#Flange manufacturing company in India

Text

Blog Manufacturer & Supplier of Flanges, Pipe Fittings, Fasteners SPP Alloys and Metals

We are passionate about serving Premium Quality material to our customers along with being their Reliable Partners. Here, we'll be sharing the latest news and insights on alloys and the manufacturing process. As a leading manufacturer of high-quality alloys, we understand the importance of staying up-to-date with the latest developments in our industry. We're committed to sharing our knowledge and expertise with our customers, partners, and anyone else who shares our passion for alloys. If you're interested in learning more about our alloys, please visit our website or contact us directly.

#Steel Pipe Manufacturing Company#Metal Sheet Manufacturer#Buttweld Fittings Manufacturer#Flange manufacturing company in India#Buttweld Pipe Fitting#Fittings Supplier In Mumbai#Stainless Steel Manufacturers

0 notes

Text

The best forgings manufacturer supplier in India 2022 includes- CD Industries CD Industries is a well-known company as a flange manufacturer in India because of the quality products we offer, and have been in the industry for 50 years. This allows us to deeply analyze what the customers want when it comes to a … Top 10 Best flanges manufacturer in Mumbai Read More

0 notes

Text

Supplier of Gate Valve in Bihar

Company Overview:

Multitech Valves and Automation a leading Manufacturer and Supplier of Gate Valve in Bihar, India.

Multitech Valves & Automation, established in 2016 in Ahmedabad, Gujarat, India, is an ISO 9001:2015 certified company.

Primarily focused on manufacturing high-quality Gate Valves adhering to global ASTM, ANSI, API, and DIN standards.

Gate valves are crucial for managing fluid flow within pipelines, utilizing a gate-shaped mechanism for regulating the passage of liquids or gases.

Suitable for water distribution, oil and gas, and industrial settings, providing complete flow control or shut-off capabilities.

Types of Gate Valve:

Bellow Sealed Gate Valves

Through Conduit Gate Valves

Pressure Sealed Gate Valves

Key Features:

Bi-directional shut-off, deep stuffing box.

Non-rotating stem with Acme threads.

Inclined seats for tight shut-off against high pressures.

Renewable Seat Rings: Welded or Threaded.

Conforms to API 600 standards.

Technical Specifications:

Trims: 13 Cr, 18 Cr 8 Ni

Manufacturing Standard: API 600

Testing Standard: API 598

End Connection: Flanged End, Butt Weld End

Size Range: 25mm to 600mm

Operation: Manual, Gear

Serving Locations:

Multitech Valves and Automation is Supplier of Gate Valve in Bihar Including Araria, Arwal, Aurangabad, Banka, Begusarai, Bhagalpur, Bhojpur, Buxar, Darbhanga, East Champaran, Gaya, Gopalganj, Jamui, Jehanabad, Khagaria, Kishanganj, Kaimur, Katihar, Lakhi-sarai, Madhubani, Munger, Madhepura, Muzaffarpur, Nalanda, Nawada, Patna, Purnia, Rohtas, Saharsa, Samastipur, Sheohar, Sheikhpura, Saran, Sitamarhi, Supaul, Siwan, Vaishali, West Champaran.

For further details and inquiries, please feel free to contact us.

Read the full article

#BellowSealedGateValves#Bihar#Exporter#India#Manufacturer#ManufacturerofGateValve#PressureSealedGateValves#Supplier#SupplierofGateValve#SupplierofGateValveinBihar#SupplierofGateValveinIndia

2 notes

·

View notes

Text

Supplier of Industrial Valves in Valsad

Luvana Metal Corporation is an ISO 9001:2015 Certified company. Supplier of Industrial Valves in Valsad.

Luvana Metal Corporation manages the organization professionally and has extensive experience in the field of all Ferrous & Non-Ferrous metals.

We have an excellent sourcing network in India and across the world to supply all stainless steel, Carbon steel, Nickel Alloy & Special alloys in the shape of Pipes, Tubes, Sheets, Plates, Rods, Pipe Fittings, Flanges, etc. and India’s Biggest Company Deal our my products.

Our management style has been the key to our success as we delegate responsibility to the specific need of every customer and we have made every customer a member of our family.

Various industries use industrial valves to control the flow of liquids, gases, and slurries as essential components.

These valves play a crucial role in regulating, diverting, and stopping the flow within pipelines and systems.

The design of industrial valves ensures efficient and safe operation by withstanding high pressures, temperatures, and corrosive environments.

Industrial valves come in different types, including gate valves, globe valves, ball valves, butterfly valves, and check valves, each suited for specific applications.

With their robust construction, precise control, and reliable performance, industrial valves contribute to the smooth functioning of processes in industries such as oil and gas, petrochemicals, water treatment, manufacturing, and more.

