#OrthopedicImplant

Text

Drill Machine

For more detail visit our website: www.sofiasurgicals.com

Call us or whatsapp on +919015555501

Email - sofias

#drillmachine

#orthopedicplates#surgicalinstruments#orthopedicsurgery#orthopedicsurgeon#orthopedicscrews#boneplate#orthopedic#orthopedics#orthopedicdoctor#lockingplates#orthoimplants#orthopedicimplants#orthoimplant#orthoimplantegroup#orthopedicimplant#surgicalimplant#ortho#lockingplate#bonefracture#bonefractures#surgicalimplants#orthopaedicimplant#orthopedicinstruments#dhsplate#titaniumimplant#medicalequipment#titaniumplate#hipprosthesis#surgicaltechnologist#austinmorehipprosthesis

2 notes

·

View notes

Text

Orthopedic Implant

Orthopedic implant a muscular embed is a gadget that is utilized to help, or supplant, a harmed bone or joint. They are regularly utilized in instances of horrible injury, or to address a deformation. There are a wide range of kinds of muscular inserts, each intended for a particular reason. The most widely recognized types are hip, knee, and shoulder inserts. Hip inserts are utilized to supplant the hip attachment, while knee and shoulder inserts are utilized to supplant the knee or shoulder joint. Muscular inserts are produced using different materials, including metals, plastics, and ceramics. The decision of material relies upon the particular application. For instance, metal inserts are ordinarily utilized for joint substitutions, while plastic inserts are frequently utilized for injury cases. Muscular inserts are gadgets that are utilized to supplant or uphold a harmed bone or joint. They are normally produced using metals, plastics, or ceramics, and are here and there utilized in mix with different materials.

There are various sorts of muscular inserts in orthopedic implant, and they can be utilized for a wide range of purposes. A few normal models incorporate hip substitutions, knee substitutions, and spinal inserts. orthopedic implant are typically positioned during a medical procedure. The specialist makes a cut in the skin and afterward embeds the embed into the bone. At times, the embed is appended deep down with screws or pins. After a medical procedure of orthopedic implant, the patient should follow a particular recovery convention. This might incorporate active recuperation and word related treatment. The recovery cycle is fundamental to the progress of the medical procedure. In the event that you are thinking about muscular medical procedure, make certain to talk with a board-guaranteed muscular specialist. They will actually want to survey what is going on and suggest the best course of treatment.The three most normal kinds of muscula orthopedic implants inserts are screws, plates, and prostheses, and you should rest assured that once your equipment is set up, you will feel like your orthopedist has resurrected you!

Process of Installing Orthopedic Implant

Screw: Inserts are objects put on or in the body for a clinical or corrective reason; screws utilized in a medical procedure are explicitly used to keep bones intact to reinforce tendons and ligaments. They can likewise be utilized to append the ligaments and tendons deep down or when the bone should be supplanted out and out.

Plate: A muscular plate is a type of interior obsession utilized in muscular medical procedure to hold cracks set up to permit bone mending. Most current plates incorporate bone screws to assist the muscular plate with remaining set up.

Prosthetics: Are intended to supplant body parts that might have been lost for various reasons. In some cases the prosthetic is utilized basically to give the presence of the body part being referred to, yet in many occurrences it can likewise assist the patient with recapturing a specific degree of capability.

Business Name - Shagun Cares Inc.

Business Owner - Deepak Gupta

Business Mail - [email protected]

Website - https://www.shaguncares.com/

Contact Number - 6015800622

0 notes

Photo

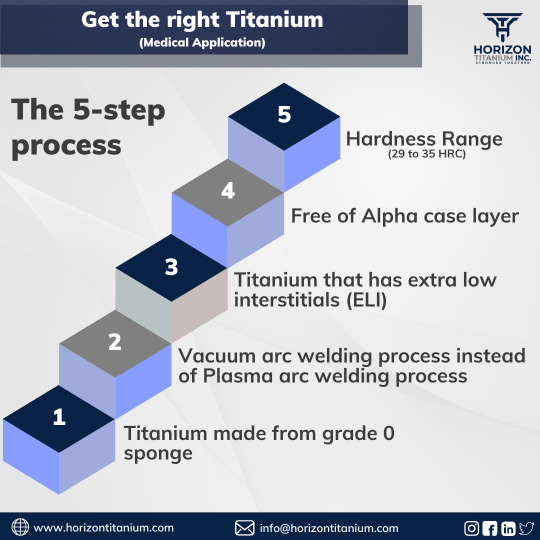

1. The Titanium sponge comes in six grades, i.e. level 0 to level 5. The level 0 grade Titanium sponge is the best material to produce Titanium raw materials because it has low impurities and lower hardness compared to other sponge grades.

