Text

Principles of Operation of Variable Reflectivity Mirror

One alternative is to apply a single layer on a relatively thick, highly reflecting mirror substrate. It could be a high-index dielectric material or a metallic covering. Furthermore, spatially changeable layer thickness dielectric Variable reflectivity mirror is conceivable. The spatial dependence can be added, for instance, by using a mask to deposit a material flux that is dependent on location. To create mirrors whose reflectivity depends exclusively on radial direction, the substrate is frequently rotated during deposition.

Other manufacturing techniques are also possible, like the spatially dependent modification of reflection properties after the production of initially homogeneous mirrors. If such surface modifications are carried out by laser light, a large range of reflectance forms can be produced.

It should be emphasized that Fractional handpiece will not be produced by a simple Gaussian variation in the layer thickness values of the Bragg mirror. This is because the interference conditions in such a mirror cause the reflectance to have a complex dependence on the Bragg wavelength. The variable reflectance could differ slightly from a flat surface or a prescribed curved surface. These modifications could be minimal for a lot of applications.

Be aware that variations in the thickness of the entire Oem laser head as well as interference effects in dielectric coatings may result in variations in optical phase alterations in addition to variations in reflectance. Only a very small minority of mirror manufacturers can create variable reflectivity mirrors, and those mirrors are quite uncommon in second-hand mirrors.

Applications of Mirrors with Variable Reflectivity

In lasers with unpredictable resonators, variable reflectivity mirrors are typically employed as output couplers. The laser beam would typically tend to get bigger and bigger in a resonator, but in this case the fluctuating reflectivity limits the diameter. Mirrors with Gaussian reflectance are commonly employed. By using this Optical design consulting technique, it is possible to create lasers with high beam quality and output beams that are nearly diffraction-limited, or mode areas with sizable mode areas. Several high-power lasers, including CO2 lasers and various solid-state lasers, are affected by this.

0 notes

Text

Why Effective Laser Design Consulting Designs Matter

It should go without saying that the performance potential of your technology can only be fully realized through good product design. It makes Laser design consulting possible to produce goods that are lightweight, durable, easy to use, dependable, and affordable to produce.

Product development that is as efficient as possible: A carefully thought-out Picosecond seed source design will maximize the efficiency of the product development process. An expedited development process results in earlier income and earlier creation of market position. When Diode pumped laser costs are taken into consideration, these factors are important but sometimes overlooked. Utilize designs with improved fabrication tolerances or designs with fewer parts to lessen manufacturing difficulties.

The Role of laser system Design in the Development Process

A Component of laser system design is typically thought of as a written document that summarizes the lessons learned at the end of the development phase. The problem with that approach is that there is too much "trial and error" and the development process could not have a solid enough basis as a result. Since they usually have undesirable side effects, problems are frequently difficult to assess in the lab and are even more difficult to solve with design changes at this point. The thorough design document must be developed before the prototype is built and tested. The goal of any design process that takes place at a desk must be to identify and resolve any possible difficulties that may occur because design adjustments may be performed here quickly and inexpensively.

There are several benefits to a well-organized development process, including:

Overall effort and cost are reduced because meticulous preparation at the desk saves money and time compared to iterations in the lab.

The final product design most likely offers better dependability, performance, and manufacturing ease.

The challenges are thoroughly understood, which is helpful for forthcoming projects.

The team's competence is reinforced and you become less reliant on the lone skill of individual employees because the outcomes are meticulously documented and discussed within the team.

0 notes

Text

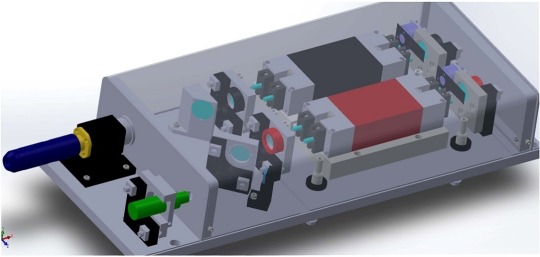

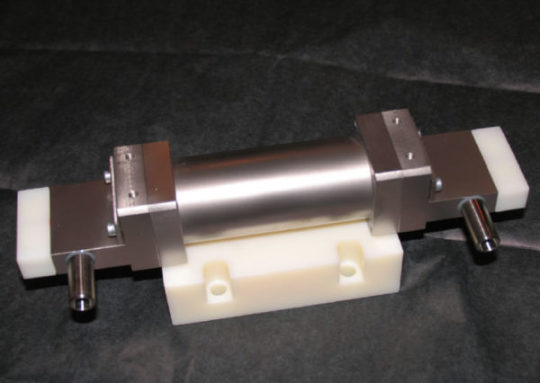

Custom OEM Modular Lasers and Its Function

High-quality precision laser modules are needed in many applications today for a range of tasks including alignment and guidance, 3D measurement and analysis, industrial, medical, and dental, as well as research and 3D printing. Because each application is unique, not all system requirements can be addressed by using a commercial laser solution. Our team works with customers to design and produce tailored laser diode-based solutions that meet these challenging application-specific criteria for wavelength, beam characteristics, output power, lifetime, and other parameters.

