#types of FIBC bags

Text

Choosing the Right FIBC Bag: A Complete Guide!

Shankar Techx provides the best FIBC Bags. Here, know how Choosing the Right FIBC Bag with Complete Guide. Like, What Makes FIBC Bags So Important, How to Choose the Right FIBC Bag for Business purpose, Some Factors FIBC Big Bags, etc. For for info on FIBC jumbo bags manufacturer in India, visit our blog!

#FIBC jumbo bags manufacturer in India#filter fabric manufacturer#scrim suppliers#FIBC Bag#types of FIBC bags

0 notes

Text

What Are the Specifications for Cross Corner FIBC Bags?

Are you finding FIBC jumbo bags manufacturers in Gujarat? Shankar Pack is the top FIBC bag supplier in Gujarat. There are many types of FIBC bags in this we discuss about specifications of cross-corner bulk bags like body structure, lift style, fabric, coating, and resistance for more info visit our website.

0 notes

Text

FIBC Bags Type B - Durable Bulk Material Handling Solution

Looking for reliable FIBC Bags Type B exporters & suppliers? Woven International offers high-quality bulk bags for all your industrial packaging needs.

0 notes

Text

#Conductive FIBC Bags#Conductive FIBC Bags Manufacturers & Suppliers India#Packing Solutions#Packaging Solutions#Packing Plastipacks#Bulk Container Bags#Uses of Conductive FIBC#Conductive FIBC Bags Manufacturer in India#Conductive C Type FIBC Bag Manufacturer#FIBC Conductive Bags#Conductive Bags Supplier#FIBC Bags Manufacturers & Supplier in India

0 notes

Text

What is Bagging Machine? - Payper India

A bagging machine is a type of industrial equipment used to automate the process of filling and sealing bags with various products. These machines are widely used in different industries, such as food, pharmaceuticals, chemicals, and agriculture, to efficiently package goods ranging from powders and granules to liquids and solids.

Image Ref : What is Bagging Machine — Payper India

Key Functions of Bagging Machines:

Filling: The machine accurately dispenses a pre-set amount of product into each bag. This can be achieved through various mechanisms, such as volumetric fillers, auger fillers, or weigh scales, depending on the nature of the product being packaged. Click here for Ref : www.payperindia.com

Sealing: After the bag is filled, the machine seals it to ensure the product is contained and protected. Sealing methods can include heat sealing, ultrasonic sealing, or using adhesive tapes, depending on the bag material and the product requirements. Click here for Ref : www.payperindia.com

Cutting/Trimming: Some bagging machines also trim excess material from the sealed bags to ensure a neat and uniform appearance. Click here for Ref : www.payperindia.com

Types of Bagging Machines:

Valve Bagging Machines: Designed for heavy-duty products such as cement, sand, or chemicals, these machines fill bags through a valve and then seal the valve to prevent leakage. Click here for Ref : www.payperindia.com

Open-Mouth Bagging Machines: Used for bulk products like grains, animal feed, or fertilizers, these machines fill pre-made bags that are manually or automatically positioned under the filling spout. Click here for Ref : www.payperindia.com

FIBC- Jumbo Bagging Machine: A jumbo bagging machine, or bulk bag filling machine, is designed to fill large bags (500–2000 kg) with bulk materials.

Why Payper ?

Payper India develops and manufactures bagging machines for all types of bulk solids such as powders or granulates. Other important product lines are palletizers and complete lines.

Our customers come from many different sectors, e.g., Chemical Industry, Agro-food Industry, Mining Industry and Building Industry. Payper India offers a comprehensive solution for each sector.

No need or demand is too small neither too big for us. We supply bagging machines for smaller industries with low volume requirements. We also provide complete turnkey projects for customers with high demands as to capacity and speed.

What matters to us is that our customer is comfortable and satisfied with the solution we have developed for them

Visit Payper at — https://www.payperindia.com/

Business LinkedIn -http://bit.ly/45Y1xMQ

Twitter — https://twitter.com/PayperIndia

Instagram — https://www.instagram.com/payperindia/

#payper#payperindia#baggingmachines#manufacturer#industry#machinery#robotics#palletisers#jumbobaggingmachine

2 notes

·

View notes

Text

UV Masterbatches: Importance and benefits

In this business-centric blog, we are going to highlight UV Stabilizer masterbatch, and why, and how it has become an integral part of the plastic industry. Also, our focus will remain on UV master batch manufacturer.

Before we take deep dive into the subject, it makes sense to learn about masterbatches.

What is a masterbatch?

Masterbatch is a solid additive engineered for plastic. It is designed for adding color to plastic-made items. At the same time, the product imparts a wide range of properties to plastics. The latter is called additive masterbatches. It is a concentrated mixture of pigments or additives. Which is encapsulated during a heat process into a carrier resin. This mixture is then cooled and cut into a granular shape.

