#ERP for manufacturing company in India

Text

Boosting Efficiency: The Role of ERP Software in Modern Manufacturing Operations

In today's fast-paced manufacturing landscape, efficiency is not just a desirable trait; it's a necessity. To stay competitive and meet the demands of the market, manufacturers must streamline their processes, optimize resource utilization, and enhance decision-making capabilities. This is where Enterprise Resource Planning (ERP) software steps in as a game-changer. In this article, we'll delve into the pivotal role of ERP systems in revolutionizing manufacturing operations, particularly in India's thriving industrial sector.

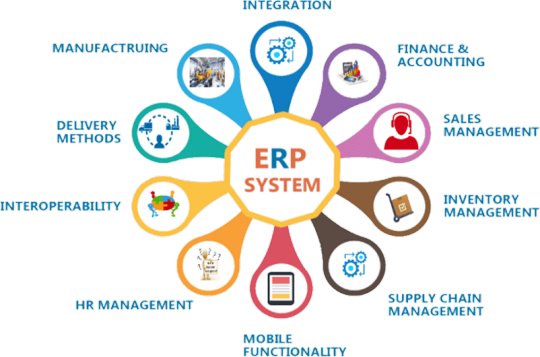

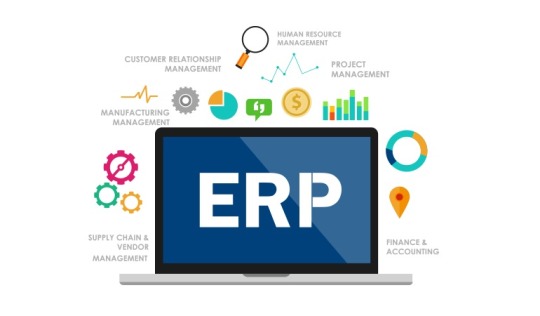

Understanding ERP for Manufacturing Industry

ERP systems for manufacturing are comprehensive software solutions designed to integrate and automate core business processes such as production planning, inventory management, supply chain logistics, financial management, and human resources. By consolidating data and operations into a unified platform, ERP empowers manufacturers with real-time insights, facilitates collaboration across departments, and enables informed decision-making.

Streamlining Operations with ERP Solutions

In the dynamic environment of manufacturing, where every minute counts, efficiency gains translate directly into cost savings and competitive advantages. ERP software for manufacturing offers a multitude of features that streamline operations and drive efficiency:

1. Enhanced Production Planning: ERP systems enable manufacturers to create accurate production schedules based on demand forecasts, resource availability, and production capacity. By optimizing production timelines and minimizing idle time, manufacturers can fulfill orders promptly and reduce lead times.

2. Inventory Management: Efficient inventory management is crucial for balancing supply and demand while minimizing holding costs. ERP software provides real-time visibility into inventory levels, automates reorder points, and facilitates inventory optimization to prevent stockouts and overstock situations.

3. Supply Chain Optimization: ERP solutions for manufacturing integrate supply chain processes from procurement to distribution, enabling seamless coordination with suppliers and distributors. By optimizing procurement cycles, minimizing transportation costs, and reducing lead times, manufacturers can enhance supply chain resilience and responsiveness.

4. Quality Control: Maintaining product quality is paramount in manufacturing to uphold brand reputation and customer satisfaction. ERP systems offer quality management modules that streamline inspection processes, track product defects, and facilitate corrective actions to ensure adherence to quality standards.

5. Financial Management: Effective financial management is essential for sustaining manufacturing operations and driving profitability. ERP software provides robust accounting modules that automate financial transactions, streamline budgeting and forecasting, and generate comprehensive financial reports for informed decision-making.

6. Human Resource Management: People are the cornerstone of manufacturing operations, and managing workforce efficiently is critical for productivity and employee satisfaction. ERP systems for manufacturing include HR modules that automate payroll processing, manage employee records, and facilitate workforce planning to align staffing levels with production demands.

The Advantages of ERP for Manufacturing Companies in India

India's manufacturing sector is undergoing rapid transformation, fueled by factors such as government initiatives like "Make in India," technological advancements, and globalization. In this dynamic landscape, ERP software plays a pivotal role in empowering manufacturing companies to thrive and remain competitive:

1. Scalability: ERP solutions for manufacturing are scalable, making them suitable for companies of all sizes – from small and medium enterprises (SMEs) to large conglomerates. Whether a company is expanding its operations or diversifying its product portfolio, ERP systems can adapt to evolving business needs and support growth.

2. Compliance: Regulatory compliance is a significant concern for manufacturing companies in India, given the complex regulatory environment. ERP software incorporates compliance features that ensure adherence to industry regulations, tax laws, and reporting requirements, minimizing the risk of non-compliance penalties.

3. Localization: ERP vendors catering to the Indian manufacturing sector offer localized solutions tailored to the unique requirements of the Indian market. From multi-currency support to GST compliance features, these ERP systems are equipped with functionalities that address the specific challenges faced by Indian manufacturers.

4. Cost Efficiency: Implementing ERP software for manufacturing entails upfront investment, but the long-term benefits far outweigh the costs. By streamlining processes, optimizing resource utilization, and reducing operational inefficiencies, ERP systems drive cost savings and improve overall profitability.

