#smart warehousing solutions

Text

AS/RS Implementation Guide: Key Considerations For Successful Deployment

Automated Storage and Retrieval Systems (AS/RS) warehouse automation solutions are a huge step forward in storage management because they are so accurate, efficient, and scalable. Nevertheless, putting AS/RS into action needs careful planning, execution, and consideration of many factors to guarantee a good deployment. Here are the main things that businesses need to think about before starting an AS/RS implementation process:

Site evaluation and Space usage

Perform a thorough site assessment to examine your building’s layout, structural limitations, and available space. Ceiling height, floor load capacity, and work area width should be considered when deciding if AS/RS integration is possible. Maximizing room utilization can be achieved by utilizing AS/RS’s capability to effectively utilize vertical storage space.

Connecting to existing systems

Integration with current operational platforms, enterprise resource planning (ERP) software, and warehouse management systems (WMS) is necessary for AS/RS deployment to go smoothly. Assuring that AS/RS technology works with your current systems will help with data sharing, keeping track of inventory, and handling orders without any problems.

Technology Choice and Setup

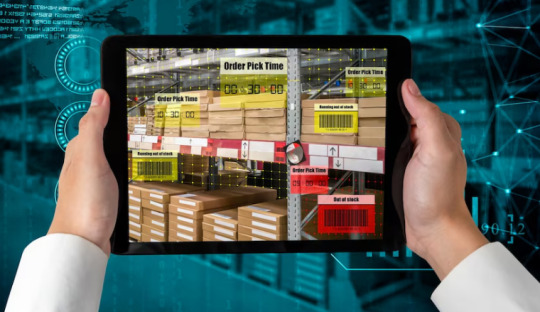

The correct smart warehousing solutions are essential for optimal operating needs and return on investment (ROI). If you need to complete orders quickly and accurately, you should think about things like storage density, throughput capacity, retrieval speed, and automation level (like unit load or mini-load systems).

Meeting safety and legal requirements

Safeguarding and following the rules should be your top priorities during the whole AS/RS adoption process. Do risk assessments with safety rules, and add the right safety features like sensors, barriers, and emergency stop devices.

Training for employees

To get your employees ready for the switch to AS/RS, you should give them thorough training on how to use the system, how to maintain it, and appropriate safety measures. Stress the advantages of automation and obtain participation from workers in the execution process to encourage acceptance and reduce resistance to change. It’s all about making sure the implementation goes smoothly and the system is optimized in the long run.

About Primus:

Primus is a top sustainable construction company that focuses on automating warehouses. Primus works with the best team of experts who can do a wide range of tasks, such as designing and building automated automation systems and analyzing data. Primus focuses on creating custom automation solutions that make warehouse operations more efficient, safe, and scalable.

For more information, visit https://www.primusbuilders.com/

Original Source:- https://bit.ly/3PWMvku

0 notes

Text

Technology-Enabled Warehouse And Logistics Services

Discover seamless warehouse storage space and logistics solutions at Xtended Space, your trusted storage platform in the bustling Delhi NCR region. Our cutting-edge AI-driven technology ensures optimized storage and efficient logistics management, tailored to meet your unique needs.

#household storage#secure storage facilities#smart warehousing solutions#storage solutions#warehouse storage#storage#Flexible Storage Options

1 note

·

View note

Text

Best Warehouse Management System In India - AWL India

Discover the power of End to End Warehouse Management System, streamlining your logistics journey from the first crate to the final delivery. Say goodbye to complexities & say hello to seamless efficiency. To know more, visit - https://www.awlindia.com/smart-warehouses

#warehouse service providers in india#rfid warehouse management#rfid warehouse management solution#iot based warehouse management system#warehouse management system using rfid#smart warehouse management system#warehouse management#warehouse management process#warehouse management system#AWL India#smart warehousing solutions#smart warehouse

1 note

·

View note

Text

Smart Warehousing: The Next Big Thing in Logistics

Innovative warehousing is emerging as a game-changer for shipping and freight forwarding in the rapidly evolving logistics landscape. As businesses in the logistics sector, especially logistic companies and freight forwarders, strive to meet the growing demands of a digitally driven market, adopting smart warehousing technologies is not just an option but a necessity. This innovative approach enhances efficiency and significantly boosts accuracy and customer satisfaction in the supply chain.

