance Enamel Tanks are The Ideal Choice for Agricultural Water Storage

In the realm of agricultural water storage, the quality and durability of tanks play a pivotal role in ensuring efficient water management. Among the array of options available, enamel tanks stand out as a testament to superior corrosion resistance, offering a robust solution for farmers and agricultural enterprises.

As a leading storage tank manufacturer in China. Center Enamel can provide GFS Tanks, SS Tanks, Epoxy Coated Bolted Steel Tanks, Galvanized Tank, Aluminum Dome Roofs, Wastewater and Biogas Project Equipments for global customers.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Enamel tanks are assembled on-site from specialized enamel steel plates, hoops, self-locking bolts, sealing glue, and other components. The steel plate raw material utilizes titanium alloy-specialized enamel hot-rolled plates developed in collaboration with leading domestic iron and steel enterprises, and it is shaped using fast and low-consumption on-site assembly technology. After high-temperature enameling at 820°-930°, the enamel glaze fuses with the surface of the steel plate, forming a solid and chemically inert inorganic coating with outstanding corrosion resistance. The enamel process is currently an advanced coating and corrosion protection technology in the steel tank market.

Enamel tanks parameters

Category

Specification

Coating Color

Black blue, Grey olive, Forest green, Cobalt blue, Desert tan etc.

Coating thickness

0.25-0.45mm

Acid and alkalinity proof

Standard PH: 3~11, Special PH:1~14

Adhesion

3450N/cm²

Hardness

6.0 (Mohs)

Service life

≥30 Years

Holiday test

>1500V

Permeability

Gas liquid impermeable

Easy to clean

Smooth, glossy, inert, anti-adhesion

Corrosion resistance

Excellent, suitable for harsh environment

Enamel tanks Advantages

Unmatched Durability

Enamel tanks, also known as Glass-Fused-to-Steel (GFS) tanks, are crafted through a meticulous process that combines glass and steel, resulting in a product renowned for its durability. This fusion creates a non-porous surface that is resistant to corrosion, rust, and chemical reactions, making it ideal for storing various types of agricultural water, including irrigation water, rainwater harvesting, and livestock drinking water.

Longevity and Low Maintenance

One of the key advantages of enamel tanks is their longevity. Unlike traditional metal tanks that may succumb to rust and degradation over time, enamel tanks offer a prolonged lifespan, often exceeding decades with proper maintenance. This longevity translates to cost savings for agricultural operations, reducing the need for frequent replacements and repairs.

Moreover, enamel tanks require minimal maintenance compared to other tank materials. Their smooth, non-porous surface prevents the buildup of algae, bacteria, and other contaminants, reducing the frequency of cleaning and disinfection processes. This low maintenance requirement not only saves time and effort but also ensures the water stored remains clean and safe for agricultural use.

Environmental Sustainability

In today's environmentally conscious landscape, the sustainability of water storage solutions is a crucial consideration. Enamel tanks align with sustainability goals by promoting water conservation and reducing environmental impact. By efficiently storing water, farmers can optimize irrigation practices, minimize water wastage, and contribute to sustainable agriculture practices.

Additionally, the recyclability of steel components in enamel tanks further enhances their eco-friendly profile. At the end of their lifespan, enamel tanks can be recycled, reducing waste and supporting circular economy principles.

Versatility and Customization

Enamel tanks offer versatility in design and customization to meet the specific needs of agricultural applications. They are available in various sizes, capacities, and configurations, allowing farmers to choose the right tank size based on their water storage requirements. Whether for small-scale farming or large agricultural operations, enamel tanks provide a scalable solution.

Furthermore, enamel tanks can be equipped with additional features such as insulation for temperature control, agitators for mixing additives, and monitoring systems for water quality management. This customization ensures that farmers can tailor their water storage infrastructure to optimize agricultural processes.

Center Enamel is a comprehensive high-tech enterprise primarily engaged in the research, development, manufacturing, and sales of enamel-assembled tanks and diversified environmental protection equipment, as well as undertaking environmental protection EPC projects and anaerobic process segments. Throughout its project practices, the company continuously increases research and development efforts, gathers scientific and technical forces, and establishes a service system covering everything from research and development to after-sales, providing tailored solutions to customers quickly and with high quality.

