#5-Axis Machining

Text

What Should Pay Attention to in the Operation of High-Speed 5-Axis Machining Center?

High-speed 5-axis machining center is an advanced processing equipment, with high precision, sound speed and high efficiency characteristics. It is usually used for processing complex and difficult parts, such as aerospace, medical equipment, automotive parts, etc. When operating a high-speed 5-axis machining center, special attention needs to be paid to the following points:

1. Familiar with the structure and principle of the equipment: the operator needs to be familiar with the structure and working principle of the high-speed 5-axis machining center, understand the name of each axis, the range of motion and restrictions, and master the control system and programming method of the machining center. Only with a deep understanding of the structure and principle of the equipment can we correctly operate and use the high-speed 5-axis machining center for processing.

2. Strictly follow the operating procedures: the operator should strictly follow the operating procedures, including wearing personal protective equipment, avoid body parts close to the moving parts, avoid strong light exposure, etc. In addition, safety devices such as safety doors, warning lights and emergency stop buttons need to be checked regularly to ensure that they are in good working condition.

3. Equipment inspection and maintenance: before use, it is necessary to maintain and check the equipment. First, check whether the tool is worn, and if it is worn, it needs to be replaced. Secondly, check whether the fixture is stable and firm. Clean the equipment to prevent dust and foreign matter from entering the equipment. At the same time, it is also necessary to carry out real-time monitoring of the equipment during the processing process to discover and deal with problems in time.

4. Material preparation and processing: before 5-axis processing, it is necessary to prepare the required materials and ensure the quality and accuracy of the materials. At the same time, in order to avoid temperature changes affecting the processing, the material should be placed in a constant temperature environment. After the processing is completed, it is also necessary to process the workpiece, including cleaning, inspection and maintenance.

5. Safety control: the operator needs to strictly control the safety risks in the processing process, such as the cutting and cutting methods, the length and diameter of the cutting county, and the setting of cutting parameters. In the processing process, it is also necessary to pay attention to observe the processing situation, adjust the cutting parameters and tool status in time, and avoid collision or over-cutting errors.

6. Programming and setting: the operator needs to be familiar with the programming language and programming method of the high-speed 5-axis machining center, and can perform the correct programming and setting according to the processing needs. In the programming process, it is necessary to pay attention to the planning of the tool path, the setting of cutting parameters, the distribution of machining allowance and other issues to ensure the stability and accuracy of the machining process.

7. Training and experience accumulation: operators need to go through professional training and practice, practice the accumulation of experience, and constantly improve their skill level and operational experience. Through continuous learning and practice, operators can better master the operation skills and maintenance methods of high-speed 5-axis machining centers, and improve the utilization rate and service life of equipment.

0 notes

Text

Discover the evolution of Computer Numerical Control (CNC) machining, from its inception in the 1950s to the modern era of multi-axis technology. This post delves into the world of 3-axis and 5-axis CNC machining, exploring their differences, applications, and the transformative impact they have had on industries such as aerospace and defense. Learn how these advanced machining techniques enable the creation of intricate, high-quality parts with unprecedented precision, speed, and versatility. Gain insights into the unique capabilities of 3-axis machining for traditional processes and the cutting-edge capabilities of 5-axis machining for complex components, paving the way for the future of manufacturing.

#CNC Machining#Precision Manufacturing#3-Axis Machining#5-Axis Machining#Multi-Axis CNC#Advanced Machining Technology#Industrial Revolution.

1 note

·

View note

Text

GD prototyping is a Prototypes&low volume manufacturer, provide (3&4&5axis)CNC machining, 3d printing, sheet metal, vacuum casting rapid tooling and surface finish. https://www.gd-prototyping.com/

2 notes

·

View notes

Note

Bro just straight up pouring molten bronze like it's not the coolest thing in the world wtf

Right now I work in a wood & metals fabrication shop and As a man of many hats if I see a piece of machinery I make it my life goal to get my dirty little hands on operating it at least once (when i was on the pour team i did most jobs but pouring from the big crucible of metal was my favorite and i was pretty good at it. never did the crane bc i have a bad sense of direction and you have to be pretty quick when pouring molten metal)

My next target is this thing:

#5 axis cnc i will get you.#i currently specialize in the 3 axis but i havent been able to learn to toolpath this thing bc its significantly more complicated#and also our shop's is kind of .broken#but i toured a shop that had 7 axis cncs in enclosed cabinets and shit literally the most insane precision machining#idk if i would be able to work in a shop like that but a man can dream#m#answers

4 notes

·

View notes

Text

The Applications of 5 axis machining Across Industries

The keys to success in the field of advanced manufacturing are accuracy and effectiveness. 5 axis machining services are a ground-breaking strategy that has expanded the potential for producing complicated and sophisticated components. In this article, we explore the realm of 5-axis machining, examining its advantages, uses, and the radical changes it has brought about across several sectors.

