#Construction Equipment Manufacturer and Supplier in India

Text

Complete Manual on Hanging Scaffold Systems or Suspended Rope Platforms for plastering

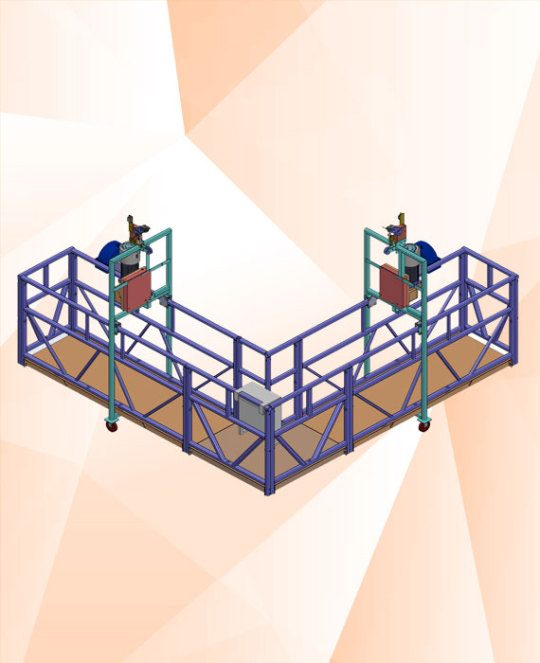

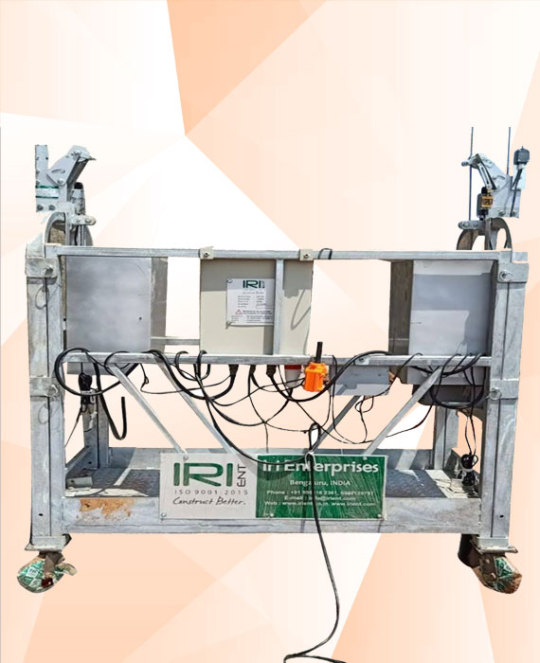

In the realm of construction and maintenance tasks, there’s a stalwart ally that stands tall, quite literally. The Suspended Rope Platform (SRP), often recognized as a gondola or working platform, has become an indispensable tool for a spectrum of vertical endeavors. Specifically, in India, these platforms have etched their place firmly in various industries, revolutionizing the way projects are undertaken.

Evolution of Rope Suspended Platforms

Initially embraced primarily by major facade contractors, the trajectory of SRPs has undergone a significant shift. Over the past three years, a seismic shift has been witnessed, with the paint industry, spanning from manufacturers to applicators, showing an avid interest. This surge in demand has propelled manufacturers of these platforms to the forefront, dominating the market for close to a decade.

The utilization of Suspended Rope Platform isn’t confined to a singular purpose. From external wall plastering, painting high-rise structures, installing glass facades to the maintenance of expansive external surfaces, the applications are diverse and extensive. Even in scenarios necessitating alterations or demolition of buildings, these platforms emerge as indispensable temporary structures.

The Rise of Rope Suspended Platforms

What sets SRPs apart is their ascendance as the preferred mode of access across construction sites. Traditionally, scaffolding held sway, but the inherent advantages of SRPs, including efficiency and versatility, have prompted their ubiquitous presence in the construction landscape.

Quality and Innovation

Platforms like the hanging rope platform hoists from Jaypee India epitomize excellence, constructed meticulously using premium materials such as stainless steel and aluminum. The emphasis on stringent quality control ensures adherence to specified durability and reliability standards, ensuring that only the finest products reach customers.

Moreover, manufacturers of SRPs have undertaken a trajectory of innovation. Varied versions of these platforms cater to diverse job site specifications. Engineers have meticulously designed these platforms, integrating multiple safety measures to mitigate the inherent risks associated with erecting and maintaining tall structures.

Safety Features and Engineering Excellence

Safety stands paramount in the realm of suspended platforms. Manufacturers have embedded an array of safety features into their products to ensure secure operations:

Rope Failure Prevention: Incorporating locks to prevent tilting due to rope failure.

Advanced Technology: Integration of sophisticated mechanical and control electronics.

Quality Wire Ropes: Utilization of high-grade steel wire ropes to guarantee robustness.

Optional Overload Sensing: Offering the option for sensing overload, further enhancing safety.

Cable Locking Angle: Ensuring a secure cable locking angle of 3–8 degrees.

Superior Suspension Systems: Technologically superior suspension systems enhancing stability.

Durability: A testament to longevity, these platforms are engineered to withstand prolonged usage without succumbing to wear and tear.

Sturdy Construction: With a solid construction, these platforms exude reliability and stability.

Energy Efficiency: Notably, the energy requirements for operating these platforms are considerably lower compared to alternative access systems.