The measurement standards for projects not only need to meet technical and quality requirements but also must shift towards overall standards of sustainability, quality improvement, energy efficiency, and carbon reduction. In response to market and policy changes, Center Enamel actively leverages its rich experience and research and development strength to empower innovative research and development technologies for enamel-assembled tanks, contributing to the smart manufacturing of diversified environmental protection equipment and environmental protection EPC projects. This aims to meet the diverse needs and project requirements of customers.

Currently, Center Enamel's business covers areas such as kitchen waste, leachate, municipal sewage, biogas projects, aquaculture wastewater, industrial wastewater, drinking water, and firefighting water. In the future, the company's research and development achievements will be further promoted and applied in more projects, striving to achieve a win-win situation for economic, environmental, and social benefits, driving the high-quality development of the environmental protection industry.

0 notes

Text

Navigating Chemical Transfer Pumps: Understanding Their Functionality and Importance in India's Manufacturing Sector

Chemical transfer pumps play a pivotal role in various industrial processes, facilitating the safe and efficient transfer of liquids, including corrosive chemicals, solvents, and acids. As integral components of manufacturing operations in India, chemical transfer pumps manufactured locally cater to the diverse needs of industries ranging from pharmaceuticals to petrochemicals. Let's delve into the intricacies of chemical transfer pumps, exploring their functionality and significance in India's manufacturing landscape.

What is a Chemical Transfer Pump?

A chemical transfer pump is a specialized device designed to transfer fluids from one location to another, typically from storage tanks or drums to processing equipment or distribution systems. Unlike standard pumps, chemical transfer pumps are specifically engineered to handle corrosive, abrasive, and viscous liquids safely and efficiently. These pumps are constructed from materials resistant to chemical corrosion, ensuring compatibility with the fluids being transferred and minimizing the risk of contamination or damage.

What Does a Transfer Pump Do?

The primary function of a transfer pump is to move fluids from a source to a destination, either within a manufacturing facility or between different locations. Here's a closer look at what transfer pumps do and their role in various industrial applications:

1. Fluid Transfer:

Transfer pumps are utilized to transfer liquids such as chemicals, solvents, acids, oils, and lubricants from storage tanks, drums, or containers to processing equipment, reactors, mixing vessels, or transportation vehicles. They ensure a consistent flow of fluids, enabling continuous production processes and efficient material handling.

2. Metering and Dosing:

In addition to fluid transfer, some transfer pumps are equipped with metering or dosing capabilities, allowing precise control over the volume and flow rate of liquids being transferred. This is particularly critical in industries such as pharmaceuticals, food and beverage, and water treatment, where accurate dosing of chemicals is essential for product quality and compliance with regulatory standards.

3. Chemical Compatibility:

Chemical transfer pumps are engineered to handle a wide range of corrosive, abrasive, and viscous fluids encountered in industrial applications. They are constructed from materials such as stainless steel, polypropylene, PVC, and fluoropolymers, which offer excellent resistance to chemical corrosion and ensure compatibility with a variety of substances.

4. Safety and Reliability:

Transfer pumps are designed with safety and reliability in mind, incorporating features such as leak-proof seals, overpressure protection, and built-in safeguards to prevent spills, leaks, and equipment damage. This is particularly crucial when handling hazardous chemicals or volatile liquids, where safety is paramount to protect personnel and the environment.

Significance of Chemical Transfer Pump Manufacture in India:

In India's thriving manufacturing sector, the local manufacture of chemical transfer pumps plays a vital role in supporting industrial growth and innovation. Here's why the manufacture of chemical transfer pumps in India is significant:

1. Customization and Adaptability:

Indian manufacturers of chemical transfer pumps have the expertise to tailor pump designs and specifications to meet the specific requirements of diverse industries and applications. This customization capability ensures that businesses have access to pumps optimized for their unique needs, enhancing operational efficiency and productivity.