Automation and Robotics

One of the critical components of intelligent warehousing is automation, which primarily involves using robots and automated systems to perform repetitive tasks. These tasks range from picking and packing to transporting goods within the warehouse. Robots, such as autonomous guided vehicles (AGVs) and autonomous mobile robots (AMRs), are increasingly commonplace in modern warehouses operated by logistic companies. They speed up the process, reduce human error, and enhance safety by taking on high-risk activities.

Enhanced Data Analytics

Smart warehousing also leverages big data and analytics to predict trends and optimize inventory management for freight forwarders. By analyzing vast amounts of data, warehouse operators can foresee demand surges, adjust stock levels accordingly, and plan resources more effectively. This predictive capability ensures that the supply chain is more responsive and less prone to overstocking or stockouts, which can be costly.

Internet of Things (IoT)

The IoT plays a pivotal role in smart warehousing by creating a network of connected devices that communicate continuously. Sensors and RFID tags track inventory in real-time, providing up-to-date information on stock levels, locations, and movements. This visibility is crucial for real-time decision-making and maintaining an agile supply chain.

Benefits of Smart Warehousing

The advantages of smart warehousing are manifold for logistic companies and freight forwarders:

Operational efficiency is significantly improved. Automated solutions mean faster order processing and reduced downtime.

Accuracy in inventory management and order fulfillment increases, reducing waste and the cost associated with returns.

Smart warehousing allows for enhanced scalability.

Businesses can adjust more fluidly to changes in demand without the need for proportional increases in labor.

Moreover, employee satisfaction can also improve as automation takes over mundane and physically strenuous tasks, allowing staff to focus on more complex and rewarding work. This not only helps retain talent but also attracts new employees in a competitive market.

Challenges and Considerations

Despite its benefits, transitioning to smart warehousing presents challenges, particularly for logistic companies and freight forwarders. The initial investment in technology can be substantial. Businesses must evaluate the cost against potential long-term savings and efficiency gains. Additionally, integrating new technologies with existing systems and training staff to manage these advanced operations is challenging.

As we move forward, smart warehousing is set to redefine the logistics landscape. Companies adopting these technologies early on will likely gain a significant competitive edge. In conclusion, as buyers' and users' expectations continue to rise and the push for faster, more accurate services grows, smart warehousing stands out as a critical solution for the future of shipping and freight forwarding logistics.

#smart warehousing#warehousing#logistic company#shipping and freight forwarding#air freight forwarder#sea freight solutions#ocean cargo logistics#customs clearance

0 notes

Text

Objectives And Functions Of Supply Chain Management

In order to maximise quality, customer satisfaction, and profitability, the whole manufacturing flow of products and services is managed through supply chain management. It encompasses everything, from the delivery of the finished product to clients. We'll look at the goals and duties of supply chain management in this post. Even in the cold chain logistics using supply chain there are multiple objectives and functions. The following are the objectives of Supply Chain Management:

To Increase the Total Value Created

The success of the supply chain increases with increasing SCM profitability. The profitability of the supply chain is the difference between the price a consumer pays for a product and what it costs an organization to make and deliver that product to the client.

Improvement in Price and Quality

This is another crucial SCM goal. Cost-quality optimization and balancing are the goals.

Finding sources of cost and income

The only source of income is from the customer. As a result, the movement of information, goods, or money should be properly managed. It is essential to the supply chain's success.

Delivery Improvement

The SCM attempts to satisfy the customer's requests for assured delivery of high quality goods at competitive prices and with short lead times. In addition, SCM reduces the time needed for ordering and fulfilling seeks to speed up the process.

Demand Satisfaction

Managing demand and supply is an important yet difficult responsibility for a business or management staff. Its goal is to satisfy consumer demand with effective resources.