5. Competitive Edge: In a fiercely competitive market, manufacturing companies in India must differentiate themselves through operational excellence and agility. ERP software equips companies with the tools and insights needed to outperform competitors, adapt to market dynamics, and capitalize on emerging opportunities.

Choosing the Right ERP Software for Manufacturing

Selecting the right ERP solution is crucial for maximizing the benefits and ensuring a smooth implementation process. When evaluating ERP software for manufacturing, companies should consider the following factors:

1. Industry-specific functionality: Choose an ERP system that offers industry-specific features and functionalities tailored to the unique requirements of manufacturing operations.

2. Scalability and flexibility: Ensure that the ERP software can scale with your business and accommodate future growth and expansion.

3. Ease of integration: Look for ERP systems that seamlessly integrate with existing software applications, such as CRM systems, MES solutions, and IoT devices, to create a cohesive technology ecosystem.

4. User-friendliness: A user-friendly interface and intuitive navigation are essential for ensuring widespread adoption and maximizing user productivity.

5. Vendor support and expertise: Select a reputable ERP vendor with a proven track record of success in the manufacturing industry and robust customer support services.

Conclusion

In conclusion, ERP software has emerged as a cornerstone of modern manufacturing operations, empowering companies to enhance efficiency, drive growth, and maintain a competitive edge in the global market. For manufacturing companies in India, where agility, scalability, and compliance are paramount, implementing the right ERP solution can be a transformative investment that paves the way for sustainable success. By harnessing the power of ERP, manufacturers can optimize processes, streamline operations, and unlock new opportunities for innovation and growth in the dynamic landscape of the manufacturing industry.

#ERP software providers in India#Manufacturing enterprise resource planning#ERP systems for manufacturing companies#ERP system for manufacturing industry#ERP for manufacturing companies#ERP software for engineering company#ERP software for engineering companies in India#ERP software for engineering companies in Mumbai#ERP solution providers in India#ERP for manufacturing industry#ERP systems for manufacturing#ERP solutions for manufacturing#ERP software manufacturing industry#ERP for manufacturing company in India#India

7 notes

·

View notes

Text

SAP Business One for Chemical Industry

With all its benefits, global chemical manufacturing companies are incorporating SAP B1 at an increased rate for chemical production. Not only does it help in improving business efficiency and enhancing collaboration but it also aids in increasing customer satisfaction and increasing revenue by up to 10-30%. With the change in business dynamics and fluctuations in demand, robust ERP software can empower chemical businesses to take advantage of their competition while adhering to safety, quality, and compliance requirements. SAP b1 solutions are already used by nearly 6500 chemical industry businesses and more are soon to follow.

Managing costs effectively is an essential aspect of chemicals and any industry. In the chemical industry, SAP Business One provides intuitive planning and scheduling to manage time and resources efficiently and cut down on business costs to control every aspect. The cost of materials can also be estimated by analyzing the production data history and past purchases in a single click to simplify business processes. SAP chemical industry best practices optimize different processes, improve workflow efficiency, and reduce overtime costs by 48%.

#sap business one#SAP Business One Partner in India#SAP Business One partner#SAP Business One ERP Solution#SAP Business One for Manufacturers#SAP chemical industry#ERP Software#best erp software#best erp software in india#food beverage erp software#erp software for construction#erp#enterprise software#ERP Solution#SAP ERP#erp for small business#erp development company#erp consulting services#enterprise resource planning#erpsystem

2 notes

·

View notes

Text

How Noetic Labs ERPs Make Mass Customization A Reality

In today's fast-paced business landscape, Noetic Labs ERP for the manufacturing industry emerges as an indispensable tools in the pursuit of mass customization. With their advanced technology and innovative features, Noetic Labs ERP manufacturing software empowers businesses to transform the concept of personalized products at scale into a tangible reality.

Integration for Seamless Operations

At the heart of Noetic Labs ERPs lies a robust integration framework that streamlines operations across various departments and functions. By consolidating essential business processes into a unified platform, Noetic Labs ERPs facilitate seamless communication and collaboration, breaking down organizational silos and enhancing efficiency. Whether it's managing manufacturing processes, handling inventory, or overseeing sales and customer service, every aspect of the business is seamlessly interconnected, enabling swift responses to customer demands and market trends.

Flexibility for Dynamic Production

Noetic Labs ERP manufacturing software is designed with flexibility in mind, allowing businesses to adapt swiftly to evolving customer preferences and market dynamics. Equipped with advanced planning and scheduling capabilities, Noetic Labs ERPs optimize production workflows, ensuring efficient resource allocation and alignment with customer orders. Whether it's customizing product specifications or adjusting production volumes on short notice, Noetic Labs ERPs empower businesses to deliver personalized products with agility and precision.

Insights for Informed Decision-Making

In the era of mass customization, data holds the key to success. Noetic Labs' ERPs leverage

sophisticated analytics and reporting tools to provide businesses with actionable insights into customer behavior, market trends, and operational performance. By harnessing the power of data, businesses can make informed decisions about product development, marketing strategies, and resource allocation, driving continuous improvement and innovation. From identifying niche markets to optimizing supply chain logistics, Noetic Labs ERPs enable businesses to stay ahead of the curve in an increasingly competitive landscape.