2. Cost-Effectiveness:

Local manufacture of chemical transfer pumps in India offers cost advantages in terms of production, labor, and logistics. This enables Indian businesses to procure high-quality pumps at competitive prices, reducing procurement costs and improving overall profitability.

3. Technical Expertise and Support:

Indian manufacturers of chemical transfer pumps possess technical expertise and industry knowledge acquired through years of experience and innovation. They provide comprehensive support services, including installation, maintenance, and troubleshooting, ensuring that customers receive timely assistance and optimal performance from their pump systems.

4. Domestic Supply Chain Resilience:

By manufacturing chemical transfer pumps domestically, India reduces its reliance on imports and strengthens its domestic supply chain resilience. This ensures continuity of supply and minimizes disruptions, especially during times of global uncertainty or supply chain challenges.

In conclusion, chemical transfer pumps play a critical role in India's manufacturing sector, enabling the safe and efficient handling of fluids in various industrial processes. With a focus on local manufacture, Indian manufacturers of chemical transfer pumps contribute to industrial growth, innovation, and sustainability, offering customized solutions, cost-effective products, and reliable support services to meet the evolving needs of the market.

0 notes

Text

Efficiency in the Ice Age: Efficiency and Sustainability in Cryogenic Tanks

for Cryogenic Gases

Cryogenic tanks are specialized vessels used for storage of liquefied gases at very low temperatures. They find widespread application across industries like healthcare, metallurgy, semiconductors, etc. where gases like nitrogen, oxygen, argon, hydrogen are required in liquid form. Cryogenic tanks offer advantages like ease of transportation of large volumes of gases over long distances. The demand for cryogenic gases is growing due to their increasing usage in welding & metal manufacturing processes and for medical applications like cryosurgery.

The global cryogenic tanks market is estimated to be valued at US$ 6.51 Bn in 2024 and is expected to exhibit a CAGR of 5.0% over the forecast period 2023 to 2030.

Key Takeaways

Key players operating in the cryogenic tanks market are ArcelorMittal, China Baowu Group, Nippon Steel Corporation, POSCO, Shagang Group, Ansteel Group, Glencore, Sumitomo Metal Mining Company, Linde, INOX India Pvt., Cryofab, FIBA Technologies, Air Products and Chemicals, Inc., M1 Engineering, Chart Industries, Wessington Cryogenics, Isisan, Lapesa, Auguste Cryogenics, and Hoover Ferguson Group, Inc.

The key opportunities in the market include increasing demand for liquified natural gas and growing research in cryogenic sciences. Countries across North America, Europe, Asia Pacific and Latin America are investing heavily in development of liquid hydrogen infrastructure which is driving the global expansion of cryogenic tanks market.

Market Drivers

The primary driver for cryogenic tanks market is the surging demand for industrial, medical and research gases. Particularly, the demand for nitrogen, oxygen and argon is growing rapidly from metal manufacturing, semiconductor fabrication, healthcare and food processing industries. Countries worldwide are also promoting usage of green fuels like liquified natural gas and liquid hydrogen which requires cryogenic storage and transportation, thereby propelling the cryogenic tanks market growth. Strict safety regulations regarding the handling and transportation of industrial gases is also driving adoption of specialized cryogenic vessels.PEST Analysis

Political: The cryogenic tanks market is impacted by regulations and standards set by organizations like ASME, DOT and National Board of Boiler and Pressure Vessel Inspectors for design, construction, testing and transportation of cryogenic vessels.

Economic: Factors like global GDP growth, industrial production and investments in end use industries influence demand for cryogenic vessels in the market.

Social: Rising demand for LNG as fuel in transportation and power generation drives usage of cryogenic vessels for storage and transportation of LNG.

Technological: Advancements in materials and manufacturing technologies enable production of cryogenic vessels that are lighter, more durable and have higher storage capacity. Insulation technologies also improve efficiency of cryogenic storage and transportation.

Geographical regions with high market concentration:

The cryogenic tanks market sees significant value concentration in regions with high industrial activity and investments in end use industries. North America, Europe and Asia Pacific hold major share of the global cryogenic tanks market value owing to strong demand from petrochemical, power generation and healthcare industries in countries like U.S., Germany, China and India.

