#Flanges Types

Text

Jay Steel Corporation is leading manufacturers, suppliers and exporters of Nickel , Titanium and Stainless steel product.

#nuts and bolts manufacturers#stainless steel products#flanges types#steel product manufacturers in india#nickel alloy products#titanium alloy products#fasteners manufacturers#pipe and tube manufacturers#pressure vessel manufacturer#ss fasteners

0 notes

Text

What are the different types of stainless steel flanges? - Arcellor Controls

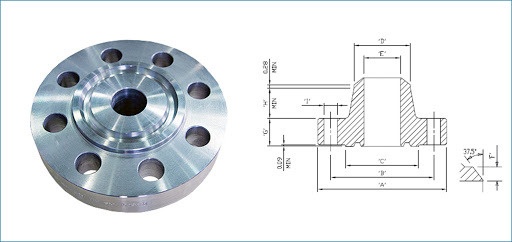

Stainless steel flanges are crucial components in a wide range of industrial applications. They are used to connect pipes, valves, pumps, and other equipment to create a piping system. Stainless steel flanges are specifically designed to offer a secure and leak-proof connection between pipes. These flanges are commonly either welded or threaded, and two flanges are connected by bolting them together with gaskets, which creates a seal and provides easy access to the piping system.

At ArcellorControls, we are the leading stainless steel flanges manufacturers, suppliers, stockiest, and exporters in India. We do offer Stainless steel flanges in various types such as Slip On Flanges, Weld Neck Flanges, Blind Flanges, Socket Weld Flanges, Blind Flanges, Spectacle Blind Flanges, Lap Joint Flanges, Threaded Flanges, Orifice Flanges, Moreover, we do also offer a wide range of stainless steel flanges to meet the requirements of different industrial applications.

Our Stainless Steel flanges are crafted with superior-quality materials and designed to establish a secure and leak-free connection between pipes. We are committed to providing our customers with top-notch products and services, ensuring their satisfaction, and building long-term relationships.

This blog post will look at various types of stainless steel flanges, reasons to choose stainless steel flanges for your industrial needs, and their applications as well!

Stainless Steel Flanges

A Stainless Steel flange is a circular ring made from forged or cast steel that is used to connect sections of pipe or join pipe to other components such as pressure vessels or pumps. Flanges are typically joined together using bolts and are connected to the piping system through welding or threading. There are several types of flanges available, including Stainless Steel Flanges (ss Flanges), Alloy steel flanges, Carbon steel flanges, Slip, Blind, Weld Neck, Threaded, Socket Weld, Lap Joint, Orifice, and more.

Types of Flanges

With Arcellor Control’s India, we offer a wide range of stainless steel flanges including:

Slip On Flanges:

Stainless Steel Slip-on Flanges enjoy widespread popularity owing to their economical cost and ease of installation. Numerous other models with varying diameters and low-pressure capacities are available to choose from. Unlike Welding Neck Flanges, this type of Flange lacks a neck to rest on the Pipe, necessitating double welding.

Weld Neck Flanges:

Weld neck flanges are extensively employed in high-pressure applications and rank among the most preferred types of flanges. They boast of a long tapered hub along with a butt-weld end. The elongated tapered hub bestows a significant reinforcement to the flange and simplifies the alignment of the bolt holes. Weld neck flanges find widespread usage in pipelines, refineries, and petrochemical plants.

Socket Weld Flanges:

Socket Weld Flanges resemble Slip-On Flanges; however, they possess a socket that the pipe is compatible with, rather than merely sliding over it. These flanges are commonly utilized in high-pressure systems and are well-suited for pipes with smaller diameters.

Blind Flanges:

Blind Flanges are put to use to hermetically seal the end of a pipe. These flanges are frequently employed in high-pressure systems that necessitate intermittent scrutiny or cleansing. Furthermore, Blind Flanges are utilized in systems where one end of the pipe is shut.

Spectacle Blind Flanges:

Stainless Steel Spectacle blind flanges are exclusively designed for employment in systems demanding isolation or flow diversion. These flanges comprise of two metal discs, wherein one of them has a hole, while the other is devoid of it. These discs can be revolved to enable or obstruct the flow of fluid.

Lap Joint Flanges:

Lap Joint Flanges find application in systems necessitating frequent disassembling. These flanges exhibit a smooth surface and possess a separate flange ring that loosely slips over the pipe. Lap Joint Flanges are predominantly preferred in scenarios that involve low pressure.

Threaded Flanges:

Threaded flanges are purposefully engineered to be screwed onto the terminal section of a pipe. These flanges are frequently utilized in scenarios where the welding process is not feasible for low-pressure applications. The installation of threaded flanges is a simple and effortless process, devoid of any welding requirements. This makes them a practical choice for temporary setups. Threaded flanges are commonly employed in the conveyance of potable water, waste disposal systems, and other circumstances with lower pressure demands.

Orifice Flanges:

The purpose of steel flanges is to allow access to a pipeline for measuring liquids or gases. Orifice flanges are specifically designed for this purpose and are typically used with orifice plates or flow nozzles to accurately measure the flow rate of a fluid in the pipeline.

Flanges based on face Type

Depending on the flange facing Types, it can be further classified as

Flat Face Flanges:

Flat Face flanges are a type of flange that has a flat sealing surface, which is typically used in low-pressure applications. The sealing surface of these flanges is flat and smooth, making them easy to seal with gaskets. They are commonly used in applications where the piping system requires frequent disassembly and reassembly, such as in maintenance or cleaning processes.

Raised Face Flanges:

Raised Face flanges are a type of flange that has a raised sealing surface, which is typically used in high-pressure applications. The raised surface allows for better alignment and prevents leakage at higher pressures. The sealing surface of these flanges is typically serrated to provide a better grip on the gasket, ensuring a tighter seal.

Raised Face flanges are commonly used in applications where high pressures are required.