5-axis Machining: Beyond Traditional Boundaries

To obtain the required form, traditional machining techniques frequently entail moving the workpiece along many axes. However, these techniques have drawbacks when it comes to creating intricate geometries. This is where 5-axis machining comes into play, expanding the realm of what is feasible.

5-axis machining adds two rotating axes (usually A and B), in contrast to 3-axis machining, which moves the workpiece along three linear axes (X, Y, and Z). This gives the tool an unmatched degree of flexibility in its movement, allowing it to approach the workpiece from several angles and orientations. A capacity for producing complex designs, speeding up production, and requiring fewer setups overall is the outcome.

5-axis Machining Shining Applications

· Aerospace: The aircraft sector requires complex, lightweight, yet robust components. In materials like titanium and aluminum, 5 axis machining enables the production of complicated geometries that are essential for airplane and spacecraft parts.

· Medical: The medical industry benefits from the accuracy of 5-axis machining in generating patient-specific components and sophisticated designs that support greater biocompatibility. This includes orthopedic implants and medical gadgets.

· Automobile: Precision 5-axis machining is utilized to create molds, prototypes, and crucial engine components in the highly competitive automobile industry, improving performance and reducing weight.

· Even in the creative sectors, such as art and design, 5-axis machining has a role. By using technology, designers, and artists can bring their imaginative ideas to life by producing elaborate sculptures, molds, and architectural models.

The Challenges and Innovations Ahead

5-axis machining is a constantly evolving field, much like any cutting-edge technology. Its capabilities are being further improved by advancements in automation, real-time monitoring, and adaptive toolpaths, which are turning it into a crucial resource in the industrial environment. Nevertheless, there are still issues like programming complexity and greater startup costs. To fully utilize the potential of 5-axis machining services at the 5 axis CNC machining center, it is imperative to understand the complexities of programming and engage in training.

Follow our Facebook and Twitter for more information about our product.

#5 axis machining#5 axis machining services#5 Axis CNC Machining Center#Custom 5 Axis Machining services#5 Axis CNC Machine Shop#5 Axis Machining Center

2 notes

·

View notes

Text

Different Types of Brush Making Machines

Nowadays, there is a booming demand for brush-making machines. With their growing popularity among various industries, looking for the best machines is of utmost importance. Your search for the best manufacturing team for these machines now comes to an end, thanks to our team from Sharma & Sons. We are offering the best brush solution you have ever laid your eyes on.

Being a leading professional company for all brush machines, we have been engaged in research and development for so many years now. Our main goal is to develop the best product machines that come in handy with the latest technology.

Major technical database:

We have a growing technical database, which has been around since the inception of our company. That makes us one of the leading names in the manufacturing field. We have an in-house team, comprising technical professionals and engineers to offer our clients premium ranges of brush machines.

We will develop the entire design range within our factories and will sell the final results to the international and domestic markets.

There is also an experienced marketing and sales team working with us to check out various aspects of customer feedback and sales regarding each consignment.

The types we follow:

Being associated with brush-making machines for such a long time, we have generated and created multiple types of brush-making machines. The differences will help in covering the maximum crowd at the same time and focus on their flexible needs. So, before you proceed further, we would like you to get the detailed information regarding the types of machines we have in store.

2 Axis Brush Tufting Machine:

Available in brand new condition and with the automatic grade, our 2 Axis Brush Tufting Machine is one to watch out for. It has the capability to produce around 2500 pieces in one go.

This machine is able to produce various kinds of brooms and brushes, which will have multiple filling angles by just changing the specified platforms.

It can be easily installed with just one tufting motor head to offer higher speed and cost-effective results in the end.

There are Touch panels and PLC control systems available from this machine with an English display on the top for better understanding.

There are different procedures performed by a single machine, which will reduce hair mechanic technology dependency.