Benefits of Industrial Valves

Efficient Flow Control: Luvana Metal's industrial valves provide precise control over the flow of liquids, gases, and slurries, ensuring optimal performance and efficiency in industrial processes.

Enhanced Safety: The design of the valves enhances safety by ensuring they withstand high pressures and temperatures, preventing leakage or system failures, minimizing the risk of accidents, and ensuring a secure working environment.

Durability and Reliability: Luvana Metal constructs its industrial valves with high-quality materials, making them highly durable and resistant to corrosion, wear, and tear.

This ensures long-term reliability and reduces maintenance and replacement costs.

Versatility and Adaptability: With a wide range of valve types and sizes available, Luvana Metal offers valves suitable for various applications and industries.

Their versatility allows for seamless integration into different systems, enabling smooth operation and compatibility with diverse process requirements.Luvana Metal Corporation is a Supplier of Industrial Valves in Valsad.

If you are interested then contact us, we will offer you our best quality product.

Read the full article

#Carbonsteel#Flanges#IndustrialValves#IndustrialValvesinValsad#LuvanaMetalCorporation#PipeFittings#Rods#Sheets#Specialalloys#SupplierofIndustrialValvesinValsad#Tubes

2 notes

·

View notes

Text

Hydraulic Manifold valve manufacturer in india by hydrofittings

In addition, an Air Manifold With Valves allows the set up of more than one solenoid valves in a centralized vicinity. A unmarried air deliver and port are shared by means of numerous valves. Manifold take a look at Valve acts as a primary distribution point for aircraft that have dual dry air pumps. If one pump of Manifold Pneumatic fails it’s miles designed to isolate the failed pump and provide continuous airflow from the operating pump. Water Manifold With Valves is designed to distribute water and has built-in ports in a section of pipe. They act as manage facilities of water distribution within the house. Solenoid Valve Manifold has a most preferred stress of 6000 psi at a hundred ranges F and has a mounting hollow that enables inside the self-supporting software. Hydraulic Valve Manifold Has a stainless steel pin that forestalls the bonnet from detaching itself from the frame due to vibration. Ball Valve Manifold has a burr-loose thread that reduces inner floor leaks accordingly offering accurate transmitter read. No O-ring is used bonnet to body pressure Transmitter Manifold seal. It is a steel-to-metallic seal. Hydraulic Valve Manifold Block has the choice of panel mounting. There are one of a kind sorts of Manifold Valves to be had within the market but the maximum typically used ones are the two valve, three valve, and 5 valve assemblies. Swagelok Manifold is designed mainly for liquid stage, static stress, and differential stress packages. Smc Valve Manifold has a blended isolating and venting in a single valve that eliminates the want for tubing and fitting. Festo Valve Manifold is simple to gather and set up and is dependable. They’ve dirt caps fitted on them that comprise stem lubricant and save you the ingress of contaminants. Rosemount 305 Manifold gets rid of the need for a flange because it suits immediately to the patented Rosemount. Why to choose hydrofittings ? About us – The briefcase of our company consists of numerous additions which include, – clever hydraulics, engineering, and digital answers. With the guide of 80 personnel, our company works like a well-oiled system to deliver most effective the very best fine product to our buyers. Proper from the responsibly sourced product by way of our procurement team to our nice manage team, many agencies have lauded our work. And that they admire the fact that we’re transparent in all our dealings. With a properly-mounted channel of communique, our customers can connect with us anytime. Our control and our body of workers, together form a competent and ambitious crew. The readability and high stage of performance make us one of the most modern but sought after manufacturers. And because we fee initiative behavior, we adore to have our studies and development crew collaborate with the opposite teams to recognize the current requirements of the hour. We frequently have checking out and great exams to maintain brilliant requirements.

An global provider of

TO KNOW MORE ABOUTS US VISITE OUR WEBSITE www.hydrofittings.com

3 notes

·

View notes

Text

Why should you use steel in crucial projects?

Steel, a metal with a wide range of possible applications, is available in many different "grades," or qualities, defined by the specific proportions of its constituent elements. In both domestic and commercial settings, mild steel seems to be the most cost-effective option. The versatility of mild steel makes it the most often used kind of steel. It's strong, durable, and weldable, plus it's magnetic.

Metal rusts easily, but it may be kept from doing so by coating it with anything that will keep the surface from being directly affected by the elements, such as paint, grease, or oil. The industrial and everyday uses of mild steel are almost endless, from mild steel plates to car and motorbike frames to huge pipes. Whenever a large amount of metal is required, mild steel is the material of choice. Alloy steel flanges manufacturers in India are always willing to provide a hand.

Carbon steel.