2. As the Titanium reacts violently with oxygen and other gases, Vacuum welding, instead of plasma arc welding of compacted briquettes during the Titanium ingot manufacturing, prevents Titanium from reacting with ambient gases.

3. To assure reduced impurity levels, Titanium ingots must be melted three times in a vacuum arc re-melting furnace.

4. The Titanium alloy must be according to ASTM F136 & ISO 5832-3, and CP Titanium must be as per ASTM F67 & ISO 5832-2 standard, which doesn't permit an alpha case layer.

5. While the above standard doesn't define the hardness range of Titanium materials, our research shows that the hardness of Titanium alloy between 29 and 35 HRC should be ideal.

Are you looking to buy Titanium materials? Send us your requirements, and we will share our technical data sheet of Titanium materials based on your application. You can email us at [email protected]

#KnowYourTitanium#Titanium#RightTitanium#SpongeGrade#VaccumArcWelding#ELI#AlphaCase#HardnessRange#TitaniumRoundbar#TitaniumSheet#TitaniumImplant#MedicalImplants#OrthopedicImplant#MedicalDevices#StrongerTogether

0 notes

Photo

Interlocking Nails are used to fix the fractures of long bones. These are inserted in the bone and are transfixed by screws at the ... https://www.orthopaedic-implants.com/interlocking-nails/

6 notes

·

View notes

Text

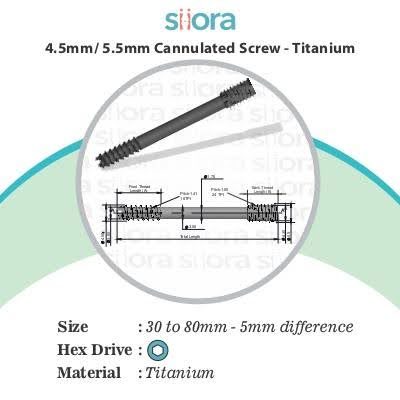

4.5/5.5 mm Cannulated Screw – Titanium

4.5/5.5 mm Cannulated Screw finds application for the treatment of fractures by fixing other orthopedic implants over fractured bone fragments. These screws have a hollow central shaft that allows them to be placed over a guide pin or guide wire. Cannulated screws can also be used for fixing articular and periarticular fractures through minimally invasive procedures. You can avail of these screws from Siora Surgicals Pvt. Ltd., a renowned orthopedic manufacturer in India.

#CannulatedScrews#OrthopedicSurgery#FractureFixation#BoneHealing#MedicalInnovation#SurgicalTools#PrecisionSurgery#Orthopedics#GuideWireTech#BoneRepair#SurgicalInnovation#OrthopedicImplants#FractureCare#SurgeonTools#SurgicalPrecision#BoneHealth

0 notes

Text

Discover the ideal solution for sterilizing single-use medical devices, surgical instruments, and more with our ETO Sterilizer. From surgical threads to orthopedic implants, ensure the highest standards of safety and cleanliness.

For more details, visit- https://www.hospitalsterilizers.com/product/fully-automatic-eto-sterilizer/

#sterilityequipmentsindia#hospitalsterilizers#etosterilizer#surgicalinstruments#surgicaltrys#surgicalthreads#orthopedicimplants

0 notes

Text

Orthopedic Devices Market Trends: Harnessing Technology for Orthopedic Advancements

The global orthopedic devices market size is anticipated to reach USD 103.9 billion by 2030 and it is projected to grow at a CAGR of 5.3% from 2024 - 2030, according to a new report by Grand View Research, Inc. Major factors driving the market growth include high demand for orthopedic surgeries due to rising road accidents and prevalence of orthopedic diseases. Rise in geriatric population prone to orthopedic conditions primarily drives the global demand for orthopedic solutions. Effects of aging, such as lowering bone density and weakening of bones due to excessive loss of bone mass, are prominent in people from 25 to 54 years of age and becomes more noticeable after 55 years.

