#FractureToughness

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

Continuing our journey to enhance Titanium bar production, we've reached a critical juncture—the eighth step. This phase involves the removal of Hydrogen from Titanium Round Bars using a Vacuum Heat Treatment Furnace.

Distinguishing Process Parameters:

Heat treatment under vacuum atmosphere

Controlled gas atmosphere

Controlled pressure, heating and cooling rate

Monitoring and control systems

Distinguishing Vacuum Heat-Treated Bars Quality:

High Purity

Free of microstructure imperfections

Low hydrogen content

Higher fracture toughness and fatigue strength

Stay connected as we journey through this exploration, providing you with an in-depth view of our production techniques. We are enthusiastic about unveiling every critical stage in the precise creation of Titanium bars designed exclusively for medical purposes.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#VacuumHeatTreatment#HydrogenRemoval#Heating#ELI#HighPurity#Microstructure#FractureToughness#FatigueStrength#ImprovedMechanicalProperties#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Poor Microstructure's Impact on Titanium Properties

Inconsistent and heterogeneous microstructure can significantly impact Titanium's properties and performance, resulting in reduced fatigue strength, fracture toughness, ductility, and biocompatibility.

For more information, you can connect with us at [email protected]

#KnowYourTitanium#Titanium#Microstructure#Properties#FatigueStrength#FractureToughness#Ductility#Biocompatibility#HorizonTitanium#StrongerTogether

0 notes

Photo

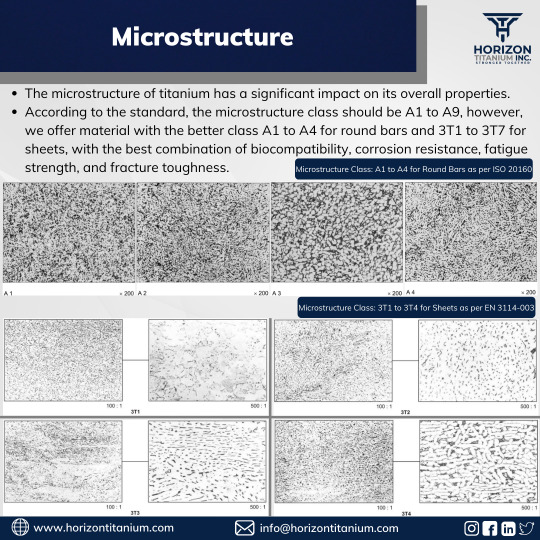

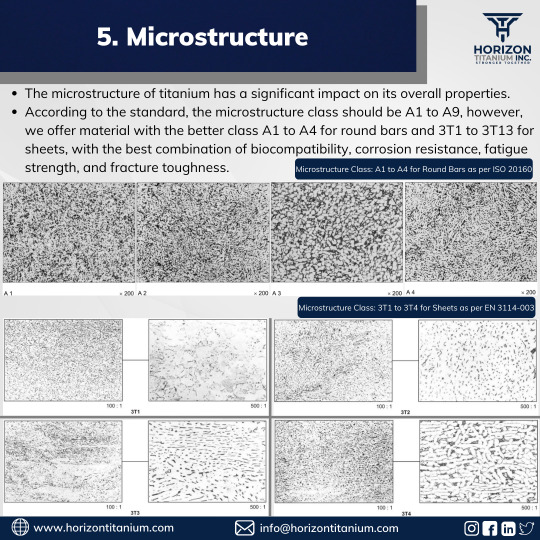

The microstructure is the most significant aspect of any material. Titanium's overall properties are determined by how the phases, grain size, and constituent particles are distributed within the Titanium.

The ISO standard recommends Microstructure class A1 to A9 for Titanium Round bars, while the EN standard recommends class 3T1 to 3T13 for sheets.