Proficient Management and Operations

One defining aspect of the Suspended Rope Platform (SRP),landscape in India is the involvement of extensively trained professionals overseeing the operation and maintenance of these platforms. Amidst a competitive market, manufacturers differentiate themselves by providing top-tier suspended platform services. These adept specialists, well-versed in every facet of access equipment, ensure superior maintenance and repair services right on the job site. From initial setup to operationalizing the platform, these professionals handle it all with finesse and expertise.

In conclusion, the evolution of suspended rope platforms for plastering and other vertical endeavors has heralded a paradigm shift in the construction and maintenance landscape. With an emphasis on safety, innovation, and efficiency, these platforms have become the linchpin in accessing vertical spaces, promising durability, reliability, and optimal performance. As the industry continues to evolve, these platforms are poised to remain at the vanguard, catering to the ever-expanding demands of vertical construction and maintenance tasks.

#Suspended rope platform for plastering#Suspended rope platform#Rope Suspended platform for plastering#Buy Suspended Rope Platform#Rope Suspended Platform (RSP)#Construction Equipment Manufacturer and Supplier in India#Construction Equipment#Facade cleaning system manufacturers in india#Gondola Suspended Rope Platform Manufacturer

3 notes

·

View notes

Text

ACE, the Made In India construction equipment company, always deploys its machines at the forefront to head India's construction growth. Embracing the rapid development of infrastructure, ACE is committed to fortifying the nation and fostering its unity through robust growth and progress.

#construction equipment company#ace#ace company#construction equipment companies in india#construction equipment supplier#building construction equipment#largest crane companies#largest crane manufacturers#biggest crane manufacturers#construction equipment manufacturing company

1 note

·

View note

Text

What are the benefits of MS Pipe angle and MS Pipe beam?

MS angle, also known as mild steel angle, is a type of L-shaped cross-section that has several applications in the building industry. MS angles, also known as metal angles, are typically used to create right angles with two equal sides with the same width and length. Equal angles are those in which each side is the same length, and unequal angles are those in which one or more of the sides is longer than the other.

While Tube Trading Co. is just one of many MS angle manufacturers in India, it is widely recognized as a leading supplier of MS Pipe angle in Vadodara. MS angles are easy to weld, drill, as well as cut to a desirable size, making them versatile for a wide range of applications. They also have exceptional mechanical qualities.

Applications of MS Angle:

Angles made of mild steel (MS) are produced using two materials, either high-strength low alloy steel or hot-rolled carbon steel, which gives them a great deal of stability for use in a variety of structural applications as well as other general fabrication and maintenance activities. It finds widespread applicability across a variety of engineering fields, including commercial, industrial, and domestic settings.

MS Angle is highly recyclable, and as a result, it is regarded as an economically viable material for the production of a wide variety of tiny and big components in virtually every industry. MS angles have a very broad range of applications since they may be utilized in a variety of contexts to perform a variety of functions to meet your needs.

The construction of bridges, buildings, as well as other types of structures, farm equipment and machinery, precipitators, transmission lines and towers, transportation corners and frames, border frames, as well as a variety of other applications are just some of the common industries that make use of MS angle.

Tube Trading Co. is one of the most reliable sources for all of your requirements if you are looking for a trusted distributor of MS Pipe angle in Vadodara, and if so, you should consider using their services.

Advantages of MS Angles:

In light of what has been discussed thus far, it should come as no surprise that the malleability and high degree of versatility inherent to MS angles confer a plethora of advantages.

The pipe angles made from Mild Steel are also available in a variety of grades, dimensions, as well as surface treatments. It has a lower carbon percentage, which makes it simpler to deal with because it can be easily drilled, cut, and welded to suit a vast range of applications, especially construction because of its tenacity. Additionally, it has a lower carbon content, which makes it more environmentally friendly. MS angles have a superb surface finish, and they are available in mild to high steel, all of which contribute to their popularity as a material for the construction of dependable building frames and structures. It is also quite versatile in nature, and as a result, it is regarded as a "green material" for the fabrication of all construction-related components because of this quality.

Therefore, regardless of the kind of building work you could be doing, you should think about using MS angle because it has such a vast array of different mechanical qualities. When it comes to acquiring items made of mild steel, it is usually suggested to purchase from reputable manufacturers and suppliers.

MS Beams:

Mild steel, often known as MS, is a common and flexible building material that may be found in the construction of large structures like skyscrapers and residential buildings alike. The Mild Steel used in construction is designed to withstand significant weight. MS Pipe beam in Vadodara is available in a variety of dimensions, and its application is determined by the needs of the construction. In order to protect a structure from being damaged by severe weather, it is common practice to make use of MS beams while constructing roof structures and the frames of homes. The ability of MS pipes and beams to be bent and shaped is an important factor in the construction industry's reliance on the usefulness of these materials.

Features of Mild Steel pipes:

● High tensile strength

● Made of a low % of Carbon

● Easily welded

● Budget-friendly

● Long-life

Primary Applications of MS Pipe Beams:

● General engineering purposes

● Mechanical purposes

● Structural purposes

● Water treatment plants

● Chemical processing plants

Advantages of MS Beams:

● Recyclable:

In contrast to the majority of other materials used in construction, structural mild steel may be recycled. This contributes significantly to the reduction of waste produced by construction.

● Durable:

Mild Steel beams and other structural components made of Mild steel are known to have a higher tensile strength that can withstand heavy weight, which contributes to their remarkable durability. It is more resistant to fracture under pressure than a mass of stone or wood of the same volume would be under the same conditions. One of the benefits that make structural mild steel structures ideal for the building of big skyscrapers and bridges is the fact that they can withstand wear and tear for a long time.