Orthopedic Devices Market Report Highlights

Based on products, orthopedic implants segment held the majority share of the market in 2023, with a revenue of USD 37.1 billion owing to rapidly rising number of knee surgeries, hip replacement surgeries, and spinal implant surgeries

Based on end-use, hospitals segment held the majority market share in 2023, with a revenue of USD 42.6 billion. This can be attributed to significant infrastructure advancements and availability of world-class treatment solutions

North America captured the largest market share of 46.2% in 2022 owing to the presence of a large number of major market players and high adoption of advanced technologies are the major driving factors

Asia Pacific is anticipated to witness the fastest CAGR of 7.7% over the forecast period. Presence of a largely untapped market and supportive government regulations are expected to fuel the market growth in this region.

For More Details or Sample Copy please visit link @: Orthopedic Devices Market Report

High adoption of minimally invasive surgeries and an increasing number of sports and road traffic accidents are expected to fuel growth of the market during the forecast period. Arthroscopy, minimally invasive total joint replacement, and spine surgeries are some of the newly adopted minimally invasive surgeries. Stringent procedures of regulatory approvals are anticipated to hinder market growth over the forecast period. In addition, high cost of devices and surgeries are some other factors likely to impede growth.

COVID-19 pandemic had a significant impact on the market. Elective orthopedic surgeries were postponed allocating resources for COVID-19 patients, leading to reduced demand. However, over time, the market adapted, focusing on infection control, remote consultations, and tele-rehabilitation. This pandemic accelerated digital health adoption, and implant materials evolved for patient safety.

Moreover, key players in the market, such as NuVasive, Inc.; Medtronic plc; Stryker Corporation; Zimmer Biomet; and Smith+Nephew, among others, are engaging in strategic initiatives such as partnerships, collaborations, new product launches, acquisitions, and expansions to strengthen their market position. In January 2022, Smith+Nephew acquired Engage Surgical, which is involved in manufacturing cementless knee systems in the U.S. This acquisition is anticipated to enhance company’s position in meniscal tear solutions and other knee arthroscopy devices.

#OrthopedicDevices#MusculoskeletalHealth#Orthopedics#OrthopedicImplants#OrthopedicCare#OrthopedicTechnology#OrthopedicTreatment#OrthopedicDevicesIndustry#OrthopedicDevicesMarket#OrthopedicRehabilitation#OrthopedicInstruments#OrthopedicProsthetics#OrthopedicResearch#OrthopedicTrends

0 notes

Text

3D Printed Medical Device Market Huge Growth in Future Scope 2024-2030 | GQ Research

The 3D Printed Medical Device market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global 3D Printed Medical Device market showcased a significant presence, boasting a valuation of US$ 3.14 Billion. This underscores the substantial demand for 3D Printed Medical Device technology and its widespread adoption across various industries.

Get Sample of this Report at https://gqresearch.com/request-sample/global-3d-printed-medical-device-market/

Projected Growth: Projections suggest that the 3D Printed Medical Device market will continue its upward trajectory, with a projected value of US$ 6.77 Billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 16.55 %, reflecting a steady and robust growth rate for the 3D Printed Medical Device market over the coming years.

Technology Adoption: In the 3D Printed Medical Device market, technology adoption is pivotal for advancing patient care, surgical outcomes, and manufacturing efficiency. Manufacturers leverage cutting-edge 3D printing technologies such as selective laser sintering (SLS), stereolithography (SLA), and direct metal laser sintering (DMLS) to produce complex, patient-specific medical devices with precision and accuracy. Additionally, the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) software enables the customization of medical devices to match individual patient anatomy, enhancing fit and functionality. Furthermore, advancements in biocompatible materials and post-processing techniques ensure the safety and efficacy of 3D printed medical devices.

Application Diversity: The 3D Printed Medical Device market encompasses a diverse range of applications across various medical specialties, including orthopedics, cardiology, dentistry, maxillofacial surgery, and prosthetics. From patient-specific implants and surgical guides to anatomical models and dental restorations, 3D printing technology enables the production of customized devices tailored to individual patient needs. Each application segment addresses specific medical conditions and treatment modalities, offering improved clinical outcomes, reduced surgical times, and enhanced patient satisfaction.

