#sewage suction machine in India

Text

What are the Functions of Sewage Suction Machine?

sewage suction machine is a specialized vehicle equipped with a vacuum system designed to efficiently collect and transport liquid waste, such as sewage, sludge, and industrial effluents, for proper disposal or treatment.

The sewage suction machine, also known as a vacuum truck or vacuum tanker, serves several important functions in waste management and sanitation:

· Wastewater Collection: The primary function of a sewage suction machine is to collect wastewater from various sources, including residential, commercial, and industrial areas. This includes sewage from households, as well as liquid waste from restaurants, factories, and other establishments.

· Drainage and Cleaning: Sewage suction machines are used to clean and clear drainage systems, including sewers, stormwater drains, and culverts. They can remove debris, silt, and other obstructions that might block the flow of wastewater, preventing backups and flooding.

· Septic Tank Emptying: In areas where homes and buildings rely on septic tanks for wastewater treatment, sewage suction machines are used to empty these tanks when they become full. Regular maintenance of septic tanks is essential for preventing overflows and groundwater contamination.

· Grease Trap Cleaning: Restaurants and food service establishments use grease traps to capture grease and oil from wastewater before it enters the sewer system. Sewage suction machines can effectively clean out these grease traps, preventing clogs and foul odors.

· Emergency Response: During emergencies such as floods, sewage overflows, or industrial spills, sewage suction machines play a crucial role in quickly removing excess water and contaminated liquids from affected areas. This helps mitigate the damage and prevents further environmental contamination.

· Transportation and Disposal: Once wastewater is collected, sewage suction machines transport it to treatment facilities for proper disposal or processing. Depending on the type of waste, it may undergo treatment to remove pollutants or be safely disposed of according to regulations.

Industrial Sewer Suction Machine

An industrial sewer suction machine is a powerful apparatus used to extract and transport large volumes of industrial wastewater, sludge, and debris from sewer systems, aiding in the maintenance and cleanliness of industrial facilities while ensuring compliance with environmental regulations.

Overall, sewage suction machines are essential tools in maintaining public health, sanitation, and environmental quality. By efficiently collecting and managing wastewater, they help prevent the spread of disease, protect water resources, and ensure the cleanliness of our communities.

Best Sewage Suction Machine Manufacturer in India

If you are looking for a best sewage suction machine manufacturer and supplier in India, look no further then, supertech engineers. Supertech Engineers is a leading manufacturer and supplier of Sewage Suction Machine in India. If you want to know Sewage Suction Truck Price in India, Please let us know your requirements!

For more details, please contact us!

Website : www.supertechengineer.co.in

Contact No. — +91–9910715032, +91–9311309436

Email — [email protected]

Address — MORTA INDUSTRIAL AREA, MORTA GHAZIABAD, Ghaziabad, Uttar Pradesh, India.

#sewer suction machine manufacturer in ghaziabad#sewer suction machine#sewer suction machine manufacturer#sewage suction machine in India#Sewage Suction Machine Manufacturer in India#supertech engineers

1 note

·

View note

Text

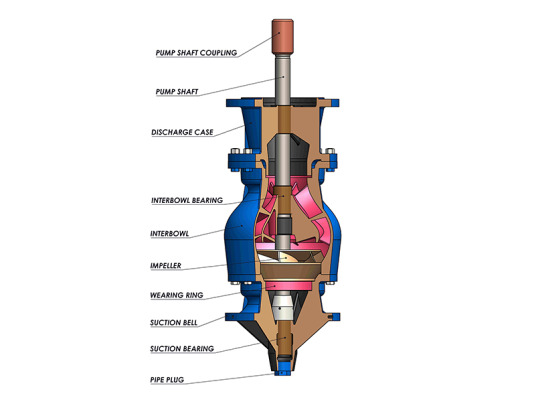

All You Need to Know About Vertical Centrifugal Pumps

A centrifugal pump helps transport fluids by converting rotational kinetic energy into hydrodynamic energy of the flow of liquid. In simpler terms, a centrifugal pump is a machine that transports fluids across various locations.

Vertical centrifugal pump employ a unique shaft and bear support configuration, which lets the volute hang in the sump while the bearings sit outside the sump.

Vertical Centrifugal Pump: Working and Mechanism

The pump is based on the principle of conversion of energy. Here is a step-by-step working of a centrifugal pump -

The pump suction nozzle lets the liquid in

The liquid further enters the rotating impeller vane through the eye

The rotating impeller generates a centrifugal force that pushes the liquid outward

The liquid then enters the volute casing, which dampens its velocity and increases the pressure while directing the fluid towards the discharge nozzle

The impeller and casing carry out the conversion of energy. The impeller ensures power transfer to the fluid, while the casing converts the same liquid head. If you wish to learn more about pumps, visit ATE India and browse Axis Valence product lineup as per your requirements.

Vertical Centrifugal Pump: Significance and Properties

A vertical centrifugal pump is the most commonly used type in different industries. Here are some of its properties-

Vertical pumps are ideal for applications with a low net positive suction head (NPSH), cooling water services and cryogenic temperatures

Vertical pumps save floor space since they take up 75% less than a horizontal pump with an electric motor drive

You can install a vertical pump in a well which eliminates the requirement for a surface reservoir

Since the driver for vertical pumps is up off the floor, the chances of damage caused by flooding are minimal

Vertical pumps are ideal for the mining industry, chemical plants and more since they have anti-friction bearing. This mechanism is safeguarded from water sprays owing to their location being in the motor above the pump

Salient Features of the Vertical Centrifugal Pump

The vertical centrifugal pump enjoys some salient features over other types, some of which include -

High head per stage

Heavy-duty impellers and casings

High-capacity water intake

Low maintenance and downtime

Robust designing and operation

Vertical Centrifugal Pump: Limitations and Challenges

As the industrial market is witnessing rapid growth, delivering high-power and maintenance-free vertical pumps is the primary challenge for different pump manufacturers.

While the vertical centrifugal pump enjoys some significant advantages over other pumps, here are some limitations that can hold it back -

Vertical pumps are slowing down by the day. They are not efficient enough to deliver enormous power to remove large volumes of water, viscous fluids, toxic chemicals, sewage and other corrosive liquids

Vertical pumps are not as efficient in removing high slurry concentrations, a shared waste product in several industries

The demand for high-pressure pumps that can swiftly eliminate high concentrations of slurry, viscous fluids, chemicals and sewage in processing plants is on the rise.

Final Words

Centrifugal pumps have different applications in several industries, which is why they come in different varieties. Depending on your requirements, you must pick one with a decent power rating, power consumption, ability to handle viscous fluids and other factors. This guide will help you understand how a vertical centrifugal pump works and which one to pick for your use case.

0 notes

Link

Before we begin to explore the applications, advantages and drawbacks of centrifugal pumps, it is important to understand what is a centrifugal pump?

A centrifugal pump is a machine used to move fluid using impellers. It converts mechanical energy into hydraulic energy. To explain centrifugal pump working in simple terms, it uses impellers submerged in water and when the machine is operational the impeller spins rapidly. The force applied by rotation of the impellers pushes the water out of the head. They are mostly used to move water from low levels to high levels. Centrifugal pumps are perfect to move liquids with low viscosity like light oil, but mostly water.

Let us know what are the main applications of a centrifugal pump?

Boost the pressure of water

Centrifugal pumps can also be used to boost the pressure of water. These pumps take water from the main source and boost it up ahead. These machines can run continuously or when powered on.

Also Read:- What Is the Best Fire Fighting Pump?