Better Utilisation Of Resources

It is another objective of the supply chain management to make better utilisation of the available resources and reduce the cost of the operations. This results in safeguarding the just in time supply while also improving the delivery reliability at the same time.

Furthermore, supply chain management is an integral part of the process. The importance of supply chain management can be explained by ensuring customer satisfaction by ensuring right delivery times and pepper sale support.

#awl india pvt ltd#Awl Warehouse#warehousing facilities in india#Private Warehouse In India#cold chain logistics company#Smart Warehouse Solutions

0 notes

Link

Logistics simplified! CSS is a complete solution for freight shipping, inventory management, order fulfillment, warehousing and distribution. Contact us today!

#logistics solutions edmonton#warehouse logistics edmonton#smart shipping edmonton#edmonton smart shipping#edmonton 3pl#edmonton 3pl companies#fulfillment warehousing edmonton#3pl companies edmonton#secure warehouse storage edmonton#pallet storage warehouse edmonton

0 notes

Link

#Smart Warehousing Management#Smart Warehouse Management#Smart Warehousing Solution#Smart Warehousing Technology#Smart Warehouse Management System LTI

0 notes

Photo

We have simplified the whole warehousing process for you. Just tell us when and where to start. We will take care of the rest with seamless updates and mobile connectivity!

#Warehousing Solutions#Warehouse Company#Warehouse Management#Logistics#Secure Storage#Storage Solutions#Smart Storage#Secure Warehouse

0 notes

Text

MonolithIoT smart shelves enable companies to check inventory levels and know when a product is out of stock.

Smart Shelf technology can also alert companies to the theft of goods.

#MonolithIoT#smart shelves#smart warehouse#warehousing#internet of things (iot)#internet of things devices#internet of things companies#internet of things solutions#automated inventory management#inventory management

0 notes

Text

Vehicle tracking system - Smart business solutions

Based in Sydney with offices in Australia (HO), New Zealand, India, and Cambodia, Sonar specialises in providing smart solutions for mobile task and resource management to businesses in field service, logistics & supply chain, assets management and healthcare in both Government and Private Sectors. Our distribution team has an extensive global partner network spanning 200 sites.

1 note

·

View note

Text

Genio 510: Redefining the Future of Smart Retail Experiences

Genio IoT Platform by MediaTek

Genio 510

Manufacturers of consumer, business, and industrial devices can benefit from MediaTek Genio IoT Platform’s innovation, quicker market access, and more than a decade of longevity. A range of IoT chipsets called MediaTek Genio IoT is designed to enable and lead the way for innovative gadgets. to cooperation and support from conception to design and production, MediaTek guarantees success. MediaTek can pivot, scale, and adjust to needs thanks to their global network of reliable distributors and business partners.

Genio 510 features

Excellent work

Broad range of third-party modules and power-efficient, high-performing IoT SoCs

AI-driven sophisticated multimedia AI accelerators and cores that improve peripheral intelligent autonomous capabilities

Interaction

Sub-6GHz 5G technologies and Wi-Fi protocols for consumer, business, and industrial use

Both powerful and energy-efficient

Adaptable, quick interfaces

Global 5G modem supported by carriers

Superior assistance

From idea to design to manufacture, MediaTek works with clients, sharing experience and offering thorough documentation, in-depth training, and reliable developer tools.

Safety

IoT SoC with high security and intelligent modules to create goods

Several applications on one common platform

Developing industry, commercial, and enterprise IoT applications on a single platform that works with all SoCs can save development costs and accelerate time to market.

MediaTek Genio 510

Smart retail, industrial, factory automation, and many more Internet of things applications are powered by MediaTek’s Genio 510.

Leading manufacturer of fabless semiconductors worldwide, MediaTek will be present at Embedded World 2024, which takes place in Nuremberg this week, along with a number of other firms. Their most recent IoT innovations are on display at the event, and They’ll be talking about how these MediaTek-powered products help a variety of market sectors.