● Rust and Corrosion resistance:

The life expectancy of construction materials such as wood is poor because of the increased likelihood that they would rot sooner. Because of the chemical structure of mild steel beams, these components are resistant to rust and corrosion, which are two factors that could otherwise reduce the structure's longevity. Because of this benefit, the life expectancy of structures that are created using mild steel beams supplied by Tube Trading Co. - an excellent supplier and distributor of MS Pipe beam in Vadodara is higher when compared to other construction materials.

#MS Pipe angle in Vadodara#MS Pipe beam in Vadodara#Businss#Industry#MS angle#MS pipe#MS steel#seamless pipe#GI pipe#stainless steel pipe#spiral welded pipe#IBR pipe#ERW pipe#pipes for fire fighting work

7 notes

·

View notes

Text

Enhance Efficiency and Flexibility with DIN Rail Mounted Terminal Blocks in India

Introduction:

In today's rapidly evolving industrial landscape, efficient and reliable electrical connections are crucial for ensuring smooth operations. DIN rail mounted terminal blocks have emerged as a preferred solution for creating secure and organized electrical connections in a wide range of applications. With their versatility, durability, and ease of installation, these terminal blocks have gained immense popularity among professionals in India. In this blog post, we will explore the benefits and applications of rail mounted terminal blocks and highlight their importance in the Indian industrial sector.

What are DIN Rail Mounted Terminal Blocks?

DIN rail mounted terminal blocks are electrical connectors that provide a convenient and standardized method for connecting and distributing power or signals in industrial control systems. These blocks are specifically designed to be mounted on DIN rails, which are widely used for organizing and securing electrical components in control panels, switchgear cabinets, and equipment enclosures.

Benefits of DIN Rail Mounted Terminal Blocks:

Space-saving and Modular Design: DIN rail mounted terminal blocks feature a compact design that allows for optimal use of available space. Their modular construction enables easy customization and expansion as per the specific requirements of an application, making them highly adaptable.

Secure and Reliable Connections: These terminal blocks ensure secure and reliable connections, thanks to their robust construction and advanced connection technologies. They provide a sturdy grip on wires and facilitate excellent contact, minimizing the risk of loose connections and electrical failures.

Easy Installation and Maintenance: With their tool-less and user-friendly design, DIN rail mounted terminal blocks simplify installation and maintenance procedures. The snap-on mounting feature of these blocks allows for quick and hassle-free assembly, reducing overall downtime during system installation or upgrades.

Enhanced Safety: Rail mounted terminal blocks adhere to stringent safety standards and offer features like finger-safe design, which prevents accidental contact with live components. This ensures the safety of both the equipment and the personnel working with them.

Applications of DIN Rail Mounted Terminal Blocks:

Industrial Automation: Rail mounted terminal blocks are extensively used in industrial automation systems, where they serve as a vital component for connecting sensors, actuators, motors, and other devices. These blocks provide a reliable interface for transmitting power and signals between various control elements.

Power Distribution: DIN rail mounted terminal blocks play a crucial role in power distribution systems, allowing for easy and organized connection of power supply lines to different equipment. They enable efficient energy management and facilitate the distribution of power to multiple devices within a control panel.

Building Automation: In building automation systems, DIN rail mounted terminal blocks provide a convenient solution for connecting various electrical components, such as lighting controls, HVAC systems, security systems, and more. Their modular design allows for easy integration and maintenance of these systems.

Rail Mounted Terminal Blocks in India:

The Indian industrial sector is witnessing significant growth, and the demand for reliable electrical connectivity solutions is higher than ever. Rail mounted terminal blocks have gained traction in India due to their versatility and ability to meet the diverse requirements of industries ranging from manufacturing to infrastructure development. Manufacturers and suppliers in India offer a wide range of DIN rail mounted terminal blocks, catering to different voltage and current ratings, wire sizes, and connection types.

Conclusion:

Rail mounted terminal blocks have revolutionized the electrical connectivity landscape in India, providing efficient, secure, and organized solutions for various industrial applications. Their space-saving design, ease of installation, and robust construction make them indispensable for creating reliable connections in control systems and power distribution networks. As the industrial sector continues to thrive in India, the importance of DIN rail mounted terminal blocks as a key component in electrical installations cannot be overstated. By embracing these advanced terminal blocks, Indian industries can enhance efficiency, reduce downtime, and ensure safe and reliable operations.

#Rail Mounted Terminal Blocks India#DIN Rail Mounted Terminal Blocks India#Power BusBar Terminal#Finger Safe Power Terminal blocks#Barrier Terminal Block Manufacturer in India#electrical wire termination technology#manufacturer#terminal block#DIN Rail Mounted Connectors#switchgear industry#solar product#PCB connectors#DIN rails channels#digital voltmeter#digital ammeter#power and signal#current transformer#railway#renewable energy#elmex#electrical company#electrical industry

2 notes

·

View notes

Text

Home Military

Indian Air Force plans to acquire 114 multifunction fighters to boost its domestic industry

Of the 114 aircraft, 96 would be manufactured in India and the remaining 18 would be imported.

Fernando Valduga By Fernando Valduga 06/13/2022 - 12:03 PM in Military

After buying 36 Rafale jets, the Indian Air Force still needs more fighters to replace its MiG-21.

The Indian Air Force (IAF) is planning to acquire 114 multifunction fighter aircraft (MRFA), with 96 aircraft to be produced in the country.