For any information regarding Titanium metallurgy, its grades, standards, or applications, you can write us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#TitaniumSheets#Metallurgy#Microstructure#MicrostructureClass#Mechanical#FatigueStrength#FractureToughness#CorrosionResistance#Biocompactibility#Properties#MedicalImplants#OrthopaedicImplants#LongLastingImplants#HorizonTitanium#StrongerTogether

0 notes

Photo

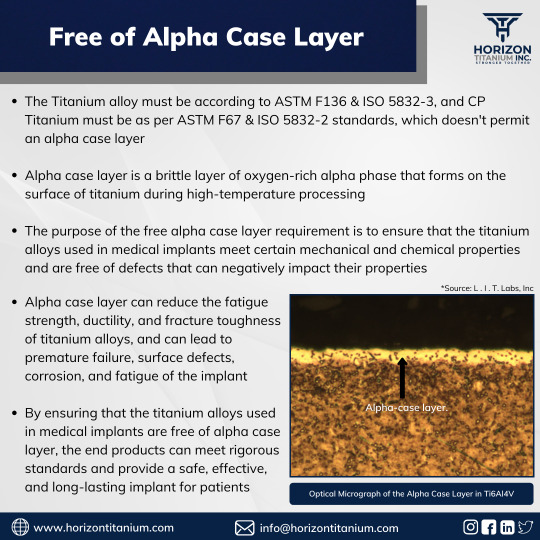

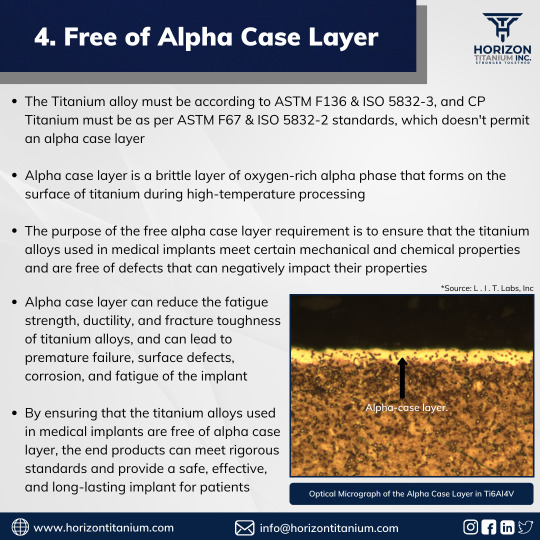

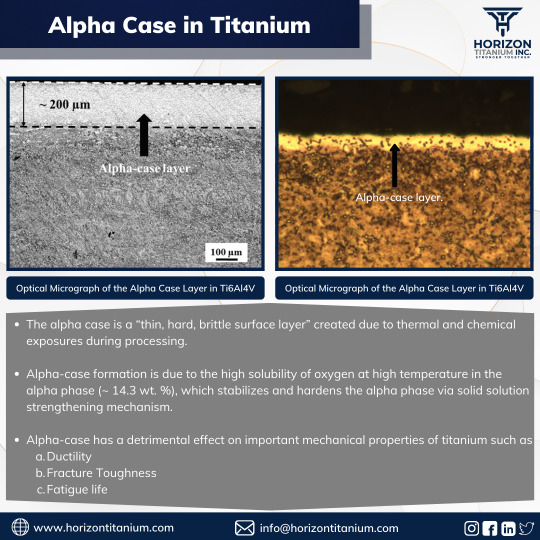

The alpha case forms when the Titanium surface reacts with oxygen at high temperatures, causing the Titanium surface to become brittle and susceptible to cracking and premature failure.

As a result, the alpha case layer is not permitted for medical applications according to ASTM F67, ISO 5832-2, ASTM F136, and ISO 5832-3.

