#3D Printing Materials Market

Text

Revolutionizing Industries: 3D Printing Materials Market Set to Surge to US$ 6.6 Billion by 2033

The market for 3D printing materials is anticipated to reach an estimated value of US$ 6.6 billion by 2033, up from US$ 1.8 billion in 2023, and grow at a compound annual growth rate of 14.2% between 2023 and 2033.

During the projection period, it is expected that the market for 3D printing materials will grow at an astounding 14.2% CAGR. Worldwide sales of 3D printers are being driven by the quick uptake of technologically superior production equipment across numerous industries, which is anticipated to expand the market in the upcoming years.

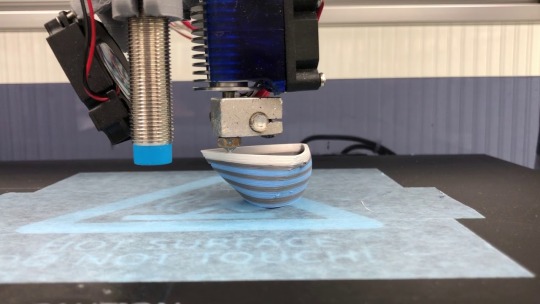

Raw materials used for 3D printing include plastics, ABS, PLA, metals & powders, carbon fibers, and resins. The market is being supported by the growing trend of using 3D printers to produce a range of small and large products.

Request a Sample of this Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-1777

Additionally, the market is anticipated to develop as 3D printing is increasingly used in the building and construction industry. Additionally, it is projected that the rise of the automotive, aerospace, electronics, and medical industries will continue to be a major growth driver of the global market for 3D printing materials.

North America is anticipated to continue to be a lucrative region in the global market for 3D printing materials, according to FMI. The rapid commercialization of cutting-edge technology like 3D printing across a variety of businesses in the area is responsible for the growth.

Key Takeaways:

By material type, sales in the metal segment are forecast to grow at a 14.9% CAGR over the assessment period.

Based on form, demand for powder 3D printing materials is projected to increase at a 13.5% CAGR through 2031.

In terms of applications, sales in the automotive sector are forecast to gain traction at a 13.6% CAGR over the forecast period.

The U.S. will emerge as a lucrative pocket in the North American 3D printing materials market.

Sales in the China 3D printing materials market are projected to increase at a 15.2% CAGR through 2031.

Competition Landscape

Key market participants in the global 3D printing materials market elaborated in the report include Covestro AG, Arkema S.A., Sandvik A.B., Evonik Industries A.G., EOS GmbH Electro Optical Systems, Ultimaker B.V., Hoganas AB, The EXONE Company, General Electrics, 3D Systems Corporation, Materialise NV, STRATASYS LTD, and MARKFORGED Inc.

Key market participants are focusing on the development of innovative 3D printing products to improve their product portfolios. Besides this, players are also investing in mergers, acquisitions, and collaborations to expand their global presence.

For instance:

In April 2021, Sandvik and its subsidiary BEAMIT Group announced a new capacity for additive manufacturing components in super-duplex stainless steel, an alloy that combines mechanical strength with extremely high corrosion resistance.

Request for Methodology:

https://www.futuremarketinsights.com/request-report-methodology/rep-gb-1777

3D printing materials Market By Category

By Material Type:

Plastics

Metals

Ceramics

Others

By Form:

Filament

Powder

Liquid

By Application:

Electronics & Consumers

Automotive

Medical

Industrial

Education

Aerospace

Others

0 notes

Text

Ceramic Substrates Market Will Reach USD 11,740.8 Million By 2030

In 2023, the ceramic substrates market was valued at USD 7,721.3 million. Forecasts indicate it will grow significantly, reaching USD 11,740.8 million by 2030, with a projected compound annual growth rate (CAGR) of 6.3% between 2024 and 2030. This growth of the industry can be credited to the increasing need for such materials in many sectors and the trend of the reduction of electronic…

View On WordPress

#3D Printing Materials Market#ceramics#Competitive Landscape#composites#growth prospects#innovations#Investors#Key players#Manufacturers#market drivers#metals#polymers#regulatory landscapes#researchers#Technological advancements#Trends

0 notes

Text

#3d Printing Materials Market#3d Printing Materials Market Trends#3d Printing Materials Market Growth#3d Printing Materials Market Industry#3d Printing Materials Market Research#3d Printing Materials Market Report

0 notes

Text

3D Printing Materials Market by Market - North America, Europe, EMEA, APAC : US, Canada, China, Germany, UK - Forecast 2023-2027

The global 3D Printing Materials Market, spanning North America, Europe, EMEA, and APAC regions, including key countries like the US, Canada, China, Germany, and the UK, anticipates a significant upsurge.