A report by Asian News International (ANI) said that the remaining 18 aircraft of the 114 would be purchased from foreign manufacturers selected in the new project.

Fighters are being purchased under the Government of India (GOI) 'Buy Global and Do in India' initiative, which allows local companies to collaborate with international suppliers.

Foreign aircraft manufacturers such as Lockheed Martin, Irkut, Boeing, Saab, Dassault Aviation and MiG must participate in the bidding process. Other sources point out that the following fighters will participate: Dassault's Rafale, Boeing's F-15EX and F/A-18 Super Hornet, Saab's JAS39 Gripen and KAI's KF-21.

ANI quoted undisclosed government sources as saying: "Recently, the Indian Air Force held meetings with foreign suppliers and asked them about how they would carry out the 'Make in India' project."

As soon as the initial 18 aircraft are acquired from international companies, India will focus on the construction of the 96 aircraft within the country.

According to the report, the payment of the first 36 of the 96 aircraft would be made in foreign and Indian currencies.

The last batch of 60 MFRA jets is expected to be the crucial responsibility of Indian partners. Payment of this lot would be made only in Indian currency.

According to the sources, this payment agreement helps suppliers in the project achieve more than 60% of 'Make-in-India' content.

In 2016, India and France signed an intergovernmental agreement for the delivery of 36 Rafale jet aircraft.

Last year, India approved the acquisition of 83 Tejas Mk-1A light combat aircraft (LCA), but still requires a larger number of capable aircraft, since a large number of MiG series aircraft have been discontinued or are in its last stages.

LCA Tejas.

The fifth-generation Advanced Medium Combat Aircraft (AMCA) project is advancing at a satisfactory pace, but it will take a long time to be introduced into an operational function.

The IAF is also looking for an economical solution to its fighter requirements, as it wants an airplane with low operational cost and that gives more capacity to the service, the sources said.

The IAF said it is very satisfied with the operational availability of Rafale fighters and wants similar capacity in its future aircraft.

Tags: Military AviationIAF - Indian Air Force/Indian Air Force

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has works published in a specialized aviation magazine in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

HOME Main Page Editorials Information Events Collaborate SPECIALS Advertise About

Cavok Brasil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

History

Military

Brazilian Air Force

Space

SPECIALS

Cavok Brasil - Digital Tchê Web Creation

7 notes

·

View notes

Text

Engine Cylinder Liner Manufacturer in India

Engine Cylinder liner Manufacturer in India is a type a part of auto parts manufacturing that is used by various industry like automotive, agriculture and construction machinery.

The reason for using the cylinder liner is their exclusive feature. Cylinder liner used for Piston rings need a surface against which they may move with the least amount of friction and the maximum amount of sealing in order to prevent combustion gases from leaking into the crankcase. Cylinder liners are generally made of cast iron, but can also be made from steel, aluminum, or composite materials.

With 36 years of industry experience, Nasrin Auto Private Limited (NAPL) offers services like engine cylinder liners manufacturer in India, serving as an OEM supplier of sleeves and air-cooled blocks or auto parts contract manufacturing and exporter. Nasrin Auto Private Limited is a market leader in contract manufacturing and OEM (Original equipment manufacturer) supply of engine cylinder liners, Wet and Dry Sleeves of Cylinders, and Air-Cooled Blocks that may be effectively used for different engine applications. Nasrin Auto Private Limited (NAPL) bears a good reputation in the market as an Engine cylinder liner manufacturer in India. We have setup our strong connection with our customers by offering state of the art products for more than 3500+ engine models for Automobiles, Marine, Diesel Engine, Truck Engine, generator, Agriculture and other Heavy Equipment Machinery items

We have been manufacturing these products from many times and our products are known to give good performance. our company has a good infrastructure and our products are tested for quality before they are dispatched. We have a team of highly skilled and experienced professionals who are always ready to meet the challenges of the market. We are committed to provide our customers with the best possible products and services. So, we are the best Engine cylinder liner manufacturer in India.

2 notes

·

View notes

Text

Sewage Treatment Plant manufacturer in India

Sewage Treatment Plant Manufacturer, Water treatment plant manufacturer

The treatment process of a water treatment plant manufacturer is to remove the impurities from the water and make it suitable for consumption.

Sewage Treatment services in Noida ..

The main aim of this process is to make sure that the drinking water is safe for human consumption.

The is responsible for treating and managing sewage in order to reduce pollution and protect public health.

The sewage treatment plant manufacturer is the one that produces the equipment for the sewage treatment plants. The equipment includes pumps, valves, tanks and other parts that are used in the process of wastewater treatment. This company is also in charge of providing the chemicals and solutions needed to keep the water clean.

Effluent Treatment Plant

A sewage treatment plant manufacturer is an important company in a community because they are responsible for making sure that all wastewater is treated so it can be reused or disposed of safely.

The treatment process starts with the primary clarifiers, which remove solids from the wastewater. The wastewater then passes through the secondary clarifiers and aeration tanks, where bacteria break down organic matter to produce carbon dioxide and hydrogen sulfide. This is followed by the oxidation ponds, which provide a surface for bacteria to grow on.

A water treatment plant is a facility that removes impurities from water by physical, chemical, and biological processes. The process begins with the water being pumped from its source to the treatment facility.

There it is fed into large tanks called clarifiers, where heavy solids such as sand settle out.