For more information on Titanium for medical applications, you can write to us at [email protected]

#KnowYourTitanium#Titanium#AlphaCase#ASTM#ISO#Oxygen#Brittle#Mechanical#Metallurgy#Microstructure#FatigueStrength#Ductility#FractureToughness#Cracking#PrematureFailure#SurfaceDefects#CorrosionResistance#MedicalImplants#HighQuality#LongLastingImplants#OrthopaedicImplants#HorizonTitanium#StrongerTogether

0 notes

Photo

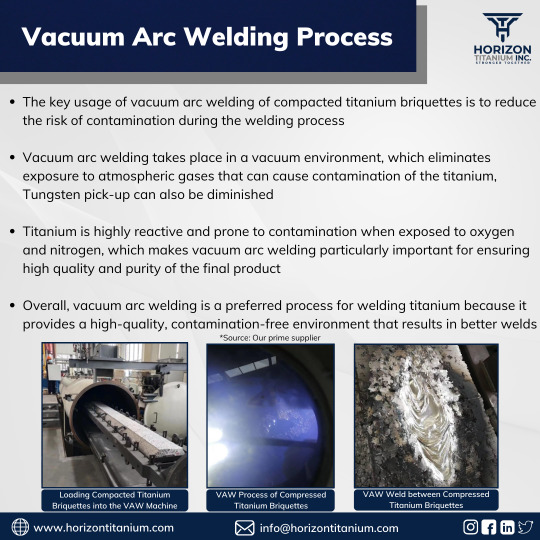

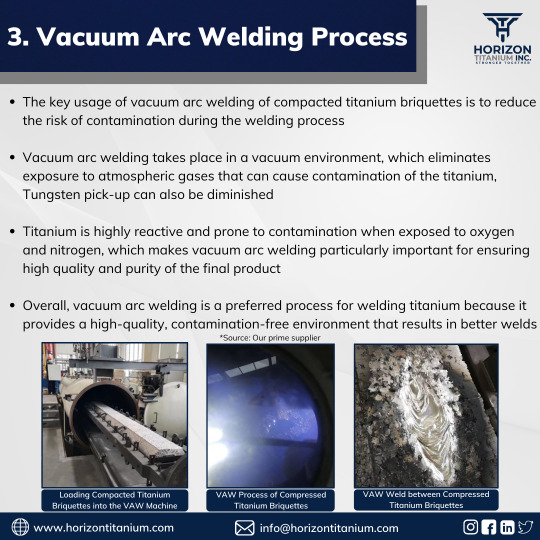

The Vacuum Arc Welding technique is used to join briquettes (compressed titanium sponge and alloying components) to make an input raw material ingot for the Vacuum Arc Re-melting process.

Vacuum Arc Welding should be chosen over Plasma Arc Welding, especially for ELI-grade production for medical applications.

#KnowYourTitanium#Titanium#VacuumArcWelding#PlasmaArcWelding#Briquettes#BetterProperties#MechnicalProperties#Metallurgy#FatigueStrength#FractureToughness#HighQuality#TungstenPickUp#Oxygen#Nitrogen#ContaminationFree#QualityWeld#HorizonTitanium#StrongerTogether