Forecasted between 2022 and 2027, the market is set to witness a substantial USD 3,786.41 million increase, boasting an impressive Compound Annual Growth Rate (CAGR) of 22.51%. This growth trajectory reflects a burgeoning demand for 3D printing materials across diverse regions and markets, indicating a transformative phase for the industry.

As innovation drives this 3D Printing Materials Market expansion, industry players strategize to leverage this promising trend, fostering a landscape ripe for technological advancements and market dominance.

#3D Printing Materials Market#3D Printing Materials Market Size#3D Printing Materials Market Share#3D Printing Materials Market Analysis#3D Printing Materials Market Report

0 notes

Text

3D Printing Materials Market Size, Share, Report 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated global 3D printing materials market size at USD 2.1 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects the global 3D printing materials market size to grow at a robust CAGR of 17.6% reaching a value of USD 6.51 billion by 2029. Major growth drivers for global 3D printing materials market include an increasing need for polymers in 3D printing, a rising demand for mass customization, and government initiatives to encourage and facilitate the adoption of 3D printing. The global 3D printing market is expected to further expand due to the rising demand for 3D printing, as well as the increased demand for better quality materials in various industries such as automotive and aerospace. Also, the use of 3D printing reduces the risk of errors and is highly advantageous for production, leading to an increase in market growth during the forecast period. However, high cost of 3D printing materials, equipment, and maintenance and limited availability of high-quality and specialized 3D printing materials are anticipated to restrain the market growth during the period in analysis.

Global 3D Printing Materials Market - Overview

3D printing, also known as additive manufacturing, is a process that produces an object in three dimensions using 3D printing materials. Initially, simple thermoplastics and wax were used for 3D printing, but now, diverse materials in powder, liquid, and filament form are widely used. The automotive industry can drive market growth in the future by using technologies such as Fused Filament Fabrication (FFF) to create prototypes and end-use components. 3D printing materials and equipment allow speedy prototyping and find their end-users in creating molds, grips, and fixtures. The increasing demand for 3D printing from the aerospace and defense industries will drive 3D printing materials and equipment market share. It offers flexibility in product design and helps in producing highly detailed and sleek models.

Sample Request @ https://www.blueweaveconsulting.com/report/3d-printing-materials-market/report-sample

Impact of COVID-19 on Global 3D Printing Materials Market

COVID-19 adversely affected the global economy and caused uncertainty in all industries, including the 3D printing materials market. However, the healthcare sector experienced a surge in demand for medical equipment and devices required for COVID-19 treatment. This increased demand for medical equipment and personal protective equipment created opportunities for 3D printing companies globally. PLA and PETG materials were predominantly used to produce face shields due to their high resistance to temperature and weather conditions, contributing to the growing demand for 3D printing materials worldwide. In 2021, the global 3D printing materials market recovered due to the rising demand from the healthcare and industrial sectors worldwide. Hospitals and healthcare organizations are increasingly seeking environmentally friendly printing materials and 3D printers to produce critical equipment.

Global 3D Printing Materials Market – By Type

By type, the global 3D printing materials market is divided into Plastics, Metals, and Ceramics segments. The plastic type segment held the highest share in the global 3D printing materials market due to several factors. Plastic is a widely available and affordable material, making it a popular choice for 3D printing. Additionally, plastics offer a wide range of properties that make them suitable for various applications. For example, ABS (Acrylonitrile Butadiene Styrene) is commonly used for prototyping and functional parts due to its durability and resistance to impact. PLA (Polylactic Acid) is another popular plastic used in 3D printing due to its biodegradability and sustainability. Furthermore, advancements in 3D printing technology have made it possible to produce high quality plastic parts with complex geometries and intricate details, making it a preferred choice for a wide range of industries.

Competitive Landscape

Major players operating in the global 3D printing materials market include Stratasys, 3D Systems, Arkema, Royal DSM, EOS GmbH, Materialise NV, Evonik Industries AG, SABIC, BASF SE, CRP Technology Srl, EnvisionTEC, Solvay SA, HP Inc., Carbon Inc., and Dow Chemical Company. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Link

TOP 10 COMPANIES IN DENTAL 3D PRINTING MATERIALS MARKET

#healthcare#Dental 3D Printing Materials Market#Dental 3D Printing Materials#Dental 3D Printing#Dental#3D Printing Materials Market#3D Printing Material#3D Printing Materials#3D Printing#Printing Materials#health

0 notes

Link

The 3D Printing Material market size is estimated to reach US$8.6 billion by 2027 after growing at a CAGR of around 22.5% from 2022 to 2027. Three-dimensional (3D) printing is a type of additive manufacturing that converts a digital design into a physical object.