Pump water for domestic use

These pumps can also be used to draw out water for household or domestic use. For domestic use, these pumps are placed in reservoirs of water with depth not more than 22 feet. If there is a suction left of more than 22 feet, they can be paired with electrical motors or use self-combustion engines powered by petrol or diesel. It is the most commonly used type of pump for irrigation and for bore wells installed at homes.

Help in fire-fighting

A centrifugal pump is very commonly used in fire-fighting operations. It can either be a single-stage or a multi-stage pump powered by steam, petrol/diesel or electricity. The main idea is that whatever the source of power, it has to continue to keep driving the pump.

Helps in hot water circulation

Centrifugal pumps are the most commonly used type of pump where circulation of hot water is required. One thing that needs to be kept in mind is that when using a centrifugal pump for hot water circulation, the casing has to be strong and the stuffing box needs to be very proficient. The stuffing box should be flexible in mounting and should be free of any vapour binding.

Used for drainage of sewage

Another useful application of centrifugal pumps is the drainage of sewage. It can either be a vertical pump or a horizontal one. Flowmore pumps are one of premier Centrifugal Pumps manufacturer India and provide solutions to all kinds of pumps requirements.

Advantages of centrifugal pumps

>They can be used to pump out harmful fluids or fluids that are risky to deal with.

>As the pump and the motor are separated, they prevent heat transfer from the motor to the pump.

>There is reduced risk of leakage as they do not have drive seals.

>Centrifugal Pumps generate low friction.

Also Read :- Why a Sea Water Pump Is Must-Have for Marine Vessel

Drawbacks of Centrifugal Pumps

>if the liquid contains ferrous particles, that is if the liquid is rich in iron content, then it can lead to rusting thus resulting in breakdown of the machine.

>Centrifugal pumps are prone to heating if the flow of the liquid is less.

>The coupling may fall in case of an intense load.

>There can be energy loss due magnetic resistance generated by coupling.

0 notes

Text

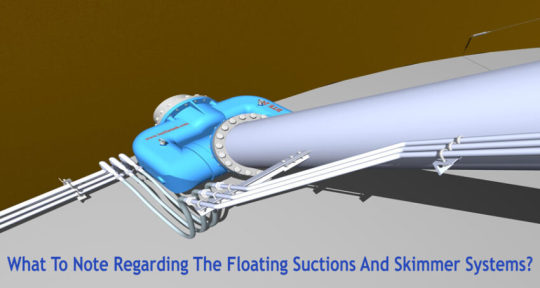

What to note regarding the floating suctions and skimmer systems?

Floating Suctions skimmers are designed specifically for clean and safe liquid removal from the storage tanks where the liquids are required to be sterilized by solids or water. The multi-patented Floating Suction Skimmer is the fast and one of the efficient and most sturdy devices that are highly durable and available for skimming as well as removing floating oil and contaminants from the industrial fluids procedure.

There are so many benefits if having Floating Suction Skimmer which are mentioned below

· It comes with a J-Tube model that has no hoses which sometimes affect the ballasting, and generate kinks and become collapsed or get robust

· The standards products for the level of the change of 7 inches, 3.5 inches, and 17 inches as well as the new pivot arm skimmers actually accommodate the level changes of up to 50 inches

· Suction Skimmer is designed with the quality-tested 304 stainless steel

· Durable, efficient, and simple to use as per the customers’ feedback

· Remove topmost fluid layer regularly o your coolant sumps and arts washer

· Easily set the calculated depth of skim which you require

· Floats with the changing fluid levels in your tanks

· Can be easily installed over the edge of the tank

Let’s have a look at the Oil skimmers as you must have the knowledge of skimmers

The oil skimmers are designed specifically to skim out the hydrocarbon liquid floating level on the top of the water. Well, the oil skimmer is designed importantly to remove the top layer of a two-phase liquid that is stored in a tank. Usually, the line size varies from 3 or 4 inches and Clear Ion Experts can design this larger size than this as per the requirement of the customers. You only have to explain your requirement and then, you will be assisted by a professional for the same.

Well, using an Oil Skimmer has various many benefits that include:

Opportunities for Recycling: In some examples, there are so many companies that can re-use the skimmed oil or they also can see it for the recycling process by selecting to keep their part of the word cleaner

Lessen the Disposal Expenses: The expense of oil disposable coolant is more costly than the oil disposing

Enhance the Coolant Life: If you have the oil-free coolant then, you are the lucky one as having it will enhance the functional life of the skimmer as well as also enhances the effectiveness while lessening the cost which you spend on the coolant and maintenance replacement.

Esthetic Benefits: Oil removal from a machine coolant tank will cut down on the smoke amount which is created from the advanced tool that is coming into the interaction with the oil-laden coolant and create a visible and cleaner workplace

EPA Violation Avoidance: There are so many metal working and machining shops that enable the aqueous parts by cleaning as the limits imposed by the EPA on the wastes and emissions discharge

Beneficial for Hygiene: Keeping coolant oil-free and oxygenated lessens the “rotten egg” smell, as well as bacterial levels, are also decreased and result in a cleaner and safer work environment

Enhance the Tool Life: The removal of floating surface oils when refresh and aerate coolant will enhance the life of the tool

There are two types of suction line:

· Roller – To use beneath an aluminum or steel floating roof

· Suspended – Generally used for fixed roof tanks

Floating Suction Assemblies are ideal for various reasons that are:

It helps to provide a cleaner and safer product portraying the fluid closest to the surface. Foreign particles, water, debris, and rust settle at the tank’s bottom via the gravity force. The suction consumption has a stop leg to maintain an uninterrupted bottom of the tank and remove the high percentage of the water as well as sediments from the aircraft fuel, heating oils, motor oils, and petrochemicals.

· It is also effective to lessen the inlet velocity with the special bellmouth therefore, the bottom stays undisturbed

· It is effective to transfer water from sewage treatment plant separation tanks. In the installation of inverted, it also can skim the oils from the water runoff settling tanks

· It is also effective in increasing the efficiency and decreasing the filter separator maintenance

These are a few things that one should keep in mind while using this floating suction oil skimmer system. If you are looking to get a Floating Suction Skimmer system in India then, Clear Ion Experts is the only answer. You can get this system in different sizes and specifications as per your demand.

Source url: https://clear-ion.com/blog/what-to-note-regarding-the-floating-suctions-and-skimmer-systems/

#Floating Suction Skimmer system in India#Oil skimmer systems#Floating Suction Skimmer#Oil Skimmer in India

0 notes

Link

Buy construction equipment, building construction equipment and building and construction machinery at leading ecommerce marketplace IndiaBizzness in budget price. There are more than thousand of manufactures, suppliers, exporters, buyer and sellers are registered with IndiaBizzness. Buy/Sell heavy equipment and building materials.

Buy various types as of construction machinery and equipment as concrete mixer, retiring cam elevator part, ladder, building material lifting, micro switches, cauldron, wheel dozers, transit vernier theodolite, mixture machine, deep well jet pump, concrete pump parts, portable reciprocating, duplex filter, dry mixer, end suction pumps, sewage pump, septic tanks receipt & treatment Stations, rotocast rrc closed oven, trolley stand ladder, wall plaster machine, multiscrub, oil cooler /hydraulic oil, building material lifting, wheel barrow, casting sheet metal, high pressure multistage and fountain & pond pumps.