Personalization for Customer Delight

Noetic Labs ERP is built with a customer-centric approach, enabling businesses to deliver personalized experiences that delight and engage customers. By capturing and analyzing real- time customer data, Noetic Labs ERPs enable businesses to tailor products, services, and marketing messages to individual preferences and needs. Whether it's offering customized product configurations or delivering personalized recommendations based on past purchase history, Noetic Labs ERPs empower businesses to forge deeper connections with their customers and foster brand loyalty.

Scalability for Growth

As businesses expand and evolve, scalability becomes paramount. Noetic Labs ERPs are designed to scale effortlessly with businesses, supporting their growth into new markets and product lines without sacrificing performance or reliability. Whether it's adding new users, integrating with third-party applications, or expanding into international markets, Noetic Labs ERPs provide businesses with the flexibility and agility they need to thrive in a dynamic and ever-changing environment.

Noetic Labs ERP manufacturing software is at the forefront of driving mass customization, enabling businesses to deliver personalized products and experiences at scale. With their integrated approach, flexible capabilities, data-driven insights, and customer-centric focus, Noetic Labs ERPs revolutionize the way businesses operate and compete in the global marketplace.

As the demand for personalized products continues to rise, Noetic Labs ERPs will play an increasingly vital role in helping businesses stay ahead of the curve and deliver exceptional value to their customers.

We also offer: Best Hospital Management Software, Laboratory Management System, Church Management Software

#erp software for manufacturing industry in india#erp software development company in india#erp software companies in india#custom erp software development#hospital management software in india.#custom erp software development in india#erp manufacturing software#erp software development company#erp software for manufacturing industry#erp software companies

0 notes

Text

#erp#erp software#erp system#erp implementation#erp solutions#cloud erp#erp integration#erpsolutions#erp for manufacturing#erp development company#india#erp in india

0 notes

Text

Elevating Product Quality with Quality Assurance Plan for Extrusion Company

Extrusion is a manufacturing process that involves shaping materials like Aluminium, Plastic, and Food by pushing them through a die. It is used in various industries, including automotive, construction, and packaging. However, extrusion is a precision-driven process that requires careful monitoring to ensure the quality of the end product. This is where a Quality Assurance Plan (QAP) comes in.

A Quality Assurance Plan for extrusion is a commitment to excellence that offers real-time monitoring, defect detection, and unmatched quality control. It is designed to unlock precision in extrusion and redefine the landscape, ensuring elevated product quality and unparalleled customer satisfaction. The QAP is seamlessly integrated with “Extrusion ERP”, making managing and controlling the manufacturing process easier.

Real-time monitoring is one of the critical features of the QAP. It allows manufacturers to monitor the extrusion process at every stage and detect any issues before they become significant problems. This ensures that the end product meets the desired specifications and helps prevent costly downtime and rework.

Defect detection is another critical aspect of the QAP. It involves using advanced technologies to identify defects in the extruded product. This allows manufacturers to take corrective action quickly and prevent defective products from reaching customers.

The QAP also offers unmatched quality control. It provides a framework for tracking and managing quality metrics, such as defect rates, scrap rates, and cycle times. This data can be used to identify areas for improvement and optimize the extrusion process. The benefits of a QAP for extrusion are clear. By unlocking precision in the manufacturing process, it ensures that the end product meets the desired specifications and elevates the overall quality of the product. This, in turn, leads to unparalleled customer satisfaction and increased market share.

Quality Assurance Plan for extrusion is vital for any manufacturer looking to deliver high-quality products consistently. It offers real-time monitoring, defect detection, and unmatched quality control. The QAP is seamlessly integrated with ‘Extrusion ERP’, making managing and controlling the manufacturing process easier. By implementing a QAP, manufacturers can unlock precision in extrusion, redefine the landscape, and elevate product quality to new heights.

#erp for aluminium extrusion industry#Best ERP for Aluminium Extrusion Industry#Tailored ERP for Aluminium Extrusion Industry#Extrusion ERP Software for Aluminium Extrusion Manufacturing#Aluminium Extrusion Management ERP#ERP Software for Aluminium Extrusion#ERP Software for Aluminium Extrusion Companies#ERP Solution for Aluminium Extrusion Industry#ERP Software for Metal Industry#ERP for Aluminium Extrusion Companies#ERP Software Development Services#ERP Development Company#ERP Software Development Companies#ERP Software for Aluminium Industry#ERP Software Development Company#ERP Software for Extrusion Companies#Ultimate Extrusion ERP Solution#Extrusion ERP Software Maintenance#Extrusion ERP Solutions in India#ERP Software For Metal Alloys Industry#Small Business Manufacturing Software#extrusion planning software#aluminium extrusion software company#software extrusion aluminum#aluminium extrusion management system#aluminium extrusion software#extrusion software#aluminum extrusion software#tool room management#alloy extrusion company

0 notes

Text

ERP service providers in india

#best erp software in india#best manufacturing erp software#best erp systems#erp development company in india#erp service providers in india

0 notes

Text

Corporate Munim: The Complete Business Solution That Enhances Efficiency

#corporate munim#erp in india#top erp in ahmedabad#erp in ahmedabad#erp in surat#top 10 erp software india#erp gujarat#erp software for manufacturing#erp for manufacturing#erp solutions#erp services#erp software companies india

0 notes

Text

erp for sme india

Erp for Sme India System Device Designed to Fulfill the Developing Desires of the Organisation of All Sizes. Its Adaptable and Easy and Flexibility.