#3D Printing Materials Market#3D Printing Materials Market Research#3D Printing Materials Market Research Report

0 notes

Text

3D Printing Materials Market - Forecast(2022 - 2027)

The 3D Printing Material market size is estimated to reach US$8.6 billion by 2027 after growing at a CAGR of around 22.5% from 2022 to 2027. Three-dimensional (3D) printing is a type of additive manufacturing that converts a digital design into a physical object. The method involves spreading down thin layers of material, such as liquid or powdered plastic, metal, cement, polyamide, polycarbonate, carbon fiber, nitinol, or acrylonitrile butadiene styrene, and then fusing them. Due to extensive research and development in 3D printing, as well as increased demand for prototype applications from numerous industrial verticals, such as healthcare, automotive, aerospace, and military, the market is expected to grow. The global impact of the COVID-19 epidemic on the 3D printing materials market has been unfavorable. Due to the significant demand for medical equipment and gadgets for COVID-19 therapy, healthcare was the least affected sector. With the widespread use in the production of face shields, the demand for biodegradable thermoplastic polymer/polylactic acid (PLA) materials has skyrocketed.

Report Coverage

The report: “3D Printing Material Market Report– Forecast (2022-2027)” by IndustryARC covers an in-depth analysis of the following segments of the industrial enzymes industry.

By Type

– Plastic (Acrylonitrile Butadiene Styrene, Nylon, Polylactic Acid, High Impact Polystyrene, Polyvinyl Alcohol, Polyethylene Terephthalate, and Others), Metal (Steel, Aluminium, nickel & Alloys, Cobalt & Alloys and Others), Ceramic and Others.

By Form

- Powder, Filament, and Liquid.

By Technology

– Stereolithography, Fuse Deposition Modelling (FDM), Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), Electron Beam Melting (EBM), Multi Jet Fusion (MJF), and Others.

By Application

– Spare Parts, Dental Products, Prosthetics, Jewellery, Glasses and Eyewear, Tooling Model Making, Functional Prototypes, and Others.

By End-use Industry

– Automotive (Passenger Cars, Light Commercial Vehicle, Heavy Commercial Vehicle), Aerospace & Défense (Commercial Aviation, Military Aviation, Medical and Healthcare, Consumer Goods), Building & Construction (Residential, Commercial, Industrial), and Others.

By Geography

- North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Middle East (Saudi Arabia, UAE, Israel, Rest of the Middle East) and Africa (South Africa, Nigeria, Rest of Africa), and Rest of the World [Middle East (Saudi Arabia, UAE, Israel, and Rest of the Middle East), and Africa (South Africa, Nigeria, and Rest of Africa)]

Key Takeaways

Asia-Pacific dominates the 3D printing materials market, owing to the increasing automotive industry in the region. The automotive industries in APAC are being fueled by rising per capita income and increasing urbanization, as well as a growing population.

Including 3D printing in the design process has several benefits, including the ability to produce high-detail, smooth, and scale models for aircraft designs. Thus, aircraft manufacturers are extensively incorporating 3D printing materials in the aerospace industry, thereby propelling the market growth.

The usage of 3D printing materials in manufacturing applications is growing rapidly around the world. Several end-use industries, such as automotive, healthcare, aerospace, and defense, have already embraced 3D printing for large component manufacturing.

3D printing is being used to make car components, mobile cases, wing mirrors, toys, and a variety of other things. End-use industries are moving toward 3D printing for bulk manufacturing because it lowers manufacturing costs, shortens lead times, and produces complex structural things.

3D printing is a more convenient way to make products, but it is costly due to high material costs, which is a major market constraint. The greater expenses are due to the higher purity and composition criteria required for 3D printing.

Figure: Asia-Pacific 3D Printing Materials Market Revenue, 2021-2027 (US$ Billion)

For more details on this report - Request for Sample

3D Printing Materials Market Segment Analysis – By Type

The plastic segment held the largest share in the 3D printing materials market and is expected to grow with a CAGR of over 21.8% during the forecast period. Plastic is the most widely used raw material for 3D printing as it is one of the most versatile materials for 3D-printed toys and household fittings. Plastic filaments come in translucent and bright colors, with red and lime green being particularly popular. They're marketed on spools and have a matte or shiny feel. Plastic's attraction is easy to understand, given its firmness, flexibility, smoothness, and wide range of color options. Plastic is a comparatively cost-effective material for both makers and consumers. The expansion of the plastic segment in the market will be driven by increased demand for 3D printing technology along with a rising need for high-performance materials from industries such as automotive, aerospace, and healthcare. Furthermore, low-cost development and production of complex designs, as well as less weight and no material costs, will raise plastic demand in the global market.