Sewage Treatment Plant Manufacturers Suppliers in India are responsible for providing customers with a solution to their sewage problems. They are capable of handling all types of wastewaters on a commercial or residential level.

The sewage treatment plant manufacturer is responsible for the design and construction of sewage treatment plants. These plants are used to treat wastewater before it is released back into the environment.

It is important to note that the sewage treatment plant manufacturer needs to have a degree in civil engineering, environmental engineering, or chemical engineering. They also need experience in designing and constructing various types of water and wastewater infrastructure projects.

Thanks & Regards

Advance Equipment & Projects Pvt Ltd

https://www.advanceequipment.in/

#water_treatment_plant#sewage_treatment#sewage_treatment_plant_manufacturers_suppliers_in_india#water_treatment_plant_services#clean_water

2 notes

·

View notes

Text

Pre-dominant SS Round Bar Dealers

Hans Metal India is an enormous Stainless Steel Round Bar Manufacturer in India.They are widely used in the construction, equipment, automotive, and aerospace industries, where their high strength and machinability make them suitable for manufacturing shafts, fasteners, and precision components. a top supplier Stainless Steel Sheet Manufacturers in India and Round Bar Suppliers in UAE.

Contact us at hansmetalindia.com.

Email address: [email protected].

Product Source: SS Round Bar Manufacturer in India and Copper Sheet Manufacturers in India

Also, visit:Round Bar Manufacturer in Mumbai and Round Bar suppliers in Saudi Arabia

#Stainless Steel Round Bar Manufacturer in India#Stainless Steel Sheet Manufacturer in India#Round Bar Suppliers in UAE#SS Round Bar Manufacturer in India#Copper Sheet Manufacturers in India#Round Bar Manufacturer in Mumbai#Round Bar suppliers in Saudi Arabia

0 notes

Text

Indian Inovatix Pvt. is a leading Full Body Harness Manufacturer in India, Discover our innovative Artemis Series Safety Harness. Designed for comfort and durability, their harnesses provide unparalleled protection in diverse work environments, from construction sites to industrial settings. Trusted by professionals worldwide, Indian Inovatix continues to innovate, offering innovative features and designs that prioritize user safety and comfort.

0 notes

Text

Get Quality-Based Cooling Tower In Nuclear Power Plant | Steam Power Plant | Thermal Power Plant.

Modern cooling towers for power plants are what Industrial Cooling Tower Mfg. Co., a top cooling tower manufacturer in India, is dedicated to providing. We are well-known cooling tower manufacturers with decades of experience; FRP, wood, and commercial cooling towers are our specialties. We have made a name for ourselves as the leading Industrial Cooling tower Manufacturers in India by being among the best cooling tower manufacturers in the country.

For pultruded cooling tower units, we provide guidance and installation support in a convenient package. Our after-sale and support services have allowed us to maintain our position as the top supplier of cooling towers.

We Provide a unique kind of heat exchanger known as a cooling tower that lowers the boiling point of water by allowing air and water to interact. The process of the cooling tower causes minute amounts of water to evaporate, lowering the temperature of the water that has been kept in the cooling water.

The primary function of a cooling tower is to remove heat from water that has been heated by manufacturing equipment and procedures. Water entering the cooling tower will be hot due to the automated process; however, it will exit as cold, chilled water and be added back into the planned process.

Our company is well known for its wide range of colors when it comes to its FRP cooling towers, FRP multicell cooling towers, FRP rectangular cooling towers, and cooling towers in thermal power plants, steam power plants, and nuclear power plants. The buyer has the option to select the cooling tower body color to blend in with the current colors of the building and industry. UV-stabilized pigment is used in the construction of the cooling towers to enhance their aesthetic appeal.

Why Choose Our— Cooling Tower For Power Plant?

"Made in India" denotes a product of the highest caliber, outstanding craftsmanship, and superior quality.

We are the top cooling tower manufacturer in India in terms of technology.

We have a wide selection of modern cooling towers.

Reasonably priced with no hidden expenses.

The advantages are outstanding!

Online reservations are simple to make.

Excellent product.

Total contentment of the client.

Very little possibility of contamination.

#cooling tower for power plant#cooling tower in nuclear power plant#cooling tower in steam power plant#cooling tower in thermal power plant

0 notes

Text

Suspended Rope Platform: How to Use It Safely

Suspended rope platforms, also known as gondolas, play a pivotal role in construction, facilitating work at considerable heights while ensuring safety and efficiency. These platforms are essential equipment used for transporting workers and engineers during installations and maintenance work in various construction projects.

Understanding the Significance

Suspended rope platforms are advanced overhead operating equipment that serves as a viable alternative to traditional scaffolding systems. There are primarily two types available in the market: manual and electric. Their usage spans across high-rise building construction, curtain wall installations, and exterior wall maintenance and cleaning.

Advantages of Using Suspended Rope Platforms

The shift from conventional bamboo and metal scaffolding to suspended rope platforms is underpinned by multiple advantages:

Enhanced Safety Features: These platforms incorporate crucial safety elements like Digital Load Cells, Anti-Tilting mechanisms, and Anti-Sway Restriction Devices, ensuring a safer work environment.

Ease of Assembly and Transport: They are simple to assemble, disassemble, shift, and store, requiring minimal manpower. Installation typically takes only 1-2 days, contributing to operational efficiency.

Longevity and Maintenance: These platforms boast a long lifespan, are easy to maintain and repair, and retain a high resale or reuse value, making them a cost-effective investment.