0 notes

Photo

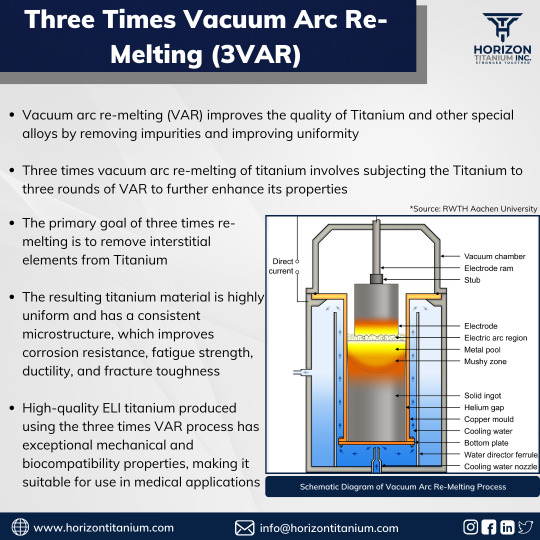

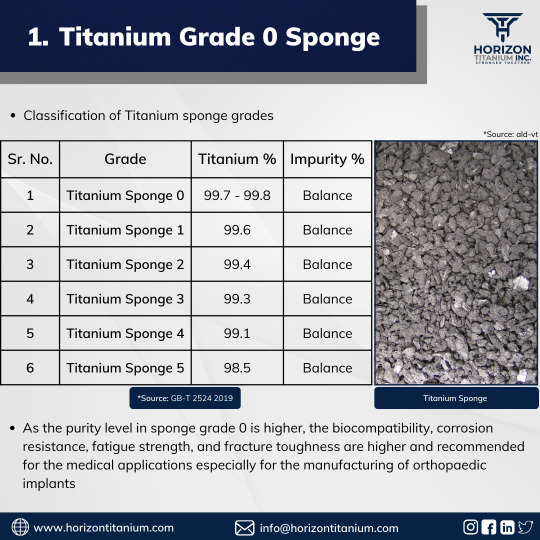

Vacuum arc re-melting is a refining process used to purify and homogenize the chemical composition and metallurgy of Titanium.

Titanium ELI grade is vacuum arc re-melted three times to eliminate interstitial elements (Impurities) for medical applications.

#KnowYourTitanium#Titanium#VacuumArcRemelting#3VAR#Impurites#InterstitialElements#Microstructure#CorrosionResistance#Biocompatibility#FatigueStrength#Ductility#FractureToughness#Mechanical#Metallurgy#MedicalApplication#MedicalImplants#OrthopaedicImplants#HorizonTitanium#StrongerTogether

0 notes

Photo

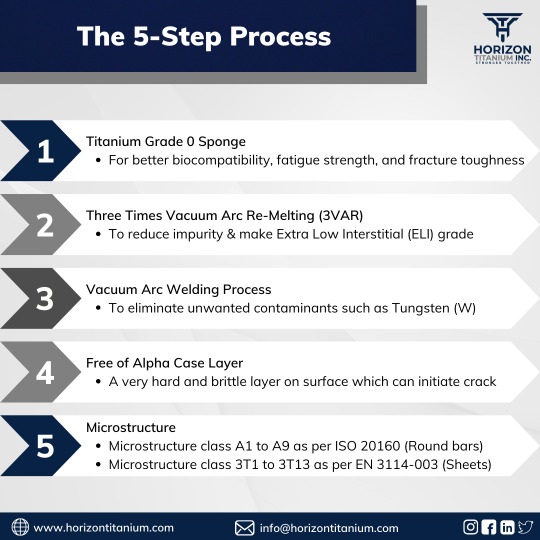

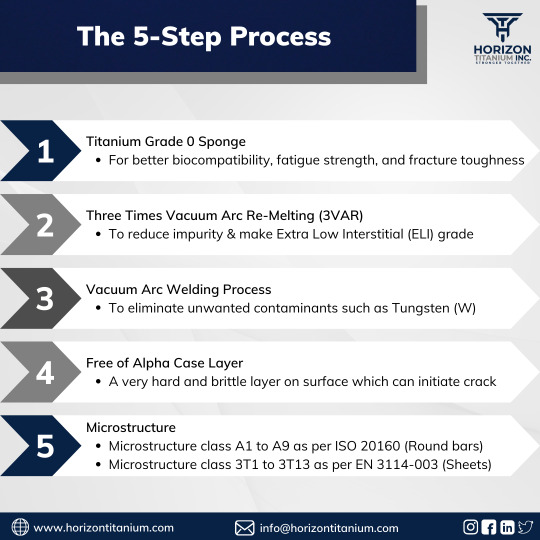

We have identified the five steps to consider when purchasing the right Titanium for medical applications.