For in-depth knowledge about the product, you can connect with a leading masterbatch manufacturer in India, Ahmedabad.

Unique features of masterbatch

Plenty of unique features make this product suitable for the plastic industry. Here are a few important qualities of masterbatches that make them ideal for various items made using plastic:

High jets

No Issues of bleed or bloom

Easy to process

UV stability

Uniform dispersion

Resistant to high-temperature

Learning about the UV Stabilizer masterbatch

Exposure to sunlight and some artificial lights can have adverse effects on the useful life of plastic products. UV radiation can break down the chemical bonds in a polymer. This process is called photodegradation. It ultimately causes cracking, chalking, color changes, and the loss of physical properties. To counteract the damaging effect of UV light, UV stabilizers masterbatch are used to solve the degradation problems associated with exposure to sunlight. In case, you have any doubt, regarding the product, you can connect with a prominent UV master batch manufacturer, UV master batch supplier, like Sumiran Masterbatches.

Properties of a quality-driven UV Stabilizer masterbatch

1% to 5% loading with polymers for better result

High resistance to extraction

Long-Term UV Resistance

Excellent surface characteristic

Applications

UV Stabilizer masterbatch has found usages in numerous applications, given its properties and salient features. These include:

Agricultural greenhouse film, FIBC bags, moulded crates, drums, garbage cans, garden furniture, outdoor articles etc…

Tarpualin, Roto moulded Water Tank

Shaded Net

Woven sacks, HDPE/PP raffia tapes, LDPE/LLDPE/PP lamination.

All types of PP/PE made products.

Industries drawing benefits from the brilliant additive

Over the years, masterbatch technology has evolved a lot, enabling UV master batch manufacturer and UV master batch supplier to manufacture quality-driven products. Numerous industries are drawing benefits from the product. These include:

Agriculture

Lamination

Packaging

FMCG (Fast Moving Consumer Goods)

Custom-made masterbatches

Prominent UV masterbatch manufacturer in India holds the expertise to deliver custom-designed solutions. Their team of engineers and technicians has the rich professional experience to manufacture masterbatches and additive masterbatches according to the requirements of clients.

About Sumiran Masterbatch

We are a professionally managed company with more than 25 years of experience as a leading manufacturer and supplier of a wide range of masterbatches and additives, including White Masterbatch, Black Masterbatch, Colour Masterbatch, and Additive Masterbatches among others. Our product range is known for optimized performance and efficiency.

Are you searching for masterbatches for your plastic industry? End your search with Sumiran Masterbatch. Why go further?

8 notes

·

View notes

Text

Things you need to know about Type A FIBC bulk bags

If your traditional bulk packing products have been costing you quite a lot of money, it is time to shift to the FIBC bulk bags. This sturdier and much more cost effective alternative will be a great addition to your business.

In case you need to store or transport agricultural products, grains or constructional materials and you do not know which FIBC will be appropriate for you, we would suggest the Type A FIBC bags or bulk bags.

The reasons behind this suggestion have been presented below:

The FIBC fabric

The basic fabric that is used for making the Type A bulk bags is woven polypropylene. This material is used as key component in almost every type of bulk bag. The major advantage of this polypropylene FIBC fabric is that it is completely eco-friendly. Hence, the production of this polypropylene fabric does not cause any environmental concern.

However, as the fabric of this Type A bulk bags do not offer any anti-static ability so static energy can be produced when goods stored in them rub against the inner part of these bags during their filling or emptying.

Labeling details

Generally, the Type A bulk bags do not come with any label comprising of detailed instructions on their usage. The reason behind this is, these bags are meant for carrying non-conductive materials only. So, no additional care is required for grounding them, or storing and transporting them.

Products stored

As already mentioned, the Type A bags are capable of storing and transporting non-conductive products. Thus, they are perfect for carrying materials like agricultural products, food products, constructional materials, non-reactive chemical products, etc. These bulk bags are not at all suitable for carrying products that are highly reactive or flammable materials that can cause ignition when not handled with care.

In nutshell, these Type A bulk bags are designed to carry flammable goods that can cause combustion during their transportation or grounding.

Precautions followed

As such, there are no stern precautionary measures need to be followed when using Type A bulk bags. However, you have to ascertain that you are you are not planning to store any flammable goods inside these bags. Similarly, you are not supposed to unload or load these bulk bags in highly flammable environment.

So, you have to ensure that you will never expose this bulk bag with flammable contents in an atmosphere where there is a minimum ignition temperature of 1000 mJ.