Consumer Preferences: Consumer preferences in the 3D Printed Medical Device market are driven by factors such as product quality, safety, regulatory compliance, and affordability. Healthcare providers prioritize medical devices that meet stringent quality standards and regulatory requirements, ensuring patient safety and efficacy. Additionally, clinicians value devices that offer precise anatomical fit, optimal functionality, and ease of use during surgical procedures. Moreover, healthcare institutions seek cost-effective solutions that provide value for money in terms of improved patient outcomes and reduced healthcare costs over the long term.

Technological Advancements: Technological advancements in the 3D Printed Medical Device market focus on enhancing printing speed, resolution, and material properties to expand the range of applications and improve patient care. Innovations in printer hardware, such as multi-material printing capabilities and high-resolution printing heads, enable the production of complex, multi-functional medical devices with superior surface finish and mechanical properties. Furthermore, advancements in biocompatible materials, including resorbable polymers, titanium alloys, and bioactive ceramics, offer improved biocompatibility, osseointegration, and tissue regeneration for implanted medical devices. Additionally, the integration of advanced imaging techniques such as CT and MRI scans facilitates the creation of patient-specific medical devices with unparalleled accuracy and precision.

Market Competition: The 3D Printed Medical Device market is characterized by intense competition among medical device manufacturers, contract manufacturers, and healthcare providers, driven by factors such as product innovation, quality, pricing, and regulatory compliance. Established medical device companies leverage their expertise in research and development, regulatory affairs, and distribution networks to introduce innovative 3D printed medical devices that address unmet clinical needs and improve patient outcomes. Meanwhile, contract manufacturers and startups focus on niche applications and customization services to differentiate themselves in the market. Additionally, strategic partnerships with healthcare institutions, research centers, and regulatory agencies play a significant role in expanding market presence and gaining competitive advantage.

Environmental Considerations: Environmental considerations are increasingly important in the 3D Printed Medical Device market, with stakeholders focusing on sustainable materials, waste reduction, and energy-efficient manufacturing processes. Manufacturers are exploring eco-friendly materials such as biodegradable polymers, recycled metals, and bioactive ceramics to minimize environmental impact and promote circular economy principles. Moreover, efforts are underway to implement closed-loop recycling systems for waste generated during the 3D printing process, reducing material waste and energy consumption. Additionally, adherence to stringent environmental regulations and certifications, such as ISO 14001 and RoHS compliance, demonstrates a commitment to sustainability and responsible manufacturing practices within the medical device industry.

Top of Form

Top of FormRegional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

Stratasys Ltd.

3D Systems Corporation

Materialise NV

Envisiontec GmbH

Eos GmbH Electro Optical Systems

Renishaw PLC

3T RPD Ltd.

Prodways Machines

Arcam AB

GE Additive.

The research report provides a comprehensive analysis of the 3D Printed Medical Device market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-3d-printed-medical-device-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

#3DPrintedMedicalDevices#PersonalizedHealthcare#InnovationInHealthcare#MedicalTechnology#OrthopedicImplants

0 notes

Text

Are your buttocks, hips, or legs hurting?

🦵 Don't let it stop you! Talk to Dr. Vaibhav Jain for help and feel better soon.

Consult For Treatment with Dr Vaibhav Jain

Book an appointment through:

Call : +91 92890 84372

Visit: www.drvaibhavjain.com

DELHI: @moolchand_healthcare

NOIDA: VISHWASTH CLINIC

#PainRelief#HipHealth#Hippain#Orthopedic#DrVaibhavJain#hipreplacement#orthopedicimplants#orthopediccenter#hipreplacementsuccess

1 note

·

View note

Text

Exploring the Variety in Orthopedic Screws for Effective Healing

Introduction:

Muscular screws assume a critical part in the field of muscular medical procedure, filling in as fundamental parts in the adjustment and obsession of cracked or harmed bones. The variety in muscular screw plans and materials has extended throughout the long term, giving specialists a scope of choices to fit medicines to individual patient necessities. This article expects to dive into the different sorts of muscular screws, their materials, and the progressions that add to compelling bone recuperating.

Customary Muscular Screws:

Customary muscular screws are commonly made of treated steel or titanium. Tempered steel screws are known for their solidarity and strength, making them reasonable for different applications. Titanium screws, then again, are esteemed for their biocompatibility and decreased hazard of erosion.