3 Axis Brush Tufting Machine:

If you are planning to create brushed with curved surfaces, then 3 Axis Brush Tufting Machine might be the right option to get from our side. There are plastic brush pieces, which are to be moulded in advance within the available holes. These holes are now vertical to the surface at around 90 degrees and they cannot be tilted at any other angle. The generic brush size is around 350mmx 180mmx 360 degrees. However, we can customize some of the other sizes as per the requirement through our 3 Axis Brush Tufting Machine models.

There are mainly two grippers available holding two brushes on the work table. Under its automatic mode, it has the power to tuff brushes continuously in a non-stop manner.

4 Axis Brush Tufting Machine:

Another interesting choice of the machine while looking for brush making category from our side has to be 4 Axis Brush Tufting Machine.

All the wearing parts and the spare parts of this machine are designed in a standard manner.

It helps in reducing hair mechanic technology dependency.

Our machines have the power to create one, two, or three colored brushes in one go.

Once proficiently installed by our team members, these machines are subject to last the longest with a little bit of maintenance from your side.

5 Axis Brush Tufting Machine:

We have specially designed 5 Axis Brush Tufting Machine for you, which is used to tuff brushes with the help of stainless steel wires. It is always recommended that the plastic brush pieces need to be molded with holes before getting into the machine. On the other hand, the wooden brushes also need to be pre-drilled with holes in them.

Here, the working table is quite flexible and the nylon filaments or the SS wires can be tufted at different angles, which in turn, will look radial.

This machine helps in processing filaments in two different colours, with a maximum length is around 120mm in 5 Axis Brush Tufting Machine.

A hand controller is widely used here to manually enter the hole positions within the program, with one hole at a time.

The best Drilling and Tufting Brush Machine at your service:

We have the best Drilling and Tufting Brush Machine in store for you, which has been a result of years of research from our side. The machine consists of a main motor, which is sprightly procured from Italy and known for its high working head speed. Then you have a premium quality precision filament box, known to offer reliable and stable performance throughout. So, next time you are looking for one such brush-making machine, focusing on us at Sharma & Sons will be a great note to consider.

#5 axis brush tufting machine#brush tufting machine from india#brush making machine#brush making machine in india#brush tufting machine exporter#brush tufting machine supplier & exporter#brush making machine at best price in india#brush making machine manufacturers & suppliers#brush tufting machine#brush broom tufting machine#2 axis brush tufting machine#3 axis brush tufting machine#4 axis brush tufting machine

0 notes

Text

Please reach out to us to know about your next project needs. We strive for a fast turnaround to get your project up and operational quickly.

#precisionmachining #cncmachining #cncmilling

0 notes

Text

Trends and Predictions for Vertical Turning Lathes and 5-Axis Turnmills

The manufacturing world is always evolving, driven by new technologies and the constant demand for more efficient and precise production methods. Computer Numerical Control (CNC) machining stands at the forefront of this evolution.

Among the many advancements in this field, Vertical Turning Lathes and 5-axis turnmills are notable for their impact on the industry. This blog explores the future trends and predictions for these technologies for special-purpose machines and their role in modern manufacturing.

What are Vertical Turning Lathes and 5-Axis Turnmills?

Before discussing the trends, it's important to understand these machines. A Vertical Turning Lathe (VTL) is a type of lathe where the main spindle is oriented vertically, which is beneficial for handling large, heavy workpieces. On the other hand, a 5-axis turnmill combines the capabilities of a turning center and a milling center in one machine, allowing complex shapes to be manufactured with high precision.

is a type of lathe where the main spindle is oriented vertically, which is beneficial for handling large, heavy workpieces. On the other hand, a 5-axis turnmill combines the capabilities of a turning center and a milling center in one machine, allowing complex shapes to be manufactured with high precision.

Trends and Predictions

Increased Automation: One of the key trends in CNC machining is the move toward greater automation. Vertical Turning Lathes and 5-axis turnmills are integrating more with automated loading and unloading systems. This speeds up the manufacturing process and reduces the likelihood of errors and improves safety by minimizing human interaction with the machines.

Enhanced Precision: As industries like aerospace and medical devices demand ever higher precision, machines' capabilities need to keep up. Advances in software and hardware are making it possible for Vertical Turning Lathes and 5-axis turnmills to achieve even greater accuracy, thereby producing parts that meet strict specifications without additional finishing processes.

Complexity Made Simple: 5-axis turnmills have a significant advantage in handling complex shapes. With improvements in CNC technology, these machines can produce intricate and detailed parts more efficiently than ever. This capability makes them invaluable in industries where complexity and precision are critical.