3D Printing Materials Market Segment Analysis - By End-use Industry

The Automotive industry segment held a significant share in the 3D printing materials market and is expected to grow with a CAGR of over 23.2% during the forecast period. In the automotive sector, 3D printing materials are frequently utilized to create scaled models for testing. Bellows, front bumpers, air conditioner ducting, suspension wishbones, dashboard interfaces, alternator mounting brackets, battery covers, and other components are also made from them. For quick prototyping, automotive OEMs are turning to 3D printing materials. The automotive industry is flourishing at a rapid pace, globally, for instance, according to the International Organization of Motor Vehicle Manufacturers (OICA), automobile output increased by 10% in the first nine months of 2021, to 57.26 million vehicles, up from 52.15 million units in the same period last year. Therefore, the automotive industry's demand for 3D printing materials is predicted to increase in the future.

3D Printing Materials Market Segment Analysis - By Geography

Asia-Pacific region held a significant share in the 3D printing materials market and is expected to grow with a CAGR of around 24.6% during the forecast period. The increased interest of APAC manufacturing enterprises in 3D printing technology, as well as several government-led plans and legislation, have contributed to the region's rapid growth. China is one of the most rapid-growing marketplaces for new technology and materials. According to the Organisation Internationale des Constructeurs d'Automobiles (OICA), automotive production and Vietnam grew by 1.2 percent and 5.5 percent from the previous year to 5,71,632 and 2,50,000 units, respectively, in 2019. According to Invest India, In FY21, India exported 4.1 million vehicles. From April 2021 to June 2021, Indian automobile exports totaled 1,419,430 units, compared to 436,500 units from April 2020 to June 2020. According to the National Bureau of Statistics of China, China accounts for 70% of the global desktop 3D printer market. Thus, with increasing, application and demand in the End-use industry, the 3D printing materials market will grow rapidly during the forecast period.

3D Printing Materials Market Drivers

Increasing Demand from Aerospace Sectors

The aerospace sector was one of the first to embrace 3D printing technology. The method is particularly beneficial for manufacturing complex pieces. It gives designers the advantage of producing the best parts at a lower cost. Many airplane parts, including wings, jigs, and engine parts, are made using 3D printing materials, such as metals. Titanium materials are commonly utilized as 3D printing materials in the aerospace sector because they have great mechanical qualities and can be manufactured with high dimensional accuracy. The automotive sector is being transformed by 3D printing technology. Technology has aided the industry in producing more complicated and lighter structures at lower costs. 3D-printed parts are used in several Formula 1, supercars, and concept cars. According to the International Trade Administration, the commercial space industry in the United Kingdom is rapidly expanding, with a turnover of more than $22.8 billion in 2020, and the country aims to capture 10% of the global space market by 2030. According to the Indian Brand Equity Foundation, The Indian aerospace and defense (A&D) sector is expected to grow to US$ 70 billion by 2030, Domestic air travel demand increased by 33% to 52 lakh passengers in October 2020, compared to September, due to rising demand for upgraded infrastructure and government initiatives. Thus, significant growth in the aerospace industry is fuelling the growth of the 3D printing materials market.

Growing Demand for 3D Printing Materials in Healthcare

In terms of volume, the healthcare industry is the 3D printing materials market's fastest-growing segment. 3D printing technology is used to make various medical products, including surgical equipment, prostheses and implants, and tissue engineering devices. Furthermore, 3D printing materials are beneficial in orthopedic, dental, craniomaxillofacial, and other medical fields. Additive manufacturing is quite helpful to create patient-specific products that fit the patient's anatomy. One of the most potential industries for additive manufacturing in healthcare, and the COVID-19 pandemic scenario is no exception. Face shields, N95 masks, and other protective gear are being manufactured to help doctors, medical professionals, and individuals combat the new coronavirus. Stratasys Inc. and 3D Systems Corporation, and a few startups are among the major manufacturers. According to the Center for medical care and medical services, Healthcare spending by the US government increased 36.0 percent in 2020, compared to 5.9 percent in 2019. Such government initiatives are set to increase the demand for 3D printing materials in the healthcare sector.