One of the regularly utilized conventional screws is the cortical screw, intended for obsession in thick bone. Another sort is the cancellous screw, highlighting a more extensive string design for improved buy in milder bone. These conventional screws have been dependable options for a long time, giving solidness and backing in muscular medical procedures.

Bioabsorbable Muscular Screws:

Bioabsorbable screws have acquired fame because of their interesting property of being progressively consumed by the body over the long run. These screws are frequently produced using materials like polylactic corrosive (PLA) or polyglycolic corrosive (PGA). The benefit of bioabsorbable screws lies in the end of the requirement briefly medical procedure to eliminate the equipment.

These screws are especially valuable in pediatric muscular health, where the embed will normally corrupt as the youngster develops. They likewise diminish the gamble of obstruction with imaging studies, making postoperative appraisals simpler.

Locking Muscular Screws:

Locking tightens give a particular component that upgrades steadiness obsession. These screws have strings intended to draw in with a plate, making a fixed-point develop. The locking highlight forestalls relative movement between the screw and the plate, further developing protection from slackening.

Locking screws are worthwhile in osteoporotic bone or circumstances where traditional screws may not give adequate dependability. This plan limits micromotion at the break site, advancing better mending results.

Variable Pitch Screws:

Variable pitch screws have a string plan that changes along the length of the screw. This variety in pitch considers various degrees of pressure at the crack site. Pressure is pivotal for advancing bone mending, and variable pitch screws offer a redid way to deal with accomplish the ideal pressure.

Specialists can pick the pitch variety in light of the particular prerequisites of the break, giving flexibility in the use of these screws. This flexibility is especially valuable in situations where a uniform pressure may not be reasonable.

Headless Screws:

Headless screws, otherwise called cannulated screws, miss the mark on noticeable head, which lessens the unmistakable quality of equipment underneath the skin. These screws are normally utilized in regions where delicate tissue bothering or noticeable quality of the embed may be a worry.

The cannulated plan takes into consideration percutaneous arrangement, limiting the obtrusiveness of the medical procedure. Headless screws are many times utilized in techniques like subtalar arthrodesis or cracks close to joints, where limiting disturbance is significant for ideal patient results.

Progressions in Material Science:

Material science plays had a huge impact in the development of muscular screws. While tempered steel and titanium stay conspicuous decisions, more current materials are being investigated for upgraded execution. Magnesium-based screws, for example, are being researched for their biocompatibility and potential to debase after some time.

Furthermore, progressions in surface coatings expect to further develop osseointegration, diminishing the gamble of embed disappointment. Hydroxyapatite-covered screws, for instance, work with better bone adherence, advancing quicker mending and lessening the gamble of non-associations.

Explored and Tweaked Screws:

With the coordination of PC helped route frameworks, specialists can now design and execute methodology with a more serious level of accuracy. Explored muscular screws consider constant following and direction, guaranteeing precise situation and ideal obsession.

Moreover, the idea of tweaked muscular inserts, including screws, is getting some forward movement. Patient-explicit inserts, planned in light of individual physical information, give a fitted way to deal with muscular mediations, possibly further developing results and decreasing entanglements.

Conclusion:

The assortment in muscular screws mirrors the unique idea of muscular medical procedure, where customized and creative methodologies are progressively pervasive. From conventional hardened steel screws to bioabsorbable other options, and from locking systems to variable pitch plans, each sort of screw fills a particular need in advancing viable bone recuperating. Headways in materials and innovation keep on pushing the limits of muscular development, promising improved results for patients going through careful mediations. As innovative work in this field progress, muscular specialists can anticipate an extending toolbox that considers more exact, patient-driven, and fruitful muscular systems.

0 notes

Text

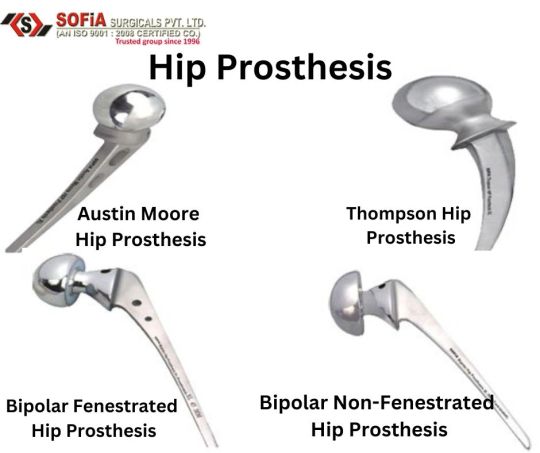

Hip Prosthesis

For more detail visit our website: www.sofiasurgicals.com

Call us or whatsapp on +919015555501

Email - [email protected]