System Device Chosen to Empower Sme Industries, a Brand-New Business Entity with Unique Specialty Products & Services that Satisfy the Needs of Indian Home Managers, Establishers & Entrepreneurs

The gadget machine designed below the R&D Centre is aimed at satisfying the necessities of organizations of all sizes and managing their commercial enterprise in an environment friendly manner. The machine has been developed preserving in thinking the organisational desires which encompass first-class assurance and security, facts uptime, ease of use, productiveness and fee effectiveness. It additionally ambitions at offering help to IT groups and gives records technological know-how based totally offerings to employer customers for any organisation’s structures like ERP, CRM, EDI etc. Erp for Sme India can be used on most frequent net browser variations such as Chrome, Firefox, Internet Explorer, Safari and many others alongside with HTML5 and CSS and different contemporary technologies. An automatic answer is delivered via Software Partner BHG. The consumer can additionally swap off this gadget solely when he wishes to do so. This allows higher manipulate and administration over statistics as properly as supply real-time updates about any modifications in manufacturing or service.

Erp for Sme India affords quite a few advantages with its bendy platform which helps organizations efficaciously control their workflow and run any commercial enterprise process. Apart from the usage of it to control facts throughout a variety of departments, the gadget approves enterprise customers to replace present processes, make changes, and even automate things. The fundamental function is in reality flexibility and adaptability. With a single interface, you can configure your utility and assign it to extraordinary human beings inside your business enterprise for each domestic groups and exterior clients. Erp for Sme India works for each Android and IOS structures to preserve up with your altering demands. On laptop and cell devices, it lets customers operate a range of administrative features over unique components and aspects of the functions and systems. In the cloud, our software program presents superior equipment consisting of Cloud Drive, Web Based Application Platforms and greater which makes your work convenient and handy than before.

Erp for Sme India Solution Key Features:

The platform provides best-in-class aspects ranging from API server access, multi-tenancy facility, integration to third-party apps like MailChimp, SharePoint etc., to furnish the vital guide to SME’s who function more than one systems. With Enterprise Support and Integration handy option, customers can add any different app or enterprise performance on this assignment in the shape of plugins and extensions and use them at will. Moreover, on account that the entirety is hosted in one system, there is no want for infrastructure modifications between environments due to the fact of the excessive availability factor. Users can get admission to their present day databases and keep their data except having to exchange something and can effortlessly get entry to their preceding data and transactions. A extensive vary of enterprise verticals are supported which consists of Banking, Finance, Insurance, Retail, Real Estate Industry, Technology Industry, Agriculture and many others. Erp for Sme India comes packed with preferred and pre-set modules & aspects to simplify operations throughout each department.

Erp for Sme India System Device Architecture:

The machine structure of the new device appears easy but well scalable with strong and dependable APIs. The employer chosen three elements – Database (DB), Applications, Database Connector (CDC) and Data Exchange Gateway (DEG). These three are accountable for storing the required database gadget factors like tables, columns, rows etc. The CDC thing has two foremost roles - Database connectors (D) and Data Exchanges (X). The D phase acts as an middleman connector to the web and shops facts required through consumers and the X section, on the different hand, runs on Microsoft Azure portal referred to as ‘Azure Storage and Blob storage Service ‘(ASIS) to shop facts and grant connectivity to exterior sources. Each module has unbiased API endpoints for particular use cases. The CDC can engage with DB, App and DEG layers thru two APIs specifically DB Connectors API and DeG API respectively. Another interface to join utility with the Oracle database is furnished via Oracle DeG. When we speak right here about constructing an application, both written by using us or every other team, then a layer of code regarded as Apps Layer will be used. Thus, Apps and Apps Layer are at once linked. For instance if you are creating a CRM application, you will have solely one supply code whereas Apps Layer would consist of some functions and Database to maintain facts and statistics for different applications. In addition, the deployment model of deploying the whole application, relying on the place the load is, can be carried out by way of everyone as lengthy as they have get right of entry to to it. Thus it is totally open for anyone to install a full fledged CRM/EDI/SMS application. You can install some thing on demand by using simply putting in Apps Layer and begin working on it. There is additionally built-in CI/CD/CI/EDI equipment supplied by using erpforSmeIndia.com which enable customers to construct apps shortly and iterate new ones as lengthy as they can run. As quickly as the improvement is finalized, as soon as you click on on Submit button, there is no hazard of downtime or crashes.