In our capacity as a distributor of laser diodes and a laser integrator with in-house engineering and manufacturing capabilities, we offer customers a special combination of design experience, strong supplier partnerships, and ongoing engineer-to-engineer help. We have a lot of years of experience developing Oem laser system design & development, and we can reduce time to market by employing our significant "design bank." We also make advantage of our existing ties with the engineers and R&D staff at the major laser diode manufacturers in order to gain early access to new technology. We provide durable, high-quality, and affordable Oem medical laser heads rapidly to provide our clients a competitive edge.

Improved Technology

With our unique mix of technology expertise and established vendor relationships, we are able to design the optimal custom laser module that is specifically matched to your application requirements using the latest laser diodes, lenses, drive electronics, and module housings. As a distributor and integrator of laser diodes for the past years, we carefully collect and store the most modern diodes with a variety of wavelengths and power outputs from several high-quality manufacturers.

Our diverse team of professionals also has a thorough understanding of the optical, mechanical, electronic, and software design approaches that enhance the performance of our custom laser modules.

Conclusion

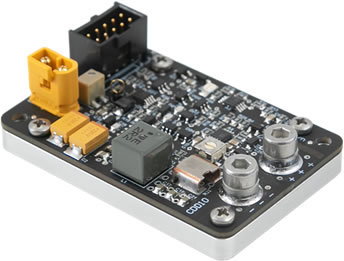

We can design drive electronics to make use of newer, more advanced technologies in order to include digital control and monitoring features that will increase the lifespan of your laser modules.