#Building Construction Machinery in India#Buy Construction Machinery Equipment Online#B2B Ecommerce Marketplace#Buy construction equipment#construction equipment#ecommerce marketplace IndiaBizzness#Manufacturers#Suppliers#Sale Electrical Supplies#B2B Ecommerce Platforms in India

0 notes

Text

Effective pumping to sustainably clean the holy River Ganges of tannery wastewater and effluents

As part of the National Clean Ganga Mission, Andritz supplied 15 pumps for conveying tannery wastewater and effluent to effluent treatment plants in Kanpur, India, to clean the River Ganges in preparation for the 2019 Kumbh Mela festival.

Usually, more than 120 million Hindu devotees participate in Kumbh Mela, making it one of the largest religious gatherings in the world. It is a central pilgrimage and festival of Hinduism, celebrated at four different Indian riverbank sites – the confluence of the Ganga, Yamuna and the mythical Saraswati rivers, and on the banks of the Ganga, the Godavari and the Shipra rivers – in a 12-year cycle. The main highlight of this event is the ritual dipping into or bathing in the water combined with a prayer. This is believed to liberate the devotee from the cycle of rebirths or result in atonement and penance for mistakes and sins committed. The motivations for bathing might be different, but the water quality of the rivers, especially the Ganges at Kanpur, India, is life-threatening due to discharge of untreated sewage, effluents, drainage, etc. into the Ganga River.

River pollution on the rise

In India, the majority of the rivers are absolutely filthy. According to a 2019 study issued by the Central Pollution Control Board, a statutory organization under the Indian Ministry of Environment, Forest and Climate Change, the number of polluted stretches in the rivers has increased from 301 to 351 in the past two years. The number of critically polluted ones has even risen from 34 to 45. Among them is also the largest river on the Indian subcontinent, the Ganga. It is considered the sixth-most polluted river in the world.

Long-term cleaning attempts

The disastrous water quality of the Ganga is, however, not a new issue. In the 1980s, the Ganga Action Plan was launched to clean the river. Sewage treatment plants were built in the three most populous provinces along the river, Uttar Pradesh, Bihar, and West Bengal. In a similar project, other sewage treatment plants were added along the river in the 1990s.

Over the years, the population along the Ganges has rapidly increased, resulting in more sewage. In Kanpur, India, lots of tanneries producing tannery wastewater and effluents, which contain fibrous material such as fats, skin, hair, sewage, and the like, discharge this waste into the Ganges due to pumping issues with the old pumps they still have installed.

Finally, a number of new governmental initiatives and programs were introduced to sustainably tackle this pollution issue over the past ten years. In 2009, the National Ganges River Basin Authority was founded to take a more holistic approach to cleaning the basin and maintaining free flow in the river. This authority was later disbanded and succeeded by the National Mission for Clean Ganges (NMCG) in October 2016. The aim is to clean the Ganges and its tributaries thoroughly and effectively. In 2014, the Namami Gange (meaning Salutations to Ganga) program was launched to clean the river. Additionally, the Ministry of Water Resources was renamed to the Ministry of Water Resources, River Development, and Ganges Rejuvenation to further underline the seriousness of intentions to improve the water quality there.

Clean Ganga Mission for Kumbh Mela

In the Clean Ganga Mission for Kumbh Mela, the scope of supply consisted of four Andritz self-priming pumps from the AD series and eleven Andritz single-stage centrifugal pumps from the ACP series.

In addition to these long-term programs, the Government Department of India for Uttar Pradesh strengthened the Clean Ganga Mission for Kumbh Mela well ahead of the religious event, which took place from January 15 to March 4, 2019. A major stimulus behind this initiative was a report by the Uttar Pradesh Pollution Control Board stating that the River Ganges at Prayagraj is unsafe for bathing both upstream and downstream. The report showed that the water contains extremely high levels of coliform bacteria, mostly fecal coliform. Large numbers of such coliform bacteria can lead to water-borne diseases such as diarrhea.

To quickly improve this situation and ensure safe Ganges water for the devotees visiting Kumbh Mela 2019 at Prayagraj, the National Mission to Clean Ganga made additional funds available and the State Mission for Clean Ganga of Uttar Pradesh took various measures to treat the wastewater discharged into the river. These included release of extra water upstream at the Tehri dam in Uttarakhand on the one hand and the temporary closure of heavily polluting tanneries in Kanpur, a city located upstream of Prayagraj. On the other hand, the main target of this mission was to replace old pumps in the effluent pumping stations along the river in Kanpur. These pumps are not able to effectively handle today’s waste and thus, they break down regularly. To tackle this issue and prevent untreated wastewater from flowing into the Ganges, existing effluent pumping stations were renovated with new pumps.

The award specifications for supply of the pumps to the effluent treatment plants were quite strict: a tight delivery time of three months and the capability to handle fibrous liquids with a density of up to 1300 kg/m3. Thanks to its ability to ensure fast delivery and commissioning within the given period as well as fulfilling the pumps’ technical requirements, Andritz was awarded the contract to manufacture and supply 15 new pumps, including 4 self-priming pumps to seven pumping stations in Kanpur, Uttar Pradesh.

The infrastructure expert

The Andritz single-stage centrifugal pump from the ACP series is particularly versatile thanks to its highly wear-resistant, open impeller design, low axial thrust, and open channels. Depending on the impeller design, the pumps can convey slightly contaminated as well as heavily contaminated media containing some solids. Thus, these pumps are suitable for conveying many different media, allowing them to be installed as process pumps in a wide range of industrial applications from pulp and paper to water supply and wastewater treatment.

Founded in 1854 in Graz, Austria, the international technology group Andritz looks back on a long tradition as a global manufacturer of machinery and industrial plants. Its Pumps division is one of the oldest within the company. The many years of experience in building hydraulic machines and the entire process know-how form the basis for the high standard of Andritz pumps technology today. However, with its approximately 29,700 employees operating from more than 280 locations in over 40 countries, Andritz is not a newcomer to India. The company currently runs eight offices on the Indian subcontinent, including a manufacturing assembly dedicated to pumps in Chennai. At the workshop, high-quality single- and double-suction centrifugal pumps are manufactured, assembled and tested according to European standards. Additionally, the international technology group is currently supporting the Indian infrastructure mega-project Jala Yagnam in a total of eleven sub-projects. These include 27 customized vertical volute pumps for three pumping stations belonging to the largest sub-project, Kaleshwaram, which is designed to store about 4.7 trillion liters of water in order to irrigate 740,000 hectares.

In the Clean Ganga Mission for Kumbh Mela, the scope of supply consisted of four Andritz self-priming pumps from the AD series and eleven Andritz single-stage centrifugal pumps from the ACP series. The latter pump type is particularly versatile thanks to its highly wear-resistant, open impeller design, low axial thrust, and open channels. Depending on the impeller design, the pumps can convey slightly contaminated as well as heavily contaminated media containing some solids and with consistencies of up to 8 percent. Thus, these pumps are suitable for conveying many different media, allowing them to be installed as process pumps in a wide range of industrial applications from pulp and paper to water supply and wastewater treatment. A modular system ensures high availability, enables the use of proven components and reduces the number of spare parts to be held in stock.

To round off the pumps order, Andritz self-priming pumps from the AD series achieve high priming and degassing performance thanks to their integrated vacuum pump. With its open impeller, the pump is designed for and insensitive to transporting high solids-containing media or even viscous media. The open impeller also provides better efficiencies with viscous media compared to closed impellers. The integrated vacuum pump prevents air from collecting at the impeller inlet and guarantees that the pump primes well, even with high gas content or unfavorable suction pipe arrangements. Thanks to these design features, the self-priming centrifugal pumps are perfectly suited for applications and processes in wastewater treatment.