2 notes

·

View notes

Text

https://fibcbigbags.com/fibc-dns/Understanding-the-functionality-of-Anti-Static-Bulk-Bags.php

It is extremely important to be perfectly aware of the types of FIBC and to know exactly which type of Bulk Bag will be required for what kind of product. The distinctive aspect of these FIBCs is that they are made from polypropylene which automatically makes them better packaging materials than conventional jute or cotton bags.

Coming to anti-static properties of packaging containers, FIBC has a certain type that offers this benefit. Read on to understand what exactly is meant by the anti-static feature and how do FIBCs help offer this property to your packaging needs.

#bulkmaterialhandling #polypropylene #packagingmaterial #packagingdesign

3 notes

·

View notes

Text

Key Role of Hermetic Bags in Product Freshness and Safety

For food producers, processors, and distributors, preserving the integrity and quality of food is extremely crucial. Ensuring your goods reach their destination fresh, safe, and bursting with flavour is paramount to customer satisfaction and brand reputation. This is where hermetic bags come in – a revolutionary packaging solution that offers unparalleled protection for your products.

What are Hermetic Bags?

Hermetic bags are a type of flexible intermediate bulk container (FIBC) designed with an airtight closure system. This closure system creates a hermetic seal, completely isolating the contents from the external environment. This eliminates exposure to air, moisture, dust, and other contaminants that are prone to negatively impact the quality and freshness of your goods.

How Hermetic Bags Benefit Your Products

Rishi FIBC's hermetic bags offer a multitude of advantages for food producers, processors, and distributors:

Extended Shelf Life: These bags significantly extend the shelf life of your products by preventing oxidation, a primary cause of spoilage. They create a controlled environment that minimizes degradation, ensuring your goods reach consumers at their peak freshness.

Preserved Flavour and Aroma: They prevent the escape of volatile compounds responsible for the unique flavour and aroma of your food products. This ensures your customers experience the full sensory experience you intended.

Enhanced Food Safety: These bags act as a barrier against external contaminants, including bacteria, insects, and other pests. It minimizes the risk of contamination and promotes food safety throughout the supply chain.

Reduced Food Waste: Extending shelf life and minimizing spoilage, hermetic bags contribute significantly to reducing food waste. This translates to cost savings for your business and a positive impact on the environment.

Moisture Control: They offer superior moisture control capabilities. Furthermore, this is particularly beneficial for hygroscopic products that are susceptible to absorbing moisture from the environment. Consequently, this can negatively affect their quality and texture.

Versatility: Hermetic bags has a wide range of sizes and materials which makes them suitable for packaging a diverse range of food products, from delicate spices and grains to coffee beans and dehydrated fruits.

Rishi FIBC: Your Partner in Hermetic Packaging Solutions

At Rishi FIBC, we offer our clients with innovative and high-quality packaging solutions. We offer a comprehensive selection of hermetic bags designed that helps to meet the unique requirements of your products.

Our bags are manufactured using food-grade materials that comply with stringent international safety standards. Our customization options ensures the perfect fit for your specific application. Additionally, our team of packaging experts is available to provide guidance and support in selecting the most suitable hermetic bag solution for your needs.

The Future of Food Packaging is Hermetic

In constantly evolving food industry consumer demand for fresh, safe, and flavourful products is on the rise. Hermetic bags represent a significant advancement in food packaging technology, offering a superior solution for preserving the quality and integrity of your products.

By choosing Rishi FIBC's hermetic bags, you can ensure your products reach consumers in their best possible condition, maximizing shelf life, minimizing spoilage, and delivering an exceptional customer experience. Contact Rishi FIBC today to discuss how our hermetic bag solutions can benefit your business and elevate your brand in the competitive food market.

0 notes

Text

FIBC Bulk Bags: The Ultimate Guide

FIBC Bulk Bag Manufacturers in Gujarat, commonly known as bulk bags, are essential in various industries for transporting and storing bulk materials. These versatile containers are designed to handle a wide range of materials, from fine powders to large granules, and are favored for their durability, cost-effectiveness, and convenience. This guide delves into the various aspects of FIBC bulk bags, including their types, uses, benefits, and frequently asked questions.

What are FIBC Bulk Bags?

FIBC bulk bags are large, woven polypropylene containers used for storing and transporting dry, flowable products. They can carry loads ranging from 500 to 2,000 kilograms, making them ideal for industries such as agriculture, construction, mining, and chemicals. These bags are known for their strength, flexibility, and ability to protect contents from contamination and moisture.

Types of FIBC Bulk Bags

There are several types of FIBC Bulk Bag Manufacturers in India, each designed to meet specific needs:

Type A: Standard bulk bags made from woven polypropylene. They are suitable for non-flammable products and environments where no electrostatic hazards exist.