0 notes

Text

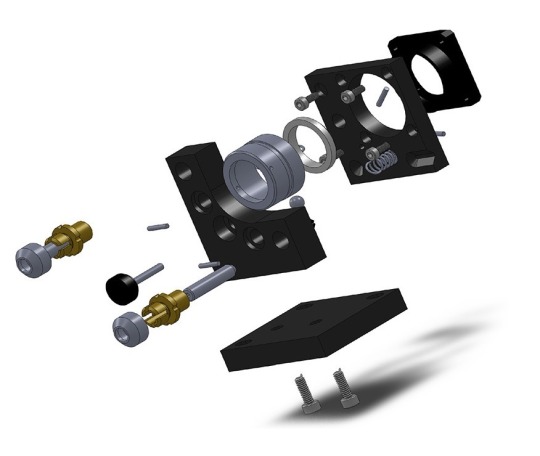

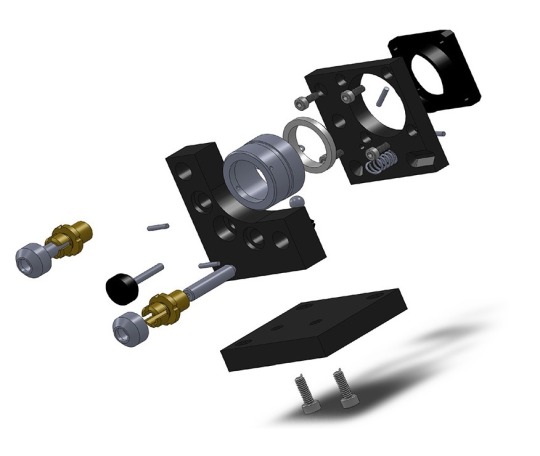

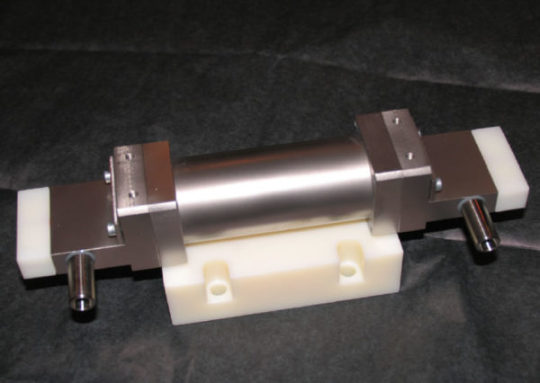

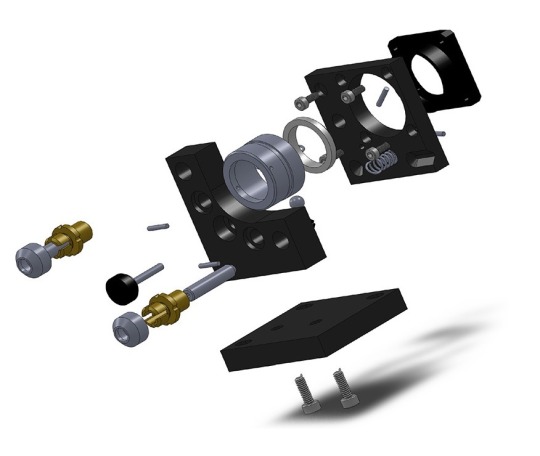

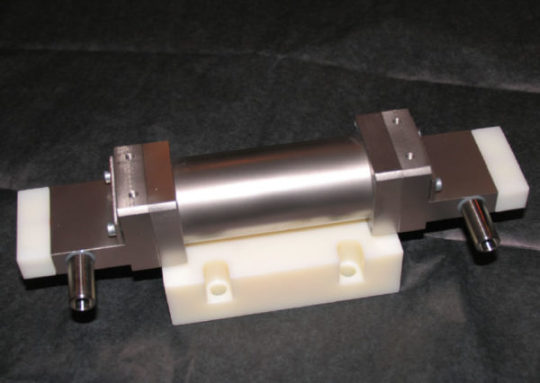

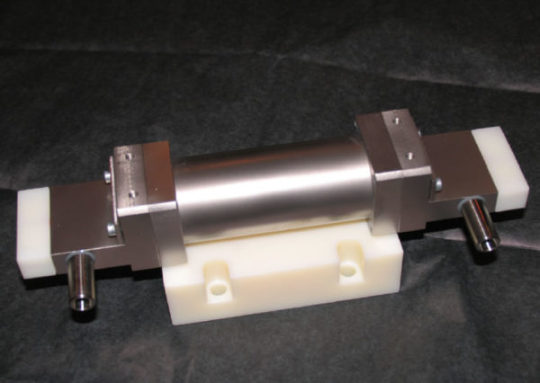

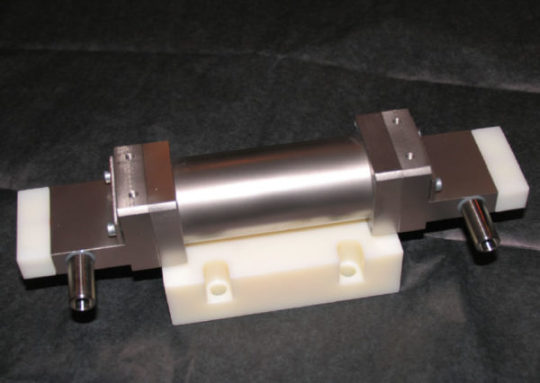

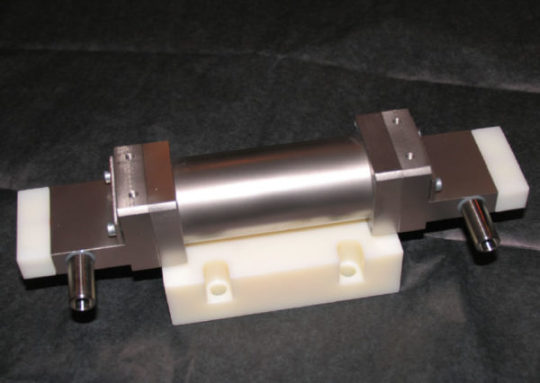

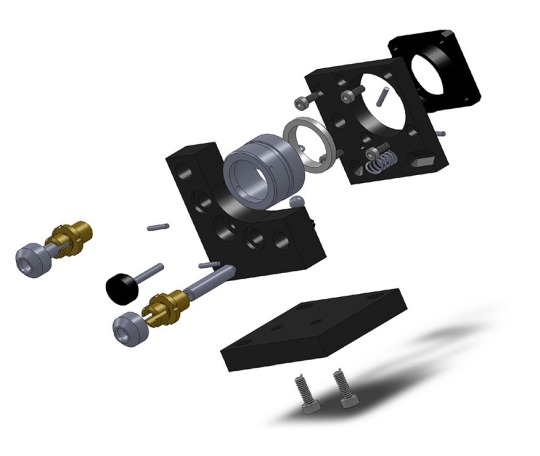

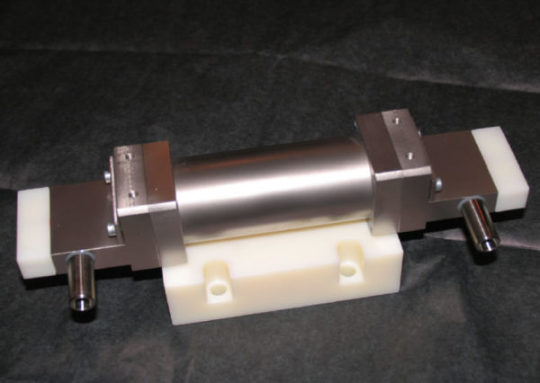

Oem Laser Head and Its Features

CO2 and fiber laser markers have been used in production lines for a long time, however, they have drawbacks. If you've ever had to deal with marking speeds that fall short of your expectations, a lack of assistance from a laser professional, or problems with part positioning to be in focus, it could be time to switch to better laser marking systems.

Why Oem laser head is used

Every time a laser is benchmarked, it performs better in terms of speed, reading rate, and positioning tolerance. Our Oem laser head experts provide you with the tools you need to guarantee consistent outcomes. Additionally, our air knife prevents dust from collecting on the lens, and our focusing mechanism modifies the marking to take positional changes into consideration.

Systems Using OEM Lasers for Integrators

Each laser series offers a range of power outputs, operates at a specific wavelength, and is specifically designed for a given application. In contrast to our fiber laser marking systems, our Oem laser head marking systems are perfect for treating organic materials.