Carbon steel, in this context, refers to steel that does not include any additional alloying elements. Depending on how much carbon is in them, we have ultra-high, high, medium, and low carbon steels. Weld neck flanges manufacturers in India has reasonable prices. To make steel strips or flat-rolled sheets for use in manufacturing vessels, automobiles, and a wide range of other products and constructions, all four variants are put to use. There are many different kinds of industrial uses for carbon steel pipe fittings. You can easily find a good astm a105 flange manufacturer.

Grade 316L Stainless Steel, Certified by the American Institute of Steel Analysis

The anti-corrosive properties of stainless steel make it an attractive material for a wide range of applications where a high standard of cleanliness and security is required. Cookware made of stainless steel, among other materials, is consequently a common fixture in modern home kitchens. Slip on flanges manufacturers in India are indeed fantastic. V-belt power transmission necessitates its usage, and this material is fashioned into sheaves to store the belts. Ingredients like nickel, chromium, and molybdenum are just a few of the many that go into making stainless steel. Stainless steel flanges manufacturers in India has been doing a great work for quite some time.

Austenitic, ferritic, martensitic, and duplex steel are the four most common kinds of stainless steel on the market. The features that make each type useful are different, as are the ways in which it is put to use. That's why you'll find them in everything from household goods to architectural facades to industrial pipes and containers to paper and pulp production, and much more besides. Stainless steel 304 flanges manufacturers in India can be contacted easily.

There seems to be a bright future for the manufacturing of steel, as the number of companies engaged in this industry continues to rise. As usual, you can count on assistance from stainless steel forged fittings manufacturer.

The tube inside the fitting is so strong that it will burst before the fitting shows any signs of leaking or movement. However, the thickness of the tube's walls does place certain restrictions on this. Astm a105 forged fittings have been proven excellent.

2 notes

·

View notes

Text

Our first post

We, Nufit Piping Solutions, are An ISO Certified Leading Manufacturer, Exporter & Supplier in India We Supply Sheet, Plate, Seamless Pipe, Welded Pipe, Pipe Fittings, Buttweld pipe fittings, Tube fittings, Forged Fittings, Flanges, Welding Rod, Bar, Valves, Fasteners & all type of industrial products.

Visit us at

For More Details Visit Our Sites

2 notes

·

View notes

Text

Supplier of PPR Pipe Fitting in Ankleshwar

Parthiv Polymers is a Supplier of PPR Pipe Fitting in Ankleshwar. We were an ISO 9001:2015 Certified Company, in Ahmedabad, Gujarat, India.

Parthiv Polymers is a Manufacturer, Exporter, and Supplier of PPRC Pipe Fittings, PPCH Pneumatic Fittings, HDPE Fittings, and PP Fittings.

Why Choose Our PPR Pipe Fittings?

Superior Material Quality

Our PPR pipe fittings are manufactured using premium-grade polypropylene random copolymer.

This material is renowned for its excellent resistance to high temperatures, pressure, and chemical corrosion, making it ideal for a wide range of applications.

Precision Engineering

Each fitting is designed with precision engineering to guarantee a perfect fit and leak-free connections.

Our advanced manufacturing processes ensure that every product meets stringent quality standards, providing you with reliable and durable solutions.

Wide Range of Sizes

We offer a comprehensive range of PPR pipe fittings in different sizes to accommodate various pipe diameters.

Easy Installation

Our PPR pipe fittings require minimal tools and effort. Their lightweight nature and straightforward assembly process help reduce installation time and labor costs.

Available PPRC Fittings:

Bend(90 Degree)

Bend(45 Degree)

Buttweld Elbow

Buttweld Tee

Tee

Reducing Tee

Coupler

Reducer

End Cap

Long Neck

Core Flange

Slip-on Flange

Union

Male Thread Elbow(Brass)

Female Thread Elbow(Brass)

Male Thread Tee(Brass)

Female Thread Tee(Brass)

Male Thread Adapter(Brass)

Female Thread Adapter(Brass)

Parthiv Polymers is a Supplier of PPR Pipe Fitting in Ankleshwar and places like Ahmedabad, Bharuch, Surat, Vadodara, Dahej, Panoli, Jhagadia, Vapi, Rajpipla, Kosamba,

Kim, Vatava, Naroda, Odhav, Santej, Changodar, Kathwada, Aslali, Rakhial, Sankheda, Vadodara, Pavi Jetpur, Dabhoi, Rangoli, Makarpura, Vaghodia, Savli, Viramgam, Vagra, Bharuch, Jambusar, Hansot, Panoli, Nabipur, Dun-gari, Valia, Naldhari, Kanerao, Bharuch, Dahej (GACL), Atali-Kaladra (Hsg), Palej, Valia, Vagra (IPCL), Vagra (Chem)-Vilayat, Panoli, Ankleshwar, Jagadia (Chem), Dahej.

For any questions or further information, please contact us.