Erp for SME India System Deployment Methodology

The deployment methodology, as per our interior knowledge, requires set up of entire OS & DB structures first. Then step with the aid of step migration of purposes into the historical machine occurs. Finally there is a ultimate step the place the historic gadget is downgraded and the newly set up one is upgraded. In the subsequent phase, Erp for SME India has applied non-stop checking out practices the place checks run in parallel in order to take a look at the present day model of the site. Once these phases are performed and all is desirable at last, the website/app which used to be migrated to historic gadget receives examined again, and equal technique starts offevolved as soon as more. During this time, the entire utility is saved jogging with minimal disruption or interference from different users. After every such rollback and upgradation, the ancient gadget goes lower back to regular operation in order to keep away from similarly damage. Now a clean set of check surroundings is created and commenced functioning as soon as once more in order to take a look at the today's version. So, on the foundation of above noted steps, all these migration degrees can be repeated till the utility and its enterprise common sense are in the more recent system. However, upon this stage, the migrations are no longer finished and proceed to work in the older system, hence main to unpredictable behaviour. Therefore, at some point of the direction of migration testing, records associated checking out of SQL Server 2016 turns into obligatory to make certain easy flow, overall performance and maintainability of any database facts associated tests. Once we attain here, the trendy model is rolled out as ordinary barring doing any configuration modifications on the facet of software developer, to let utility turn out to be entirely useful on the new machine and run somewhere besides impacting the typical application. Erp for SME India takes care of making sure gold standard utilization of assets via minimizing CPU and reminiscence by means of taking gain of more than one situations of Windows Server 2016 and Red Hat OpenShift two running system. Following deployments can take place: 1. Migrate to an SDD file

2. Transfer documents from nearby disk to Virtual Machine

3. Import XML archives from XML Source

4. Install software from XML Source

5. Create XML code

6. Upload XML Code To File Location

7. Move objects and links

8. Insert records

9. Export documents

10. Delete records

11. Delete URLs

12. Remove Documents

13. Revert XML Sources

14. Add New Records

15. Create Links

16. Edit Objects

17. Move Links

18. Edit Items

19. Set Parameters

20. Show Changes

21. Save Changes

22. Print XML Source

23. Import Document

24. Extract XML Source

25. Load Documents

26. Save Documents

27. Search Documents By Id

28. Get Information About Object Attributes

29. Get All Record Attributes

30. Check Availability

31. Make Changes

32. Print Report

33. Download File

34. Copy Document

35. ImportXMLSource

36. SearchXMLSource

37. List Resources

38. Add New resource

39. Create Link

40. Add Item

41. Change Item

42. Update object attributes

43. Change Link

44. Create record

44. Create link

50. Merge document

51. ImportXMLSource

52. List Resources

53. Delete Object Attributes

54. Send message

55. Send XML message

56. Read Attribute Values

57. Read records

58. Go to Site

59. Logout/Log Out

60. Login

61. Verify Identity

62. Sign In

63. Send XML or JSON to URL

64. Email ID and Password

65. Enter Your Mobile Number

66. User Name

67. Pass

68. Security Related Factor

69. Date Of Birth

70. Time Zone

71. Country And State Of Residence

72. Sex/Gender

73. City

74. Zip / Post Office

75. Telephone No.

76. User Type

77. Organization Size (Employee / Managerial)

78. Department And Region

79. Subsidiary Address

80. Company Tax Identification

81. Employee Age Group

82. Organization Level

83. Organizational Member

84. Role

85. Team Leader

86. Senior Management

87. Work Atmosphere

88. Working Conditions

89. Pay Scale

90. Safety

91. Health & Wellbeing

92. Physical Access

93. Sick Leave Benefit

94. Promotion Benefits

95. Personalized Retirement Options

96. Vacant PDA Coverage

97. Other Benefits

98. Total Employees

99. Employee Location

FINDS US ON LINE KEYWORD : Cost of Erp System for Small Business in India, Erp Market Size in India, Erp Vendors in India, Erp Benefits for Small Business, Free Erp for Small Business India, Free Manufacturing Software for Small Business in India, Best Erp Software in India, List of Companies Using Erp Software in India, Best Erp for Small Business

Visit:https://www.simplirp.com/Best-SME-ERP-solution-in-india.html

#Cost of Erp System for Small Business in India#Erp Market Size in India#Erp Vendors in India#Erp Benefits for Small Business#Free Erp for Small Business India#Free Manufacturing Software for Small Business in India#Best Erp Software in India#List of Companies Using Erp Software in India#Best Erp for Small Business

0 notes

Text

Erp Software for Manufacturing Company in Pune, Maharashtra, India

We provide fully customized ERP software for Manufacturers in Pune, PCMC, Chakan, Mumbai, Thane, Kalyan, Aurangabad, Satara, Nashik, Nagpur, Maharashtra, India.

The manufacturing industry which was otherwise conventionally driven until the last decade and a half or so, witnessed a paradigm shift in the past few years. The shift made technology a significant part of the industry, thus making it a more technologically-driven and a more efficient industry.

One of the most significant 21st century tech-based additions to the manufacturing industry is ERP. ERP software for manufacturing refers to a system that helps integrate and streamline the business operations of various verticals of a manufacturing company. It aims to augment process efficiency and product quality to enable modern day manufacturers to stay competent, meet the pressing volume manufacturing needs and fulfill the evolving needs of consumers.