Ring Joint Flanges:

Ring-type joint flanges are suitable for use in high-pressure and high-temperature applications. They are designed with a groove that can be compressed onto blind, slip-on, or weld neck flanges. This compression helps to prevent leaks in pipelines where fluids or gases are transferred at high pressure and high temperature. Ring-type joint flanges are commonly used in the oil and gas industry, chemical plants, and other industrial applications.

Why Choose Steel Flanges Made of Stainless Steel?

When it comes to your budget, you want to get the most bang for your buck. Here are some reasons why you should choose stainless steel flanges as a good investment!

Corrosion Resistance

Corrosion can significantly impact the performance and longevity of any metal used in various applications. Rust, pollutants, and other environmental factors can affect the integrity of the metal over time. Therefore, it is crucial to select flanges that can withstand these circumstances. Stainless steel is an excellent choice due to its high corrosion resistance, which helps to prevent degradation and prolong the lifespan of the flange.

Durability

Stainless steel is a resilient metal that has high durability against abrasion and fatigue. On the other hand, aluminum is a cost-effective substitute, but it lacks the ability to endure the same level of stress.

Resistance to High-Temperature

Certain industries may expose their equipment to extremely high temperatures, which can pose a safety hazard. However, Flange fittings made of stainless steel have the capacity to withstand elevated temperatures without deforming or warping. This attribute ensures that your system remains secure and free from any potential threats.

Materials used to manufacture steel flanges

With Arcellor Controls India, we offer steel flanges in various materials and grades such as,

Materials

Grades

Stainless Steel ASME B16.5 Flange

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel ASME B16.5 Flange

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Carbon Steel ASME B16.5 Flange

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

Low-Temperature Carbon Steel ASME B16.5 Flange

ASTM A350, LF2, LF3

Alloy Steel ASME B16.5Flange

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Copper Alloy Steel Flange ASME B16.5

ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy ASME B16.5 Flange

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

ASME / ANSI B16.5 Flange Specification

Standard

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawing

Dimensions

½” (15 NB) to 48” (1200NB)

Size

150 LBS, 300 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16,25,40 Etc.

Type

DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673

Flange Face Type

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Applications of Stainless Steel Flanges

Stainless steel flanges find applications in various industries owing to their durability, corrosion resistance, and high strength.

Some of the applications of stainless steel flanges are as follows:

Food and beverage industry

Oil and Gas Industries

Water Supply Industries

Transportation

Aerospace Industry

Pharmaceutical industry

Water treatment industry

Chemical industry and So on.

Final Words!..

Stainless steel flanges are an essential component in piping systems due to their strength, durability, and corrosion resistance. As a leading stainless steel flange manufacturer, Arcellor Controls India offers a wide range of flange types suitable for various industrial applications. The most commonly used types of flanges include Weld Neck, Slip-On, Socket Weld, Lap Joint, Threaded, and Blind flanges. Each type of flange has different features and benefits, making it suitable for specific applications.

As a well-known exporter of Stainless Steel flanges, we do export them to various countries such as Africa, Nigeria Algeria Angola Tanzania Libya Egypt Sudan Equatorial Guinea The Republic Of Congo Gabon NORTH AMERICA USA Canada Mexico Costa Rica Trinidad And Tobago Jamaica Denmark.

Middle East Asia Saudi Arabia Iran Iraq Uae Qatar Bahrain Oman Kuwait Turkey Jordan SOUTH AMERICA Argentina Bolivia Brazil Chile Venezuela Colombia Ecuador Guyana Paraguay Uruguay.

EUROPE Norway Germany France Italy Uk Spain Netherland Belgium Greece Czech Republic Portugal Hungary SOUTH AFRICA.

ASIA India Singapore Malaysia Indonesia Thailand Vietnam South Korea Japan Sri Lanka Maldives Bangladesh Mayanmar Taiwan Cambodia.

If you want to learn more about our products and services, please visit our website or contact us today. We will be happy to assist you.

0 notes

Text

Penstock Pipes For Hydropowers Manufacturer Supplier India

Manufacturer, Supplier, Exporter of MS Mild Steel Penstock Pipes, Penstock Pipes For Hydropowers from Ahmednagar, Maharashtra, India.

Flange Adapter, Flange Adapters, Flange Type Adapter, Flange Type Adapters, MS Flange Adaptor, MS Flange Adaptors, MS Dismantling Joint, MS Dismantling Joints, Weldable Type Flange Adapter, Weldable Type Flange Adapters, Flange Type Flange Adapter, Flange Type Flange Adapters, Dismantling Joint, Dismantling Joints, Slip Type Expansion Joint, Slip Type Expansion Joints, Slip Type Flanged Expansion Joint, Slip Type Weldable Expansion Joints, Pipe Compensator, MS Slip Type Expansion Joint, MS Slip Type Expansion Joints, Expansion Joint, Expansion Joints, Slip Type Expansion Joint, Slip Type Expansion Joints, Mechanical Slip Type Expansion Joint, Mechanical Slip Type Expansion Joints, Mechanical Joint, Mechanical Joints, Mechanical Expansion Joint, Mechanical Expansion Joints, Steel Fabricated Expansion Joint, Steel Fabricated Expansion Joints, Fabricated Steel Mechanical Expansion Joint, Fabricated Steel Mechanical Expansion Joints, MS PSC Pipe Mould, Penstock Pipes For Hydropower, Penstock Pipes For Hydropowers, MS Penstock Pipe, MS Penstock Pipes, Manufacturer Supplier Exporter, Ahmednagar Maharashtra India.