Versatile Design: The flexibility and ample size of these platforms offer enhanced comfort to workers, promoting productivity and safety.

Safety Gadgets Integrated into Suspended Rope Platforms

Ensuring the safety of workers is a top priority in the design and implementation of suspended rope platforms. Some crucial safety devices incorporated into these platforms include:

· Centrifugal Speed Limiter

· Electromagnetic Brake with Manual Release

· Over Hoist/Top Limit Switch

· Anti-Tilting Cut-off Mechanism

· Anti-Sway Restriction Features

· Locking Arrangement for Upper Counterweights

· Hammer Weight for Wire Rope Locking

· Panelboard Lock & Key Mechanism

Ensuring Safe Usage

As esteemed suppliers of suspended rope platforms in Gujarat, ensuring the safe usage of gondolas is a primary responsibility. Accidents involving these platforms often stem from inadequate knowledge of their operation. Thus, it's imperative to highlight the necessary precautions for their safe utilization.

Implementing a Safe Work System

Every operation involving a suspended working platform must adhere to a comprehensive safe work system. Project engineers, safety professionals, Jobsite staff, and building management should collaboratively establish and endorse safety protocols. A competent individual should oversee and supervise the implementation of this system, ensuring the safety of all personnel associated with the platform.

What is suspended rope platform?

A suspended rope platform, also known as a gondola, is a crucial construction tool for working at heights. It's an overhead operating equipment used to transport workers during installations and maintenance. With safety features like Anti-Tilting and Anti-Sway devices, it ensures safe, efficient work at elevated levels in construction projects.

Rope Suspended Platform manufacturers in India

In India, several manufacturers specialize in rope suspended platforms. Irri Equipment one of them offering high-quality equipment for construction needs They manufacturers prioritize safety features and efficient design, catering to the diverse demands of the construction industry. They provide reliable solutions for working at heights with precision and safe.

Safety Protocols and Best Practices

To guarantee the safe operation of suspended rope platforms, adherence to strict safety protocols is crucial:

· Thorough Operational Planning: This involves selecting the appropriate platform for the job and evaluating the working environment.

· Secure Installation Methods: Employ tried-and-tested installation techniques to ensure stability.

· Regular Maintenance: Implement both on-site and periodic maintenance routines to keep the platform in optimal condition.

· Documentation and Certification: Maintain detailed operation and maintenance records, repair logs, and certificates of examination.

· Competent Personnel: Only qualified individuals should handle the installation, movement, and dismantling of these platforms.

· Avoiding Hazardous Conditions: Use of the platform should be prohibited in hazardous conditions to prevent potential risks.

· Continuous Supervision: Regular monitoring and supervision of safety measures should be in place to ensure ongoing compliance.

Prioritizing safety protocols and measures is pivotal for the seamless and secure operation of suspended rope platforms. At our company, we emphasize these precautions to safeguard the well-being of our customers and all involved in construction projects. Should you require further guidance or assistance in utilizing these platforms safely, our team of suspended rope platform suppliers is always available to offer support and expertise.

Source - https://iriequipment.com/

#Buy Suspended Rope Platform#Suspended Rope Platform#Rope Suspended Platform#Suspended rope platform for plastering#Bar bending machine#Construction Equipment Manufacturer and Supplier in India#Construction Equipment

1 note

·

View note

Text

Atmanirbhar Mission - India's First Electric Crane

#Atmanirbhar Mission - India's First Electric Crane#india's 1st electric crane#india's first electric crane#india's 1st electric construction equipment#electric crane#f150 electric crane#electric mobile crane#electric crane manufacturer#electric crane supplier

1 note

·

View note

Photo

Are you looking for the best quality tool steel, die steel, and mold steel suppliers for your engineering work in India?

As one of India’s leading special steel suppliers, #ViratSpecialSteels can supply the following industries requirement of steel practically off-the-shelf.

Virat Special Steels Pvt. Ltd., is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Forging Industry - Forging is a process in which metal is being shaped using compressive forces with a Hammer or a press. Forging are classified into Cold forging, warm forging or hot forging. Mainly material used: Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343(H11).

Pressure Die Casting – Die casting is performed by forcing molten metal under high pressure into a mold cavity & the cavity (mold cavity) is manufacture by using two hardened tool steel dies & perform similar to an injection mold. Mainly material used: Hot die steel i.e. DIN 1.2344(H13), DIN 1.2343(H11), and DIN 1.2581(H21).

Aluminum Extrusions - In Extrusion process material is pushed through a die to the desired cross section & in this manufacturing process it creates very complex cross section. The parts are being formed with an excellent surface finish. Mainly material used: - Hot die steels i.e. DIN 1.2344 (H13) grade.

Automotive Industry - Automotive industry are wide range of companies is mainly involved in manufacturing, design, development, of motor vehicles. Mainly material used: - Din 1.2714(DB6), DIN 40NiCrMo84(EN24), DIN 3343(M2), 16Mncr5, 20Mncr5.

Plastic industry - Polymer materials are manufactures in plastic industry and offers services to aerospace, building, construction, electronics, packaging and transportation. Mainly material used: - DIN 2738 (P20+ Ni), DIN 2311(P20).

Railways - They are involves mainly in manufacturing railways components i.e. Railway gear holder, Railway bogie cast parts, Railways axles, railways Sets of pins, Ground lever frame, adjustable crank, Compressor pistons, Compressor bearings. Mainly material used:-Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343 (H11), DIN 40NiCrMo84(EN24), 20NiCrMo5(EN353).