Fastest growing region:

The Asia Pacific region is projected to be the fastest growing market for cryogenic tanks during the forecast period. This rapid growth can be attributed to increasing industrialization, rising LNG demand and investments in new production capacities in major economies of China and India. Factors like government initiatives to increase usage of cleaner fuels and expand industrial infrastructure also support market growth in the Asia Pacific region.

0 notes

Text

Storage Solution Providers in India - Bhupati Engineering

Bhupati Engineering is committed to providing high-quality products and services to its customers at competitive prices. The company's products and services are used by a wide range of industries in India, including agriculture, food processing, chemicals, and storage solution providers. Bhupati Engineering is dedicated to providing sustainable solutions that meet the needs of its customers and the environment.

#Storage Solution Providers#Agricultural Storage Tanks#Material Handling Equipment Manufacturers & Suppliers#Grain Storage Silo Manufacturers#Industrial Material Handling Equipment#Conveyor Manufacturing Companies#Conveyor Belt Manufacturers In India#Vertical Bucket Elevator Manufacturers#Liquid Storage Tank Manufacturers#Storage Solutions Companies In India#Flat Bottom Silos#Grain Storage System Equipment#Turnkey Project Solutions#Water Storage Solutions#Flat Bottom Silos Manufacturers#Hopper Bottom Silos Manufacturers#Zincalume Water Storage Tank Manufacturers#Underground Water Tank Manufacturers#Underground Tank Exporters#Agricultural Water Tank Manufacturers & Suppliers#Irrigation Water Tank Manufacturers#Overhead Water Tank Manufacturers & Exporters#Storage Tank Manufacturers & Suppliers#Water Storage Tanks Manufacturers#Exporters#Drinking Water Storage Tank Exporters#Rain Water Storage Tank Manufacturers#Rain Water Harvesting Tanks Exporters#Zincalume Water Tank Manufacturers#Zincalume Water Storage Tanks Exporters

1 note

·

View note

Text

Why Choose Stainless Steel Over Plastic for Your Water Tank Needs?

Plastic tanks pose health issues to both humans and the environment at large. This is why many prefer Stainless Steel water tanks. These durable, environment-friendly tanks provide several benefits over their plastic competitors. Read on to learn the various consequences of plastic tanks and the importance of safer choices.

Impact on Human Health

Plastic tanks are extremely hazardous for people due to the presence of dangerous chemicals. One main problem is the leaching of these chemicals into the stored liquid. It can be mostly ingested or absorbed through skin contact. Here are some potential health risks:

Bisphenol A (BPA) is the most common plastic additive. It is mostly associated with reproductive disorders, obesity, and the increased possibility of various cancers.

Phthalates used as plasticizers, these chemicals interfere with the endocrine system and can lead to problems in development.

Polyvinyl Chloride (PVC) produces and emits toxic dioxins during production and disposal. This can upset hormones and cause immune system problems.

Environmental Consequences

Some of the many environmental consequences of plastic tanks are:

Plastic pollution:

Failure to discard plastics properly may result in environmental pollution that damages the ecosystem and wildlife.

Non-biodegradable:

The majority of plastic tanks are non-biodegradable, piling up in landfills and oceans for centuries.

Greenhouse gas emissions:

In the production and shipping of plastic tanks, greenhouse gases are highly released, which aggravates global warming.

Benefits of Stainless Steel Water Tanks

SS Water Tanks are the most popular tanks used for water storage. Also, many manufacturers even offer customized water tanks made of SS. A few benefits of SS water tanks are:

Human Health and Safety

All the SS water tanks are preferably built of top-grade, non-toxic stainless steel that does not cause chemical contamination. This ensures the cleanliness and safety of the water for drinking purposes. In addition, they are resistant to corrosion and therefore safe from possible contamination.

Environmental Sustainability

As opposed to plastic tanks, SS water tanks are 100% recyclable and eco-friendly. They do not give off toxic chemicals to the environment, both in their production and disposal stages. Also, they are very robust and last a long time, so you do not have to replace the old ones often. Consequently, waste reduction is also ensured.