#Flange Adapter#Flange Adapters#Flange Type Adapter#Flange Type Adapters#MS Flange Adaptor#MS Flange Adaptors#MS Dismantling Joint#MS Dismantling Joints

0 notes

Text

Unveiling the Superiority of SOP Type Flanges: Emirerri Steel's Premium Solutions

Introduction:

In the intricate network of industrial piping systems, the choice of flanges plays a pivotal role in ensuring seamless operations and structural integrity. Among the array of flange types available, SOP (Standard Operating Procedure) Type Flangesstand out for their versatility, reliability, and ease of installation. Emirerri Steel, a leading manufacturer of stainless steel pipe fittings, proudly offers a range of SOP Type Flanges engineered to meet the diverse needs of industries worldwide. Let's explore the unparalleled advantages of SOP-type flanges and why Emirerri Steel remains the epitome of excellence in flange manufacturing.

Understanding SOP Type Flanges:

SOP Type Flanges, also known as Standard Operating Procedure flanges, are a standardized form of flanges widely used across industries for their simplicity and efficiency. These flanges adhere to specific dimensional standards, ensuring compatibility and interchangeability with various piping systems. SOP Type Flanges are characterized by their flat face and are typically used in applications where fluid leakage prevention and ease of assembly are paramount.

Emirerri Steel's Commitment to Excellence:

Emirerri Steel stands at the forefront of stainless steel pipe fittings manufacturing, and their SOP Type Flanges exemplify the brand's commitment to quality, precision, and innovation. Crafted from high-grade stainless steel, Emirerri Steel's SOP Type Flanges undergo meticulous manufacturing processes to ensure superior durability, corrosion resistance, and flawless performance in diverse industrial environments.

Advantages of SOP Type Flanges:

1. Ease of Installation: SOP Type Flanges are renowned for their simplicity of design, making them easy to install and maintain, thereby reducing downtime and labor costs.

2. Interchangeability: SOP Type Flanges adhere to standardized dimensions, facilitating interchangeability with compatible flange types, enhancing operational flexibility, and reducing inventory management complexities.

3. Leakage Prevention: The flat face design of SOP Type Flanges ensures tight sealing, minimizing the risk of fluid leakage and enhancing operational safety.

4. Versatility: SOP Type Flanges find applications across a wide range of industries, including oil and gas, petrochemical, water treatment, and manufacturing, showcasing their versatility and adaptability to diverse operating conditions.

Emirerri Steel's Range of SOP Type Flanges:

Emirerri Steel offers a comprehensive range of SOP-type flanges meticulously crafted to meet the exacting standards of various industries. Whether it's ANSI, DIN, or JIS specifications, Emirerri Steel's SOP Type Flanges are engineered to deliver superior performance and reliability, surpassing customer expectations and industry standards alike.

Conclusion:

SOP Type Flanges stand as a testament to simplicity, efficiency, and reliability in industrial piping systems. Emirerri Steel's dedication to excellence shines through in their premium SOP Type Flanges, engineered to meet the diverse needs of industries worldwide. Experience the Emirerri Steel difference today by exploring our range of SOP Type Flanges at https://emirerristeel.com/sop-type-flange/ and elevate your piping solutions to new heights of performance and reliability.

#steel manufacturing#success#marketing#butt weld pipe fittings#steel flange#forged steel fittings#forged fittings#pipe fittings#steel manufacturer#flanges#SOP#SOP Type Flanges

0 notes

Text

Double Flange Butterfly Valves: The Game-Changer Your Facility Needs!

In the dynamic world of industrial operations, every component plays a crucial role in ensuring smooth functionality. One such vital component is the Double Flange Butterfly Valve, a true game-changer for facilities in the oil and gas industries. Let's dive into the realm of HTC Valves' innovative creation and explore why it's a must-have for your operations.

Understanding Butterfly Valves

Butterfly valves are essential components in industrial pipelines, allowing control and regulation of flow. They operate similarly to a disc rotating on a central axis, regulating flow by turning perpendicular to the direction of the fluid.

Introducing Double Flange Butterfly Valves

HTC Valves introduces the Double Flange Butterfly Valve, an innovative solution designed to enhance performance and reliability in industrial settings. Unlike traditional butterfly valves, double flange variants offer added stability and durability, making them ideal for high-pressure applications.

How Double Flange Butterfly Valves Work

The operation of double flange butterfly valves is straightforward yet effective. When fully open, the disc aligns with the flow direction, minimizing resistance and pressure drop. Conversely, closing the valve involves rotating the disc perpendicular to the flow, effectively blocking it.

Advantages of Double Flange Butterfly Valves

Double flange butterfly valves offer several advantages over their counterparts. Their design ensures a tight seal, reducing leakage and minimizing maintenance requirements. Additionally, their lightweight construction and compact size make them easy to install and integrate into existing systems.

Applications in Oil and Gas Industries

In the oil and gas industries, where efficiency and reliability are paramount, double flange butterfly valves excel. Their ability to handle high pressures and temperatures makes them indispensable in pipeline systems, storage tanks, and processing plants.

Installation and Maintenance Considerations

Installing and maintaining double flange butterfly valves is relatively straightforward. Proper alignment during installation ensures optimal performance, while regular inspection and lubrication prolong valve life and prevent issues.

Comparing Double Flange vs. Standard Valves

Compared to standard butterfly valves, double flange variants offer enhanced stability and sealing capabilities. While both serve similar functions, double flange valves are preferred for applications requiring higher pressures and greater reliability.

Innovations in Valve Technology

The realm of valve technology is constantly evolving, with innovations aimed at improving efficiency, durability, and sustainability. HTC Valves continues to lead the way with cutting-edge designs and materials, ensuring their products meet the ever-changing needs of industries worldwide.

Sustainability and Environmental Impact

As industries focus more on sustainability, the environmental impact of valve systems comes into focus. Double flange butterfly valves, with their efficient design and reduced leakage rates, contribute to lower energy consumption and emissions, aligning with sustainability goals.

Choosing the Right Valve for Your Facility

Selecting the right valve for your facility is crucial to ensure optimal performance and longevity. Factors such as operating conditions, fluid characteristics, and system requirements should be carefully considered when choosing between double flange and other valve types.