For more information on Titanium for medical applications, you can write to us at [email protected]

#KnowYourTitanium#The5StepProcess#TitaniumSponge#Sponge0#ThreeTimeVacuumRemelting#VacuumArcWelding#FreeAlphaCaseLayer#Microstructure#Biocompatibility#FatigueStrength#FractureToughness#ELI#OrthopaedicImplants#MedicalImplants#HorizonTitanium#StrongerTogether

0 notes

Photo

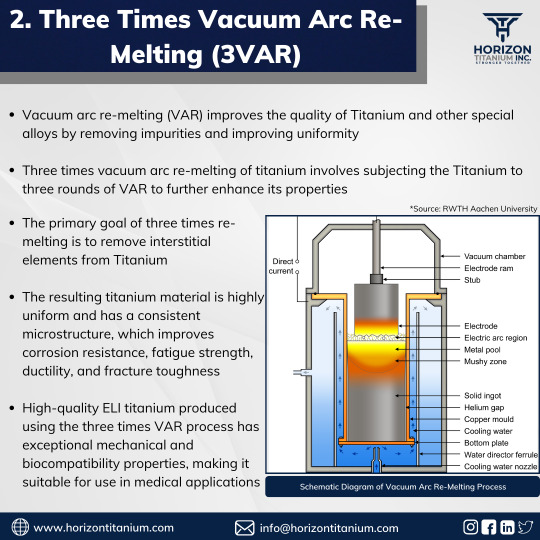

At Horizon Titanium, we understand how important it is to purchase high-quality medical grade titanium for implant manufacturing purposes. That's why we want to share some expert tips with you to help you make the right purchase decision without compromising on quality.

We believe that when it comes to medical applications, quality should never be compromised, and we are here to help ensure that your purchase meets the highest standards.

If you have any questions or need more information on titanium for medical applications, please reach out to us at [email protected]. We would be more than happy to assist you in any way we can.

#KnowYourTitanium#TitaniumSponge#SpongeGrade0#VacuumArcReMelting#3VAR#VacuumArcWelding#FreeAlphaCaseLayer#Microstructure#HighQualityTitanium#MedicalApplications#TitaniumRoundbars#TitaniumSheets#FatigueStrength#FractureToughness#CorrosionResistance#Biocompatibility#ExpertTips#OrthopaedicImplants#MedicalImplants#HorizonTitanium#StrongerTogether

0 notes

Photo

What is the Alpha case in Titanium?

The alpha case is a hard and brittle layer formed due to the reaction of Titanium with Oxygen at a higher temperature.

What are the effects of the Alpha case on Titanium materials/end-products?

When subjected to repetitive or sudden load, crack initiation can occur at the alpha case layer leading to a material failure. The alpha case in Titanium implants is not desirable as it can cause an implant failure.

What are the ways to avoid the Alpha case?

Titanium raw materials must be as per ASTM F136 & ISO 5832-3 standards. These standards suggest there is no possibility of Alpha case in the Titanium materials.

Processes such as machine milling, mechanical machining or chemical milling can remove this layer.

For more information, you can write to us at [email protected].

#KnowYourTitanium#Titanium#Metallurgy#Microstructure#AlphaCase#Hard#Brittle#Oxygen#Mechanical#Properties#Ductility#FractureToughness#FatigueLife#TitaniumImplant#MedicalImplant#OrthopedicImplant#ImplantMaterial#MedicalDevices#OrthopedicSurgeon#Quality#HorizonTitanium#StrongerTogether