Type B: Similar to Type A but with a lower breakdown voltage. These bags are used to transport dry, flammable powders but not in flammable environments.

Type C (Conductive Bags): Made from conductive threads, these bags are used for transporting flammable powders where grounding is essential to prevent static discharge.

Type D (Anti-static Bags): These bags are designed with anti-static properties that dissipate static electricity safely without grounding. They are ideal for transporting flammable products in environments with explosive dust or gases.

Food-Grade Bags: Manufactured in clean rooms and meet stringent food safety standards. They are used for transporting food products and pharmaceuticals.

Ventilated Bags: These bags have ventilated strips for products that need airflow, such as potatoes and onions.

UN Certified Bags: Designed for transporting hazardous materials, these bags comply with international safety standards and regulations.

Uses of FIBC Bulk Bags

FIBC Bulk Bag Manufacturers in Ahmedabad are used across various industries due to their versatility:

Agriculture: For storing and transporting seeds, grains, fertilizers, and animal feed.

Construction: For handling sand, gravel, cement, and other building materials.

Chemicals: For transporting chemical powders, granules, and other industrial materials.

Food: For bulk storage and transport of sugar, flour, grains, and other food products.

Mining: For handling mined materials like ores, minerals, and coal.

Benefits of Using FIBC Bulk Bags

Cost-Effective: FIBC bulk bags are more affordable compared to other bulk packaging options. Their reusability and durability further enhance cost savings.

Space-Saving: These bags are designed to be stackable, optimizing storage space. When not in use, they can be folded flat, reducing storage requirements.

Durability: Made from high-quality woven polypropylene, FIBC bulk bags are resistant to punctures and tears, ensuring safe transport and storage of heavy materials.

Versatility: With various types available, FIBC bulk bags can be used for a wide range of materials and industries.

Environmental Impact: Many FIBC bulk bags are recyclable and reusable, contributing to sustainability efforts by reducing waste.

Safety: Designed with safety in mind, these bags come with features such as lifting loops, discharge spouts, and anti-static properties to ensure safe handling.

Conclusion

FIBC bulk bags are an indispensable tool for industries that handle bulk materials. Their versatility, durability, and cost-effectiveness make them a preferred choice for transporting and storing a wide range of products. By understanding the different types of FIBC bulk bags and their applications, businesses can select the right bag for their needs, ensuring safe and efficient handling of materials. Whether you are in agriculture, construction, chemicals, or food industries, FIBC bulk bags offer a reliable solution to your bulk packaging requirements.

Frequently Asked Questions (FAQs)

What are FIBC bulk bags made of?

FIBC bulk bags are primarily made from woven polypropylene, a durable and flexible plastic material. Some bags include additional materials like conductive threads for specific applications.

How much weight can an FIBC bulk bag hold?

FIBC bulk bags can typically hold between 500 and 2,000 kilograms (1,100 to 4,400 pounds), depending on the design and type of bag. It's essential to choose a bag rated for the specific weight of the material being transported.

Are FIBC bulk bags environmentally friendly?

Yes, FIBC bulk bags are considered environmentally friendly because they are often reusable and recyclable. Using these bags can reduce the reliance on single-use packaging materials, contributing to sustainability efforts.

How should FIBC bulk bags be stored?

FIBC bulk bags should be stored in a dry, clean environment away from direct sunlight. They should be kept off the ground to prevent moisture absorption and contamination. Proper storage ensures the bags maintain their integrity and usability.

What are anti-static FIBC bulk bags?

Anti-static FIBC bulk bags (Type D) are designed to dissipate static electricity safely. These bags are used for transporting flammable products in environments where static discharge could ignite dust or gases, ensuring safe handling and transport.

Can FIBC bulk bags be customized?

Yes, many suppliers offer customization options for FIBC bulk bags. Customizations can include size, shape, material, and additional features like liners, printing, and specific filling and discharge mechanisms. Custom bags ensure they meet the specific requirements of your application.