They will be showcasing the recently released MediaTek Genio 510 SoC in one of their demos. The Genio 510 will offer high-efficiency solutions in AI performance, CPU and graphics, 4K display, rich input/output, and 5G and Wi-Fi 6 connection for popular IoT applications. With the Genio 510 and Genio 700 chips being pin-compatible, product developers may now better segment and diversify their designs for different markets without having to pay for a redesign.

Numerous applications, such as digital menus and table service displays, kiosks, smart home displays, point of sale (PoS) devices, and various advertising and public domain HMI applications, are best suited for the MediaTek Genio 510. Industrial HMI covers ruggedized tablets for smart agriculture, healthcare, EV charging infrastructure, factory automation, transportation, warehousing, and logistics. It also includes ruggedized tablets for commercial and industrial vehicles.

The fully integrated, extensive feature set of Genio 510 makes such diversity possible:

Support for two displays, such as an FHD and 4K display

Modern visual quality support for two cameras built on MediaTek’s tried-and-true technologies

For a wide range of computer vision applications, such as facial recognition, object/people identification, collision warning, driver monitoring, gesture and posture detection, and image segmentation, a powerful multi-core AI processor with a dedicated visual processing engine

Rich input/output for peripherals, such as network connectivity, manufacturing equipment, scanners, card readers, and sensors

4K encoding engine (camera recording) and 4K video decoding (multimedia playback for advertising)

Exceptionally power-efficient 6nm SoC

Ready for MediaTek NeuroPilot AI SDK and multitasking OS (time to market accelerated by familiar development environment)

Support for fanless design and industrial grade temperature operation (-40 to 105C)

10-year supply guarantee (one-stop shop supported by a top semiconductor manufacturer in the world)

To what extent does it surpass the alternatives?

The Genio 510 uses more than 50% less power and provides over 250% more CPU performance than the direct alternative!

The MediaTek Genio 510 is an effective IoT platform designed for Edge AI, interactive retail, smart homes, industrial, and commercial uses. It offers multitasking OS, sophisticated multimedia, extremely rapid edge processing, and more. intended for goods that work well with off-grid power systems and fanless enclosure designs.

EVK MediaTek Genio 510

The highly competent Genio 510 (MT8370) edge-AI IoT platform for smart homes, interactive retail, industrial, and commercial applications comes with an evaluation kit called the MediaTek Genio 510 EVK. It offers many multitasking operating systems, a variety of networking choices, very responsive edge processing, and sophisticated multimedia capabilities.

SoC: MediaTek Genio 510

This Edge AI platform, which was created utilising an incredibly efficient 6nm technology, combines an integrated APU (AI processor), DSP, Arm Mali-G57 MC2 GPU, and six cores (2×2.2 GHz Arm Cortex-A78& 4×2.0 GHz Arm Cortex-A55) into a single chip. Video recorded with attached cameras can be converted at up to Full HD resolution while using the least amount of space possible thanks to a HEVC encoding acceleration engine.

FAQS

What is the MediaTek Genio 510?

A chipset intended for a broad spectrum of Internet of Things (IoT) applications is the Genio 510.

What kind of IoT applications is the Genio 510 suited for?

Because of its adaptability, the Genio 510 may be utilised in a wide range of applications, including smart homes, healthcare, transportation, and agriculture, as well as industrial automation (rugged tablets, manufacturing machinery, and point-of-sale systems).

What are the benefits of using the Genio 510?

Rich input/output choices, powerful CPU and graphics processing, compatibility for 4K screens, high-efficiency AI performance, and networking capabilities like 5G and Wi-Fi 6 are all included with the Genio 510.

Read more on Govindhtech.com

#genio#genio510#MediaTek#govindhtech#IoT#AIAccelerator#WIFI#5gtechnologies#CPU#processors#mediatekprocessor#news#technews#technology#technologytrends#technologynews

2 notes

·

View notes

Text

How Warehouse Automation Leads To Change In Economic Management?