Durability and Low Maintenance

SS water tanks are incomparably durable and can withstand extremes of temperature, ultraviolet radiation, and harsh climate. These tanks only require a little attention, which promotes steady and efficient operation throughout the long term.

Versatility and Customization

Many manufacturers offer SS water tanks in different sizes and designs. This makes them the perfect choice for commercial, residential, and industrial uses. You can customized water tanks based on, e.g., capacity, shape, and installation site.

Conclusion

The extensive use of plastic tanks without a doubt improves our daily living standards. Yet, it also has serious health and environmental issues. By taking these dangers into account and investing in SS water tanks, you may prevent these effects. Besides that, picking these tanks assures the journey to a sustainable future. Upgrade to A-grade SS water tanks from Purever Technix LLP today. They provide high-quality and customized water tanks that are a priority for your health and the environment. Choose them for a sustainable and reliable water storage solution.

#Stainless Steel products#custom Stainless Steel water tanks#reliable water storage solution#plastic tanks#ss water tanks#customised water tanks#Stainless Steel Water Tanks

1 note

·

View note

Text

Supplier of PP Tank in Andhra Pradesh

Company Overview:

Polytech Projects LLP is a Manufacturer and Supplier of PP Tank in Andhra Pradesh, India.

The company is ISO 9001:2015 certified, specializing in crafting Polypropylene & HDPE Storage equipment, setting industry standards, and expanding possibilities.

Their product range includes Pickling Tanks, Storage Tanks, Plating Tanks, HDPE Tanks, Fume Hoods, Fume Extraction Systems, Wet Scrubbing Systems, Hot Dip Galvanizing Lines, Surface Treatment Lines, and more.

PP tank stands for polypropylene tank, a common type of plastic tank used for storing and transporting liquids, semi-liquids, and gases.

PP tanks are significantly lighter than metal tanks, making them easier to transport and install. They can withstand a wide range of temperatures, impacts, and exposure to chemicals without degrading.

Their recyclability allows for efficient resource utilization, reducing waste and minimizing environmental footprint.

Features of PP Tank:

Excellent chemical resistance

Durability

Lightweight construction

UV resistance

Corrosion resistance

Easy maintenance

Versatility in storage applications

Compliance with safety standards

Applications of PP Tank:

Chemical processing

Pharmaceuticals

Water treatment

Food and beverage

Agriculture

Electronics

Metal finishing

Service Coverage:

Polytech Projects LLP serves as a Manufacturer and Supplier of PP Tank in Andhra Pradesh, covering locations such as Adoni, Amaravati, Anantapurm, Chandragiri, Chittoor, Dowlaiswaram, Eluru, Guntur, Kadapa, Kakinada, Kurnool, Machilipatnam, Rajahmundry, Srikakulam, Tirupati, Vijayawada, Visakhapatnam, Vizianagaram, and Yemmiganur.

For more information and inquiries, feel free to contact Polytech Projects LLP.

Read the full article

#Adoni#Agriculture#Ahmedabad#Amaravati#Anantapurm#AndhraPradesh#Chandragiri#Chemicalprocessing#Chittoor#Dowlaiswaram#Electronics#Eluru#Exporter#ExporterofPPTanks#Guntur#Kadapa#Kakinada#Kurnool#Machilipatnam#ManufacturerofPPTanks#Metalfinishing#Polypropylene&HDPEStorageequipment#PolypropyleneTank#Rajahmundry#Srikakulam#Supplier#SupplierofPPTankinAndhraPradesh#SupplierofPPTanks#SupplierofPPTanksinAndhraPradesh#SupplierofPPTanksinIndia

0 notes

Text

Unlock Efficiency with Our Tank Weighing Systems!

Our tank weighing systems offer precise measurements for your liquid and gas storage needs, ensuring accuracy and efficiency in your operations. From inventory management to process control, trust our technology to streamline your workflow.

Tank weighing systems are used in industries like chemicals, food and beverage, pharmaceuticals, oil and gas, water treatment, manufacturing, logistics, and waste management for precise measurement and inventory control.