3D Printing Materials Market Challenges

Reducing Lead Time

Reducing the lead time associated with these materials, particularly metals, is one of the main issues 3D printing material manufacturers face. A decrease in lead time would imply a reduction in inventory and a decline in costs. The ultimate things made from metal take a long time to complete. Manufacturers must build on existing materials and technology that appeal to the 3D printing sector to solve this problem. The industry's lengthy lead time is preventing most businesses from moving to additive manufacturing from their traditional manufacturing process, which is slowing 3D printing adoption in major end-use industries, including aerospace and defense, automotive, and electrical and electronics.

3D Printing Materials Industry Outlook

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the 3D printing materials market. 3D printing materials market top 10 companies include:

3D Systems, Inc.

Arcam AB

CRP TECHNOLOGY S.r.l.

ENVISIONTEC, INC.

EOS GmbH-Electro Optical Systems

ExOne GmbH

LPW Technology Ltd

Royal DSM N.V.

Stratasys Ltd.

The Arkema Group

Recent Developments

In November 2021, iAMfootwear Consortium consisting of Framas, Dyemansion, EOS, Siemens, Twikit, and Arkema is bringing to life a shoe with a customized high-performance 3D printed midsole made from Pebax® elastomers using the DigitalFoam™ concept.

In June 2021, Covestro AG and Nexeo Plastics have announced the creation of a new PC/ABS filament for 3D printing called Addigy FPB 2684 3D. Nexeo Plastics' distribution platform is where the company offers this product.

In May 2021, Covestro AG launched Arnite AM2001 GF (G) rPET, a glass-fiber filled recycled polyethylene terephthalate (rPET) for 3D pellet printing generated from post-consumer PET waste.

#3D Printing Materials Market#3D Printing Materials Market share 3D Printing Materials Market foreacast 3D Printing Materials Market size

0 notes

Link

#3D Printing Materials Market#3D Printing Materials Market Size#3D Printing Materials Market Share#3D Printing Materials Market Report

0 notes

Text

The Journey Ahead: 3D Printing Materials Market on Track to US$ 6.6 Billion by 2033

The market for 3D printing materials is anticipated to reach an estimated value of US$ 6.6 billion by 2033, up from US$ 1.8 billion in 2023, and grow at a compound annual growth rate of 14.2% between 2023 and 2033.

During the projection period, it is expected that the market for 3D printing materials will grow at an astounding 14.2% CAGR. Worldwide sales of 3D printers are being driven by the quick uptake of technologically superior production equipment across numerous industries, which is anticipated to expand the market in the upcoming years.

Raw materials used for 3D printing include plastics, ABS, PLA, metals & powders, carbon fibers, and resins. The market is being supported by the growing trend of using 3D printers to produce a range of small and large products.

Request a Sample of this Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-1777

Additionally, the market is anticipated to develop as 3D printing is increasingly used in the building and construction industry. Additionally, it is projected that the rise of the automotive, aerospace, electronics, and medical industries will continue to be a major growth driver of the global market for 3D printing materials.

North America is anticipated to continue to be a lucrative region in the global market for 3D printing materials, according to FMI. The rapid commercialization of cutting-edge technology like 3D printing across a variety of businesses in the area is responsible for the growth.

Key Takeaways:

By material type, sales in the metal segment are forecast to grow at a 14.9% CAGR over the assessment period.

Based on form, demand for powder 3D printing materials is projected to increase at a 13.5% CAGR through 2031.

In terms of applications, sales in the automotive sector are forecast to gain traction at a 13.6% CAGR over the forecast period.

The U.S. will emerge as a lucrative pocket in the North American 3D printing materials market.

Sales in the China 3D printing materials market are projected to increase at a 15.2% CAGR through 2031.

Competition Landscape

Key market participants in the global 3D printing materials market elaborated in the report include Covestro AG, Arkema S.A., Sandvik A.B., Evonik Industries A.G., EOS GmbH Electro Optical Systems, Ultimaker B.V., Hoganas AB, The EXONE Company, General Electrics, 3D Systems Corporation, Materialise NV, STRATASYS LTD, and MARKFORGED Inc.

Key market participants are focusing on the development of innovative 3D printing products to improve their product portfolios. Besides this, players are also investing in mergers, acquisitions, and collaborations to expand their global presence.

For instance:

In April 2021, Sandvik and its subsidiary BEAMIT Group announced a new capacity for additive manufacturing components in super-duplex stainless steel, an alloy that combines mechanical strength with extremely high corrosion resistance.