Special-purpose Machines

As manufacturing challenges grow, the role of special-purpose machines in CNC machining becomes more significant. These machines are designed for specific tasks and can offer solutions that general-purpose machines cannot. For instance, they might be optimized for ultra-high precision or designed to handle particular materials or part sizes. The future will likely see an increase in the deployment of these machines as manufacturers seek tailored solutions to meet unique production needs.

The Role of WIDMA in Shaping the Future

WIDMA, a manufacturing and machining technology leader, is at the forefront of the trends discussed. Their expertise in developing advanced CNC machines, including Vertical Turning Lathes and 5-axis turnmills, positions them well to drive innovation in the industry. WIDMA's commitment to research and development ensures that it remains at the cutting edge, providing machines that are not only highly efficient but also versatile and capable of meeting the demands of modern manufacturing.

By focusing on customization and incorporating the latest technologies into their machines, WIDMA helps customers stay competitive in a rapidly changing industry. Their approach to embracing sustainable practices and promoting automation further underscores their role as a key player in the future of CNC machining.

Conclusion

The future of CNC machining looks promising with continuous advancements in technology such as Vertical Turning Lathes and 5-axis turnmills. As these machines become more automated, precise, and capable of handling complex and varied tasks, they will play an increasingly important role in manufacturing.

0 notes

Text

5-Axis Machining Perth

Our 5-axis machining in Perth enables us to produce intricate components with unparalleled precision and efficiency, meeting the demands of even the most complex projects. Our team works dedicatedly to offer you the desired results.

0 notes

Text

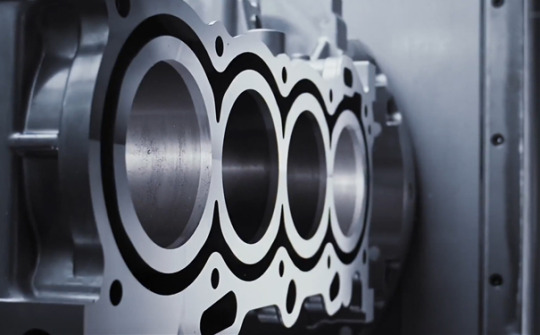

Application of CNC 5-axis machining technology in the field of automobile manufacturing

In the field of automobile manufacturing, CNC 5-axis machining technology with its high precision and high efficiency characteristics is gradually becoming one of the key technologies to improve the level of automobile manufacturing. With the increasing demand of consumers for automotive performance, appearance and comfort, the requirements of automotive manufacturing for processing technology are becoming more and more stringent, and CNC 5-axis machining technology just meets this demand.

CNC 5-axis machining technology enables high-precision machining of complex surfaces, which is essential for the manufacture of many key components in automotive manufacturing. For example, the cylinder head, crankshaft and other parts of the automobile engine have complex shapes and high precision requirements, and traditional processing methods are difficult to meet these requirements. The CNC 5-axis machining technology can easily meet these challenges and ensure the precision and quality of the parts, thereby improving the performance and reliability of the vehicle.

In addition, CNC 5-axis machining technology also has high efficiency. In the automobile manufacturing process, time is money, and efficient processing technology can greatly shorten the production cycle and reduce production costs. CNC 5-axis machining technology can complete multiple surface machining at one time, reducing the number of tool changes and repositioning, thereby improving processing efficiency. At the same time, the technology can also automate production, further improving production efficiency.

In the field of automobile manufacturing, the application of CNC 5-axis machining technology is also reflected in personalized customization. With the increase of consumers' personalized demand for automobiles, automobile manufacturers need to be able to quickly and accurately produce personalized products that meet consumers' needs. CNC 5-axis machining technology can quickly adjust processing parameters and procedures according to the specific needs of consumers, achieve rapid customized production, and meet the individual needs of the market.

Looking forward to the future, the application prospect of CNC 5-axis machining technology in the field of automobile manufacturing is very broad. With the rapid development of new vehicles such as new energy vehicles and intelligent vehicles, the requirements for processing technology in automobile manufacturing will further increase. CNC 5-axis machining technology will continue to play its advantages of high precision and high efficiency, providing more powerful support for automotive manufacturing. At the same time, with the continuous progress of technology and cost reduction, CNC 5-axis machining technology is expected to be applied and promoted in more automobile manufacturing enterprises.