#orthopedicplates#surgicalinstruments#orthopedicsurgery#orthopedicsurgeon#orthopedicscrews#boneplate#orthopedic#orthopedics#orthopedicdoctor#lockingplates#orthoimplants#orthopedicimplants#orthoimplant#orthoimplantegroup#orthopedicimplant#surgicalimplant#ortho#lockingplate#bonefracture#bonefractures#surgicalimplants#orthopaedicimplant#orthopedicinstruments#dhsplate#titaniumimplant#medicalequipment#titaniumplate#hipprosthesis#surgicaltechnologist#austinmorehipprosthesis

1 note

·

View note

Text

0 notes

Photo

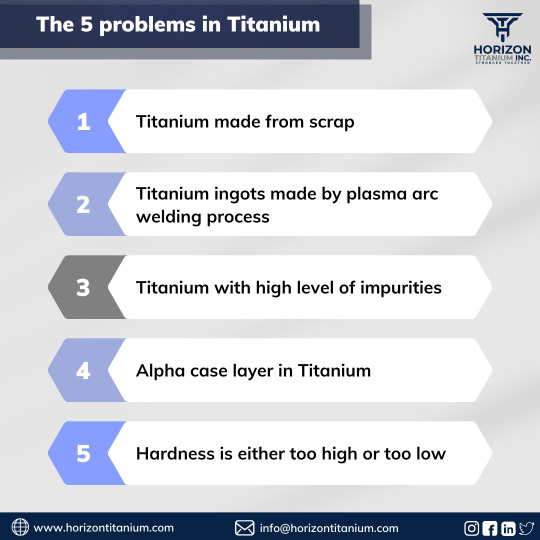

We have listed some of the problems you may need to take care of while purchasing Titanium.

1. Iron, oxygen, and tungsten carbide (added during the machining process) are heavily contaminated in titanium scrap and are challenging to remove while melting titanium scrap.

2. Titanium is highly reactive with oxygen and other gases. Titanium may react with atmospheric gases while welding compacted briquettes during the Titanium ingot manufacturing process.

3. Higher impurity content (Oxygen, Iron, Nitrogen) makes Titanium brittle and decreases its fatigue life & fracture toughness.

4. The alpha case is a brittle and hard layer that can readily break the material when the material is under sudden or repeating stress.

5. If the hardness of Titanium is high, the machining process becomes more complex, and tool life diminishes. When the hardness is low, the performance of the finished product weakens.

There are a few more things you may want to know before deciding to buy Titanium rods/sheets for medical applications.

To learn more about such problems, DM us or email us at [email protected].

#KnowYourTitanium#Titanium#Problems#TitaniumScrap#TitaniumWelding#Impurities#AlphaCase#Hardness#ELI#TitaniumRoundbar#TitaniumSheet#TitaniumImplant#MedicalImplants#OrthopedicImplant#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Photo

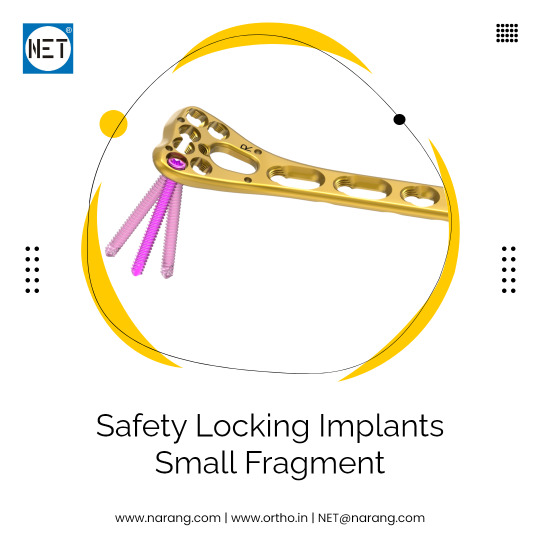

Safety Locking Plates are similar to Standard Plates that have numeral-8 shaped holes, on one side the hole is threaded so that it can accommodate ... https://orthopaedic-implants.com/small-fragment-locking/safety-locking-implants…

4 notes

·

View notes