Request for Methodology:

https://www.futuremarketinsights.com/request-report-methodology/rep-gb-1777

3D printing materials Market By Category

By Material Type:

Plastics

Metals

Ceramics

Others

By Form:

Filament

Powder

Liquid

By Application:

Electronics & Consumers

Automotive

Medical

Industrial

Education

Aerospace

Others

0 notes

Text

Seeing crochet clothing being 'in' now is always kind of frustrating as someone who can actually crochet for shit (evidence attached) because as much as I'd love to be able to maybe sell some of that work, ultimately you can't compete with that store (machine?)grade shit. A crochet maxi-skirt made from granny squares is selling for AUD $60. AUD $60 wouldn't even cover the cost of the materials (in a nice, wearable quality yarn). :/

Well at least when I make something I know it's not gonna be basic bitch shit -

#kerytalk#crochet#fuck corpos#I guess I can file this under that#also no joke this has been on the last row for nearly a year because I'm just 'if I finish it what the fuck do I do#I think it cost me idk ... 150? AUD for materials#this is just acrylic but it doesn't feel shit#I flip flop on starting a small business for money because I do have a lot of creative hobby knowledge I can sell#crochet and then I can make seed-bead earrings#I can sew decent too#made a bunch of masks during the pandemic#I just really do not have the energy to market that shit though#right now I'm considering learning to sculpt jewellery for 3D printing#but I think I'd need someone to team up with because managing that commercially is beyond me#I GUESS#ventpost

23 notes

·

View notes

Text

Revolutionizing Healthcare: The Intersection of 3D Bio-Printing and Organ-on-a-Chip Technology

Introduction:

In the ever-evolving landscape of healthcare technology, the convergence of 3D bio-printing and organ-on-a-chip (OOC) technology represents a monumental leap forward. This groundbreaking synergy holds the promise of revolutionizing drug discovery, toxicology testing, and personalized medicine.

In this article, we delve into the transformative potential of combining 3D bio-printing with OOC technology and its implications for the future of healthcare.

According to Next Move Strategy Consulting, the global 3D Bio Printing Market is predicted to reach USD 4.10 billion with a CAGR of 17.6% by 2030.

Download FREE Sample: https://www.nextmsc.com/3d-bio-printing-market/request-sample

Understanding Organ-on-a-Chip Technology: Organ-on-a-chip technology involves the fabrication of microscale devices that mimic the structure and function of human organs. These miniature systems, often referred to as "organs-on-chips," consist of microfluidic channels lined with living cells that replicate the physiological complexity of native tissues. By recapitulating key aspects of organ physiology, such as tissue architecture, cellular interactions, and biomechanical forces, OOC platforms offer a more physiologically relevant model for studying human biology and disease.

The Promise of 3D Bio-Printing: On the other hand, 3D bio-printing enables the precise fabrication of three-dimensional tissue constructs using a layer-by-layer deposition of biomaterials and living cells. This innovative technology allows researchers to engineer complex tissue structures with spatial organization and cellular diversity, closely resembling native tissues and organs. By harnessing the power of 3D bio-printing, scientists can create custom-designed tissue models for a wide range of applications, from regenerative medicine to drug screening.

Inquire before buying: https://www.nextmsc.com/3d-bio-printing-market/inquire-before-buying

The Synergy Unleashed: When 3D bio-printing meets organ-on-a-chip technology, the result is a synergistic platform that combines the structural fidelity of bio-printed tissues with the physiological functionality of OOC devices. By integrating bio-printed tissues into microfluidic chambers, researchers can recreate the microenvironment of human organs and study their responses to drugs, toxins, and disease stimuli in a controlled and reproducible manner.

Revolutionizing Drug Discovery: One of the most promising applications of 3D bio-printing combined with OOC technology is in drug discovery. Traditional two-dimensional cell culture models often fail to accurately predict the efficacy and toxicity of drugs in humans, leading to high failure rates and costly clinical trials.

With 3D bio-printed organ-on-a-chip platforms, pharmaceutical companies can conduct more accurate preclinical testing, identifying promising drug candidates and potential adverse effects early in the development process. This not only reduces the time and cost associated with drug discovery but also enhances patient safety by ensuring that only the most effective and safe therapies advance to clinical trials.

Geographical Analysis:

North America region is expected to continue holding the lion share of 3D bio printing market during the forecast period. This is attributed to factors such as highly developed healthcare infrastructure, technological advancements, growing elderly population, and increasing prevalence of chronic ailments.

However, Asia-Pacific region is expected to show a steady rise in the 3D bio printing market due to technological developments in pharmaceutical sector.