LORI is a high-tech enterprise engaged in 5-axis machining and other high-precision parts machining. Especially 5-axis machining, widely used in all kinds of high-tech precision industries, such as robot parts, UAV parts, aviation parts, automation equipment parts

0 notes

Text

5 axis stone cutting machine: profiling cutting

0 notes

Text

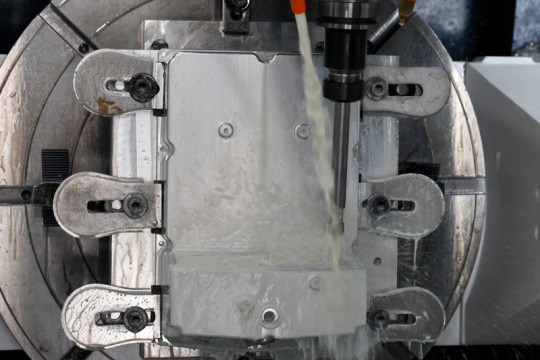

GD prototyping precision automotive parts processing, Simultaneous 5-axis CNC milling is an advanced processing technique that can manufacture high-precision and complex parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#auto parts#precision machining

0 notes

Text

RAY Mechatronics & Machinery Pvt Ltd is an authorized supplier of cutting-edge Computer Numerical Control (CNC) machines designed for advanced manufacturing processes. Our machines operate based on CAD programs, streamlining instructions for precise production. Our CNC units stand out by significantly reducing manufacturing duration and enhancing precision. Our Takumi VMC enables workpiece rotation along two additional axes beyond the standard three, significantly enhancing precision and flexibility. This innovative feature contributes to minimized material wastage and reduced reliance on specialized labor. Experience heightened accuracy and efficiency with our advanced Takumi VMC technology.

Our product spectrum accommodates diverse needs and comprises the BC, G, H, PV, UB, UC, UR, and U series, each tailored to specific requirements, notably in tool and mold fabrication. To improve your manufacturing efficiency, elevate operational speed, and utilize an upgraded industrial approach, contact us at 080-28394443. Upgrade your manufacturing process with RAY Mechatronics & Machinery Pvt Ltd.

#Takumi VMC#Takumi Milling Machine#Takumi Vertical Machine Center#Takumi machine tool#5 Axis Machining Centers#double column machining center#double column vmc machine

1 note

·

View note

Video

youtube

Smart intelligent 5 axis Co2 laser cutting machine made in CHINA STARMAC...

#youtube#Smart intelligent 5 axis Co2 laser cutting machine made in CHINA STARMACNC group STARMACNC laser three -dimensional five -axis laser cuttin

0 notes

Text

Practical Tips On Buying A Sewing Machine

That describes an important question - a person you obtain an offshore drilling rig job before this appears in an ad? The simplest way is to go shopping for all the small offshore drilling contractors that the create the large offshore drilling companies like Halliburton, Schlumberger, Transocean, give up. Most of these small oil service companies usually tend to cluster around two types of places - the headquarters of big companies that subcontract to them; and around the area where your offshore oil rigs can be (in the US, these would become Gulf Coast states of Alabama, Louisiana, Mississippi and Texas).

The Craftsman CNC router is aimed towards the woodworker and dabbler. Anyone basically who has a need to create a one-of-a-kind masterpiece in their backyard and from wood, this machine has been designed these.

Toys -- there certainly variety of toy projects you can create with a CNC Wood router. Obtain make checkers and checker boards, elaborate chess sets, game pieces for a variety of video. These projects merely limited by your imagination.

From routers to mills, laser cutters, plasma cutters and more, there is really a CNC machine that you may incorporate in to your hobby which can help you not waste time and be a little more creative. Sculpting, tapering, cutting, and engraving are a totally of the features that these appliances can a person to do. Wouldn't it be nice to have a machine to in order to taper the ends persons chair legs in far less time computer system would call for to carried out manually? Or, how about cutting wings for that model airplane that an individual been enhancing?

Forstner bits are top for drilling flat bottom holes that don't go right up through the wood. For instance, chair legs that don't to help come through the seat. https://www.mskcncmachine.com/Boring-Tapping-Tleeve-Flat-Radial-Drilling-Machine-pd42701701.html have a pilot to steer the bit, it uses a fluke from the outside that cuts a nice clean edge as the chips are cut released. These bits cost above and beyond twist or paddle bits but substantial the excellent for good finish work.

The rotary core and wire line is the two main regarding diamond drilling techniques. Rotary drilling is when boreholes have with regard to dug though coring in rocks. Wire line drilling is used to treat mineral discovery. Here radial drilling machine is not just in dig a dent but and get a core small sample.