Completed within a record time of three months from award of the order to the pumps’ erection and commissioning, the hydraulic machines were installed at the most critical application in the process. They pump the tannery wastewater up to the effluent treatment plant. To perform this task reliably, the pumps are capable of handling fibrous liquids with a density of up to 1300 kg/m3. Since their start-up, all the pumps have been working successfully without any problems and to the customer’s full satisfaction.

On the right path

Most of the 150 million pilgrims attending the event reported that the water was much cleaner due to these special temporary and long-term efforts. However, making and keeping a river clean is a continuous process. The Clean Ganga Mission initiative for Kumbh Mela was another important step in the right direction as its mixture of both temporary and permanent measures, such as renewing the pumps in the sewage and effluent treatment plants, contributed to noticeably cleaner water in the downstream Ganges region, covering a 135-kilometer route from Allahabad.

Company profile:

Andritz is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where Andritz offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the company is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas and exhaust gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

Andritz stands for passion, partnership, perspectives and versatility – core values to which the company is committed. The listed Group is headquartered in Graz, Austria. With almost 170 years of experience, approximately 29,600 employees, and more than 280 locations in over 40 countries worldwide, Andritz is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.

Contact by mail

www.andritz.com/pumps

Read the full article

#Andritz#centrifugal#Deltap#drinkingwater#Ganga#Ifat#India#self-priming#single-stage#VirtuelleIFAT2020#Wastewater#Water#watermanagement#watersupply

0 notes

Text

Swimming Pool Equipment Market Leading Manufacturers, Consumption, Analysis & Forecast to 2022

The global Swimming Pool Equipment market is valued at XX million USD in 2016 and is expected to reach XX million USD by the end of 2017, growing at a CAGR of XX% between 2016 and 2022.

Japan plays an important role in global market, with market size of xx million USD in 2016 and will be xx million USD in 2017, with a CAGR of xx%.

This report, with focus on top players in the global and Japan, studies the Swimming Pool Equipment market's development status and future trend in the global and Japan. It splits Swimming Pool Equipment market by type and by applications to fully and deeply research and reveal market profile and prospect.

Download Free Sample Report @ https://www.radiantinsights.com/research/2017-2022-global-and-japan-swimming-pool-equipment-market-analysis-report/request-sample

The major players include

• EMAUX(Australia)

• Desjoyaux(France)

• Hayward(US)

• Pentair(US)

• DSL(China)

• WATERCO(Australia)

• AQUA(Italy)

• JT(China)

• AQUATECHNIQUE(Australia)

• Astralpool(Spain)

• Arch(US)

• HENGTAI(China)

• LASWIM(China)

Geographically, this report splits the Global market into the following regions:

• Asia Pacific

• Japan

• Tokyo

• Yokohama

• Osaka

• Nagoya

• Others

• China

• Korea

• India

• Others

• Europe

• France

• Germany

• United Kingdom

• Italy

• Russia

• Others

• North America

• United States

• Canada

• Latin America

• Brazil

• Mexico

• Others

• Southeast Asia

• Singapore

• Malaysia

• Vietnam

• Myanmar

• Thailand

• Indonesia

• Philippines

• Others

• Middle East & Africa

• Saudi Arabia

• Iran

• UAE

• Turkey

• Israel

• Egypt

• South Africa

• Others

On the basis of product, the Swimming Pool Equipment market is primarily split into By Pool Classification

• Indoor Pool

• Outdoor Pool

By Swimming Pool Equipment Types

• Power Equipment

• Filtration Equipment

• Disinfection Equipment

• Constant Temperature Equipment

• Sewage Suction Equipment

By Cycle Mode

• Downstream

• Countercurrent

• Mixed Flow

• No Machine-room

By Water Temperature Design

• Heated Pool

• Non-constant Temperature Pool

Key Applications

• Home Use

• Commercial Use

• Stadium Use

Browse Full Research Report with TOC @ https://www.radiantinsights.com/research/2017-2022-global-and-japan-swimming-pool-equipment-market-analysis-report