Common Challenges and Solutions

While double flange butterfly valves offer numerous benefits, they are not without challenges. Issues such as corrosion, erosion, and fouling can impact valve performance over time. Regular maintenance, proper material selection, and preventive measures can mitigate these challenges effectively.

Future Trends in Valve Design

Looking ahead, the future of valve design is exciting, with advancements in materials, automation, and smart technologies shaping the industry. HTC Valves remains committed to innovation, ensuring their products continue to meet the evolving needs of tomorrow's industries.

Conclusion

In conclusion, Double Flange Butterfly Valves offered by HTC Valves stand as a testament to innovation and reliability in industrial valve technology. With their superior performance, durability, and efficiency, they are indeed the game-changer your facility needs.

FAQs

1. What distinguishes double flange butterfly valves from standard butterfly valves?

Double flange butterfly valves offer enhanced stability, durability, and sealing capabilities compared to standard valves, making them suitable for high-pressure applications.

2. Are double flange butterfly valves suitable for use in the oil and gas industries?

Yes, double flange butterfly valves excel in the oil and gas industries, where they are used in pipeline systems, storage tanks, and processing plants due to their ability to handle high pressures and temperatures.

3. How do I ensure proper installation of double flange butterfly valves?

Proper alignment during installation is crucial for optimal performance. Ensure that the valve is correctly positioned and securely fastened to prevent leaks or malfunctions.

4. What maintenance procedures are required for double flange butterfly valves?

Regular inspection, lubrication, and cleaning are essential maintenance procedures to ensure the longevity and optimal performance of double flange butterfly valves.

5. Can double flange butterfly valves contribute to environmental sustainability?

Yes, double flange butterfly valves, with their efficient design and reduced leakage rates, can contribute to lower energy consumption and emissions, aligning with sustainability goals in industrial operations.

1 note

·

View note

Text

JIS B2220 10K flanges

Introduction:

In the realm of industrial piping systems, precision and reliability are non-negotiable factors. JIS B2220 10K flanges stand as pillars of strength, offering robust solutions for a multitude of applications. From dimensions to types and reliable suppliers, understanding the intricacies of these flanges is crucial for seamless operations. Join us as we delve into the world of JIS B2220 10K flanges, exploring their dimensions, types, and trusted suppliers in Mumbai, India.

Dimensions of JIS B2220 10K Flanges:

JIS B2220 10K flanges adhere to specific dimensions to ensure compatibility and ease of installation. The standard dimensions typically include flange outer diameter (OD), bolt circle diameter (BC), bolt hole diameter (BH), and thickness (T). These standardized dimensions streamline the integration of flanges into diverse piping systems, enhancing efficiency and reliability.

Types of JIS B2220 10K Flanges:

Forged Flanges: Engineered for durability and strength, JIS B2220 10K forged flanges offer robust solutions for high-pressure applications, ensuring leak-free connections and long-term performance.

Reducing Flanges: Designed to accommodate pipes of different diameters, JIS B2220 10K reducing flanges facilitate smooth transitions between piping systems, optimizing flow dynamics and minimizing pressure drop.

Flat Flanges: Featuring a flat surface, JIS B2220 10K flat flanges provide a reliable sealing mechanism, making them ideal for applications where leakage prevention is paramount.

Blind Flanges: Employed to seal the end of a piping system, JIS B2220 10K blind flanges offer versatility and convenience, allowing for easy isolation and maintenance of pipelines.

Weld Neck Flanges: Known for their superior strength and reliability, JIS B2220 10K weld neck flanges provide secure connections in high-stress environments, minimizing the risk of leakage or failure.

Trusted Suppliers of JIS B2220 10K Flanges in Mumbai, India:

[Supplier Name 1]: Renowned for their extensive inventory and commitment to quality, [Supplier Name 1] is a trusted source for JIS B2220 10K flanges in Mumbai, India.

[Supplier Name 2]: With a proven track record of excellence and customer satisfaction, [Supplier Name 2] offers competitive prices and prompt delivery of JIS B2220 10K flanges to meet diverse industrial requirements.

[Supplier Name 3]: Committed to exceeding customer expectations, [Supplier Name 3] provides comprehensive support and timely solutions for JIS B2220 10K flanges, ensuring seamless integration into industrial projects.

Conclusion:

In conclusion, JIS B2220 10K flanges represent the epitome of reliability and precision in industrial piping systems. With standardized dimensions, diverse types, and trusted suppliers in Mumbai, India, these flanges offer versatile solutions for a wide range of applications. By partnering with reputable suppliers and adhering to industry standards, businesses can harness the full potential of JIS B2220 10K flanges, ensuring efficient operations and optimal performance in their projects.

0 notes

Text

Flange is used to connect valves, pumps, pipes, and many other different types of components and plumbing equipment to form a strong, reliable, and seal-proof piping system. There are many different types of flanges available in the market with varying flanges prices, and this guide will introduce you to some of the most widely used common and uncommon flanges.

0 notes

Text

Monolithic Insulating Joint Gasket in Canada By Goodrich Gasket.

Now the Monolithic Insulating Joint gasket is also available in Canada by Goodrich Gasket. The Monolithic Insulating Joint in Canada is a welded pre-fabricated 3-piece union applicable for pipeline electrical sectioning and commonly used when cathodic protection is present to prevent any interference in corrosion control. The gasket has the right facilities to do several non-destructive tests. Goodrich gasket is a wide range of industrial gasket manufacturers and exporters across the world, especially in Canada. Know more about Goodrich's Monolithic Insulting Joint:- www.goodrichgasket.com/Monolithic-Insulating-Joint

#goodrich gasket#gasket manufacturers#industrial gasket#gasket exporter#monolithicinsulatingjoint#ring type joint gasket#flange insulting gasket

1 note

·

View note

Text

Ring Type Joint Flanges Stockists in India

Nutech Overseas Flanges Aspects are reasonable for high-weight and high-temperature applications. ASME B16.5 RTJ Flanges are relentlessly applied to brilliant, going with Alloy Steel Ring Type Joint Plate flanges. Which accordingly guarantees thrilling, with the right assurance of profiles and material in the ASME B16.47 Series An and B RTJ Flanges.