0 notes

Photo

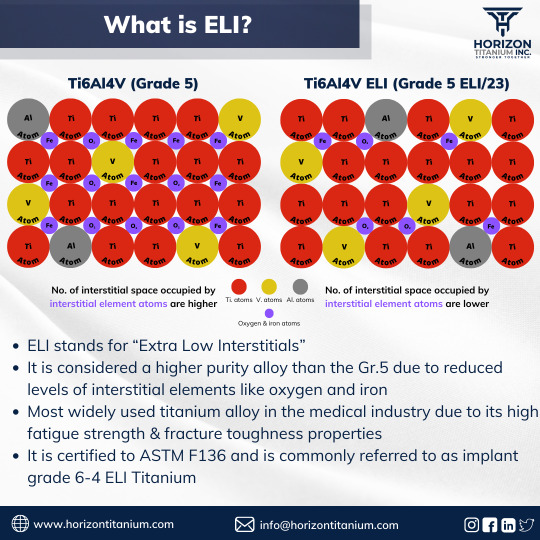

In the case of medical applications, stringent user specifications require controlled microstructures and freedom from melt imperfections. The interstitial elements of iron and oxygen are melt imperfections that are carefully controlled while manufacturing Titanium alloy to improve ductility, fracture toughness, and fatigue strength. Controlled interstitial element levels are designated ELI (extra low interstitials).

We have a huge inventory of Titanium Extra Low Interstitial (Ti6Al4V ELI) grade round bars and sheets, according to ASTM F136 & ISO 5832-3 standards for medical applications.

For inquiries, you can mail us at [email protected].

#knowyourtitanium#titanium#titaniumgrade5#TitaniumGrade5ELI#ELI#ExtraLowInterstitial#Medical#RawMaterial#MedicalDevices#Orthopaedics#OrthopaedicImplants#TitaniumImplants#TitaniumRoundBars#TitaniumSheets#LowImpurity#FatigueStrength#FractureToughness#Ductility#HorizonTitanium#StrongerTogether