0 notes

Text

### What is a Bulk Bag (Ton Bag)? A Comprehensive Guide!

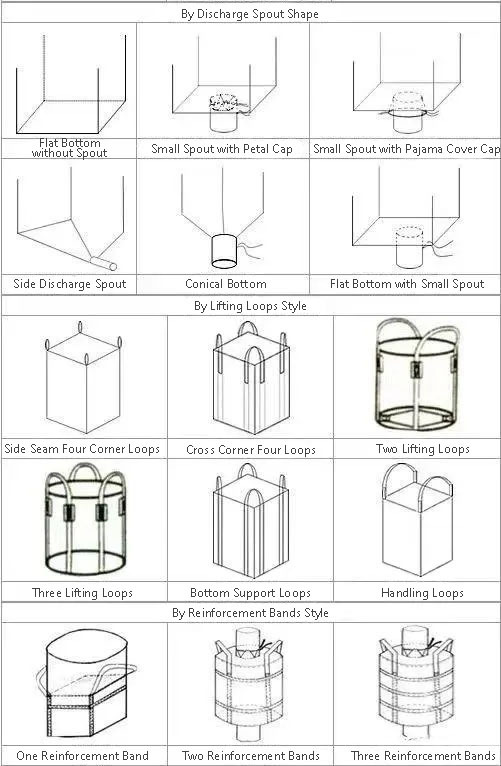

#### International Standard Bulk Bag Patterns

Bulk bags, also known as FIBC (Flexible Intermediate Bulk Containers), super sacks, big bags, ton bags, or jumbo bags, are flexible transport packaging containers. They are characterized by their moisture-proof, dust-proof, radiation-resistant, strong, and secure properties. Structurally, they possess sufficient strength, making loading and unloading highly efficient and convenient. As a result, bulk bags have seen rapid development in recent years. These bags are generally made from woven polyester fibers such as polypropylene (PP) or polyethylene (PE).

### Features

Bulk bags facilitate the transportation of large quantities of bulk powdered materials. They are known for their large volume, lightweight, and ease of loading and unloading, making them one of the most common packaging materials. Key characteristics include simple structure, light weight, foldability, minimal space occupancy when empty, and cost-effectiveness.

### Characteristics

1. **Load Capacity**: Ranges from 0.5 to 3 tons, with volumes between 500 to 2300 liters. The safety factor can be designed to 3:1, 5:1, or 6:1 based on user requirements.

2. **Content Type**: Divided into bulk goods bags and small package goods bags, suitable for both single-use and reusable applications.

3. **Shape**: Available in round, square, and U-shaped configurations.

4. **Lifting Structure**: Includes top lift, side lift, and bottom lift types, typically featuring inlet and outlet spouts.

### Performance

- **Usage Types**: Reusable / Single-use

- **Shapes**: Square / Rectangular

- **Lifting Methods**: Top lift / Side lift / Bottom lift

- **Inlet**: With inlet spout / Without inlet spout (large opening / waterproof cover)

- **Outlet**: With outlet spout / Without outlet spout

- **Materials**: Polypropylene (PP)

- **Load Capacity**: 0.3 tons - 2 tons

### Usage Precautions

1. Do not stand under the bulk bag during lifting operations.

2. Attach the hook to the center of the lifting loop or sling; avoid tilting, single-sided lifting, or diagonal pulling.

3. Prevent the bag from rubbing, hooking, or colliding with other items during operations.

4. Do not pull the lifting loops outward.

5. When using a forklift, avoid contact between the fork and the bag body to prevent punctures.

6. Use pallets during warehouse handling to avoid carrying the bag by hooks to prevent swinging.

7. Keep the bag upright during loading, unloading, and stacking.

8. Do not drag the bag on the ground or concrete.

9. For outdoor storage, place the bag on a pallet and cover it tightly with an opaque tarpaulin.

10. After use, wrap the bag in paper or an opaque tarpaulin and store it in a ventilated area.

### Applications

Suitable for packaging chemical raw materials, pharmaceutical raw materials, plastic raw materials, food additives, feed additives, metallurgical powders, ore powders, refractory materials, and other industries using bulk bags.

Shenzhen East Green International Freight Forwarding company, specializing in the transportation of bulk and oversized cargo via sea. Such as engineering vehicles, large machinery, steel materials, ton bags, etc.. We look forward to cooperate with you and are available for any inquiries at your convenience.

Tyin Meng

Contact Information:(+86) 18528265381 (Wechat or Whatsapp)

1 note

·

View note

Text

Which Industries Are Using FIBC Bulk Bags?

looking for which industry are use FIBC Jumbo Bag In India? Many industries use Products that are transported to the customer, they must be taken carefully, and special needs must be taken so the products can reach safely to the end consumer. Agricultural, consumer goods, pharmaceutical products and other valuable products must be packed securely to reach the market and consumers without any default.

#Fibc Bags Manufacturer in India#Industrial Bulk Bags#Bulk Bags Manufacturer#FIBC Bag#FIBC Jumbo Bag#Types of FIBC Bags

0 notes

Text

FIBC Bags Type A - Durable and Reliable Jumbo Bags

Looking for reliable FIBC Bags Type A exporters & suppliers? Silvassa Woven Sacks has got you covered. Get high-quality bags at competitive prices today.

0 notes

Text

Industrial Packaging Market Overview: Growth Factors and Future Trends (2023-2032)

The global industrial packaging market is anticipated to grow at a substantial CAGR of 4.50% in the upcoming years. The global Industrial packaging industry was estimated to be worth USD 59.1 billion in 2021 and was expected to be worth USD 76.96 billion by 2028.