ASME B16.5 RTJ Flanges manufacturers and exporter in India. We are exporing Ring Type Joint flanges, Level Confronted Ring Type Joint Flanges, Ring Type Joint Weld Flanges and Ring Type Joint Raised Face flanges at dumbfounding expense because of sensible expert hours in India and complete wellspring of astounding ANSI B16.5 Class 150 Ring Type Joint flanges, most very smart arrangement, cost open in Mumbai, India. You ought to check ASME B16.5 Ring Type Joint Flanges Aspects, RTJ Flanges weight structure and RTJ Flanges groove assessments. We have organized stock in various assessments like rtj Flanges examinations 1500 and rtj Flanges assessments 900.

Ring Type Joint Flanges Manufacturers, Ring Type Joint Flanges Suppliers, Ring Type Joint Flanges Stockists, Ring Type Joint Flanges Exporters

We are financial expert of Duplex Steel RTJ flanges, most very smart arrangement, cost as we are one of the most exceptional suppliers and vendor of Hastelloy C22 Ring Type Joint Flanges in India. We have our stocking traders in Delhi, Bangalore, Surat, (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. Check once our ANSI B16.5 RTJ flanges cost going before purchasing Class 300 Ring Type Joint Flanges from India or China. other than mail for our live deftly of Inconel Ring Type Joint Flanges to check types and sizes with our set up stock we can give you best cost of DIN86029 PN10 Ring Type Joint Flanges.

We can correspondingly give free event of Alloy 20 Ring Type Joint Flanges, Nutech Overseas is having our Seller and Wholesaler in Chhattisgarh, Karnataka, Faridabad, Gujarat, Karnataka, Gurgaon, Bhosari, Rajkot, Ghaziabad, Delhi, Chennai (Madras), Ahmedabad, West-Bengal, Haryana, Kolkata, Pune, Raipur, Uttar Pradesh, Nagpur, Madhya Pradesh, Khopoli, Ludhiana, Aurangabad, Jaipur, Bangalore, Punjab, Maharashtra, Tamil Nadu, Rajasthan, Kolhapur, Indore, Vadodara. So on the off chance that you are searching for best cost of MSS SP-44 RTJ Flanges or ASME B16.5 Ring Type Joint Flanges, RTJ Flanges Class 1500 close to you with most limited time transport or free illustration of Stainless Steel RTJ Flanges.

#Ring Type Joint Flanges Manufacturers in India#Ring Type Joint Flanges Suppliers in India#Ring Type Joint Flanges Stockists in India#Ring Type Joint Flanges Exporters in India

0 notes

Text

The Ultimate Guide to DME Breast Pumps: 7 Must-Know Facts for New Moms

Navigate the world of DME breast pumps with confidence. Learn about the different types, insurance coverage, and expert tips for choosing the perfect pump.

Introduction

Welcome to the ultimate guide on DME (Durable Medical Equipment) breast pumps! If you’re a new mom, you’re probably navigating the labyrinth of motherhood, and breast pumps are likely on your radar. This comprehensive guide aims…

View On WordPress

#Baby Care#Breast Pump Types#breastfeeding#DME Breast Pumps#Electric Pumps#Expert Recommendations#Flange Size#Hospital-Grade Pumps#Insurance Coverage#lactation#Manual Pumps#Milk Supply#motherhood#New Moms#Pump Maintenance#Pump Sterilization#Pumping#Pumping Challenges#Pumping Efficiency#Pumping Resources#Pumping Tips#support groups#Transition to Nursing#Troubleshooting

0 notes

Text

Uses and Benefits of Stainless Steel Round Bars

Stainless steel round bars are a versatile and durable material that can be found in a wide variety of industries, including manufacturing, food and beverage, chemical, power generation, and architecture. They are known for their excellent corrosion resistance, high-temperature resistance, strength, durability, and aesthetic appeal.

At Jay Steel Corporation, one can get stainless steel round bars in various grades such as SS 13-8 Mo Round Bars, SS 316/316L/316Ti Round Bars, SS 440C Round Bars, and SS 904L Round Bars many more. As each of the grades has its own features according to its properties so you can choose the perfect Stainless Steel Round to be used for your project!

In this guide, we will explore the many uses and benefits of stainless steel round bars in detail.

Stainless Steel Round Bars

Stainless Steel Round Bars are a type of stainless steel product that is in a cylindrical shape and made up of stainless steel grades- 304, 321, and 316 most commonly. These stainless steel round bars are usually used in sectors like the food industry or construction businesses.

Stainless steel benefits in numerous applications especially in high-temperature conditions so they are easy to manufacture. They are also used in applications where most of the welding is not needed. It makes it more affordable. Stainless steel round bars are available in a range of grades, from 17-4PH through 316 stainless steel.

Properties of Stainless Steel Round Bars

Corrosion Resistance

Higher Strength

Durability

Heat Resistance

Machinability

Aesthetic appeal

Hygenic

Grade Available in Stainless Steel Round Bars

Stainless Steel 13-8 Mo Round Bar

Stainless Steel 15-5 PH Round Bar

Stainless Steel 17-4 PH Round Bar

Stainless Steel 17-7 PH Round Bar

Stainless Steel 304/304L/304H Round Bar

Stainless Steel 310/310S Round Bar

Stainless Steel 316/316L/316Ti Round Bar

Stainless Steel 317/317L Round Bar

Stainless Steel 321 Round Bar

Stainless Steel 347 Round Bar

Stainless Steel 430 Round Bar

Stainless Steel 440C Round Bar

Stainless Steel 446 Round Bar

Stainless Steel 446 Round Bar

Stainless Steel 904L Round Bar

Here are some of the benefits and uses of Stainless Steel Round Bars Used Often.