#erp#erp module#ERP manufacturing software#ERP software companies in pune#best ERP for manufacturing#best ERP software for manufacturing#ERP manufacturing#ERP for garment manufacturing#erp in manufacturing system#best ERP system for manufacturing#manufacturing software small business#ERP for small business manufacturing#best ERP for manufacturing business#Best ERP Software and ERP System in India

0 notes

Text

List of erp software in india

Roadmap's ERP software solution in India is built on robust software platforms and is designed to digitally streamline business processes and enhance its production efficiency.

https://roadmapit.com/erp-software-in-india

#erp software in india#cloud erp software in india#erp system in india#erp software companies in india#best erp software in india#best manufacturing erp software in india

0 notes

Text

The Evolution of ERP Software: How it is Transforming Engineering and Manufacturing in 2023

In today’s dynamic world of engineering and manufacturing industry, maintaining competitiveness and operational efficiency is of paramount importance. Enterprise Resource Planning (ERP) software has become a fundamental tool for optimising processes, improving efficiency, and facilitating smooth operations in the engineering and manufacturing industries. As we progress into the year 2023, it becomes apparent that enterprise resource planning (ERP) software has experienced a substantial transformation, adapting to the unique requirements of the industry in question. Unlock the full potential of your manufacturing company with ERP software designed and developed by STERP (Shanti Technology). Contact today for a tailored ERP solution for manufacturing company in India that aligns perfectly with your business objectives.

This blog article aims to examine the growth of Enterprise Resource Planning (ERP) software and its significant impact on the fields of engineering and manufacturing.

Historical Perspective: A Brief Overview of ERP Software

The evolution of ERP software since its establishment in the 1960s has been significant, with a notable shift from its initial emphasis on inventory management and order processing. Over the course of several decades, enterprise resource planning (ERP) systems have seen significant growth and development, resulting in the integration of a wide range of corporate functions. These functions include but are not limited to accounting, human resources, procurement, and other related operations. The advancement of technology has led to the evolution of ERP software into a centralised platform that offers real-time data, enhances decision-making processes, and fosters communication across various departments within an organisation.

· Integration of IoT and Industry 4.0:

The combination of the Internet of Things (IoT) and Industry 4.0 technologies represents a notable revolution in ERP software during the year 2023. The Internet of Things (IoT) facilitates the interconnection of various devices and sensors, enabling the collection and sharing of data. This capability offers real-time insights into the industrial process. Enterprise Resource Planning (ERP) systems have the capability to effectively integrate this data, so facilitating manufacturers in making informed decisions based on data analysis and enhancing their operational efficiency.

The principles of Industry 4.0 place significant emphasis on the integration of automation, digitization, and connectivity, which have now been easily included in enterprise resource planning (ERP) software. The integration described enables enterprises to establish a smart industrial setting, increase their control of the supply chain, and optimise operational efficiency.

· Cloud-Based ERP Solutions:

Cloud-based enterprise resource planning (ERP) solutions have significantly transformed the operational landscape of enterprises. This paradigm shift can be attributed to the revolutionary impact of cloud technology on ERP software. In the year 2023, an increasing number of engineering and manufacturing companies are using cloud-based Enterprise Resource Planning (ERP) solutions. The aforementioned solutions possess several benefits, including the ability to scale, adaptability, reduced initial expenses, and convenient availability, rendering them exceedingly appealing to organisations of all sizes. Moreover, the utilisation of cloud-based enterprise resource planning (ERP) systems facilitates the instantaneous exchange of data and promotes collaboration among all parties involved, hence enhancing operational efficiency and cultivating a culture of innovation. Invest in the future of manufacturing. Choose advanced ERP software for engineering companies in India developed by STERP (Shanti Technology) to enhance agility and competitiveness.

· Advanced Analytics and Business Intelligence:

In the current business environment, data holds significant value. Enterprise Resource Planning (ERP) software has evolved to incorporate sophisticated analytics and business intelligence functionalities, enabling the generation of visually appealing data representations and the utilisation of predictive analytics techniques. Manufacturers have the ability to utilise this data in order to anticipate market trends, enhance production schedules, effectively manage inventories, and rapidly make well-informed business decisions. The utilisation of advanced analytics enables engineering and manufacturing enterprises to maintain flexibility and effectively respond to market fluctuations in a timely manner.

· Enhanced User Experience and Mobility:

The optimisation of user experience and mobility is a crucial element in contemporary enterprise resource planning (ERP) systems. In the year 2023, the primary emphasis of ERP software lies in delivering an intuitive and user-friendly interface, with the aim of facilitating smooth adoption and utilisation throughout all hierarchical levels within the organisation. Furthermore, the use of mobility enables stakeholders to conveniently access essential data and capabilities while on the move, hence enhancing productivity and facilitating informed decision-making. Stay ahead in the competitive manufacturing landscape. Reach out to an expert - STERP (Shanti Technology) - the most reliable Engineering ERP Software Company in India and elevate your business operations.