Businesses these days face a lot of economic issues ranging from all kinds of things like scalability, labor, and more. However, in between all these challenges, a business still can grow by using the power of automation and cold room insulation solutions. It can revolutionize the way things are stored and shipped in any warehouse. This way it can act as a catalyst to solve economic problems. Let’s look at some key ways warehouse automation can help with these problems.

Improving big productivity of the warehouse

Warehouse automation surely brings a lot of productivity in a warehouse. Programmed machines can go through repetitive tasks with ease and solve packing, positioning, or navigating tasks with precision. Most tasks in a warehouse are repetitive like inventory management, order fulfillment, sorting, and packaging. The best example of this working methodology is Amazon’s fulfillment centers. These centers have shown us how hours of work can be done in minutes.

Mitigating shortage of labor

With diversity in work profiles and increasing demands for workers, there is a high labor shortage in the market. With warehouse automation, this problem can be solved too. Businesses can reduce their dependence on manual labor by using more and more programmed machines that are intelligent enough to do labor work. Most companies have reduced the cost of recruiting, training, and maintaining workers to balance their economic condition.

Improving supply chain resilience

Disruptions are easy to come in today’s fluctuating economy. But with warehouse automation, you can at least minimize the risks and increase agility. The same thing happened during COVID-19 pandemic. Using automation technologies such as predictive analytics and robotic inventory management, most companies were able to optimize inventory levels, reroute shipments, and maintain business continuity in the face of unprecedented challenges.

Driving innovation and competitiveness

More can be done with smart warehouse solutions and insulated wall panels for cold storage facilities. Businesses like Alibaba have been able to use artificial intelligence and robots to develop routing algorithms, reduce delivery times, and optimize all similar-looking tasks to optimize the customer experience.

About Primus:

Primus is a top company that provides smart warehousing solutions. They focus on automation technologies and insulated wall panels for cold storage facilities. Primus offers creative ways to improve warehouse operations and boost economic growth. These include handling labor shortages, making fulfillment processes better, improving scalability, and putting safety first.

For more information, visit https://www.primusbuilders.com/

Original Source:- https://bit.ly/3I3PgfB

0 notes

Text

Innovating the Seas: Technological Advancements in Shipping Services UAE

The maritime landscape of the United Arab Emirates (UAE) has witnessed a remarkable transformation in recent years, owing to groundbreaking technological advancements that have revolutionized shipping services. As a pivotal hub for international trade, the UAE has been at the forefront of embracing innovation to enhance its shipping industry's efficiency, sustainability, and global competitiveness.

In this article, we embark on a captivating voyage to explore the cutting-edge technologies that are propelling shipping services UAEinto the future. From state-of-the-art port facilities to smart logistics solutions, we uncover the digital innovations that are reshaping the seascape of this thriving nation.

At the heart of this technological revolution lies the UAE's commitment to being a maritime leader on the global stage. By leveraging digitalization, automation, and artificial intelligence, the nation's shipping services have enhanced their operational capabilities, optimizing the movement of goods and streamlining supply chain management.

Join us as we delve into the advanced infrastructure and smart port solutions that epitomize the UAE's dedication to seamless trade facilitation. We will explore how advanced container tracking systems, real-time data analytics, and blockchain technology have elevated transparency, security, and efficiency in cargo handling and customs clearance processes.

Moreover, sustainability is a paramount concern for the shipping services UAE, and our blog will showcase the eco-friendly initiatives driving the nation's maritime sustainability agenda. From green shipping practices to energy-efficient vessels, the UAE's commitment to environmental responsibility sets a shining example for the global shipping community.

A deeper dive into autonomous vessels and drones reveals the UAE's willingness to explore futuristic possibilities for shipping services. These cutting-edge technologies not only enhance safety and navigation but also minimize human intervention, making maritime operations more cost-effective and eco-friendly.

Innovative collaborations between the shipping services UAE and technology companies have paved the way for groundbreaking solutions, benefiting both local and international businesses. From e-commerce integration to smart warehousing, these partnerships exemplify the UAE's commitment to embracing digital transformation across the entire logistics ecosystem.