Read the full article

0 notes

Text

Best Flange Manufacturer in bhavnagar

JRH Engineering Company: Leading the Way as Bhavnagar's Best Flange Manufacturer

Bhavnagar, located in Gujarat, India, has long been a hub for industrial manufacturing, particularly known for its expertise in producing high-quality flanges. Among the top manufacturers in this competitive landscape, JRH Engineering Company stands out as a leader, renowned for its commitment to excellence, innovation, and customer satisfaction.

The Vital Role of Flanges in Industry

Flanges are essential components used to connect pipes, valves, pumps, and other equipment in piping systems across various industries, including oil and gas, petrochemicals, power generation, and water treatment. The reliability and performance of these systems heavily depend on the quality of the flanges used. Hence, choosing the right manufacturer is critical.

Why JRH Engineering Company is the Best in Bhavnagar

1. Uncompromising Quality Assurance

JRH Engineering Company prioritizes quality at every step of its manufacturing process. The company adheres to stringent international standards such as ASTM, ASME, DIN, and ISO. Their quality assurance protocols include comprehensive material testing, precise manufacturing techniques, and thorough inspection processes to ensure that every flange meets the highest standards of quality and reliability.

2. State-of-the-Art Manufacturing Technology

JRH Engineering Company utilizes advanced manufacturing technology to produce flanges with exceptional precision and durability. Their facility is equipped with cutting-edge CNC machines, automated welding equipment, and advanced heat treatment systems. This technological edge allows JRH to deliver products that meet the most demanding specifications and performance requirements.

3. Customization and Versatility

Recognizing that different industries have unique requirements, JRH Engineering Company excels in providing customized flange solutions. Whether clients need standard flanges or specialized designs such as blind flanges, weld neck flanges, or slip-on flanges, JRH can tailor products to meet specific needs. Their versatility in production ensures they can cater to a wide range of industrial applications.

4. Expertise and Experience

With years of experience in the flange manufacturing industry, JRH Engineering Company boasts a team of highly skilled engineers and technicians. Their deep industry knowledge and expertise enable them to handle complex projects and deliver flanges that meet stringent quality and performance criteria.

5. Exceptional Customer Service

JRH Engineering Company is dedicated to providing outstanding customer service. From initial consultation to after-sales support, their team is committed to ensuring complete client satisfaction. They offer expert guidance to help customers select the right flanges for their applications and provide prompt, efficient support to address any issues that may arise.

Highlighting JRH Engineering Company's Achievements

Quality Certifications

JRH Engineering Company has earned several prestigious certifications, including ISO 9001:2015, reflecting their adherence to international quality standards. These certifications demonstrate their commitment to producing high-quality, reliable flanges.

Technological Innovations

JRH Engineering Company continuously invests in the latest technology to enhance their manufacturing capabilities. Their use of advanced machinery and innovative techniques ensures they remain at the forefront of the flange manufacturing industry.

Customized Solutions

JRH's ability to provide tailored solutions has made them a preferred supplier for many industries. Their willingness to work closely with clients to develop flanges that meet specific requirements sets them apart from competitors.

Experienced Team

The expertise of JRH Engineering Company's team is a cornerstone of their success. Their experienced professionals bring a wealth of knowledge to every project, ensuring that each flange they produce meets the highest standards of quality and performance.

Conclusion

In the competitive landscape of flange manufacturing in Bhavnagar, JRH Engineering Company has distinguished itself as the best choice for industries seeking reliable, high-quality flange solutions. Their unwavering commitment to quality, advanced manufacturing technology, ability to provide customized solutions, and exceptional customer service make them a standout leader in the field. For businesses looking for a trusted partner in flange manufacturing, JRH Engineering Company is the premier choice in Bhavnagar.

1 note

·

View note

Text

A Comprehensive Guide to Indian Manufacturers of Stainless Steel Pipe Fittings

India has soon become a key source of manufacture, aiding the demands of the global world in outshining stainless steel pipe fittings. Indian producers are known for the high evaluation of their products and low prices, making it possible to compete with other industries worldwide. In this exhaustive article, we will discuss the situation of stainless steel pipe fitting manufacturers in India.

Wide Range of Product Offerings

Stainless steel pipe fitting manufacturers in India attend to a myriad of varying requirements of the industrial sectors through the variety of products that they supply. Indian manufacturers specialize not only in simple things like elbows, tees, and couplings but also in specified goods like duplex tube fittings, nickel super alloy pipe fittings, and Hastelloy C-276 pipe fittings at their disposal, which are their products in various materials and grades.

India turns out fittings from Stainless Steel 304 and Stainless Steel 316 widely. Such offerings feature a long lifespan and excellent corrosion resistance, resulting in diverse applications.

Duplex 2205 fittings and super duplex pipe fittings is also produced by Indian manufacturers which maintains the high strength and corrosion resistance for the industries that require this.