Challenges and Future Directions: While the advancements in biomaterials have propelled the field of 3D bio-printing to unprecedented heights, several challenges remain on the horizon. Achieving regulatory approval for bio-printed products, ensuring reproducibility and scalability, and addressing biocompatibility concerns are among the key hurdles that researchers must overcome.

Furthermore, optimizing the printing parameters and bio-ink formulations to mimic the complexity of native tissues remains a formidable task. However, with ongoing research and collaborative efforts, the future holds immense promise for emerging biomaterials in 3D bio-printing.

Transforming Toxicology Testing: In addition to drug discovery, 3D bio-printed organ-on-a-chip platforms have the potential to revolutionize toxicology testing. Traditional animal models often fail to accurately predict human responses to environmental toxins and industrial chemicals, leading to regulatory challenges and public health concerns. By utilizing human-derived cells in bio-printed OOC devices, researchers can mimic the physiological responses of human organs to toxic compounds, providing more relevant and reliable toxicity data. This enables regulators to make informed decisions about chemical safety and environmental risk assessment, ultimately protecting human health and the environment.

Pioneering Personalized Medicine: Furthermore, the combination of 3D bio-printing and organ-on-a-chip technology opens new avenues for personalized medicine. By utilizing patient-specific cells and tissues in bio-printed OOC devices, clinicians can create customized models of disease pathology and drug responses, allowing for tailored treatment strategies. This personalized approach holds promise for improving patient outcomes and reducing adverse drug reactions, particularly in complex diseases such as cancer and neurological disorders. Moreover, bio-printed OOC platforms can serve as valuable tools for studying rare genetic conditions and developing targeted therapies for individual patients.

Enhanced Drug Testing: Bio-printed organ-on-a-chip (OOC) platforms enable more accurate and efficient drug testing processes. By mimicking the microenvironment of human organs, these platforms provide better insights into drug efficacy and toxicity, leading to the development of safer and more effective medications.

Accelerated Drug Development: The integration of 3D bio-printing with organ-on-a-chip technology expedites the drug development process. Researchers can rapidly prototype and test various drug formulations on bio-printed OOC devices, reducing the time and cost associated with traditional preclinical studies.

Advancements in Regenerative Medicine: Bio-printed tissues and organs-on-chips hold immense potential for regenerative medicine applications. These technologies enable the fabrication of complex tissue structures with precise control over cellular composition and spatial organization, facilitating the development of novel therapies for tissue repair and regeneration.

Patient-Specific Drug Screening: With bio-printed OOC models incorporating patient-specific cells, clinicians can perform personalized drug screening assays. This approach allows for the identification of drugs that are most effective for individual patients, optimizing treatment outcomes and minimizing adverse reactions.

Simulation of Disease Progression: Bio-printed organ-on-a-chip systems can simulate the progression of various diseases, providing researchers with valuable insights into disease mechanisms and progression. This capability enables the development of more targeted therapeutic interventions and personalized treatment regimens.

Integration with AI and Machine Learning: The combination of bio-printing and organ-on-a-chip technology with artificial intelligence (AI) and machine learning algorithms enhances predictive modeling and data analysis. This integration enables researchers to uncover complex relationships between genetic factors, disease pathways, and drug responses, leading to more precise diagnostics and therapies.

Competitive Landscape:

The 3D bioprinting industry comprises of various players such as Cyfuse Biomedical K.K., CELLINK, Organovo Holdings Inc., BioBots, Aspect Biosystems Ltd., Ourobotics, Aerotech Inc.,3D Bioprinting Solutions, GE Healthcare Life Sciences, Bio3D Technologies, Advanced Solutions Inc. These manufacturers are actively indulging in R&D initiatives, product & technology innovations, and industrial collaborations to enhance their products and increase their growth and geographical reach.

For instance, in January 2021, 3D Systems announced the expansion of its regenerative and bioprinting solutions. This decision was taken by collaborating with United Therapeutics Corporation. They are aiming to enable novel laboratory testing methods to accelerate the development of new drug therapies while reducing the need for animal testing.

Also, in January 2020, GE Healthcare Life Sciences inaugurated an additive manufacturing facility and manufacturing footprints in Sweden. This new facility would be dedicated to integrating 3D-printed parts into the company’s production of bio-manufacturing equipment.

Conclusion:

In conclusion, the intersection of 3D bio-printing and organ-on-a-chip technology represents a paradigm shift in healthcare research and development. By combining the structural complexity of bio-printed tissues with the physiological relevance of OOC platforms, researchers can create powerful tools for drug discovery, toxicology testing, and personalized medicine.