Principles of operation and variable-reflectivity mirrors

One alternative is to apply a single layer on a relatively thick, highly reflecting mirror substrate. For example, it could be a high-index dielectric material or a metallic covering. Furthermore, spatially changeable layer thickness dielectric multilayer mirrors are conceivable.

The spatial dependence can be added, for instance, by using a mask to deposit a material flux that is dependent on location. To create Variable reflectivity mirror whose reflectivity depends exclusively on radial direction, the substrate is frequently rotated during deposition.

Other manufacturing techniques are also possible, like the spatially dependent modification of reflection properties after the production of initially homogeneous mirrors.

Conclusion

If surface modifications are carried out by laser light, a large range of reflectance forms can be produced. This is because the interference conditions in such a mirror cause the reflectance to have a complex dependence on the wavelength.

0 notes

Text

Why Picosecond Alexandrite are Useful

Picosecond laser technology promotes the synthesis of collagen, which makes the skin smooth and wrinkle-free, in addition to curing wrinkles, blemishes, and freckles. A picosecond laser can also be used to get rid of tattoos. It is now feasible to completely break down the color pigment with less treatment time than with traditional laser techniques because to the introduction of the Picosecond alexandrite, which delivers significant energy in a short amount of time. Furthermore, it removes a specific color pigment without endangering neighbouring tissues or thinned skin. It can also be used to treat pigmentation that appears on the lips, armpits, and base of the breasts.

The results

Results for people with freckle problems can usually be seen after 1-2 sessions. After five to six sessions of persistent therapy, people with more severe problems will start to experience improvements. Nevertheless, depending on the quality and intensity of the pigment used to make the tattoo, the outcomes of a Fractional handpiece technique may vary. Laser therapy should be used twice for tattoo removal and once a month for freckle removal.

Pre- and post-picosecond laser guidance

In advance of the process

You are advised to avoid outdoor activities for at least two weeks prior to treatment. You should inform your doctor if you have ever had a drug allergy, especially to anaesthetics or other drugs, before starting therapy. However, cosmetics, nourishing creams, and hairspray shouldn't be applied to the laser-treated area.

After the treatment

Avoid bathing or applying cosmetics to the laser treatment area until the scabs are completely gone.

Stay out of the water for two days after the treatment. Dry the wound with a clean cloth if it comes in contact with water.

Apply ointment or any other topical medication as advised by your doctor.

Avoid touching the wound by refraining from scraping, peeling, or engaging in any other action that might have an impact.

Consult a doctor as soon as possible if the wound exhibits any anomalies, such as a rash, swelling, discomfort, or itching.

0 notes

Text

How Oem Laser Electronics are Very Useful

Instead of being marketed as complete laser systems, industrial lasers are usually sold as OEM laser modules. As a result, a laser OEM sells lasers to one or more other producers who then combine them into larger gear, including laser material processing equipment.

When this happens, each company can concentrate on its particular areas of accountability without needing to completely understand the system. In particular, understanding the nuances of how an OEM module functions internally shouldn't be frequently required of the integrator.

Features of Oem laser electronics

Oem laser electronics can contain gas lasers, lamp-pumped lasers, diode-pumped solid-state lasers, lamp-pumped solid-state lasers, and less frequently other kinds of lasers. Additional optical components for beam sizing and perhaps nonlinear frequency conversion may also be present in the housing. For instance, there are green laser modules that generate Nd: YAG laser beams that are frequency-doubled at the typical wavelength. Another option is to send the light output as a free-space er glass through an optical connection.

An OEM laser typically, but not always, has its own full enclosure, even if the device is to be integrated into a larger product with its own closed housing. This encourages even more labor separation between laser manufacturers and system integrators.

Differentially Reflective Mirrors

The Graded reflectivity mirror offers a high damage threshold, spectral stability, and fine spatial control of the intensity and phase characteristics of laser beams. Through the use of very precise Ion Beam Sputtered technology, our graded reflectivity laser mirrors meet the needs of demanding and harsh applications, such as cavity optics in unstable resonator lasers, by offering environmental stability and mechanical durability.

Conclusion

Additionally, it improves the optical performance of the output beam, especially at low magnifications. The tapered reflectivity profile also reduces ripples in the field profile when employed with high intensity lasers, reducing the risk of optical damage.

0 notes

Text

Why Laser Design Consulting is Useful

To help you obtain the exact designing of anything you're going to make, Laser design consulting are frequently required in many different industrial verticals. In the medical sector, where accuracy is crucial, laser design advice services are in high demand. Depending on your desire, you must carefully weigh the particulars and select the finest options in accordance with your particular needs.

Our greatest companies are online in order to do this. There are a number of reputable businesses in this industry that can give you precise answers and complete help at every turn. The best applicant must be chosen, they must understand the procedure, and they must be given the remaining task. The majority of diode-pumped lasers are solid-state lasers, also referred to as diode-pumped solid-state lasers. This Diode pumped laser are bulk lasers that use a sort of laser crystal or bulk pieces of glass, or users although it is usually used for fiber lasers. Both categories of equipment contain high-power lasers, which have output levels ranging from a few mille watts to many kilowatts.