Smart Ports: Revolutionizing Port Operations One of the key pillars of technological advancements in UAE's shipping services is the transformation of traditional ports into smart ports. Equipped with cutting-edge technologies, these ports have streamlined operations and improved overall efficiency. Advanced container tracking systems and real-time data analytics enable precise monitoring of cargo movement, reducing waiting times and enhancing port productivity. Automated cranes and robotic systems further expedite loading and unloading processes, ensuring swift vessel turnaround times. Additionally, smart ports in the UAE have integrated blockchain technology for secure and transparent documentation, simplifying customs procedures and reducing paperwork. The seamless flow of information between stakeholders has elevated the UAE's ports to global standards of excellence.

Digitalization of Supply Chain Management In the digital age, the UAE's shipping services like Focal Shipping have embraced sophisticated supply chain management solutions to optimize efficiency and meet customer demands. With real-time data sharing across the supply chain, stakeholders can track cargo movement, inventory levels, and delivery status, enhancing transparency and reducing lead times. Advanced analytics and machine learning algorithms help predict demand patterns, enabling proactive inventory management and timely replenishment. Furthermore, e-commerce integration has facilitated seamless online transactions, empowering businesses to reach global markets with ease. By embracing digitalization, the UAE's shipping industry has ensured uninterrupted supply chain operations, even during challenging times.

Green Shipping Practices for Environmental Sustainability Recognizing the importance of environmental responsibility, the shipping services UAE have embraced green practices to minimize their carbon footprint. Adoption of energy-efficient vessels, powered by alternative fuels, has significantly reduced greenhouse gas emissions. Additionally, some ships have been equipped with emission reduction technologies, such as scrubbers and catalytic converters, to lower air pollution. The UAE's shipping industry has also invested in eco-friendly port infrastructure, including electric cranes and renewable energy-powered facilities. By prioritizing sustainability, the UAE's shipping services are playing a vital role in global efforts to combat climate change and protect marine ecosystems.

Autonomous Vessels and Drones: The Future of Shipping Innovation in the UAE's shipping industry goes beyond the present, with a focus on autonomous vessels and drones. Autonomous ships, driven by artificial intelligence and sensors, have the potential to revolutionize maritime operations. They can optimize route planning, monitor vessel performance, and reduce the risk of accidents caused by human error. Additionally, the integration of drones in shipping services enables efficient surveying of port facilities, cargo inspections, and even last-mile deliveries. By exploring futuristic concepts like autonomous vessels and drones, the UAE's shipping industry like Focal Shipping is at the forefront of shaping the future of maritime trade.

Collaborative Partnerships and Innovation Hubs The shipping services UAE have fostered collaborative partnerships with leading technology companies and research institutions. These partnerships create innovation hubs that focus on developing groundbreaking solutions for the shipping industry. Joint ventures between shipping companies and tech firms have resulted in digital platforms that offer end-to-end supply chain visibility, facilitating seamless communication and coordination between stakeholders. Such collaborations enable the rapid adoption of emerging technologies and provide a fertile ground for experimentation and advancement.

The UAE's shipping services have embarked on an exciting journey of innovation and technological progress, setting new standards for the global maritime industry. With smart ports, digitalized supply chain management, green shipping practices, and a focus on autonomous vessels and drones, the UAE is at the forefront of revolutionizing shipping services. By embracing collaboration and strategic partnerships, the nation's shipping industry is nurturing a culture of innovation and continuous improvement. As the UAE's shipping services navigate the ever-changing seas of technology, they are poised to shape a sustainable, efficient, and advanced future for maritime trade.

2 notes

·

View notes

Text

The Common Reasons For Warehouse Accidents

The warehouse has become a dangerous place for you. The effectiveness of warehouse accidents will have a direct impact on the effectiveness of the business. It has become critical to adopt warehouse safety protocols in order to avoid these types of hazards. The following are some of the most prevalent causes of warehouse accidents, as well as some solutions to prevent them.