Table of Contents

2017-2022 Global and Japan Swimming Pool Equipment Market Analysis Report

1 Swimming Pool Equipment Overview

1.1 Product Overview and Scope of Swimming Pool Equipment

1.2 Global and Japan Swimming Pool Equipment Market by Applications/End Users

1.2.1 Japan Swimming Pool Equipment Sales (K Units) and Market Share Comparison by Applications (2012-2017)

1.2.1.1 Japan Swimming Pool Equipment Sales (K Units) and Market Share by Applications (2012-2017)

1.2.1.2 Japan Swimming Pool Equipment Sales Growth Rate (%) by Applications (2012-2017)

1.2.1.3 Market Drivers and Opportunities

1.2.2 Japan Swimming Pool Equipment Sales (K Units) and Market Share Comparison by Applications (2012-2017)

1.2.3 Global Swimming Pool Equipment Sales by Application (2012-2017)

1.2.3.1 Global Swimming Pool Equipment Sales (K Units) and Market Share by Applications (2012-2017)

1.2.3.2 Global Swimming Pool Equipment Sales Growth Rate (%) by Applications (2012-2017)

1.2.3.3 Market Drivers and Opportunities

1.2.4 Global Swimming Pool Equipment Sales (K Units) and Market Share Comparison by Applications (2012-2017)

1.2.5 Home Use

1.2.6 Commercial Use

1.2.7 Stadium Use

1.3 Global and Japan Market Size (Sales and Revenue) of Swimming Pool Equipment (2012-2017)

1.3.1 Japan Market Size (Sales and Revenue) of Swimming Pool Equipment (2012-2017)

1.3.1.1 Japan Swimming Pool Equipment Sales (K Units) and Growth Rate (%) (2012-2017)

1.3.1.2 Japan Swimming Pool Equipment Revenue (Million USD) and Growth Rate (2012-2017)

1.3.2 Global Market Size (Sales and Revenue) of Swimming Pool Equipment (2012-2017)

1.3.2.1 Global Swimming Pool Equipment Sales (K Units) and Growth Rate (%) (2012-2017)

1.3.2.2 Global Swimming Pool Equipment Revenue (Million USD) and Growth Rate (2012-2017)

1.4 Global and Japan Classification of Swimming Pool Equipment by Pool Classification

1.4.1 Japan Swimming Pool Equipment Sales (K Units) and Market Share by Pool Classification (2012-2017)

1.4.2 Global Swimming Pool Equipment Sales (K Units) and Market Share by Pool Classification (2012-2017)

1.4.3 Japan Swimming Pool Equipment Revenue (Million USD) and Market Share by Pool Classification (2012-2017)

1.4.4 Global Swimming Pool Equipment Revenue (Million USD) and Market Share by Pool Classification (2012-2017)

1.4.5 Japan Swimming Pool Equipment Price (USD/Unit) by Pool Classification (2012-2017)

1.4.6 Global Swimming Pool Equipment Price (USD/Unit) by Pool Classification (2012-2017)

1.4.7 Japan Swimming Pool Equipment Sales Growth Rate (%) by Pool Classification (2012-2017)

1.4.8 Global Swimming Pool Equipment Sales Growth Rate (%) by Pool Classification (2012-2017)

1.4.9 Indoor Pool

1.4.10 Outdoor Pool

1.5 Global and Japan Classification of Swimming Pool Equipment by Swimming Pool Equipment Types

1.5.1 Japan Swimming Pool Equipment Sales (K Units) and Market Share by Swimming Pool Equipment Types (2012-2017)

1.5.2 Global Swimming Pool Equipment Sales (K Units) and Market Share by Swimming Pool Equipment Types (2012-2017)

1.5.3 Japan Swimming Pool Equipment Revenue (Million USD) and Market Share by Swimming Pool Equipment Types (2012-2017)

1.5.4 Global Swimming Pool Equipment Revenue (Million USD) and Market Share by Swimming Pool Equipment Types (2012-2017)

1.5.5 Japan Swimming Pool Equipment Price (USD/Unit) by Swimming Pool Equipment Types (2012-2017)

1.5.6 Global Swimming Pool Equipment Price (USD/Unit) by Swimming Pool Equipment Types (2012-2017)

1.5.7 Japan Swimming Pool Equipment Sales Growth Rate (%) by Swimming Pool Equipment Types (2012-2017)

1.5.8 Global Swimming Pool Equipment Sales Growth Rate (%) by Swimming Pool Equipment Types (2012-2017)

1.5.9 Power Equipment

1.5.10 Filtration Equipment

1.5.11 Disinfection Equipment

1.5.12 Constant Temperature Equipment

1.5.13 Sewage Suction Equipment

1.6 Global and Japan Classification of Swimming Pool Equipment by Cycle Mode

1.6.1 Japan Swimming Pool Equipment Sales (K Units) and Market Share by Cycle Mode (2012-2017)

1.6.2 Global Swimming Pool Equipment Sales (K Units) and Market Share by Cycle Mode (2012-2017)

1.6.3 Japan Swimming Pool Equipment Revenue (Million USD) and Market Share by Cycle Mode (2012-2017)

1.6.4 Global Swimming Pool Equipment Revenue (Million USD) and Market Share by Cycle Mode (2012-2017)

1.6.5 Japan Swimming Pool Equipment Price (USD/Unit) by Cycle Mode (2012-2017)

1.6.6 Global Swimming Pool Equipment Price (USD/Unit) by Cycle Mode (2012-2017)

1.6.7 Japan Swimming Pool Equipment Sales Growth Rate (%) by Cycle Mode (2012-2017)

1.6.8 Global Swimming Pool Equipment Sales Growth Rate (%) by Cycle Mode (2012-2017)

1.6.9 Downstream

1.6.10 Countercurrent

1.6.11 Mixed Flow

1.6.12 No Machine-room

1.7 Global and Japan Classification of Swimming Pool Equipment by Water Temperature Design

1.7.1 Japan Swimming Pool Equipment Sales (K Units) and Market Share by Water Temperature Design (2012-2017)

1.7.2 Global Swimming Pool Equipment Sales (K Units) and Market Share by Water Temperature Design (2012-2017)

1.7.3 Japan Swimming Pool Equipment Revenue (Million USD) and Market Share by Water Temperature Design (2012-2017)

1.7.4 Global Swimming Pool Equipment Revenue (Million USD) and Market Share by Water Temperature Design (2012-2017)

1.7.5 Japan Swimming Pool Equipment Price (USD/Unit) by Water Temperature Design (2012-2017)

1.7.6 Global Swimming Pool Equipment Price (USD/Unit) by Water Temperature Design (2012-2017)

1.7.7 Japan Swimming Pool Equipment Sales Growth Rate (%) by Water Temperature Design (2012-2017)

1.7.8 Global Swimming Pool Equipment Sales Growth Rate (%) by Water Temperature Design (2012-2017)

1.7.9 Heated Pool

1.7.10 Non-constant Temperature Pool

2 Global and Japan Swimming Pool Equipment Market Competition by Players/Manufacturers

2.1 Japan Swimming Pool Equipment Market Competition by Players/Manufacturers

2.1.1 Japan Swimming Pool Equipment Sales and Market Share of Key Players/Manufacturers (2012-2017)

2.1.2 Japan Swimming Pool Equipment Revenue and Share by Players/Manufacturers (2012-2017)

2.1.3 Japan Swimming Pool Equipment Average Price (USD/Unit) by Players/Manufacturers (2012-2017)

2.1.4 Japan Swimming Pool Equipment Market Competitive Situation and Trends

2.1.4.1 Japan Swimming Pool Equipment Market Concentration Rate

2.1.4.2 Japan Swimming Pool Equipment Market Share of Top 3 and Top 5 Players/Manufacturers

2.1.4.3 Mergers & Acquisitions, Expansion in Japan Market

2.1.5 Japan Players/Manufacturers Swimming Pool Equipment Manufacturing Base Distribution, Sales Area, Product Types

2.2 Global Swimming Pool Equipment Market Competition by Players/Manufacturers

2.2.1 Global Swimming Pool Equipment Sales and Market Share of Key Players/Manufacturers (2012-2017)

2.2.2 Global Swimming Pool Equipment Revenue and Share by Players/Manufacturers (2012-2017)

2.2.3 Global Swimming Pool Equipment Average Price (USD/Unit) by Players/Manufacturers (2012-2017)

2.2.4 Global Swimming Pool Equipment Market Competitive Situation and Trends

2.2.4.1 Global Swimming Pool Equipment Market Concentration Rate

2.2.4.2 Global Swimming Pool Equipment Market Share of Top 3 and Top 5 Players/Manufacturers

2.2.4.3 Mergers & Acquisitions, Expansion in Global Market

2.2.5 Global Players/Manufacturers Swimming Pool Equipment Manufacturing Base Distribution, Sales Area, Product Types

Read all Reports of this category @ https://www.radiantinsights.com/catalog/machinery

About Radiant Insights

Radiant Insights is a platform for companies looking to meet their market research and business intelligence requirements. It assists and facilitate organizations and individuals procure market research reports, helping them in the decisions making process. The Organization has a comprehensive collection of reports, covering over 40 key industries and a host of micro markets. In addition to over extensive database of reports, experienced research coordinators also offer a host of ancillary services such as, research partnerships/ tie-ups and customized research solutions.

Media Contact:

Company Name: Radiant Insights, Inc

Contact Person: Michelle Thoras

Phone: (415) 349-0054

Toll Free: 1-888-928-9744

Address: 201 Spear Street 1100, Suite 3036,

City: San Francisco; State: California; Country: United States

Email: [email protected]

Website: https://www.radiantinsights.com/

0 notes

Text

Kamlesh Tandon Hospital | Dr. Vaishali Tandon | Elawoman

Kamlesh Tandon Hospital

Dr. Kamlesh Tandon Hospital and Test Tube Baby Centre is a multispecialty hospital in Lajpat Kunj, Agra with numerous contemporary centers for the comfort and improved stories of sufferers. Various hi-tech medical devices with progressed generation are utilized in the processes and treatments on the centre. The entire health facility has over 80 beds.

Among these, 7 beds are found in ICU and 11 beds are found in NICU. Also, centers like cardiac video display units, ventilators, phototherapy devices and crucial station oxygen gasoline line are supplied at the centre to improve treatment effects. The fertility associated offerings to be had on the centre encompass IVF, Donor sperms and eggs, Laparoscopy, MESA, Surrogacy, Hysterectomy and Testicular Biopsy. Dr. Vaishali Tandon is the working towards medical doctor at Dr. Kamlesh Tandon Hospital and Test Tube Baby Centre.

Dr. Kamlesh Tandon Hospital & Test Tube Baby Centre is a multispecialty health facility having hellotech extremely-contemporary medical devices for diagnosis and treatment with well qualified and skilled docs.