Stainless steel 304 Round bars offer a number of benefits that make them highly desirable for use in a wide range of applications. Some of the key benefits of stainless steel round bars include:

Corrosion Resistance:

Stainless steel round bars have excellent corrosion resistance, making them ideal for use in environments that are exposed to moisture, salt, or other corrosive substances. This makes them ideal for use in marine applications, as well as in chemical processing plants, food and beverage processing facilities, and many other industrial settings.

Strength and Durability:

Stainless steel round bars are strong, durable, and long-lasting. They are able to withstand heavy loads and stresses without bending, breaking, or becoming deformed. This makes them ideal for use in structural applications, as well as in high-wear applications.

Heat Resistance: Stainless steel round bars are able to withstand high temperatures without losing their strength or shape. This makes them ideal for use in high-temperature applications, such as in the manufacturing of engines, boilers, and turbines.

Hygiene: Stainless steel round bars are easy to clean and sanitize, making them ideal for use in food and beverage processing facilities, as well as in medical and laboratory settings. They do not absorb bacteria or other contaminants, which helps to ensure that products remain pure and free from contamination.

Aesthetics: Stainless steel round bars have a sleek, modern appearance that can be polished to a high shine or finished in a variety of textures and colors. This makes them ideal for use in architectural and decorative applications, as well as in consumer products such as appliances and jewelry.

Sustainability: Stainless steel is a highly sustainable material, as it is recyclable and can be used again and again without losing its properties or quality. This helps to reduce waste and promote sustainable manufacturing practices.

Applications of Stainless Steel Round Bars

Stainless steel round bars have a wide variety of applications in different industries!

Aerospace Industries

Automotive Industries

Constructional line

Pharmaceutical Industries

Oil and Gas Industries

Power Generation Industries; Power Plants & Boilers

Equipment and Machinery Industries

Architectural Industry; Stainless Steel round bars are used for building facades, handrails, and other decorative elements.

How to Select the Right Stainless Steel Round Bar

Selecting the right stainless steel round bar for your application is essential to ensuring that you get the most out of your investment.

Some factors to consider include corrosion resistance, strength and durability, aesthetic appeal, cost, and application.

Choosing the right grade of stainless steel is also critical, as different grades have different properties and characteristics that make them suitable for specific applications. Working with a reputable supplier that specializes in stainless steel round bars can help ensure that you select the right material for your application.

Final Thoughts

Stainless steel round bars are a versatile and durable material that can be found in a wide variety of applications in different industries. Their excellent corrosion resistance, high-temperature resistance, strength, durability, and aesthetic appeal make them an ideal material for many different applications. By understanding the different types and grades of stainless steel round bars and how they are used, you can select the right material for your application and get the most out of your investment.

We at, Jaysteelcorporation Manufactures these types of plumbing fittings in compliance with National and International standards like ASTM, BS, IS, DIN, ASME, ANSI, MSS, etc. As we are the leading manufacturers, suppliers, and exporters of pipe fittings all over India.

To know more information on all our product ranges visit us now!

#Stainless Steel Products#pressure vessel manufacturer#Steel Product manufacturers in India#Flanges Types#Nuts and Bolts manufacturers#Pipe and tube manufacturers#Nickel alloy products#Titanium alloy products

0 notes

Text

Where can I buy Top Flanges from at a reasonable price in Germany?

Flanges serve as indispensable components in business piping systems, imparting a steady and leak-proof connection among pipes, flange valve, and different gadgets. As an important detail in fluid and gas coping with procedures, selecting wonderful flanges is paramount to ensuring operational performance, safety, and reliability. In Germany, corporations seeking top-grade flanges at reasonable prices turn to us as a company of premium flange solutions. Let's delve into the world of flanges, discover the various kinds presented via us and find out why they are the preferred desire for discerning clients in Germany.

Understanding Flanges:

Flanges are flat, round discs with frivolously spaced bolt holes across the circumference. They are welded or screwed onto pipes or devices to facilitate the connection and meeting of piping structures. Flanges come in diverse sorts, sizes, and materials, every designed to satisfy specific operational requirements and requirements.

Types of Flanges:

It gives a complete variety of flange sorts to cater to various industrial programs. Some of the important thing types consist of:

Weld Neck Flanges: These flanges are designed with a protracted, tapered neck that is welded to the pipe, supplying reinforcement and preventing leakage at the joint.

Slip-On Flanges: Slip-on flanges slide over the stop of the pipe and are then welded in vicinity. They are clean to install and suitable for low-pressure packages.

Blind Flanges: Also known as blanking flanges, blind flanges are used to seal the quit of a pipe or vessel, stopping the drift of fluid or gas. They are generally used for pressure checking out and preservation purposes.

Socket Weld Flanges: Socket weld flanges have a recessed region or socket into which the pipe is inserted after which it is welded. They provide a smooth bore and are best for small-bore piping systems.

Why Choose Arcellor Controls Flanges in Germany:

Premium Quality: We are devoted to handing over types of flange of the best first-rate, manufactured the use of advanced substances and advanced production strategies. Their flanges undergo rigorous checking out and inspection approaches to ensure compliance with international requirements and specs.

Competitive Pricing: Despite providing top-grade flanges, it maintains aggressive pricing to offer customers a super price for their investment. Their obvious pricing rules and value-powerful solutions cause them to favor companies in Germany.

Extensive Inventory: Arcellor Controls keeps an intensive inventory of flange types, sizes, and materials to satisfy the diverse needs of customers throughout industries. Whether you require general or custom flanges, they've the functionality to fulfill your necessities right away and effectively.