Industrial Packaging Market encompasses a wide range of packaging solutions designed to protect, store, and transport industrial goods across various sectors, including manufacturing, automotive, construction, chemical, and pharmaceuticals. This market is integral to the global supply chain, ensuring that goods are delivered safely and efficiently from producers to end-users. Industrial packaging solutions include drums, containers, crates, pallets, sacks, and barrels, often made from materials such as plastic, metal, wood, and corrugated cardboard. The market is driven by the increasing demand for durable and robust packaging that can withstand harsh environmental conditions and rough handling during transit.

The growth of industrial activities, globalization of trade, and expansion of manufacturing sectors in emerging economies are key factors propelling the market. Moreover, there is a rising emphasis on sustainability, leading to innovations in recyclable and reusable packaging materials. Advanced technologies, such as smart packaging with sensors and RFID tags, are being integrated to enhance tracking and monitoring of goods. Additionally, regulatory requirements for safe and compliant packaging, especially in the transportation of hazardous materials, further influence market dynamics. Overall, the Industrial Packaging Market is evolving rapidly, driven by the need for efficient, safe, and sustainable packaging solutions to support industrial operations worldwide.

The Industrial Packaging Market includes a variety of packaging types, each designed to meet specific needs and requirements of various industries. Here are some key types of industrial packaging:

1. Drums and Barrels:

Metal Drums: Typically made of steel or aluminum, these are used for storing and transporting liquids such as chemicals, oils, and solvents. They offer excellent durability and protection.

Plastic Drums: Made from high-density polyethylene (HDPE), these are lightweight and resistant to corrosion, suitable for storing a wide range of liquids and semi-liquids.

Fiber Drums: Constructed from thick, rigid paperboard, these drums are used for dry and solid materials. They are lighter and more cost-effective compared to metal drums.

2. Intermediate Bulk Containers (IBCs):

Plastic IBCs: Often used for the bulk storage and transportation of liquids and granulated substances, plastic IBCs are durable and reusable.

Metal IBCs: Made from stainless steel or other metals, these containers provide high strength and are suitable for transporting hazardous materials.

Composite IBCs: These combine a plastic inner container with a metal outer frame, offering the benefits of both materials.

3. Crates and Pallets:

Wooden Crates and Pallets: Commonly used for shipping heavy or bulky items, wooden pallets and crates provide sturdy support and can be easily customized to fit specific dimensions.

Plastic Pallets: These are durable, reusable, and resistant to moisture, making them ideal for hygiene-sensitive industries like pharmaceuticals and food.

Metal Pallets: Offering high strength and durability, metal pallets are used in applications requiring heavy-duty support and long-term storage.

4. Sacks and Bags:

Bulk Bags (FIBCs): Flexible Intermediate Bulk Containers (FIBCs) are large, durable bags made from woven polypropylene, used for transporting dry, flowable products like sand, fertilizers, and grains.

Valve Bags: Designed for high-speed filling and secure closure, these are commonly used for cement, chemicals, and other fine materials.

Paper Bags: Used for lighter products such as powders, grains, and animal feed, paper bags offer a cost-effective and environmentally friendly packaging solution.

5. Corrugated Boxes:

Heavy-Duty Corrugated Boxes: Made from multi-layered corrugated cardboard, these boxes provide excellent protection for heavy and fragile items during shipping.

Custom Corrugated Solutions: Tailored to specific dimensions and requirements, these boxes can include inserts and dividers to securely hold items in place.

6. Protective Packaging:

Foam Inserts and Cushioning: Used to protect sensitive and fragile items from shock and vibration during transit.

Bubble Wrap and Air Cushions: Provide lightweight and flexible protection for delicate products.

Stretch Wrap and Shrink Wrap: Used to secure and stabilize loads on pallets, preventing movement and damage during transport.

7. Strapping and Banding:

Steel Strapping: Provides high tensile strength and is used for securing heavy loads.

Plastic Strapping: Made from materials like polyester and polypropylene, plastic strapping is lightweight, flexible, and suitable for a wide range of applications.

8. Specialty Containers:

Hazardous Material Containers: Designed to safely transport dangerous goods, these containers comply with regulatory standards and offer features like leak-proof seals and impact resistance.

Temperature-Controlled Packaging: Includes insulated containers and refrigerants used to maintain temperature-sensitive products during transport, such as pharmaceuticals and perishable foods.

Major Key Players-

Mondi

International Paper

Westrock Company

Orora Limited

Mauser Packaging Solutions

Sigma Plastics Group

Taihua Group

Snyder Industries

Ven Pack

Chem-Tainer Industries

B.A.G. Corp.