Dr. Kamlesh Tandon Hospital & Test Tube Baby Centre is a multispecialty health center having hellotech extremely-modern-day clinical devices for diagnosis and treatment with well certified and experienced medical doctors. Hospital is having a electricity of over eighty beds which is consisting of a separate 7 bedded ICU and a 11 bedded NICU with valuable station oxygen line, suction, cardiac monitors, phototherapy units, defibrillators, ventilators and so on.

The health facility constructing is aesthetically designed and centrally placed in the coronary heart of Agra. It has adequate power deliver from the Torrent Power ltd. With three stand by means of turbines, of sixty two.5 kva, 125 kva & 250 kva capacity, water supply and sewage connection from Jal Nigam. Water supply is supplemented by way of the clinic’s very own bore properly. The clinic has certification from Pollution Control Board and follows a nicely-described scientific Waste Disposal programme.

Services:- IVF,IUI,IVF, Freezing of Sperms/Embryos/Oocytes

Location:- Lajpat Kunj, Agra

Timing:- Monday - Saturday, 6:00 pm - 7:00 pm

Rating :- 3.9 / 5

Dr. Vaishali Tandon

Dr. Vaishali Tandon is a Gynecologist and IVF Specialist in Lajpat Kunj, Agra. She has MBBS and MS in Obstetrics and Gynecology degrees. She became a gold medalist throughout her post graduation. She specializes in excessive hazard obstetrics, pelvic floor surgery, IVF and Preimplantation, IVF Failure instances, laparoscopic and hysteroscopic surgeries.

Dr. Vaishali Tandon has good sized years of revel in in treating patients with the infertility troubles in these fields. She has numerous medical publications to her credit. She is currently training at Dr. Ramesh Tandon Hospital and Test Tube Baby Centre, Agra. You can check out in addition information of Dr. Vaishali Tandon at elawoman.Com

Dr. Vaishali Tandon (Dr Kamlesh Tandon Hospital And Test Baby Centre) in Lajpat Kunj has built up the center and has picked up a loyal demographic inside the path of new years and is additionally every now and again went by using some well-known human beings, attempting models and different respectable clients and global sufferers additionally.

They additionally count on extending their commercial enterprise in addition and giving administrations to three more sufferers inferable from its prosperity within the direction of recent years. The productiveness, dedication, accuracy and empathy supplied on the facility assure that the affected person's prosperity, solace and wishes are kept of first-class need. The facility is furnished with maximum latest sorts of hardware and gloats notably advanced surgical instruments that help in experiencing cautious surgical procedures or techniques.

Dr. Kamlesh Tandon Hospital and Test Tube Baby Centre is a multispecialty restoration facility having welcome tech ultra-show off day restorative gadgets for guarantee and treatment with all round qualified and experienced masters. Healing center is having a nature of greater than 80 beds that's complete of an trade 7 laid down with ICU and a 11 had members of the family with NICU with imperative station oxygen line, suction, coronary heart displays, phototherapy units, defibrillators, ventilators et cetera.

Services:- IVF,IUI,IVF SPECIALIST, Gynae Laparoscopy & Hysteroscopy surgery

Location:- Lajpat kunj, Agra

Timing:- MON - SAT 6:01 PM - 7:00 PM

Rating :- 3.6 / 5

IVF Centres in Agra

Below are the Top IVF Centres in Agra with options to e book your first appointment FREE. Check Reviews, IVF Cost, Success charges, Fees, Contact Number and Address for all In Vitro Fertilization treatment. Also discover low cost test tube baby prices.

Aakanksha Test Tube Baby Center

Aakanksha Test Tube Baby Center is an IVF Clinic in Ram Nagar Colony, Agra. The hospital changed into set up in 2002. The services provided by using the center are In Vitro Fertilization (IVF), Infertility evaluation, Intrauterine Insemination (IUI), Ovary Stimulation and Laparoscopy surgical procedure. The sanatorium additionally expertises in providing Ovarian drilling, Tubal patency test, Semen evaluation, and Pregnancy transport methods.

It is a Federation of Obstetric and Gynaecological Societies of India (FOGSI) certified IVF center located in Agra. Aakanksha Test Tube Baby Center serves its patients spherical the clock. Dr. Anupam Gupta who is an IVF expert practices at this clinic. He offers various offerings associated with Infertility assessment, IUI (Intrauterine Insemination), In-Vitro Fertilization (IVF), Semen Analysis, Pregnancy care, and transport. He has an revel in of extra than a decade on this sphere. Click on the map and know the directions to reach Aakanksha Test Tube Baby Center.

Services:- IVF,IUI,IVF

Location:- Ram Nagar Colony, Agra

Timing:- Monday - Saturday, 10:00 am - 2:00 pm

Rating :- 4.3 / 5

Women Pulse Hospital & Research Centre

Women Pulse Hospital & Research Centre is the Gynecology and Obstetrics health center placed in Civil Lines, Agra. Women Pulse Hospital and Research Centre was established within the year 1995. It is one of the pinnacle gynecology and obstetrics hospital in Agra which serves parents with the required solutions to the infertility problems.

The centre offers quite a number infertility area of interest treatment answers like IVF, ICSI, Dilatation and Curettage, Laparoscopic Surgery, Hysterectomy, Adiana System, and Oophorectomy strategies. Dr. Babita Gupta, gynecologist and infertility expert practices at Women Pulse Hospital and Research Centre.

Women Pulse Hospital & Research Centre is a Gynecology/Obstetrics Clinic in Sanjay Place, Agra. The clinic is visited by using medical doctors like Dr. Babita Gupta.

The timings of Women Pulse Hospital & Research Centre are: Mon-Sat: 10:00-14:00, 18:00-21:00. Some of the offerings furnished by means of the Clinic are: Adiana System,Intracytoplasmic Sperm Injection (ICSI),Obstetrics & Gynaecology,Laparoscopic Surgery and In-Vitro Fertilization (IVF) and many others. Click on map to discover instructions to reach Women Pulse Hospital & Research Centre.

Services:- IVF,IUI,IVF, Intra Cytoplasmic Sperm Injection (ICSI)

Location:- Civil Lines, Agra

Timing:- Mon-Sat: 10:00-14:00, 18:00-21:00

Rating :- 4.1 / 5

Amit Jaggi Memorial Hospital

Amit Jaggi Memorial Hospital is a multispecialty hospital placed in Vibhav Nagar, Agra. The medical institution changed into established within the year 1971. The sanatorium affords diverse medical treatments to the patients. Various contemporary facilities and the modern ultrasound technology are carried out within the clinical approaches on the health facility.

It has also built a modern computerized pathology lab for the improved enjoy to the patients. The operation theatres are to be had of various sorts including A/C and non-A/C ones. It affords splendid IVF services for people and parents. Some of the gynecological services supplied by means of the medical institution encompass IVF, TESA, IUI, Baby Delivery and Gynecology Surgeries. Dr. Kavita Jaggi Agrawal is one of the quality gynecologists at Amit Jaggi Memorial Hospital.

This Hospital include General (Male/girl) Wards, Pvt. "& Semi Pvt. Air cooled Rooms , a/c & a/c Deluxe rooms ready with ultra-modern & modern Equipment like:-

Ultrasound machines- Aloka , Wipro-GE-RT 3200 & Toshiba for all type of Ultrasound Scanning.

X-Ray Machine .

A modern-day computerized pathology laboratory prepared with state-of-the-art model of Acto-1 automated chemistry analyzer.

Intensive care unit with cardiac monitor with defibrillator, pulse oximeter, 02 treatment unit & ventilator & aerobic web Digital ECG.

Well ready two A/C operation theatre with resuscitation equipments & ohmeda (USA) Bio x 3700 pulse oximeter & ventilator.