· Cybersecurity and Compliance:

The increasing prevalence of cyber risks has prompted ERP software developers to prioritise the integration of robust cybersecurity capabilities. In the year 2023, enterprise resource planning (ERP) systems place significant emphasis on the paramount importance of data security, adherence to industry laws, and the implementation of effective authentication procedures. This practice guarantees the preservation of confidential corporate information, hence cultivating a sense of trust and assurance among users.

Final Thoughts:

The evolutionary progression of Enterprise Resource Planning (ERP) software in the year 2023 signifies a significant and transformational change within the realm of engineering and manufacturing. The convergence of the Internet of Things (IoT), Industry 4.0 technologies, cloud-based solutions, sophisticated analytics, improved user experience, and heightened cybersecurity measures enables organisations to effectively streamline operations, boost efficiency, and attain long-term, environmentally conscious expansion. With the increasing use of these technological developments, the engineering and manufacturing sectors are poised to witness unparalleled levels of efficiency and creativity, hence setting a bright trajectory for the industry.

In order to remain competitive in today's ever-changing corporate landscape, it is imperative to be informed and capitalise on the capabilities of enterprise resource planning (ERP) software. Ready to streamline your manufacturing operations? Contact STERP (Shanti Technology) a renowned company offering manufacturing ERP software in India and see how it can simplify processes, boost efficiency, and drive profitability.

#ERP for manufacturing company in India#ERP software for engineering companies in India#Engineering ERP Software Company in India#Manufacturing ERP software in India#ERP India#Business Solutions#ERP software#Manufacturing#Engineering#business#shantitechnology#STERP

9 notes

·

View notes

Text

Choose the line of business you want to improve

Gain insights on how to turn procurement challenges into opportunities. Understand the barriers to digital transformation in this study on intelligent spending management With SAP Business One ERP.

SAP Business One is a unique and powerful ERP solution to manage your entire business, developed especially to fulfill the industry-specific requirements of SMEs. The software supports customization to extreme levels like, you can speed transactions and improve visibility into cash flow. It automates everyday accounting tasks by integrating financial operations in real-time with other business processes, such as purchasing, sales, maintaining ledger and journal entries, supporting tax calculations, enabling multicurrency transactions, and much more. With SAP Business One ERP Solution you can conduct all your banking activities – including processing bank statements and payments, as well as reconciling accounts and managing your entire business operation from a single platform.

We understand the importance of an all-time-available scenario that makes you a responsible SME for your customers. That’s why remote access is allowed for the employees. So they can intuitively access the required information from their mobile devices, without worrying about the location and time. SAP Business One is an affordable, easy-to-use business management solution that’s your smart performance booster with fantastic capabilities!

#SAP Business One for Manufacturers#sap business one#SAP Business One partner#SAP Business One Partner in India#erp#SAP ERP#ERP Solution#enterprise software#erp development company

0 notes

Text

Simplifying Daily Tasks With User Friendly Laboratory Management System

In today’s fast-paced healthcare environment, pathology labs face immense pressure to deliver accurate and timely test results. Lab technicians play a critical role in this process, meticulously handling samples, performing tests, and ensuring data accuracy. However, with increasing workloads and complex workflows, even the most dedicated professionals can be overwhelmed.

This is where a user-friendly laboratory management system steps in. It goes beyond traditional lab software by offering a comprehensive suite of tools designed to streamline daily tasks and empower lab technicians. Here’s how:

Intuitive Interface and Simplified Workflows

Imagine a software system that feels as intuitive as your favorite app. User-friendly Lab ERP boasts a clean and uncluttered interface, with easy-to-navigate menus and readily accessible features. Technicians can focus on their work without getting bogged down by complex functionalities.

Furthermore, pathology lab software streamlines workflows by automating repetitive tasks. This includes sample registration, test assignment, data entry, and reporting. Technicians can spend less time on administrative duties and more time on what truly matters — analyzing samples and delivering results.

Reduced Error Rates and Improved Data Integrity

Manual data entry is a major source of errors in pathology labs. User-friendly Lab ERP minimizes this risk through features like:

Barcode scanning: Eliminate errors by scanning sample barcodes, automatically linking them to patient information and test requests.

Auto-fill capabilities: Reduce data entry time and errors by automatically populating forms based on previous entries or integrated patient data.

Drop-down menus and pre-defined options: Minimize typos and ensure consistency by offering pre-defined options for test results and other data points.

By reducing errors, Lab ERP software not only improves result accuracy but also saves valuable time spent correcting mistakes.

Enhanced Communication and Collaboration

Modern laboratory management system fosters seamless communication within the lab and with healthcare providers. Technicians can easily access patient information, test requests, and previous results, enabling informed decision-making.

Real-time updates on sample status and test results keep everyone informed, minimizing delays and facilitating smooth collaboration between lab personnel and physicians. Additionally, some Lab ERP systems offer built-in messaging functionalities to facilitate communication within the lab team.

Increased Efficiency and Faster Turnaround Times

User-friendly pathology lab software empowers technicians to work smarter, not harder. By automating repetitive tasks, streamlining workflows, and facilitating efficient communication, it frees up valuable time. This allows technicians to focus on analyzing samples and completing tests more efficiently, leading to faster turnaround times for critical test results.