Vertical external-cavity surface-emitting lasers, optically pumped semiconductor lasers, and some extremely exotic varieties of diode-pumped gas lasers, including vapor lasers, are less common. Patients heal and recover more quickly with the Fractional handpiece, which uses a cutting-edge YSGG laser and water atomization. The incident photon energy, must match the energy differences between the excited states and the ground state since optical pumping is a resonant operation. The expression for optical pumping is where A is the atom in its ground state and A* is its counterpart atom in its stimulated state. Features and amenities:

FDA-approved for popular, effective, and secure dermatologic skin resurfacing therapy

Both hands can use the handpiece with its ergonomic design.

Numerous procedures don't require the use of a local or topical anesthetic.

Compared to more intrusive therapies, there is a lesser chance of complications

Conclusion

If the laser light's wavelengths are inside the active medium's absorption bands, we can use it for pumping. Due to its incredibly narrow bandwidth, laser light has the potential for quite high pumping efficiency.

0 notes

Text

Five Ways to be More for VIGITEK MEDICAL

VIGITEK MEDICAL LASER CONSULTANTS offers our best medical device service for use in medical areas. We shall provide all types of laser service devices. If interested our service then contacts us now.

https://vigitek.biz/

0 notes

Text

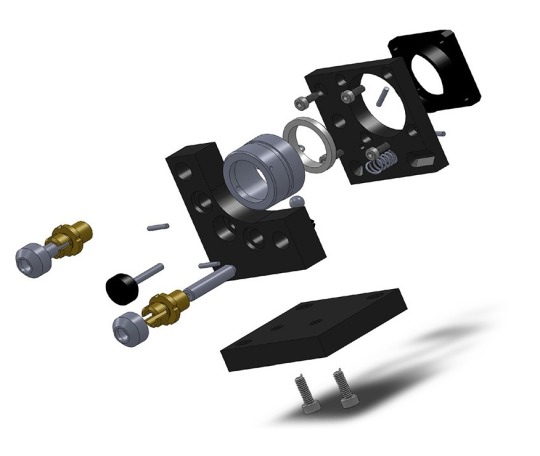

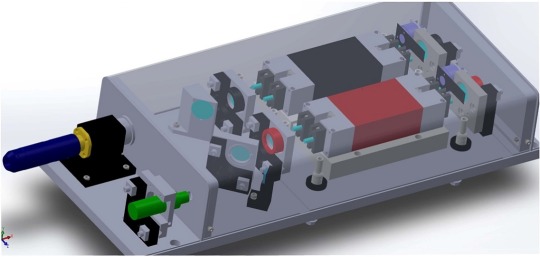

Laser Resonator Design with Complete Solutions Online

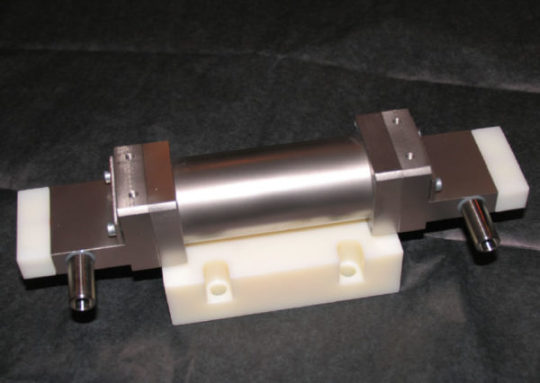

Laser solutions are frequently required for varied processes. Choosing the right tools, component and systems is important. Laser resonator design is equally important that plays a crucial role in the operation and performance of laser systems. A laser resonator is an optical cavity that consists of two mirrors that form a feedback loop for the laser beam.

These mirrors are carefully designed to create a resonant cavity that allows for the amplification and generation of coherent light. The resonator design and its components greatly influence the output characteristics of the laser like beam quality, power, and stability. Another key part of laser resonator design is the choice of mirror configuration. A resonator consists of two mirrors

A high reflectivity mirror (HR)

A partially transmitting mirror (output coupler).

The first one reflects most of the laser light, while the output coupler allows a fraction of the light to exit the cavity as the laser beam. The reflectivity and transmission characteristics of these mirrors determine the laser's output power and efficiency.

Another important design consideration is the stability of the resonator. Stability is crucial to maintain a well-defined and predictable laser output. The most commonly used stable resonator configurations are the plane-parallel resonator and the confocal resonator.

Find the top company and you will also get some other solutions like alexandrite regenerative amplifier, Flashlamp ignition circuit, Laser pump cavity and a lot more. Stay in touch with experts and get the right solutions.

0 notes

Text

Variable Reflectivity Mirrors and Their Uses in Different Ways

Variable reflectivity mirrors are versatile devices that dynamically adjust their reflectivity to optimize visibility and control light transmission. They are commonly used in automobiles to reduce glare and enhance driving safety. Such types of mirrors find applications in architecture to regulate light and heat in buildings, as well as in scientific instruments to improve image quality. With their ability to adapt to changing lighting conditions, variable reflectivity mirrors offer practical solutions for various industries.