Competitive Pricing and Cost Advantage

The other major advantage and factor that is a source of passion for Indians is the lower cost of production in India compared to the international ones. Via cheaper labor benefits, more efficient production methods, and a good business environment, stainless steel pipe fittings manufacturers in India can now sell high-quality fittings at a low price compared with manufacturers from other countries.

This cost efficiency has actually been the major magnet for buyers who are after reduced sourcing costs while maintaining quality. Indian producers of the products offer lower prices and are also able to provide customised solutions to meet the specific patient’s requirements.

Strong Manufacturing Infrastructure and Skilled Workforce

India has a vibrant manufacturing industry and a workforce that is known for its expertise, which has greatly contributed to the current size that the stainless steel pipe fittings market is today. Ukraine's economy is serviced by a high level-developed network consisting of metal foundries, forging units, and machining plants that allow producing fittings cost-efficiently.

Although stainless steel pipe fittings manufacturers in India have the disadvantage of high wages compared to the cheaper labor in China and Brazil, they are well-versed in a large number of highly skilled professionals with the necessary experience and knowledge to enable them to create high-quality fittings. By this competent staff and modern manufacturing technologies, Indian producers can now offer products that are not only of high quality but also meet standards laid down by countries in the global sphere and satisfy their clients.

Conclusion

With a steady inflow of orders from stainless steel flange manufacturers in India, exporters have become a sought-after yet inexpensive supply source in the world market. Stainless steel flanges manufacturers in India are increasingly assured of the ability to reach the level of growing requirements in the global market with the growing number of world companies. It can not be emphasized enough that the most important thing when shopping for stainless steel pipe fittings, including water connection fittings and water and gas pipes, is choosing a reliable manufacturer of such products as KK Fittings.

0 notes

Photo

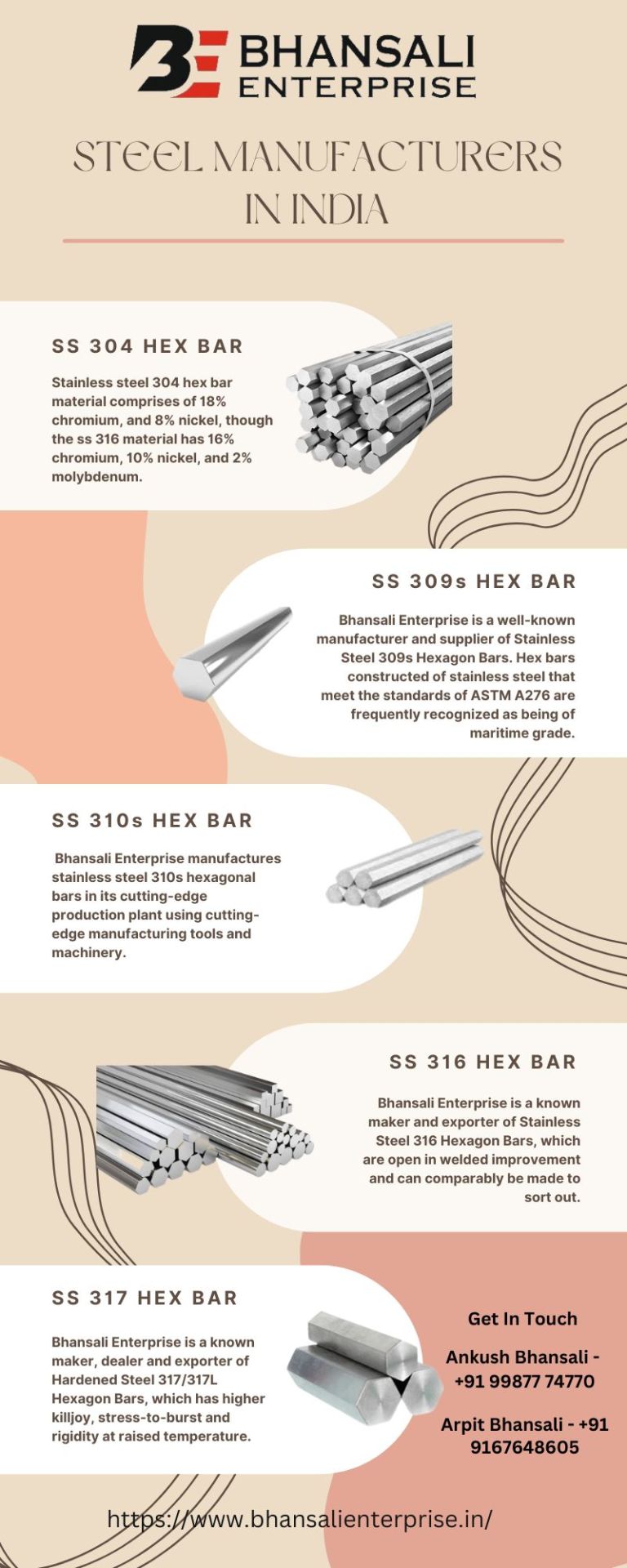

"SS Hex Bars Manufacturers & Exporter."