Accidental fall: Vertical tubes are commonly used in warehouses to store items. These storage units are frequently tall, which may be the cause of a fall. Almost half of all workplace injuries occur at a height of 15 feet or less. It is critical to prevent these types of mishaps by restricting workers from mounting ladders to collect things and other associated mechanisms utilised in the warehouse, such as an automated system or a forklift.

Slips And Trips: A simple slip on the warehouse's moist flooring can cause significant damage. That is why a slip is one of the most common injuries in the warehouse management process. There are several methods for avoiding these types of accidents. Such as making sure your warehouse is well-organized, filling gaps in the flooring, and so on.

Motion: Every year, the most injuries in the warehouse are caused by motion. This involves repeated action and improper lifting of goods. There are several ergonomic methods for preventing this that benefit the workforce and are worth considering. Start with the fundamental warehouse automation procedure.

Poisonous And Hazardous Substances: The poisonous and hazardous commodities, such as corrosive acid, are the second most dangerous items in the warehouse. You must guarantee that your employees are properly equipped for handling these types of items. Gloves, ventilation, a face mask, and other such items are examples. Make sure your warehouse has a designated area for handling anything poisonous or possibly harmful. Train your employees in various tactics so that they can respond fast and avert major harm.

Anyspaze, one of the best warehouse management companies in India, has professionals on board who are well-known for doing a thorough analysis of the business requirements of any sector while keeping all safety protocols in mind. The company handles all of your logistical activities, including transportation, quality control, storage, and reporting, while ensuring the employee's complete safety. Tracking the whereabouts of items in the warehouse becomes much easier with tech-based inventory management systems. So, with Anyspaze, you can get the greatest logistics and warehousing services at the most inexpensive pricing.

Forklifts, for example, have a high potential for mishaps and are the cause of many injuries in the warehouse every year. Employee training has become increasingly crucial in preventing this. Also, ensure that any heavy machinery in your warehouse is in good working order and is regularly maintained.

Anyspaze, market leading warehouse storage provider, the greatest commercial storage solutions for all of your business's storage issues. The company provides flexible warehouse storage space for rent to keep your items safe at extremely inexpensive costs. Anyspaze is a countrywide network of retailers that may greatly assist your business in ensuring on-time last-mile delivery. Businesses may rent customised and smart warehouses with centralised networks and tech-based logistics services from the company. Anyspaze is a well-known company in the storage and logistics market, specialising in FMCG, Oil & Gas, Lubricants, and other industries. With Anyspaze smart warehouse solutions, you can enjoy reduced inventory management expenses, better delivery speed, comprehensive fulfilment solutions, and 0% weight discrepancy.

Source: https://anyspaze.livejournal.com/7723.html

3 notes

·

View notes

Text

Basic Warehouse Facilities Requirements

A warehouse is much more than just a space to dump all your goods in. It is a place where dedicated processes take place; processes that make up an essential part of the supply chain. Every growing business needs space for warehousing but investing in a space that lacks facilities for efficient warehousing might just be a waste.

AWL India is among the leading warehouse service providers in Gurgaon that offers optimized warehouse spaces where businesses can sort their warehousing operations seamlessly. For businesses that struggle with optimizing these operations to improve their overall supply chain management, working with a partner like AWL India can be really beneficial. Being a pioneer in the logistics and supply chain management industry, AWL India understands 360-degree warehousing and logistics and provides reliable advice and solutions for the same. Their solutions come from their years of experience, and are, thus, trustable.

According to AWL India, there are some facilities that should be in an ideal warehouse, in order to make operations easy and effortless. In this blog, I will be discussing the same.

#warehousing companies in india#warehouse#awl warehouse#smart warehouses#smart warehouse technology#smart warehouse solutions

0 notes

Link

Complete Shipping Solutions is your 3PL ecommerce fulfillment and order management logistics provider. Learn more about our ecommerce fulfillment system.

#edmonton 3pl warehouse#logistics solutions edmonton#3pl warehouse edmonton#edmonton smart shipping#fulfillment warehousing edmonton#fulfilment logistics edmonton#fulfillment warehouse edmonton

0 notes