Myers Container

Ameriglobe LLC

Wuxi Sifang Group Co., Ltd

Composite Containers, LLC

Cleveland Steel Container Corporation

The Industrial Packaging Market presents significant growth opportunities driven by several key factors. The increasing globalization of trade and the expansion of manufacturing industries in emerging economies are major drivers, as they boost the demand for robust packaging solutions that can withstand long-distance transportation and rough handling. The trend towards sustainability is another critical growth area, with a rising emphasis on eco-friendly and recyclable packaging materials. This shift is leading to innovations in biodegradable plastics, reusable containers, and efficient recycling processes, meeting both regulatory requirements and consumer demand for environmentally responsible solutions.

The growing need for safe and compliant packaging for hazardous materials, particularly in the chemical and pharmaceutical sectors, further propels market growth, as stringent regulations mandate specialized packaging solutions. Moreover, the rise of e-commerce and the increased focus on automation in logistics and warehousing create demand for advanced packaging systems that can streamline operations and reduce costs.

Customized packaging solutions tailored to specific industry needs, such as temperature-controlled packaging for perishables and pharmaceuticals, also present lucrative opportunities. Companies that can innovate and adapt to these trends, offering sustainable, smart, and specialized packaging solutions, are well-positioned to capitalize on the expanding industrial packaging market.

More About Report- https://www.credenceresearch.com/report/industrial-packaging-market

The Industrial Packaging Market is driven by several key factors that influence its growth and development:

1. Globalization and International Trade:

Expansion of Trade: The increasing globalization of trade has heightened the need for reliable packaging solutions to safely transport goods across long distances. As businesses expand their operations internationally, the demand for durable and efficient packaging to protect products during transit has surged.

2. Growth of Manufacturing and Industrial Sectors:

Industrial Expansion: The continuous growth of manufacturing and industrial activities, particularly in emerging economies, drives the demand for industrial packaging. Sectors such as automotive, chemicals, pharmaceuticals, and electronics require robust packaging solutions to ensure product integrity and safety.

3. E-commerce and Retail Sector Growth:

Rise of E-commerce: The rapid growth of the e-commerce sector has significantly increased the need for efficient and secure packaging. Industrial packaging solutions play a crucial role in ensuring that products reach consumers in good condition, handling the demands of warehousing, logistics, and delivery.

4. Stringent Regulatory Requirements:

Compliance and Safety: Regulatory requirements for the safe packaging and transportation of hazardous materials and chemicals drive the demand for specialized industrial packaging solutions. Compliance with international standards, such as those set by the United Nations and other regulatory bodies, ensures the safety and security of these goods during transit.

5. Technological Advancements:

Innovation in Packaging Technologies: Advancements in packaging technologies, such as smart packaging, RFID tags, and sensor-based monitoring systems, enhance the functionality and efficiency of industrial packaging. These innovations enable real-time tracking, condition monitoring, and improved supply chain transparency.

6. Sustainability and Environmental Concerns:

Eco-friendly Packaging: Growing environmental awareness and the push for sustainability are driving the development and adoption of eco-friendly packaging materials. Industrial packaging companies are increasingly focusing on recyclable, biodegradable, and reusable materials to reduce environmental impact and meet consumer and regulatory demands for sustainability.

7. Demand for Customized Solutions:

Tailored Packaging: The need for customized packaging solutions to meet specific industry requirements is a significant driver. Industries such as pharmaceuticals, food and beverages, and electronics require specialized packaging to ensure product safety, maintain quality, and comply with industry-specific standards.

8. Supply Chain Optimization:

Efficiency and Cost Reduction: The emphasis on optimizing supply chain efficiency and reducing costs drives the demand for advanced industrial packaging solutions. Efficient packaging helps minimize product damage, reduce waste, and streamline logistics operations, contributing to overall cost savings and operational efficiency.

9. Economic Growth and Urbanization:

Increased Consumption: Economic growth and urbanization lead to increased consumption of goods, thereby driving the demand for industrial packaging. As urban populations grow and consumer spending rises, the need for effective packaging solutions to support the distribution of goods also increases.

10. Rising Awareness of Product Safety and Integrity:

Protecting Product Integrity: Ensuring the safety and integrity of products during storage and transportation is a critical concern for industries. High-quality industrial packaging solutions protect products from physical damage, contamination, and environmental factors, ensuring that they reach their destination in optimal condition.