As this transformative technology continues to evolve, we can expect to see accelerated progress in understanding human biology, discovering new therapies, and improving patient care. The future of healthcare is here, and it's being shaped by the innovative synergy of 3D bio-printing and organ-on-a-chip technology.

0 notes

Text

3D Printing Extrusion Materials Market: Exploring UV-Curable Resins for Rapid Prototyping

3D Printing Extrusion Materials is Booming on the Back of Growing Adoption of Additive Manufacturing

The global 3D printing extrusion materials market is experiencing significant growth driven by rapid developments in additive manufacturing technology. 3D printing extrusion materials such as photopolymers, filaments, and pellets offer advantages including high dimensional accuracy, lightweight and durable designs, and cost-effective production of complex geometries. The ability of 3D printing extrusion materials to produce intricate functional parts without tooling or fixtures has boosted their use across various end-use industries including aerospace, automotive, healthcare, consumer goods, and construction.

The Global 3D Printing Extrusion Materials Market is estimated to be valued at US$ 12.77 Billion in 2024 and is expected to exhibit a CAGR of 19% over the forecast period from 2023 to 2030.

3D printing extrusion materials enable mass customization and on-demand manufacturing, which has increased their demand for prototyping and production applications. Continuous technological advancements focused on developing enhanced material properties such as strength, durability, and temperature resistance are further driving the market.

Key Takeaways

Key players operating in the 3D printing extrusion materials are 3D Systems Corporation, Stratasys Ltd., Materialise NV, EOS GmbH, Arkema S.A., SABIC, Evonik Industries AG, DuPont de Nemours Inc., BASF SE, Dow Chemical Company, HP Inc., Royal DSM N.V., EnvisionTEC GmbH, CRP Group., Carbon, Inc. These companies are focusing on new product launches and capacity expansion strategies to strengthen their market position.

The growing demand for 3D printed parts and components across various industries is a major factor propelling the 3D printing extrusion materials market. Industries are increasingly adopting 3D printing for rapid prototyping, tooling, and production applications due to advantages such as low costs and reduced turnaround times.

The market is also witnessing increased global expansion as players are enhancing their distribution networks across emerging economies. The rising investments in additive manufacturing technologies and growing R&D activities globally present significant growth opportunities for 3D printing extrusion materials over the forecast period.

Market Key Trends

Particle size reduction and new material formulations are notable trends being observed in the 3D printing extrusion materials market. Market players are focusing on further miniaturization of particle sizes to enable the production of micro-scale features and complex geometries. Continuous innovation in specialty polymer materials including carbon-reinforced, flame-retardant, and biocompatible varieties are expanding the application horizons for 3D printing extrusion materials. The market is also witnessing new opportunities through the development of hybrid and composite materials with blended properties. With the rising popularity of additive manufacturing, the demand for high-performance 3D printing extrusion materials is expected to exhibit strong growth over the next decade.

Porter's Analysis

Threat of new entrants: New companies find it difficult to enter the market due to the significant capital investments required for manufacturing 3D printing extrusion materials.

Bargaining power of buyers: Buyers have moderate bargaining power due to the availability of alternatives and substitutes.

Bargaining power of suppliers: Suppliers have moderate bargaining power due to the availability of options for buyers and dominance of few players.

Threat of new substitutes: threat of substitutes is moderate with emerging new alternative 3D printing technologies.

Competitive rivalry: The market is dominated by few major players and there is intense competition.

Over the years, North America has been dominating the 3D printing extrusion materials market owing to increasing demand from industries such as aerospace & defense and healthcare. USA holds a significant share in North America. The aerospace & defense industry in USA is increasingly utilizing 3D printing for lightweight components and complex parts for aircraft. The region has witnessed high investments in R&D and new product launches by key players such as 3D Systems Corporation and Stratasys, Ltd.

Asia Pacific region is expected to grow at the highest CAGR during the forecast period owing to growing demand from application industries such as consumer goods and foundry in countries such as China and India. Foundry application offers vast opportunities for 3D printing extrusion materials market in Asia Pacific. Expanding manufacturing sector, easy availability of skilled labor force, and government initiatives are promoting adoption of advanced technologies including 3D printing.

#3D Printing Extrusion Materials Market gowth#3D Printing Extrusion Materials Market share#3D Printing Extrusion Materials Market Trend

0 notes

Text

3D Printing Filament Material Market is expected to grow at a significant rate of around 19% during the forecast period.

0 notes