Technical Expertise: With years of enjoyment within the enterprise, boasts a team of skilled engineers and technical professionals who provide treasured assistance and guide for the duration of the procurement procedure. From product choice to setting up steering, they make certain a continuing revel in for customers.

In the end, for groups in Germany looking for top-pleasant flanges at reasonable prices, emerged as the favored supplier. With their complete variety of flange kinds, unwavering commitment to high-quality, aggressive pricing, and tremendous customer service is poised to meet the evolving wishes of industrial operations in Germany. Choose Arcellor Controls for your flange necessities and experience reliability, performance, and peace of thoughts for your operations.

0 notes

Text

Stainless Steel Uses and Applications in Aviation and Aerospace Industry - SPP Metals & Alloys

Stainless steel is a highly versatile metal that is widely used in various industries due to its exceptional properties. Among these industries, aviation and aerospace are among the most prominent users of stainless steel. This metal is used extensively in the manufacturing of aircraft components and parts due to its high strength, durability, and resistance to corrosion.

In this article, we will discuss stainless steel and the applications stainless steel uses in the aviation & aerospace Industries

Definition of Stainless Steel:

Stainless steel is a type of steel alloy that contains a minimum of 10.5% chromium by mass. The addition of chromium to the steel creates a passive layer of chromium oxide on the surface of the metal, which gives it excellent corrosion resistance properties. This layer also helps to prevent staining, rusting, and other types of surface degradation.

Properties of Stainless Steel:

Stainless steel has a unique set of properties that make it an ideal material for use in the aviation and aerospace industry.

Here are some of the most notable properties:

High strength and durability

Excellent corrosion resistance

Resistance to high and low temperatures

Non-magnetic

Easy to fabricate and weld

Hygienic and easy to clean

Types of Stainless Steel grades that are available:

At SPP Metal & Alloys we provide stainless steel in various types such as

Flanges

Fittings

Fasteners

Plates

Coils

Sheets,

Pipes,

Tubes & Round Bars.

Welded Tubes

Seamless Pipes

Sheets, Plates and Coils

Advantages of Stainless Steel in the Aviation and Aerospace Industry

Stainless steel offers many benefits in the aviation and aerospace industry, including:

Reduced maintenance costs

Longer service life

Improved safety and reliability

Enhanced resistance to corrosion, erosion, and fatigue

Lower weight compared to other metals

Easy to sterilize and maintain hygiene

Types of Stainless Steel

There are several types of stainless steel that are used in the aviation and aerospace industry. The most commonly used types are:

Austenitic stainless steel

Martensitic stainless steel

Ferritic stainless steel

Duplex stainless steel

Precipitation hardening stainless steel

Applications of Stainless Steel in the Aviation and Aerospace Industry:

Stainless steel is used in various applications in the aviation and aerospace industry, including:

Stainless Steel Uses in Aerospace:

Stainless steel is used in the aerospace industry in a variety of applications, including spacecraft components, satellites, and missiles.

Spacecraft components, such as fuel tanks and rocket engines, require high strength, durability, and resistance to corrosion, which stainless steel provides.

Stainless steel is also used in the manufacture of satellite components, including antennas, reflectors, and structural supports. These components must be able to withstand extreme temperatures and harsh space environments, and stainless steel provides excellent resistance to both.

In addition, stainless steel is used in the manufacture of missile components, including guidance systems and rocket motor casings. These components require high strength and durability, which stainless steel provides.

· Aircraft Structures

Stainless steel is used in the manufacture of aircraft structures, including wings, fuselage, landing gear, and engine components. It is highly resistant to corrosion and fatigue, which makes it an ideal material for use in these critical parts.

· Aircraft Interiors

Stainless steel is also used extensively in the manufacture of aircraft interiors, including cabin fittings, lavatories, and galleys. Its easy-to-clean and hygienic properties make it a popular choice for these applications.

· Aerospace Fasteners

Stainless steel is used in the manufacture of aerospace fasteners, including bolts, screws, and rivets. These fasteners require high strength and resistance to corrosion, and stainless steel provides both.

· Aerospace Exhaust Systems

Stainless steel is used in the manufacture of aerospace exhaust systems, which must withstand high temperatures and corrosive gases. Its high-temperature resistance and corrosion resistance make it an ideal material for these applications.

· Aircraft Engine Components

Stainless steel is used in the manufacture of aircraft engine components, such as combustion chambers, exhaust nozzles, and turbine blades. These components require high strength, heat resistance, and resistance to corrosion, which stainless steel provides.

· Aircraft Hydraulic Systems

Stainless steel is used in the manufacture of aircraft hydraulic systems, including pipes, fittings, and valves. These components must be able to withstand high pressures and corrosive fluids, and stainless steel provides excellent resistance to both.

· Aircraft Fuel Systems

Stainless steel is also used in the manufacture of aircraft fuel systems, including tanks, pipes, and fittings. These components must be able to withstand the corrosive effects of fuel, and stainless steel provides excellent resistance to fuel corrosion.

Stainless Steel Uses in Aviation:

Stainless steel is used in the aviation industry in a variety of applications, including aircraft engine components, hydraulic systems, and fuel systems.

Aircraft engine components, such as combustion chambers, exhaust nozzles, and turbine blades, require high strength, heat resistance, and resistance to corrosion, which stainless steel provides.

Stainless steel is also used in the manufacture of aircraft hydraulic systems, including pipes, fittings, and valves. These components must be able to withstand high pressures and corrosive fluids, and stainless steel provides excellent resistance to both.

Conclusion

Stainless steel is an essential material in the aviation and aerospace industry due to its exceptional properties, including high strength, durability, and resistance to corrosion. SPP Metals & Alloys is a leading stainless steel products manufacturer and supplier in India, providing high-quality stainless steel products for use in the aviation and aerospace industry.