Ambulance service :- Fully Air conditioned ambulance VERSA VAN designed & changed by using DRAEGER MEDICAL – German Company Equipped with 02 treatment,suction machine, cardiac monitor with pulse oximeter,ventilator version MX10L(Latest Version)& AED Model CR Plus(Lifepak-USA) i.E. Automatic Electronic Defibrillator, Stretcher cum Trolley & trained para clinical personnel to be had round the clock.

Services:- IVF,IUI,IVF, Intra Cytoplasmic Sperm Injection (ICSI)

Location:- Vibhav Nagar, Agra

Timing:- Monday - Saturday, 11:00 am - 2:00 pm

Rating :- 3.9 / 5

For more information, Call Us : +91 – 7899912611

Visit Website : www.elawoman.com

Contact Form : https://www.elawoman.com/contact

Ela Facebook Ela Twitter Ela Instagram Ela Linkedin Ela Youtube

0 notes

Text

Centrifugal Pump Manufacturers in India Provide Faultless Products

Centrifugal pumps and hydraulic barrel pumps are mostly used in many industries. These pumps make your tasks easier and faster, hence these pumps very popular in industries to give accurate performance.

Centrifugal pumps are mostly used for pumping the water in residential and industrial properties. These machineries transfer liquids with the aid of kinetic energy that is saved in the motor. Although, their key function is to shift the water and cause the fluid to flow, centrifugal pumps are also helpful in food processing plants, sewage, chemical and petroleum industries manufacturing plants, water treatment plants and have become tremendously popular down the years.

There are many entrepreneurs interested to develop these pumps and hence several centrifugal pump manufacturers in India engage in making these pumps and deliver faultless machines in all over the country to fulfill the need of many industries.

Generally, centrifugal pumps find their applications in pumping all kinds of low tackiness liquids at temperate pressure. Then can also simply handle fluids having high extent of suspended solids present in them. The centrifugal pump manufacturers in India develop the product with the help of lots of skilled and certified expert professionals who fully trained in centrifugal pump making procedure.

Hydraulic Barrel Pump is a pressure pump connected to a barrel containing a fluid spray. It consists essentially of two intermeshing pointy gears covered in a general housing. There are several hydraulic Barrel Pumps Manufacturers in India that developed errorless products. A shaft, the drive tube, extends away from the housing. This tube is connected to one of the gears which, when it is moved by the tube, drive the second gear. The hydraulic fluid is intent in the gaps amid the gear teeth and pushed along the inside of the housing from the suction inlet port to the force outlet port. The vacuum needed in the suction chamber for illustration in the fluid is produced by the augment in volume which outcomes when one of the cog teeth and its mating tooth gap go out of net.

Generally, hydraulic barrel pumps available in two types which are rotary and linear pump. The hydraulic Barrel Pumps Manufacturers in India generate both the types of pumps for their clients.

The hydraulic barrel pumps are used in various industries such as textile industries, plants, water desalination plants, power stations and food industries. The centrifugal pumps are used in some industries like refineries, oil and energy companies, power plants, air conditioning, Heating and ventilation, fire protection sprinkler systems, pressure boosting, manufacturing industries, waste water processing plants, municipal, boiler feed applications, industrial applications, irrigation, flood protection and drainage, chemical and process industries, cellulose, pharmaceuticals, sugar refining, beverage and food production, cryogenics and refrigerants.

The enhancing demand of pumps becomes popular of its manufacturers and hence manufacturers develop accurate device and deliver on time to their clients.

0 notes

Text

Are You Looking for Sewer Suction Machine Manufacturers in India

We are a successful manufacturer and supplier of Sewer Suction Mchines in India, which is used to create a vacuum that is essential for siphoning of various materials like mud, slurry, and grit from storm, sanitary, and combined sewerage systems. This machine is manufactured using the best grades of material that ensures its finest quality and high performance. This hydraulic sewer suction machine comes with an unloader or a pressure relief valve that is used for controlling the pressure.

Sewer Suction Machine Manufacturers play a vital role in the efficient removal of sewage and waste materials from various drainage systems. These machines are designed to suction and transport liquid and solid waste, helping to maintain clean and functional sewer networks.

What is a Sewer Suction Machine?

A sewer suction machine, also known as a vacuum tanker or sewer cleaning truck, is a specialized vehicle equipped with powerful suction pumps and storage tanks. It is used for clearing blockages, cleaning sewer lines, and transporting sewage and sludge to treatment facilities.

How Does a Sewer Suction Machine Work?

Sewer suction machines utilize vacuum technology to create suction pressure, which effectively pulls waste materials into the storage tank. The collected waste is then transported to disposal sites or treatment plants for proper disposal or processing.

Types of Sewer Suction Machines

There are various types of sewer suction machines available, including truck-mounted units, trailer-mounted units, and skid-mounted units. Each type offers unique features and capabilities to suit different applications and environments.

Applications of Sewer Suction Machines

Sewer suction machines are used in a wide range of applications, including municipal waste management, industrial cleaning, and emergency response services. They are essential for maintaining clean and functional sewer systems in urban and rural areas alike.

Benefits of Using Sewer Suction Machines

Efficiency: Sewer suction machines offer efficient waste removal, reducing the risk of blockages and backups in sewer lines.

Versatility: These machines can handle various types of waste, including liquid and solid materials, making them versatile tools for waste management.

Cost-Effectiveness: By preventing costly repairs and minimizing downtime, sewer suction machines help save money in the long run.

Safety Precautions When Operating a Sewer Suction Machine

Operating a sewer suction machine requires adherence to strict safety protocols to prevent accidents and injuries. Always wear appropriate personal protective equipment (PPE), follow operational guidelines, and exercise caution when working near sewer lines.

Contact us right away, if you want to learn more about our wide range of sewer suction machine products. Call us at .+919311309436 or send an email to [email protected], we are India’s largest sewer suction machine manufacturers and suppliers.

#sewer suction machine manufacturers#sewer suction machine#sewer suction machine manufacturers in India#sewer suction machine manufacturers in Ghaziabad#sewer suction machine manufacturers in Uttar Pradesh#sewer suction machine suppliers#sewer suction machine suppliers in India#sewer suction machine suppliers in Ghaziabad#sewer suction machine suppliers in Uttar Pradesh

0 notes

Text

How does a Sewer Suction Machine Works?

What is Sewer Suction Machine?

A sewer suction machine, often referred to as a sewer vacuum truck or sewer cleaner truck, is a specialized vehicle equipped with a powerful vacuum system designed for the cleaning and maintenance of sewer and drainage systems. These machines are essential tools used by municipalities and sanitation departments to efficiently remove debris, sediment, sludge, and other waste materials from sewer lines, storm drains, and catch basins. They operate by creating a strong suction force through a nozzle-equipped hose, collecting the waste in a sealed vacuum tank, and often employing filtration and separation systems to separate solids from liquids. Once the vacuum tank is full, the waste is transported to an appropriate disposal facility, helping ensure the proper functioning of urban wastewater systems and environmental and public health.

Working and Functions of Sewer Suction Machine?

The working and function of a sewer suction machine can be summarized as follows:

Suction System: Sewer suction machines are equipped with a powerful vacuum system, typically featuring a vacuum pump or blower. This system creates a strong suction force, generating low pressure within the machine's vacuum tank.

Suction Hose and Nozzle: The machine has a long, flexible suction hose with a specialized nozzle at one end. The nozzle is designed to create a tight seal with the sewer line, storm drain, or catch basin to be cleaned.