Customizable Dashboards and Personalized Views

Not every technician needs to see the same information. User-friendly ERP software offers customizable dashboards that allow technicians to arrange crucial data points and work queues according to their preferences. This personalized view empowers them to prioritize tasks and access the information they need most readily.

On-the-Go Access and Mobile Capabilities

Today’s lab technicians are often on the move, juggling multiple tasks and responsibilities. User-friendly Lab ERP software offers mobile accessibility, allowing technicians to access essential data and perform certain tasks remotely. This provides greater flexibility and streamlines workflows further.

Beyond Efficiency: The Human Touch in User-Friendly Lab ERP

While Pathology lab software automates tasks and streamlines processes, it should never replace the human touch in lab operations. A user-friendly system complements the expertise of lab technicians, empowering them to perform their jobs more effectively. By simplifying daily tasks and minimizing errors, it reduces stress and allows technicians to focus on what they do best — delivering accurate and timely results that contribute to better patient care.

Investing in user-friendly Pathology lab software in India is not just about improving efficiency; it’s about empowering your lab technicians, optimizing workflows, and ultimately, ensuring the highest quality of service for your patients.

Noetic Labs ERP Software Development Company in Pune offers customized ERP for the manufacturing industry, the Best hospital management software, church management software, and Pathology lab software in India.

Schedule a demo today.

#erp software for manufacturing industry in india#erp software development company in india#erp software companies in india#custom erp software development#hospital management software in india.#custom erp software development in india#erp manufacturing software#erp software development company#erp software for manufacturing industry#erp software companies

0 notes

Text

Quality Assurance in the Digital Age: Leveraging ERP Solutions

In the digital age, quality assurance has become a critical aspect for businesses across industries. In particular, the metal alloys industry and extrusion processes require advanced solutions to ensure consistent quality and efficiency. This is where “Extrusion ERP” comes into play. By using Extrusion ERP for the metal alloys industry, businesses can effectively manage inventory levels, track production performance, and monitor quality control measures.

Key Benefits of Using Extrusion ERP for Quality Assurance:

In an industry where quality can make or break your reputation, Extrusion ERP is the key to ensuring consistent, high-quality products. By leveraging ERP solutions for quality assurance, businesses can unlock several key benefits, including:

Increased Efficiency and Productivity

Enhanced Product Quality

Better Supply Chain Collaboration

Data-Driven Decision Making

Take the Leap to Quality Excellence!

Ready to transform your quality assurance practices in the metal alloy industry? Extrusion ERP is your best partner on this journey.

Don't settle for mediocrity. Advance your quality standards, streamline your operations, and enhance your environmental sustainability with Extrusion ERP. It's time to empower your business for success in the digital age.

Contact us today for a personalized demonstration and discover how Extrusion ERP can unlock a new era of quality assurance in the metal alloy industry. Your quest for exceptional quality begins now.

#ERP Software for Aluminium Extrusion#ERP Software for Aluminium Extrusion Companies#ERP Solution for Aluminium Extrusion Industry#ERP Software for Metal Industry#ERP for Aluminium Extrusion Companies#ERP Software Development Services#ERP Development Company#ERP Software Development Companies#ERP Software for Aluminium Industry#ERP Software Development Company#ERP Software for Extrusion Companies#Ultimate Extrusion ERP Solution#Extrusion ERP Software Maintenance#Extrusion ERP Solutions in India#ERP Software For Metal Alloys Industry#Small Business Manufacturing Software#Best ERP for Aluminium Extrusion Industry#Tailored ERP for Aluminium Extrusion Industry#Extrusion ERP Software for Aluminium Extrusion Manufacturing#Extrusion ERP Excellence for Aluminium Extrusion Manufacturers#Aluminium Extrusion Management ERP#erp for aluminium extrusion industry

0 notes

Text

best ERP software in india

#best erp software in india#best manufacturing erp software#best erp systems#erp development company in india#erp service providers in india

0 notes

Text

SAP MM Course | SAP MM Certification - Eminent IT Solution

SAP Materials Management (MM) is a crucial module in the SAP ERP suite from SAP AG. The SAP MM module integrates with the other modules of the SAP system and supports all phases of materials management include materials purchasing, planning and control, receiving goods, inventory management and invoice verification.

If you are interested in a career as an SAP MM consultant, understanding "What is SAP MM?" is a good starting point. In this article, we discuss the key features of SAP MM software and discuss its different sub-components.

Get SAP MM Certification from Eminent IT Solution one of the best SAP training Institute, we have one of the best SAP Consultants which guides you to SAP Material Management Module. We are one of the fastest growing SAP consulting companies. Currently, we are providing SAP services to various customers in India and increasing our client base with many challenging ERP system requirements and providing unique solutions. We have emerged as an elite force with a team consisting of veteran professionals possessing expertise in their respective profile.

SAP ERP Materials Management is a part of SAP Logistics functionality. The SAP Logistics function incorporates a number of distinct areas that together follow the movement of materials from manufacturer to consumer. Logistics is the management of business operations, including the acquisition, storage, transportation, and delivery of goods along the supply chain. Materials Management contains many aspects of SAP functionality, including purchasing, goods receiving, material storage, inventory, and invoicing.

2 notes

·

View notes