The Stainless Steel Hex Bars have improved strength and for that reason they are utilized in many applications. The extra strength is because of the mathematical state of the hex bars. On the off chance that the hex bar is made of austenitic treated steel, they have more prominent strength and higher erosion opposing properties. The Stainless Steel Hex Bars can be altered to various shapes and sizes as per the particular necessities. Bhansali Enterprise manufactures ASME SA276 Stainless Steel 309s Hex Bars using state-of-the-art tools and machinery to guarantee complete dimensional accuracy. Customers can choose from a variety of ASTM A276 SS 309s Hexagon Bars at Bhansali Enterprise. We produce 310 stainless steel hexagonal bars that fulfil national and international quality standards using only the best raw materials. Bhansali Enterprise is known in the business for the reliability of the goods we offer. Bhansali Enterprise is a known maker and exporter of Stainless Steel 316 Hexagon Bars, which are open in welded improvement and can comparably be made to sort out. SS 316 Hexagon Bar is utilized in blend process gear; tank trucks; propeller screws, and spent atomic fuel part recuperation. Bhansali Enterprise is a known maker, dealer and exporter of Hardened Steel 317/317L Hexagon Bars, which has higher killjoy, stress-to-burst and rigidity at raised temperature. SS 317 Hex Bars doesn’t respond to warm treatment, which can be additionally solidified by chilly working.

#stainless steel round bar#stainless steel 316l#stainless steel 304#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#steel grades#round bar#polished stainless steel#stainless steel 304 price per kg in delhi#stainless steel manufacturers in india#flange manufacturer in india

0 notes

Text

Check Valve: Essential Component in Fluid Control Systems

A check valve, also known as a non-return valve, is a crucial component in fluid control systems. Its primary function is to allow fluid (liquid or gas) to flow through it in only one direction. This unidirectional flow is critical in various applications to prevent backflow, which could potentially damage equipment or cause system failures.

Types of Check Valves

There are several types of check valves, each suited for specific applications and operating environments:

Swing Check Valve: This type uses a swinging disc to allow or block flow. It's commonly used in water and wastewater treatment plants, as well as in fire protection systems.

Lift Check Valve: Featuring a disc that moves vertically, lift check valves are typically used in high-pressure applications. They are often found in steam and gas lines.

https://www.freture.com/site/assets/files/1238/lift-check-valve.png

Ball Check Valve: This valve uses a ball to block flow in the reverse direction. It's particularly effective in handling viscous fluids and is frequently used in pumping systems.

Diaphragm Check Valve: Utilizing a flexible diaphragm to control flow, these valves are ideal for applications where a tight seal is necessary, such as in chemical processing.

Wafer Check Valve: Compact and lightweight, wafer check valves are installed between two flanges. They are suitable for applications with limited space.

Advantages of Check Valves

Check valves offer several benefits that make them indispensable in many industries:

Prevention of Backflow: By ensuring unidirectional flow, check valves protect pumps, compressors, and other equipment from damage caused by reverse flow.

Minimal Maintenance: Most check valves are designed to operate automatically without the need for external control, reducing maintenance requirements.

Versatility: With various types and materials available, check valves can be used in a wide range of applications, from residential plumbing to industrial processing.

Cost-Effectiveness: Simple design and ease of installation make check valves an economical choice for controlling fluid flow.

Applications of Check Valves

Check valves are used in numerous applications across different industries, including:

Water Supply Systems: To prevent contamination of clean water by backflow from contaminated sources.

Oil and Gas Industry: For maintaining the integrity of pipelines and preventing reverse flow of hazardous materials.

Chemical Processing: To ensure safe and efficient operation by preventing cross-contamination.

HVAC Systems: To maintain the proper flow of refrigerants and air in heating, ventilation, and air conditioning systems.

Pharmaceuticals: For maintaining sterile conditions and preventing contamination.

Installation and Maintenance Tips

Proper installation and maintenance are crucial for the optimal performance of check valves. Here are some tips:

Correct Orientation: Ensure that the valve is installed in the correct direction of flow, as indicated by the arrow on the valve body.

Regular Inspection: Periodically inspect the valve for any signs of wear or damage, especially in high-pressure or corrosive environments.

Cleanliness: Keep the valve and the surrounding piping clean to prevent debris from obstructing the valve operation.

Freture Techno Pvt. Ltd.: Leading Manufacturer of Check Valves in Mumbai, India

Freture Techno Pvt. Ltd. is a leading company that manufactures high-quality check valves in Mumbai, India. With a commitment to innovation and excellence, Freture Techno Pvt. Ltd. offers a wide range of check valves designed to meet the diverse needs of various industries. Their products are known for their durability, reliability, and superior performance, making them a trusted choice for fluid control solutions. Whether you need check valves for industrial, commercial, or residential applications, Freture Techno Pvt. Ltd. provides the expertise and quality you can rely on.