A variable reflectivity mirror, also known as an electrochromic mirror or auto-dimming mirror

It is a type of mirror that can automatically adjust its reflectivity based on external lighting conditions

This innovative technology offers several benefits and finds applications in various fields.

The primary purpose of a variable reflectivity mirror is to reduce glare and improve visibility for the driver of a vehicle

Such mirror type contains an electro-chromic gel or film between two layers of glass, which changes its opacity in response to an electric current.

When the mirror detects bright lights, such as headlights from other vehicles, it darkens to reduce the glare and provide a clearer view for the driver. In low-light conditions, the mirror remains transparent, allowing maximum visibility.

For variable reflectivity mirrors, what all you have to do is search for the right company that is convenient for you and places your order accordingly. Find the right one and you will also get Fractional handpiece, OEM laser head, Optical design consulting and similar other devices.

0 notes

Text

Diode Pumped Laser and Component of Laser Systems at Competitive Rates

Are you looking for the right solutions for laser designs or need component for laser systems along with diode pumped laser and details about their working procedure?

Do you want to get support from experienced professionals for laser design consulting?

You will get the right solutions and support from top companies, where experts are working dedicatedly to provide you with the right solutions and support for diode pumped lasers, component of laser systems with a complete guide, Picosecond seed source and laser design consulting services. You have to search for the right company and choose the best one after going through the reviews and knowing about their previous work record.

If you don’t have any idea, you will get precise solutions by going online that is counted as one of the convenient ways to help you in finding what exactly you are looking for. Check all details and get the right solutions according to your specifications.

Among some of the top names in this domain from where you will get the right solutions for laser design consulting, Picosecond seed source, diode pumped laser and component of laser system, you will find name of Vigitek on top – solving your queries successfully and providing you with complete peace of mind. You have to make a contact as per your requirement, go through the details and get the right solutions according to your specifications and details.

0 notes

Text

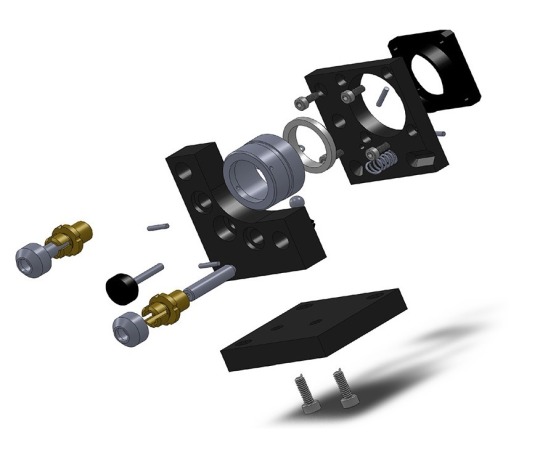

The Power of Oem Laser Modules in Body Shaping

Advanced technology plays a crucial role in the quest for perfect body contours. Laser body shaping has emerged as a popular non-invasive technique to sculpt and reshape various body areas. The OEM laser module is at the heart of this transformative process, accompanied by key components such as the IGBT discharge circuit. This blog will explore the significance of OEM laser modules & IGBT discharge circuits in revolutionizing laser body shaping.

Importance Of These Laser Techniques

1. OEM laser modules

OEM laser module are meticulously designed and manufactured to deliver precise energy for body-shaping applications.

These incorporate high-performance laser diodes and optical components, providing a reliable and efficient laser source.

With their compact size and versatile integration options, OEM laser modules enable seamless integration into body-shaping devices, ensuring effective treatment and optimal results.

2. Laser Body Shaping:

Laser body shaping techniques have gained popularity as they target specific body areas.

The controlled energy emitted by the OEM laser module can effectively reduce unwanted fat deposits.

The precision and versatility of laser body shaping techniques offer patients a less invasive alternative to traditional surgical procedures.

3. IGBT Discharge Circuit:

The IGBT discharge circuit is a critical component in laser body shaping devices, enabling efficient and controlled delivery of laser energy.

This circuit regulates the electrical discharge needed to activate the laser diodes within the OEM laser module.

The IGBT circuit ensures optimal performance and safety by precisely controlling the discharge timing and energy levels.

Conclusion

In conjunction with the IGBT discharge circuit, OEM laser modules have revolutionised the field of laser body shaping. These advanced technologies enable precise and controlled laser energy delivery. With the versatility and reliability of OEM laser modules, patients can achieve their desired body aesthetics through non-invasive procedures.

0 notes

Text

The Synergy of Stem Design & Development in Laser Body Shaping

Laser body shaping has become a popular non-invasive cosmetic procedure for achieving desired body contours. Behind the scenes of this transformative technology lies a convergence of STEM (Science, Technology, Engineering, and Mathematics) design and development, particularly in laser optical system and flashlamp drivers.

In this blog, we will explore the significant role of STEM in the design and development of laser body-shaping technologies, enabling safe and effective procedures.

Role of Stem in Design & Development

Laser Optical System:

STEM design and development are pivotal in optimizing laser optical systems for body shaping.