Oil & Gas - Oil & Gas they supply more than 60 percent of our nation’s energy. Natural gas also helps generate the electricity that powers our daily lives.

They also have a fully equipped quality assurance and process examination facility that conducts tests such as hardness and analyses of grain structure.

Find us:

Website: https://www.viratsteels.com/

Email us: [email protected]

Call Us Now: +91-9814021775

#viratspecialsteels#viratsteelsindia#viratsteels#2714steel#h13steel#din2714#din2738#db6steel#din2344#diesteel#mouldsteel#mouldsteelstockist#tool steels#toolsteelsupplier#delhincr#gurugram#ludhiana#gurgaon#pune#india#forging#metalworking#steel#alloy steel#cold work steel#high speed steel#hot work steel#manufacturing#construction#iso9001

3 notes

·

View notes

Text

A Workhorse for Quarries and Mines - Made by Kashdra Group

The LD4 Machine is a reliable and efficient piece of equipment used extensively in quarries and mines. Known for its portability, ease of operation, and affordability, the LD4 has become a popular choice for contractors and small businesses alike. In this blog post, we'll delve deeper into LD4's features and explore why Kashdra Group stands out as a leading LD4 rock drill manufacturer in India.

Understanding the LD4 Rock Drill

The LD4 is a lightweight and versatile drilling machine designed for various applications, including:

Stone quarrying: Creating holes for controlled blasting and dimension stone extraction.

Mines: Drilling holes for anchor bolts, injection grouting, and exploration purposes.

Construction: Drilling holes for foundations, footings, and utility installations.

The LD4's key features include:

Lightweight Design: The compact design allows for easy transportation and maneuverability, especially in tight spaces. A single person can operate the machine, making it ideal for smaller projects.

Versatility: The LD4 can drill both vertically and horizontally, offering flexibility for various drilling needs. The 15-degree ball joint between the feed beam and anchoring frame further enhances maneuverability during operation.

Durability: Kashdra Group manufactures the LD4 using high-grade components, ensuring its robustness and longevity in harsh working environments.

Ease of Use: The LD4 boasts a user-friendly design with simple controls. This makes it ideal for operators with minimal training.

Cost-Effective: Compared to heavier drilling rigs, the LD4 is a more affordable option. It also helps reduce labor costs due to its single-person operation capability.

Why Choose Kashdra Group for Your LD4 Rock Drill?

Leading manufacturer and supplier of LD4 rock drills in India. Here's what sets them apart:

Experience and Expertise: With decades of experience in the industry, Kashdra Group possesses in-depth knowledge of rock drilling technology. This expertise translates into high-quality, reliable LD4 machines.

Focus on Quality: Kashdra Group prioritizes quality by using top-notch materials and employing stringent manufacturing processes. This ensures that their LD4 drills are built to last.

Competitive Pricing: Kashdra Group offers competitive prices for their LD4 rock drills, making them an attractive option for businesses of all sizes.

Excellent Customer Service: The company is committed to providing exceptional customer service. They offer technical support and guidance to ensure you get the most out of your LD4 machine.

Beyond the LD4: Diverse Product Portfolio

While the LD4 is a popular product, Kashdra Group offers a wider range of equipment to cater to diverse needs in the stone quarrying and mining industries. Some of their other offerings include:

By exploring their product catalog, you can find a comprehensive solution for your rock-drilling and stone-cutting requirements.

Conclusion: Investing in an LD4 Rock Drill

The LD4 rock drill, manufactured by Kashdra Group, is a valuable asset for any business involved in quarrying, mining, or construction activities. Its portability, versatility, and affordability make it a perfect choice for projects requiring efficient drilling solutions. With Kashdra Group's commitment to quality, customer service, and a diverse product portfolio, you can be confident in finding the right equipment to meet your specific needs.

For further information on the LD4 rock drill or to explore Kashdra Group's product offerings, you can visit their website or contact them directly.

0 notes

Text

Supplier of Check Valve in Bihar

Company Overview:

Multitech Valves and Automation is a well-known Supplier of Check Valve in Bihar, India.

They are also manufacturers of Check Valves, based in Ahmedabad, Gujarat, India.

Recognized for producing high-efficiency valves, MVA controls and guides a variety of liquids, specializing in high-pressure valves trusted across multiple Indian industries.

The company, known for its technologically advanced products and innovative engineering, is committed to safety in all its operations.

The success of MVA can be attributed to the dedication and expertise of its skilled technicians.

Check valves, also known as non-return or one-way valves, are designed to allow fluid flow in one direction and prevent backflow in the other to protect upstream equipment.

Technical Specifications:

Materials of Construction (MOC): Cast Steel (WCB), Stainless Steel (CF8, CF8M, CF3, CF3M), Alloy Steel, Cast Iron (FG 260)

Manufacturing Standard (Mfg. Std.): BS 1868

Inspection and Testing Standard (Insp & Testing Std): BS 6755

End Connection: Flanged End / Buttweld End

Size Range: 1½" to 24" (15 mm to 600 mm)

Pressure Classes: 150#/300#/600#/900#

Features:

Bi-Directional Flow

Excellent Shut-Off Capability

Quick Operation

Straightforward Design

Durable Construction

Applications:

Water and Wastewater Treatment

Oil and Gas Industry

Power Generation

Chemical Processing

Petrochemical Industry

Pharmaceutical Industry

Textile Industry

Agriculture

Marine and Shipbuilding

Food and Beverage Industry

Geographical Coverage:

Multitech Valves and Automation Supplier of Check Valve in Bihar, India including cities like Araria, Arwal, Aurangabad, Banka, Begusarai, Bhagalpur, Bhojpur, Buxar, Darbhanga, East Champaran, Gaya, Gopalganj, Jamui, Jehanabad, Khagaria, Kishanganj, Kaimur, Katihar, Lakhi-sarai, Madhubani, Munger, Madhepura, Muzaffarpur, Nalanda, Nawada, Patna, Purnia, Rohtas, Saharsa, Samastipur, Sheohar, Sheikhpura, Saran, Sitamarhi, Supaul, Siwan, Vaishali, West Champaran.