Contact us today to learn more:

📞 +91-98-2413 5305 | ✉️ [email protected] | 🌐 www.endeavourweigh.com/product/tank-weighing/

#TankWeighing#PrecisionMeasurement#EfficientOperations#LiquidStorage#GasStorage#Endeavour#EndeavourWeigh#EndeavourInstruments#WeighWithEndeavour#ElevateWithEndeavour#EIPLOfficial

0 notes

Text

Industrial Boilers and Parts Manufacturer & Supplier in Pune, India

Industrial Boilers and Parts Manufacturer & Supplier in Pune, India.

Sterling Engineers and Boilers Pvt. Ltd.

Top Industrial Boiler Pressure Parts Manufacturers in Pune

Founded in the year 2012, Sterling Engineers & Boilers Private Limited has admirable position in manufacturing and service providing of Industrial MFG, Pressure Vessel Tank, Industrial Tanks, Industrial BoilersCharcoal Filter, Regeneration Oxidation Plant, Industrial Piping Service Ducting Service. These products are extremely admired owing to their top nominal costs. Our products are developed employing the industry permitted and advanced technique. We Are Manufacturer Industrial MS Chimney Manufacturers in Pune | Boiler Pressure Parts In Pune | Industrial Pressure Vessel In Pune | Industrial Storage Tank In Pune | Industrial Bending Service In Pune | Industrial Fire Fighting System In Pune | Hot and cold insulation industrial piping service In Pune | Structural Fabrication Services In Pune | Industrial MS Chimney Suppliers in Pune.

Quality Assurance

Client Satisfaction

Mass Man Power

+91-968-901-1211 CALL US

Popular Products

Our company is committed to design, manufacture, supply, erect and commission Boiler Pressure Parts and its equipments in scheduled time as per the quality norms to the utmost satisfaction of our clients.

Pressure Vessel Tank:Fabricated chimneys manufactured with /without flanges or readymade pipes with all accessories used to discharge gases.

Industrial Chimney:Capacity from 1 KL to 10000000 Kl for Steam,water,molasses, Liquids, Petrol, Diesel, Chemical and all forms of semi liquids, liquids with or without lining

Industrial Tanks:While engrossing on varied demands of many industries, we have been offering SS Pressure Vessel Tank that is used for specific purposes.

OUR PRODUCTS

Industrial Chimney:

India’s Best manufacture company of Industrial MS Chimney In Pune

One of India’s premier manufacturers of Industrial MS Chimneys in Pune is renowned for its excellence in designing and fabricating high-quality chimney solutions for industrial applications. With a rich history of delivering reliable and efficient chimneys, this company combines cutting-edge technology with skilled craftsmanship. Their chimneys are built to withstand harsh industrial environments, ensuring durability and safety. They offer custom design and engineering services to meet specific client requirements, adhering to stringent quality standards and regulatory compliance. With a commitment to innovation and customer satisfaction, this company is a trusted partner for industrial chimney solutions in Pune and beyond.(https://www.sterlingengineers.in/industrial-ms-chimney-pune

2. Piping Services:

Supply, Fabrication, Welding, Laying & Testing of Pipelines (AG & UG) along with supply of pipe, pipe fittings, valves etc. We have capable supplier chain with us for supply of required pipe material along with fittings as per client spec. We execute pipe fabrication & laying projects for water reagent steam process in chemical plants, pharma plants, refineries, fertilizer plants, dairy plants, food processing units, sugar plants etc.Pune hosts India’s foremost manufacturer of diverse industrial piping solutions. Renowned for their expertise, they provide a wide range of high-quality piping products tailored to meet the rigorous demands of industrial applications. Trusted for their precision engineering and reliability, they are the industry leader in Pune.(https://www.sterlingengineers.in/industrial-piping-service-pune)