These systems incorporate lenses, mirrors, and filters to ensure precise beam delivery and controlled energy distribution.

Through meticulous design and engineering, STEM professionals enhance the efficiency and effectiveness of laser body-shaping treatments, targeting specific areas while minimizing the impact on surrounding tissues.

Laser Body Shaping:

Laser body shaping involves the application of controlled laser energy to target unwanted fat deposits and promote skin tightening.

By combining optics, engineering, and mathematics expertise, STEM professionals design laser systems that maximize efficacy while ensuring patient safety and comfort.

Flashlamp Driver

The flashlamp driver is a critical component of laser body shaping systems, providing the high-intensity light pulses needed for the laser to operate.

STEM professionals employ their electrical engineering and circuit design knowledge to develop efficient and reliable flashlamp driver.

Conclusion

Oem Laser STEM design and development are indispensable in advancing laser body shaping technologies. Through optimizing laser optical systems, STEM professionals enhance the precision and effectiveness of treatments, targeting specific areas for fat reduction and skin tightening. As STEM continues to drive innovation, the field of laser body shaping will benefit from ongoing advancements, offering individuals new possibilities for achieving their desired aesthetic goals.

0 notes

Text

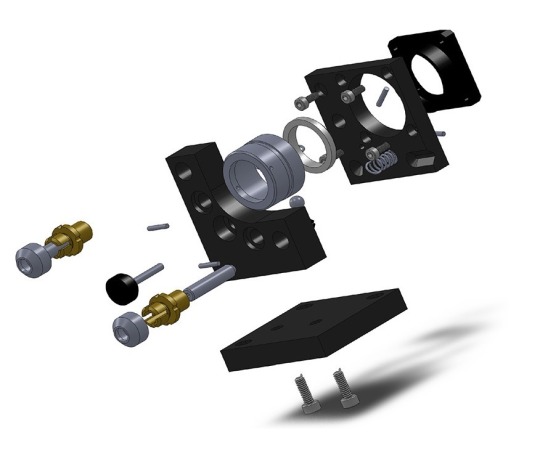

Harnessing Precision: The Role of Laser Design Consulting

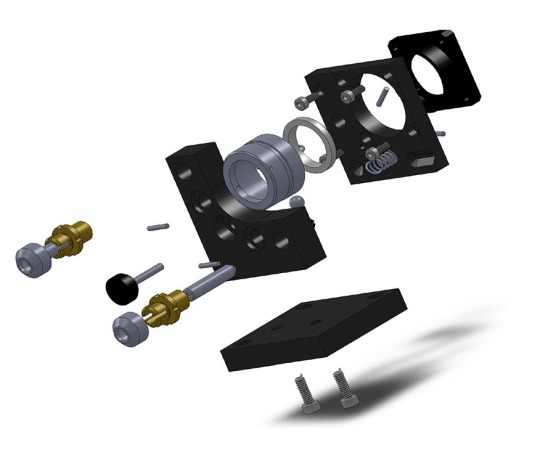

In advanced technology and scientific breakthroughs, lasers have emerged as an indispensable tool across various industries. However, designing an efficient laser system requires specialised expertise, where laser design consulting comes into play.This blog will explore key components such as laser pump cavities, laser diode controllers, and graded reflectivity mirrors that are crucial in laser design consulting

The actual Roles of Laser Design Consulting

Let us discuss some of the important roles of laser designing control:

Laser pump controller:

The laser pump cavity is the heart of a laser system, providing the necessary energy to stimulate the lasing medium.

Laser design consultants analyze and optimize the pump cavity to ensure efficient energy transfer and minimal losses.

By carefully selecting the appropriate pump source, such as laser diodes, consultants maximize output power and improve overall system performance.

Laser Diode Controller:

A laser diode controller regulates the current and temperature of laser diodes, ensuring their stable and reliable operation.

Laser design consultants work closely with manufacturers to select and integrate the most suitable controllers for specific laser applications.

They consider power requirements, wavelength stability, and protection mechanisms to optimize laser performance while extending the diode's lifespan.

Graded Reflectivity Mirror:

Graded reflectivity mirror play a crucial role in laser resonators by allowing the extraction of a highly coherent laser beam while reflecting unused energy into the cavity. Laser design consultants collaborate with optics specialists to design and optimize these mirrors for specific laser systems.

Conclusion:

Laser design consulting offers invaluable expertise in optimizing laser systems for various applications. Consultants ensure the highest performance and efficiency through meticulous analysis and optimization of key components such as laser pump cavity, laser diode controller, and graded reflectivity mirrors. Whatever the process, laser design consulting provides the necessary guidance to harness the power of lasers effectively. As technology advances, laser design consulting becomes increasingly crucial.

0 notes

Text

Revolutionizing Laser Technology: The Power of Picosecond Alexandrite

Are you tired of the same old laser treatments that take forever to show results? Look no further than picosecond Alexandrite technology! This innovative laser treatment is revolutionizing the industry, offering faster and more effective results for various skin concerns. Say goodbye to long sessions and hello to beautiful, glowing skin in no time. Read on to learn more about the power of picosecond Alexandrite.