#check valves#types of check valves#check valve applications#check valve manufacturers#freture techno

1 note

·

View note

Text

Supplier of Stainless Steel Flats in Andhra Pradesh

Meghmani Metal Industries is a Manufacturer and Supplier of Stainless Steel Flats in Andhra Pradesh, India.

Since its establishment in 2011, the company has remained committed to delivering premium products, with a focus on customer contentment, employee welfare, and environmental responsibility at its core.

Our extensive range of stainless steel offerings encompasses plates, coils, bars, pipes, tubes, flanges, valves, fittings, fasteners, channels, and flats, precisely tailored to meet diverse industrial needs with meticulous customization.

Stainless Steel Flats, also known as stainless steel flat bars, are long, thin strips of steel with a uniform rectangular profile.

Our Stainless steel flats are easily cut, welded, and formed, allowing for intricate designs and customizations.

They are relatively lightweight compared to other metals with similar strength, making them easier to handle and transport. Their long lifespan minimizes replacement needs, reducing long-term costs.

Our Stainless Steel Flats can be easily fabricated into a wide range of shapes and sizes to meet specific requirements, whether it's for machinery components, conveyor systems, or storage tanks.

Stainless steel flats are available in various grades, each offering specific properties suited for different applications, such as 304, 316, and 430 grades.

Stainless steel flats, with their corrosion resistance and durability, find applications in construction, kitchen appliances, automotive, and manufacturing industries. They offer strength, hygiene, and aesthetic appeal in diverse structural and decorative uses.

Meghmani Metal Industries is a Manufacturer and Supplier of Stainless Steel Flats in Andhra Pradesh and places like Adoni, Amaravati, Anantapurm, Chandragiri, Chittoor, Dowlaiswaram, Eluru, Guntur, Kadapa, Kakinada, Kurnool, Machilipatnam, Rajahmundry, Srikakulam, Tirupati, Vijayawada, Visakhapatnam, Vizianagaram, Yemmiganur.

Feel free to contact us for more information and inquiries.

Read the full article

0 notes

Text

Supplier of Industrial Flanges in Chennai

Simplex Steel is a Manufacturer and Supplier of Industrial Flanges in Chennai, Tamil Nadu, India.

Established in 2012, Simplex Steel is headquartered in Ahmedabad, Gujarat, India. Holding ISO 9001:2015 certification, the company showcases its commitment to maintaining high standards of quality and excellence.

Our specialty lies in the fabrication of a wide range of stainless steel products, encompassing sheets, plates, coils, pipes, tubes, bars, wires, rods, channels, flats, industrial flanges, and various other items.

Industrial flanges play a crucial role in connecting pipes, valves, pumps, and other equipment in various industrial settings.

These components are meticulously designed to provide a secure and leak-proof connection, ensuring the seamless flow of fluids or gases within a system.

Our industrial flanges are available in a wide range of sizes, pressure ratings, and configurations, industrial flanges can be customized to meet specific project requirements.

Common types include weld neck flanges, slip-on flanges, socket weld flanges, threaded flanges, blind flanges, and lap joint flanges, each serving unique purposes depending on the application and operating conditions.

Our industrial flanges also contribute to the overall safety and efficiency of industrial operations. Properly installed flange connections help prevent leaks, minimize downtime, and ensure the integrity of the system, ultimately enhancing productivity.

Industrial flanges undergo stringent quality testing and adhere to industry standards and certifications, such as ANSI, ASME, ASTM, and DIN, to guarantee performance and reliability.

Simplex Steel is a Manufacturer and Supplier of Industrial Flanges in Chennai and locations like Advadi, Kanagam, Ennore, Chetpet, Minjur, Kolathur, Mylapore, Ennore, Adyar, MRC Nagar, Pallikaranai, Egattur, Nesapakkam, Perungalathur, Kottivakkam, Kazhipattur.

For detailed information or inquiries, please feel free to contact us.

0 notes

Text

The Use of SS Round Bars in the Oil and Gas Industry

Introduction to SS Round Bars

The possible areas that the round bars would be put to use are unlimited within the dynamic world of the oil and gas industry: ranging from the drilling process to the construction of pipelines, these rough cylindrical bars exude the strength, durability, and reliability necessary for survival under the tough conditions the industry is known for.Hans Metal India is the major Stainless Steel Round Bar Manufacturer in India

SS Round Bars: A Vital Ingredient to Oil and Gas Infrastructure

The round bar, solid bar, or rod is nothing but a cylindrical metal bar of a circular cross-section. Such bars are most commonly made out of high-strength steel alloys—carbon, stainless, or alloyed steel. They have been proven very appropriate for the hostile conditions during oil and gas exploration and production. We are alos the top supplier of Stainless Steel Sheet Manufacturer in India and Round Bar Suppliers in UAE.