0 notes

Photo

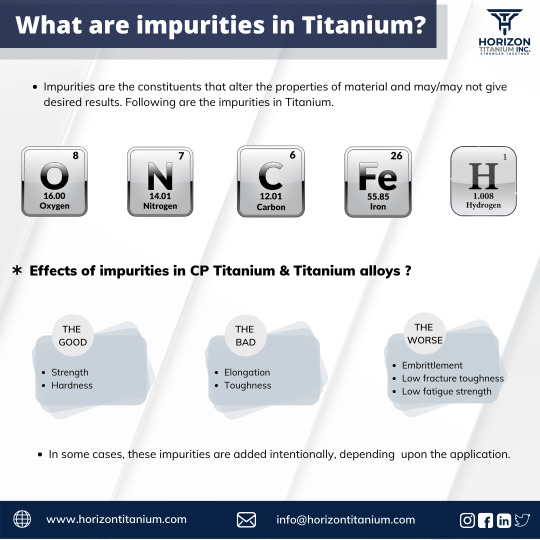

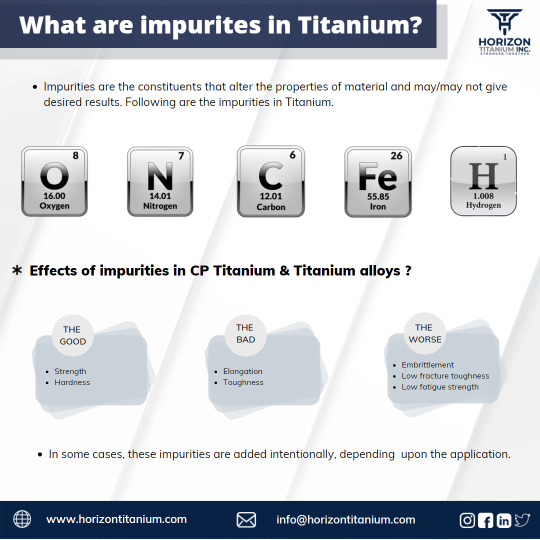

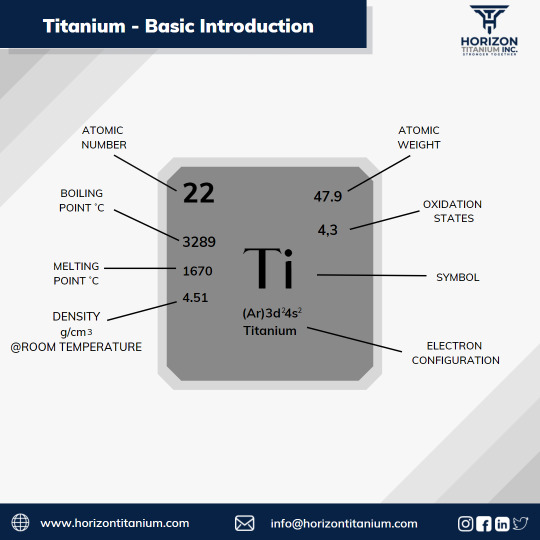

Titanium and its alloys are one of the most important materials for the medical, aerospace, chemical, oil, and refinery industries due to their superior properties.

The properties of Titanium and its alloys are affected by interstitial and substitutional elements in their chemistry.

Here we have tried to make the technical content to understand how those elements can alter the properties of Titanium and its alloys.

#knowyourtitanium#titanium#impurities#interstitial#ductility#elongation#strength#hardness#brittle#FractureToughness#fatiguestrength#mechanical#metallurgy#metals#crystalstructure#dislocation#atoms#bond#deformation#Lattice#latticestrain#interstitalelements#oxygen#nitrogen#carbon#titaniumbars#titaniumrods#titaniumsheets#titaniumplates#titaniumpipes

1 note

·

View note

Photo

Oxygen is a predominant interstitial impurity, widely adopted in titanium-based alloys to enable a potent strengthening effect for diverse applications. Titanium is also inherently expensive due to the tight control of interstitial impurities during its manufacturing process.

Oxygen has a deleterious effect on ductility, fracture toughness, and fatigue strength of titanium.

If your application requires high fracture toughness and fatigue strength, we have such titanium material in stock.

For more information, please write to us at [email protected].

#KnowYourTitanium#Titanium#Oxygen#Impurities#Interstitial#FatigueStrength#FractureToughness#Ductility#ELI#MedicalImplants#TitaniumImplants#Aerospace#Metals#Metallurgy#HorizonTitaniumInc#StrongerTogether

0 notes

Photo

The interstitial elements like oxygen, nitrogen, carbon, and hydrogen are likely to be picked during titanium manufacturing operations and have large effects on its properties.

Above impurities can increase the strength and hardness as their level increases in Titanium and Titanium alloys. While the elongation and toughness decrease.

For medical applications, embrittlement, reduced ductility, low fracture toughness & fatigue strength are some non-desired results due to presence of these impurities at the interstitial sites.

Strict processing controls can greatly reduce the occurrence of interstitial defects.

For more information, kindly write to us at [email protected]

#KnowYourTitanium#titanium#impurities#interstitial#ductility#elongation#strength#hardness#brittle#fracturetoughness#fatiguestrength#mechanical#metallurgy#metals#titaniumroundbars#titaniumbars#titaniumrods#TitaniumSheets#TitaniumPlates#titaniumpipes#titaniumtubes#TitaniumWires#titaniumimplants#MedicalImplants#Orthopaedic#OrthopaedicImplants#medicaldevices#HorizonTitanium#strongertogether

0 notes

Photo

To provide important information regarding Titanium metal, its applications, properties, technical behavior and metallurgical solutions, we are trying to make a small effort by starting a #KnowYourTitanium campaign.

For any further information or technical support for Titanium and its alloys, kindly reach out to us by email.

#KnowYourTitanium#titanium#titaniumroundbars#titaniumsheets#titaniumplates#titaniumpipes#titaniumwires#titaniumforaerospace#titaniumformedical#titaniumimplants#orthopaedicsurgery#orthopedic#orthopaedicimplants#titaniuminindia#medicaldevices#engineering#ductility#tensilestrength#fatiguestrength#fracturetoughness#corrosionresistance#biocompatibility#passivation#metallurgy#horizontitaniuminc#strongertogether

0 notes