With its wide range of applications, stainless steel will continue to play a crucial role in the growth and advancement of the aviation and aerospace industry for many years to come.

If you are looking for high-quality stainless steel products for use in the aviation and aerospace industry, look no further than SPP Metals & Alloys. Contact us today to learn more about our products and services.

#flange types#steel pipe manufacturing company#metal sheet manufacturer#aerostructures market#aerospace#airplain

0 notes

Text

Get Top-Quality Industrial Piping Products online at metalforgeindia

We offer a wide range of piping products, including inconel piping spools, all types of flanges, buttweld fittings, and cross manufacturers. Our products are made with top-quality materials and are designed to meet the most demanding industrial applications.

0 notes

Text

Exploring JIS B2220 Flanges: Unveiling SOP, SOH, and BL Types

Introduction:

JIS B2220 flanges play a crucial role in various industrial applications, providing a reliable means of connecting pipes, valves, and other equipment. This Japanese Industrial Standard (JIS) defines the specifications for flanges used in piping systems, ensuring compatibility and adherence to quality standards. In this article, we will delve into three prominent types of JIS B2220 flanges – SOP, SOH, and BL – each serving distinct purposes in different engineering scenarios.

1. SOP Type Flange:

The SOP (Slip-On Plate) type flange is a widely used component in piping systems. Recognizable by its slip-on design, this flange allows for easy installation and removal. The SOP flange is characterized by a raised face, where the sealing surface is positioned slightly above the bolting circle. This design facilitates alignment during installation and ensures a secure connection between the flange and the adjoining equipment.

Key features of SOP Type Flange:

- Slip-on design for easy installation.

- Raised face for improved alignment.

- Suitable for low-pressure applications.

- Commonly used in industries such as water supply, plumbing, and general-purpose piping.

2. SOH Type Flange:

The SOH (Slip-On Hub) type flanges are designed to accommodate higher pressure and temperature conditions compared to SOP flanges. The distinguishing feature of the SOH flange is the extended hub, providing additional strength and support. This design enhances the overall stability of the flange, making it suitable for applications where increased durability and performance are essential.

Key features of SOH Type Flange:

- Slip-on design with an extended hub for added strength.

- Suitable for higher pressure and temperature applications.

- Commonly used in industries such as petrochemical, oil and gas, and power generation.

- Enhanced stability and durability.

3. BL Type Flange:

The BL (Blind) type flange serves a different purpose in piping systems compared to slip-on flanges. Instead of connecting two pipes, a BL flange is used to close the end of a pipe or valve. This type of flange is particularly useful when periodic access to the piping system is required for maintenance or inspection, as it can be easily removed and reinstalled.

Key features of BL Type Flange:

- Designed for closing the end of a pipe or valve.

- Provides a solid barrier, preventing the flow of fluid or gas.

- Suitable for applications where periodic access is necessary.

- Widely used in industries such as chemical processing, pharmaceuticals, and refineries.

Conclusion:

JIS B2220 flanges, with their SOP type flange, SOH type flange, and BL type flange, offer versatile solutions for diverse piping system requirements. Whether it's ease of installation, high-pressure applications, or closing off pipelines, these flanges contribute to the efficiency and reliability of industrial processes. Understanding the specific characteristics and applications of each type is crucial for selecting the right flange for a given engineering scenario, ensuring optimal performance and longevity in various industries.

0 notes

Text

ic

#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering

#DrugFreeSociety#needlebearing

A main advantage of needle roller bearings is their ability to use mating surfaces as inner or outer raceways, or both. Bearing load ratings typically are based on raceway hardness of 58 Rc or equivalent. If it is lower, the capacity of the bearing-raceway combination is reduced

Ritbearing presents a range of needle roller bearings which offer a higher load carrying capacity and can withstand oscillation with greater rigidity. With needle roller bearing solutions, Ritbearing has a wide variety of styles including inch series and metric dimensions.

Simply place the jaws of your vernier caliper around the width of the outer ring of the bearing and close it until it meets the ring. Again, it should feel snug but not tight. The value which is displayed on the caliper is the width of the bearing.

Suitable across a range of operating conditions, these bearings feature rings made of carefully selected vacuum-degassed bearing steel or carburized steel and precision-ground, heat-treated rollers.

Suitable across a range of operating conditions, these bearings feature rings made of carefully selected vacuum-degassed bearing steel or carburized steel and precision-ground, heat-treated rollers.

#ic#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering#DrugFreeSociety#needlebearing#Needle bearings are a small cylindrical type of roller bearings which are used to prevent friction between moving surfaces which have low r#Spherical roller bearings are used in car hubs and can support large radial and thrust loads. Needle roller bearings use elongated cylindri#Compact solution with a high load carrying capacity and high stiffness#made of carbon chromium bearing steel#supplied with or without flanges on the outer ring and with or without an inner ring.#There are two main types of needle roller bearings with machined rings - needle roller bearings without inner rings#and needle roller bearing with inner rings. Needle roller bearings without an inner ring are used with hardened and ground shafts#which allows for use of a larger shaft#offering increased stiffness#A main advantage of needle roller bearings is their ability to use mating surfaces as inner or outer raceways#or both. Bearing load ratings typically are based on raceway hardness of 58 Rc or equivalent. If it is lower#the capacity of the bearing-raceway combination is reduced#Ritbearing presents a range of needle roller bearings which offer a higher load carrying capacity and can withstand oscillation with greate#Ritbearing has a wide variety of styles including inch series and metric dimensions.#Simply place the jaws of your vernier caliper around the width of the outer ring of the bearing and close it until it meets the ring. Again#it should feel snug but not tight. The value which is displayed on the caliper is the width of the bearing.#Suitable across a range of operating conditions#these bearings feature rings made of carefully selected vacuum-degassed bearing steel or carburized steel and precision-ground#heat-treated rollers.

0 notes