3. Boiler Pressure Parts:

Best manufacturers company of 80 TPH High pressure boiler in Pune

In Pune, one of the standout manufacturers for 80 TPH high-pressure boilers is renowned for its exceptional expertise and quality offerings. With a rich history of engineering excellence, this company specializes in crafting cutting-edge, high-capacity boilers capable of withstanding extreme pressures. These 80 TPH boilers are designed for industries that demand substantial steam generation, like power plants and large manufacturing units. The company’s commitment to innovation, precision engineering, and adherence to stringent quality standards make it a trusted provider in Pune. They ensure reliable and energy-efficient solutions, reflecting their dedication to meeting the demanding requirements of high-pressure industrial applications.(https://www.sterlingengineers.in/80-tph-high-pressure-boiler-pune)

4. Pressure Vessel:Best manufacturers company of industrial pressure vessels in Pune

Spherical or cylindrical subjected to internal pressure of steam or liquids. In Pune, a leading manufacturer stands out as the go-to provider for industrial pressure vessels. Renowned for their exceptional craftsmanship and precision engineering, this company specializes in designing and fabricating top-quality pressure vessels for a wide range of industrial applications. Their vessels are built to meet stringent safety and performance standards, catering to the unique needs of various industries such as petrochemical, pharmaceutical, and manufacturing. With a strong commitment to innovation and quality, they offer customized solutions, ensuring reliability and durability in the most demanding environments. Trusted for their expertise and reliability, they are the preferred choice for industrial pressure vessels in Pune.(https://www.sterlingengineers.in/industrial-pressure-vessel-pune)

GET QUOTE

5. Storage Tank:Stainless Steel Storage Tanks Manufacturers in Pune

Pune boasts reputable manufacturers specializing in Stainless Steel Storage Tanks. These companies are known for their expertise in crafting high-quality, corrosion-resistant storage solutions. Utilizing premium stainless steel materials and advanced fabrication techniques, they create tanks that excel in durability and hygiene. These tanks find applications across various industries such as food and beverage, pharmaceuticals, and chemical processing, ensuring the safe and efficient storage of liquids and materials. With a commitment to precision engineering, regulatory compliance, and customization options, these manufacturers are trusted partners in Pune’s industrial landscape, delivering reliable stainless steel storage solutions that meet the stringent demands of diverse industries.(https://www.sterlingengineers.in/ss-storage-tank-pune)

6. Fire Fighting System:

Industrial Fire Protection Systems and Service in Pune

Following safety norms and industry standards, we offer highly proficient Fire Fighting Services. Fire Fighting Services are important for providing utmost protection to people in a building in case of a fire hazard. Our highly skilled and experienced professionals are equipped with the latest tools required during such scenario. They execute the service as per industrial norms, and regarded for their flexibility, effectiveness and timely implementation in any environment. Customers from across the country can avail our Fire Fighting Services at nominal rates.(https://www.sterlingengineers.in/industrial-fire-fighting-service-system-pune

7. Insulation:India’s leading manufacturer company for hot & cold insulation in Pune

All insulations (cold and hot) as required at projects along with acoustic insulation. Pune is home to India’s leading manufacturer company specializing in hot and cold insulation solutions. With a stellar reputation for excellence, this company offers top-tier insulation materials and services for a wide range of industries. Their insulation solutions are designed to enhance energy efficiency, reduce heat transfer, and maintain temperature control in industrial processes. Using cutting-edge technology and adhering to rigorous quality standards, they provide custom-tailored insulation solutions that meet the specific needs of clients across Pune and beyond. Trusted for their expertise, commitment to sustainability, and impeccable service, they are the preferred choice for hot and cold insulation solutions in India’s industrial landscape.(https://www.sterlingengineers.in/hot-cold-insulation-service-pune)

Useful Links

Projects

Our People

Resources

Our Clients

Gallery

Contact Us

Sitemap

Contact Us

+91-968-901-1211

T-71/1-A/7, General Block

MIDC, Bhosari, Pune - 411026

#Industrial MS Chimney#Boiler Pressure Parts#Industrial Pressure Vessel#Industrial Storage Tank#Industrial Bending Service#Industrial Fire Fighting System#Hot and cold insulation industrial piping service#Various Structural Fabrication Services In Pune#Maharashtra.

0 notes