The Picosecond Alexandrite Laser Pump Chamber

The previous decade has seen tremendous advancements in laser technology. Today's lasers are powerful and efficient, producing many different types of beams with pinpoint accuracy. But there is one area where lasers still have room to improve - their pump systems.

Laser pump chamber is essential components of laser technology, responsible for rapidly moving the amplified light beam from the laser source to the target. Pump systems can be expensive and challenging to build, limiting their usage in more affordable lasers.

Pwm-Igbt Driver Circuit

Picosecond Alexandrite lasers might transform laser technology. Picosecond pulses power this laser's high-power beams. It may be used for lithography and area marking.

Picosecond Alexandrite lasers are multifunctional. It produces short or lengthy pulses and may be pointed in any direction. Pwm igbt driver circuit is ideal for medicinal and industrial uses.

Conclusion

In today's world, lasers are ubiquitous and essential for various applications. But what makes a laser beam so powerful and helpful? The answer lies in the way that picosecond Alexandrite lasers emit their light. These devices have revolutionized laser technology by allowing scientists to create microscopic beams of light and study phenomena in unprecedented detail.

Thanks to these fantastic lasers, can now detect subatomic particles and make incredible advances in medical treatment. So whether you're using a standard laser pointer or one of the latest high-power models, thank picosecond Alexandrite lasers for making your life easier!

0 notes

Text

Maximizing Efficiency with a High-Quality Pulsed Laser Diode Driver

Manufacturing and industrial workers realize the need for dependable and efficient equipment to keep operations operating smoothly. Original equipment manufacturer laser heads are standard. What is an original equipment manufacturer laser head, and how can it help your business? This blog article will discuss the benefits of using an OEM laser head for industrial applications. Get ready to learn about cutting-edge technology that might change your workplace!

Benefits of OEM Laser Head for Industrial Applications

Industrial Original equipment manufacturer laser heads have numerous advantages:

• Increased productivity — Original equipment manufacturer laser heads provide quicker and more precise machine connection.

• Improved quality – Original equipment manufacturer laser heads cut more precisely and consistently, improving product quality.

• Reduced downtime – Original equipment manufacturer laser heads eliminate machine calibration and adjustment, reducing downtime.

How Does the Variable Reflectivity Mirror Work?

Laser heads have fixed or variable reflectance. Fixed reflectivity mirrors have a constant reflectivity, whereas variable reflectivity mirror may be modified. This article focuses on the latter.

How do variable mirrors work? It alters light reflection using electro-optics. Voltage may enhance or decrease mirror reflectivity. It is perfect for industrial laser beam control.

Industrial variable mirrors have several advantages. It improves laser beam control. Laser-targeting is more precise. Second, it saves energy by reflecting just the light required. Third, lowering laser beam strength promotes safety. Variable mirrors improve industrial laser control and accuracy.

Conclusion

Laser body shaping for industrial applications can provide many benefits to various industries. It is an incredibly versatile tool used in diverse and complex applications. By understanding this technology's advantages, businesses can leverage its capabilities and reduce costs while increasing efficiency and improving product quality. With its wide range of features, an Original equipment manufacturer laser head could be just what your business needs to remain competitive in today's challenging industrial environment.

0 notes

Text

Why Optical Design Consulting is Critical for High-Performance Laser Systems

Need a powerful laser system for your company or research? Do you realize how crucial optical design consultancy is to success?

Laser Design Consulting prioritizes diode-pumped lasers. Compared to standard laser systems, semiconductor diodes pump the laser medium in these lasers, improving efficiency and performance. Materials production, medicinal therapies, and scientific research employ diode-pumped lasers.

Consulting of Laser Design also knows fractional handpiece. These handpieces heal scars, wrinkles, and pigmentation defects in cosmetic and medical operations. Laser handpieces generate regulated micro-injuries in the skin to encourage the body's natural healing mechanism and collagen synthesis.

Laser Design also consults on optical design. Optical designers employ complex software and modeling tools to improve lenses, mirrors, and prisms. Laser systems' performance and efficiency depend on these systems' design and optimization.

Laser Design Consultancy specializes in laser technology and optical design consultancy. Diode pumped laser, handpieces fractional, and optical design advice assist customers in creating and optimizing laser systems for various applications.

What are the Benefits of Optical Design Consulting?

Optical design consultancy has various advantages, but three are:

Reducing System Costs: Laser optics cost the most. You may customize optical requirements for your application by engaging with an optical design specialist from the outset. This may reduce optics and system costs.

Enhancing System Performance: Optical design improves system performance. The system will fulfill performance criteria with fewer components and complexity. An efficient optical system will also reduce operational expenses.

Boosting System Reliability: Optical systems commonly work in challenging or demanding settings. Experienced optical designers may include these issues in system design. This improves system reliability and reduces downtime.

Conclusion

High-performance laser systems need optical design consulting. By studying optical design, manufacturers may make more powerful, efficient lasers for many purposes. Companies may optimize designs quickly and cheaply with an optical designer. Thus, companies must recognize optical design consultants' contributions to laser system success and reliability.

0 notes