We sometimes call this emotional fat. Emotional baggage comes in the form of trapped emotional energies created relation as may be now finished external situations or imagined events. We have not completed the internal emotional release cycle connected them locations causes in order to remain alive inside of us; you would like as though these things are still happening now.

#cnc lathe machine#5 axis cnc machine#stand drill machine#bench drilling machine#radial drilling machine

1 note

·

View note

Text

The Evolution of Manufacturing With Specialised Machinery

Manufacturing has always been about making things. From the simple tools of early humans to the complex gadgets of today, the way we make things has evolved. This evolution is not just about what we make but also about how we make it. In this journey, three important machines have been pivotal: Vertical Turning Lathes, 5-axis turnmills, and Special-purpose machines. Let's dive into how these machines have changed manufacturing and where WIDMA fits into this landscape.

Vertical Turning Lathe: A Game Changer in Precision

The Vertical Turning Lathe (VTL) has transformed how we think about machining large, heavy parts. Unlike traditional lathes, where the workpiece spins horizontally, in a VTL, the piece is held vertically. This simple change makes a big difference. It allows more accurate cutting, especially for heavy and awkwardly shaped parts. Plus, it's easier to set up and operate, making it a favorite in aerospace and heavy machinery industries.

5-Axis Turnmill: Flexibility Meets Precision

Next in our evolutionary tale is the 5-axis turnmill. This machine takes flexibility and precision to a whole new level. Imagine cutting a piece from five different angles without resetting the workpiece. That's exactly what a 5-axis turnmill does. It combines the capabilities of a turning center with a milling center, allowing for complex shapes to be made much more efficiently. This is a big win for industries that require intricate parts, like medical devices and automotive.

Special-Purpose Machines: Custom Solutions for Unique Needs

While VTLs and 5-axis turnmills are versatile, sometimes you need a machine that's a perfect fit for a very specific job. That's where Special-purpose machines come in. These machines are designed and built to do one thing but do it well. Whether it's a machine that only makes a specific gear or is designed for a particular manufacturing process, these machines fill a unique niche. They may not be as versatile as their counterparts, but they are unmatched when it comes to efficiency and precision for specific tasks.

Integrating the Three: The Modern Manufacturing Environment

Today's manufacturing environment is all about integration. It's not just about having a Vertical Turning Lathe, a 5-axis turnmill, or a Special-purpose machine. It's about how these machines work together to create a seamless, efficient production line. This integration allows manufacturers to be more flexible, adapting quickly to new market demands or changes in production needs. It also opens up possibilities for innovation, as each machine's unique capabilities can be combined creatively to solve complex manufacturing challenges.

The Role of WIDMA in This Evolution

WIDMA has been at the forefront of this manufacturing evolution. With a deep understanding of the industry's needs and a history of innovation, WIDMA has developed a range of machines that push the boundaries of what's possible. Their offerings include advanced Vertical Turning Lathes, versatile 5-axis turn mills, and Special-purpose machines tailored to meet specific manufacturing challenges. But WIDMA's contribution goes beyond just the machines.

Expertise and Innovation

WIDMA's expertise in integrating these machines into cohesive manufacturing solutions sets them apart. They don't just sell machines; they provide solutions. Whether it's a complete production line incorporating a VTL for rough machining, a 5-axis turnmill for precision work, or a Special-purpose machine for unique tasks, WIDMA ensures that each component works flawlessly together.

Support and Service

Moreover, WIDMA's commitment to support and service ensures that manufacturers can maximize their investment. From initial setup to ongoing maintenance, WIDMA ensures their machines keep running at peak performance. This level of support is crucial in a manufacturing environment where downtime can be costly.

Training and Education

Finally, WIDMA recognizes that having the right machines is only part of the equation. The other part is having skilled people who know how to use them. That's why they offer comprehensive training and education programs, ensuring operators and technicians have the skills they need to maximize the potential of their Vertical Turning Lathes, 5-axis turnmills, and Special-purpose machines.

Conclusion

The evolution of manufacturing is a story of innovation, precision, and efficiency. At the heart of this story are the Vertical Turning Lathes, 5-axis turnmills, and Special-purpose machines that have transformed how we make things. Integrating these machines has opened up new possibilities, making manufacturing more flexible and responsive. And with companies like WIDMA leading the way, the future of manufacturing looks brighter than ever. As we continue to innovate and integrate, who knows what we'll be able to make next?

0 notes