Applications of SS Round Bars in Oil and Gas Operations

Drilling Equipment: Used as a drill string, a drill collar, and in the making of a stabilizer, it provides structural support and stabilization as one drills through. They transfer both torque and weight to the drill bit and support the effective penetration of the earth's crust to expose potential oil and gas deposits.You could possible like SS Round Bar Manufacturer in India and Copper Sheet Manufacturers in India

Pipes and Tubing: Round bars are used for the manufacturing of pipes and tubing, in addition to cases made for oil and gas wells. These are the elements that convey unprocessed crude oil, natural gas, and other fluids from the reservoir to the surface in addition to bearing the structure of downhole equipment.

Valves and Fittings: Valves, flanges, and fittings for pipes in oil and gas pipelines and processing facilities can be found with round bars as well. This equipment gives room for the control and direction of fluid flow, pressure control, and connection of the different portions of the pipeline system.Also, check out:Round Bar Manufacturer in Mumbai and Round Bar suppliers in Saudi Arabia

Benefits of Using Round Bars in the Oil and Gas Operations

Strength and Durability: Round bars with high tensile strength and resistance to corrosion will ensure reliability and a long life in critical infrastructure needed to support the working of oil and gas operations.

Versatile: Round bars can be custom-designed in size, diameter, and material composition as per the specific needs of varied applications in the oil and gas industry. Economically

Viable: Though robust, round bars prove to be an economically viable solution for oil and gas companies in the long run, as they require less maintenance.

Conclusion

In conclusion, round bars are supportive in activities of oil and gas as they serve the integrity of structures and strength, and versatility of drilling equipment, piping systems, and processing facilities. These are some of the main aspects that any oil and gas company has to understand and know about the products in order to have efficient, safe, and reliable operations.

#Stainless Steel Round Bar Manufacturer in India#Stainless Steel Sheet Manufacturer in India#Round Bar Suppliers in UAE#SS Round Bar Manufacturer in India#Copper Sheet Manufacturers in India#Round Bar Manufacturer in Mumbai#Round Bar suppliers in Saudi Arabia

0 notes

Text

Supplier of Industrial Valves in Pune

Luvana Metal Corporation is a Manufacturer and Supplier of Industrial Valves in Pune, Maharashtra, India.

We are an ISO 9001:2015 certified company, Having extensive experience in the field of all Ferrous & Non-Ferrous metals.

We offer a comprehensive range of stainless steel, carbon steel, nickel alloy, and special alloy products, including pipes, tubes, sheets, plates, rods, pipe fittings, flanges, and more.

Industrial valves are devices used to control the flow of liquids, gases, or slurries within a piping system in various industries.

From ball valves to gate valves, butterfly valves to globe valves.

Understanding the unique functionalities of each valve type is crucial for selecting the most suitable option for your needs.

Selecting the right material for industrial valves is paramount.

Options include stainless steel for strength and cast iron for cost-effectiveness.

And plastic for lightweight suitability in low-pressure and corrosive fluid environments.

Regular maintenance is key to ensuring the continued functionality and longevity of industrial valves.

Industrial valves boast corrosion resistance, high tensile strength, temperature resilience, ease of formability, low-maintenance durability, appealing aesthetics.

Industrial valves find versatile applications in regulating, controlling, and directing the flow of fluids such as water, gas, and oil.

And steam across diverse industries, ensuring efficient operations and optimal performance.

Luvana Metal Corporation is a Manufacturer and Supplier of Industrial Valves in Pune and locations like Chakan, Bhosari, Ranjangaon, Hadapsar, Shirwal, Shikrapur, Amravati, Nashik, Latur, Solapur, Sangli, Kolhapur, Aurangabad, Nagpur, Nanded, Nashik, Sangli, Satara, Vasai-Virar, Wardha, Yavatmal.

For any questions or further information, please contact us.

Read the full article

#AmravatiIndustrialValves#AurangabadValves#ballvalves#BhosariIndustrialSector#butterflyvalves#CarbonSteelValves#CastIronValves#ChakanIndustrialSupplies#CorrosionResistantValves#CustomValveSolutions#DiverseIndustryApplications#EasyFormability#Eco-FriendlyValves#FerrousMetals#FlangeSupplies#FlowControlValves#FluidRegulation#GasControlValves#gatevalves#globevalves#HadapsarIndustries#HighTensileStrengthValves#IndustrialFluidManagement#IndustrialMetalSupplier#IndustrialOperations#IndustrialPipes#IndustrialRods#IndustrialValveApplications#IndustrialValveDurability#IndustrialValves

0 notes