Segmentation of Global Industrial Packaging Market-

Global Industrial Packaging Market – By Type

Drums

IBCs

Sacks

Crates

Pails

Corrugated boxes

Others (Include pallets, wrap films, wrapping strips, and flexible packaging materials)

Global Industrial Packaging Market – By Material

Plastic

Wood

Metal

Paperboard

Browse the full report – https://www.credenceresearch.com/report/industrial-packaging-market

Browse Our Blog: https://www.linkedin.com/pulse/industrial-packaging-market-report-opportunities-6c1wf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Complete Information for Fibc Jumbo Bags

Fibc Jumbo Bags, commonly referred to as Flexible Intermediate Bulk Containers (FIBC), are industrial containers composed of flexible fabric used for the storage and transportation of dry, flowable goods. The following are some typical FIBC bag types and their uses:

1. FIBC Standard Bags:

- Capacity: 500 kg to 2000 kg on average.

- Design: One or two loops are available.

- Applications: Sand, fertilizer, and plastic granules are among the commodities this is used to package.

2. FIBC Bags with Baffle Lining:

Features: Comes with interior baffles to help keep the form during filling.

- Applications: Perfect for products that require stability and fine powders.

3. FIBC Bags with Vents:

- Goal: Designed to facilitate airflow.

- Uses: For fruits, vegetables, and other perishable items.

4. FIBC Bags with Aluminum Lining:

Material: Moisture-resistant aluminum lining.

- Applications: Fit for chemicals and materials that are hygroscopic.

5. FIBC Bags with Circular Bags:

- Design: A single loop in a circular shape.

Applications: Applied to many types of bulk materials.

Recall that FIBC bags are available in various shapes, sizes, and capacities to satisfy particular needs.

0 notes

Text

Various types of masterbatches by Sumiran and their applications

In this plastic industry-centric blog, we are going to highlight about Sumiran Masterbatches, a leading masterbatch manufacturer in Ahmedabad, India, at the same time, we will highlight about the applications and significance of color masterbatch, additive masterbatch, nucleating agents, biodegradable polymer Moving forward, let’s first understand the masterbatch, since it will remain the core of this blog.

Learning about masterbatch

Over the years, masterbatches have become an integral part of plastic manufacturing industries, given their properties, benefits, and applications. In simple language, it is basically a concentrated mixture processed by the distribution of colors and additives into a polymer carrier. The entire process is carried out by heat treatment in a high shear mixing extruder. What next? The mixture processed inside the extruder is then left to cool. After this stage, it is cut into granules with the support of pelletiser. Here it’s important to mention that pigment and additive parts need to be merged into the base polymer equally.

Types of masterbatches

Continued research and development in masterbatches have led to the processing of different types of masterbatches. Some of the common masterbatches include:

White Masterbatch

Black Masterbatch

Colour Masterbatch

Additive Masterbatch

As a leading UV masterbatch manufacturer, Sumiran Masterbatches supplies the product across India to numerous industries.

Properties and salient features of the product

Plenty of reasons to choose the product in the plastic industry.

High thermal stability

Reduces agglomeration of TiO2 during production

Acts as a UV protector

Durability

High Jetness

UV Stability

Uniform Dispersion

High Temperature Resistance

No Issues of bleed or bloom

Ease of processibility

Improves heat resistance

Improves resistance to weather

UV Masterbatches

Coming to masterbatches, the product is basically designed to minimize the damaging effect of UV light.

Applications

UV has been changing the fortune of many industries with its applications. These include:

Agricultural green house film, FIBC bags, moulded crates, drums, garbage cans, garden furniture, outdoor articles etc…

Tarpualin, Roto moulded Water Tank

Shaded Net

Woven sacks, HDPE/PP raffia tapes, LDPE/LLDPE/PP lamination.

All types of PP/PE made products

Industries using masterbatches

The quality-driven range of color masterbatch, additive masterbatch, nucleating agents, biodegradable polymer, etc. processed by Sumiran Masterbatches is used in numerous industries, including:

Building & Construction.

Consumer Goods.

What is so special about masterbatches?

Why plastic industry prefers the product? Over the years, plastic manufacturers have shifted towards the product from pigment-based solutions. Former is easy to handle and store. At the same time, the product is economical. Before masterbatches, the industry was depending on resin. It is a derivative of petroleum.

Custom-made masterbatch

Excellent industry expertise is required to deliver custom-designed products. Many plastic-based industries require specific types of masterbatches to fulfill their business requirement. Backed by rich professional experience and cutting-edge technology, Sumiran Masterbatches deliver custom-made solutions.

Depending on your industrial requirement, you can get a specific range of masterbatches.

Join Hands with Sumiran

Are you into the plastic industry? Are you looking for a leading masterbatch manufacturer? If your answer to these two questions is yes, then join Hands with Sumiran Masterbatches. The professionally managed company is a leading manufacturer and supplier of a wide range of masterbatches, including White Masterbatch, Black Masterbatch, Colour Masterbatch, and Additive Masterbatches among others.

9 notes

·

View notes