Please feel free to contact us with any questions or for additional information.

Read the full article

#Araria#Arwal#Aurangabad#Banka#Begusarai#Bhagalpur#Bhojpur#Bihar#Buxar#CheckValve#Darbhanga#EastChamparan#Exporter#ExporterofCheckValve#Gaya#Gopalganj#India#Jamui#Jehanabad#Kaimur#Katihar#Khagaria#Kishanganj#Lakhi-sarai#Madhepura#Madhubani#Manufacturer#ManufacturerofCheckValveinAhmedabad#Munger#Muzaffarpur

0 notes

Text

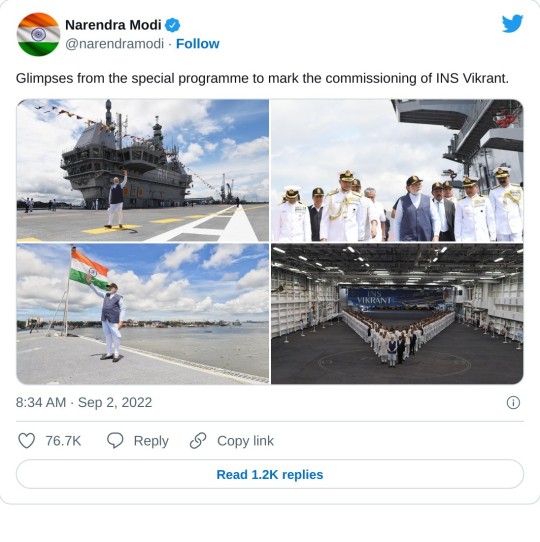

India commissions its first home-built aircraft carrier, the INS Vikrant

Fernando Valduga By Fernando Valduga 09/02/2022 - 13:00in Military

Indian Prime Minister Narendra Modi today commissioned the first aircraft carrier built in India, highlighting his government's efforts to increase domestic production to provide aid to the military deployed on two contentious borders.

After 17 years of construction and testing, Modi commissioned the INS Vikrant - the navy's second operational aircraft carrier and the largest warship ever built in India - on a state shipyard in the south.

"Today, India has joined the countries of the world that can manufacture such a large aircraft carrier with native technology," Modi said. "It is a symbol of Indian potential, Indian resources and Indian skills."

Designed to accommodate a crew of about 1,600 people and a fleet of 30 aircraft, the Vikrant will feature MIG-29K aircraft designed in Russia that already operate from another aircraft carrier from India, INS Vikramaditya, which India bought from Russia.

Boeing and the French Dassault are seeking to supply India with more than two dozen jets for the Vikrant.

India is one of the largest importers of weapons in the world, spending $12.4 billion between 2018 and 2021, but has been seeking to develop its own manufacturing capabilities while Russia, the main supplier, is waging a war in Ukraine and facing sanctions.

Among the imports are about 8,000 defense items worth about US$ 1.03 trillion in 2022-23 that you want their companies to produce, according to the Ministry of Defense.

Currently, India has 1.38 million people in its armed forces, with a large number deployed on the borders with its nuclear-weapon rivals China and Pakistan.

"India is working with all its forces to become self-sufficient," Modi said, referring to the Texas lightweight combat aircraft and artillery, built at home.

The Vikrant will significantly increase India's maritime capabilities, allowing the navy to operate an aircraft carrier on each coast, alongside its 10 destroyers, 12 frigates and 20 corvettes.

China, which also has two operational aircraft carriers and is working on a third, has a much larger fleet of 335 ships, including about 48 destroyers, 43 frigates and 61 corvettes.

"Security concerns in the Indo-Pacific region and the Indian Ocean have been ignored for a long time," Modi said. "But today this area is a great defense priority for our country."

Source: Reuters

Tags: Military AviationINS VikrantIndian Navyaircraft carrier

Previous news

Argentina's main military officer visits Pakistan to inspect JF-17 Thunder fighters

Next news

Romania seeks parliamentary approval to buy 18 Bayraktar drones for $300 million

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. It has works published in specialized aviation magazines in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

MILITARY

Japanese Air Force presents F-15J with painting "Top Gun: Maverick"

02/09/2022 - 18:58

MILITARY

Pratt & Whitney delivers the 1,000th F135 engine

02/09/2022 - 16:00

MILITARY

Romania seeks parliamentary approval to buy 18 Bayraktar drones for $300 million

02/09/2022 - 14:00

MILITARY

Argentina's main military officer visits Pakistan to inspect JF-17 Thunder fighters

02/09/2022 - 12:00

MILITARY

Bangladesh acquires 36 F-7BGI jets from China to increase its military capacity

02/09/2022 - 11:00

MILITARY

Government of India approves development of LCA Tejas Mk2

02/09/2022 - 10:00

homeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

1 note

·

View note