Suction Process:

An operator extends the suction hose into the sewer or drainage system through an access point, such as a manhole or cleanout.

When the vacuum system is activated, it generates a powerful airflow that draws air and various materials (like debris, sediment, sludge, and water) into the hose.

Material Collection: The collected materials are transported through the hose and into the vacuum tank of the machine. The vacuum tank is a sealed container designed to store the waste materials until disposal.

Filtration and Separation: Many sewer suction machines are equipped with filtration and separation systems to separate solids from liquids. This allows the machine to separate water and other liquids, which can often be safely discharged back into the sewer system, from the solid waste, which is retained in the vacuum tank.

Disposal: Once the vacuum tank is filled with waste material, the operator transports the sewer suction machine to an appropriate disposal facility, such as a wastewater treatment plant or a landfill, to empty the tank.

Cleaning and Maintenance: Regular cleaning and maintenance of the sewer suction machine are crucial to keep it in proper working condition. This includes servicing the vacuum system, hoses, and filtration components.

The primary function of a sewer suction machine is to efficiently clean and maintain sewer and drainage systems, helping to prevent clogs, blockages, and other issues. These machines are essential for the proper functioning of urban wastewater systems, contributing to environmental and public health by ensuring the continuous flow of sewage and stormwater.

Best Sewer Suction Machine Manufacturer in India

If you are looking for the best sewer suction machine manufacturer in India, then look no further than Supertech Engineers. With a proven track record of delivering high-quality and efficient sewer suction machines, Supertech Engineers has established itself as a reliable and trusted provider in the industry. Their commitment to innovation, quality, and customer satisfaction sets them apart, making them an excellent choice for all your sewer maintenance needs.

For any type of queries, please contact us!

Website - www.supertechengineer.co.in

Contact No. - +91-9910715032, +91-9311309436

Email - [email protected]

#sewer suction machine#sewer suction machine manufacturer#sewer suction machine supplier#sewer suction machine manufacturer in India

0 notes

Text

Sewer Suction Machine Manufacturer in India

A sewer suction machine, also known as a sewer vacuum truck or sewage tanker, is a specialized vehicle equipped with a powerful pump and suction system designed to remove liquids, sludge, and debris from underground sewage systems, septic tanks, and other drainage infrastructure.

The machine typically consists of a large tank, a powerful vacuum pump, and a high-pressure water jet system. The vacuum pump creates a powerful suction force that draws in the wastewater and debris into the tank, while the water jet system uses high-pressure water to break up and dislodge any stubborn blockages.

Sewer suction machines are used in a variety of applications, including:

Septic tank cleaning: The machines are commonly used to empty and clean out septic tanks, which require periodic maintenance to prevent blockages and backups.

Drain cleaning: Sewer suction machines are used to clear blockages and remove debris from underground drainage systems, such as storm drains and culverts.

Sewer line maintenance: The machines can be used to remove sediment and debris from sewer lines, helping to prevent clogs and backups.

Industrial cleaning: Sewer suction machines are also used in industrial settings, such as factories and manufacturing plants, to clean up spills and remove waste materials.

Therefore, sewer suction machines are a critical tool in maintaining the health and safety of our communities by helping to ensure that wastewater and sewage systems are operating effectively and efficiently.

For further information, Please Contact us!

Website: https://www.supertechengineer.co.in/

#sewer suction machine manufacturer#sewer suction machine manufacturer in India#sewer suction machine manufacturer in delhi#sewer suction machine manufacturer in Ghaziabad#sewer suction machine Supplier in India#sewer suction machine Supplier in Ghaziabad#sewer suction machine Supplier in Delhi#Best sewer suction machine in India#sewer suction machine manufacturers in India#sewer suction machine manufacturers in Delhi#best sewer suction machine manufacturers in India#sewer suction machine near me

1 note

·

View note

Text

What to note regarding the floating suctions and skimmer systems?

Floating Suctions skimmers are designed specifically for clean and safe liquid removal from the storage tanks where the liquids are required to be sterilized by solids or water. The multi-patented Floating Suction Skimmer is the fast and one of the efficient and most sturdy devices that are highly durable and available for skimming as well as removing floating oil and contaminants from the industrial fluids procedure.

There are so many benefits if having Floating Suction Skimmer which are mentioned below

· It comes with a J-Tube model that has no hoses which sometimes affect the ballasting, and generate kinks and become collapsed or get robust

· The standards products for the level of the change of 7 inches, 3.5 inches, and 17 inches as well as the new pivot arm skimmers actually accommodate the level changes of up to 50 inches

· Suction Skimmer is designed with the quality-tested 304 stainless steel

· Durable, efficient, and simple to use as per the customers’ feedback

· Remove topmost fluid layer regularly o your coolant sumps and arts washer

· Easily set the calculated depth of skim which you require

· Floats with the changing fluid levels in your tanks

· Can be easily installed over the edge of the tank

Let’s have a look at the Oil skimmers as you must have the knowledge of skimmers

The oil skimmers are designed specifically to skim out the hydrocarbon liquid floating level on the top of the water. Well, the oil skimmer is designed importantly to remove the top layer of a two-phase liquid that is stored in a tank. Usually, the line size varies from 3 or 4 inches and Clear Ion Experts can design this larger size than this as per the requirement of the customers. You only have to explain your requirement and then, you will be assisted by a professional for the same.

Well, using an Oil Skimmer has various many benefits that include:

Opportunities for Recycling: In some examples, there are so many companies that can re-use the skimmed oil or they also can see it for the recycling process by selecting to keep their part of the word cleaner

Lessen the Disposal Expenses: The expense of oil disposable coolant is more costly than the oil disposing

Enhance the Coolant Life: If you have the oil-free coolant then, you are the lucky one as having it will enhance the functional life of the skimmer as well as also enhances the effectiveness while lessening the cost which you spend on the coolant and maintenance replacement.

Esthetic Benefits: Oil removal from a machine coolant tank will cut down on the smoke amount which is created from the advanced tool that is coming into the interaction with the oil-laden coolant and create a visible and cleaner workplace

EPA Violation Avoidance: There are so many metal working and machining shops that enable the aqueous parts by cleaning as the limits imposed by the EPA on the wastes and emissions discharge

Beneficial for Hygiene: Keeping coolant oil-free and oxygenated lessens the “rotten egg” smell, as well as bacterial levels, are also decreased and result in a cleaner and safer work environment

Enhance the Tool Life: The removal of floating surface oils when refresh and aerate coolant will enhance the life of the tool

There are two types of suction line:

· Roller – To use beneath an aluminum or steel floating roof

· Suspended – Generally used for fixed roof tanks

Floating Suction Assemblies are ideal for various reasons that are:

It helps to provide a cleaner and safer product portraying the fluid closest to the surface. Foreign particles, water, debris, and rust settle at the tank’s bottom via the gravity force. The suction consumption has a stop leg to maintain an uninterrupted bottom of the tank and remove the high percentage of the water as well as sediments from the aircraft fuel, heating oils, motor oils, and petrochemicals.

· It is also effective to lessen the inlet velocity with the special bellmouth therefore, the bottom stays undisturbed

· It is effective to transfer water from sewage treatment plant separation tanks. In the installation of inverted, it also can skim the oils from the water runoff settling tanks

· It is also effective in increasing the efficiency and decreasing the filter separator maintenance

These are a few things that one should keep in mind while using this floating suction oil skimmer system. If you are looking to get a Floating Suction Skimmer system in India then, Clear Ion Experts is the only answer. You can get this system in different sizes and specifications as per your demand.

Source url: https://clear-ion.com/blog/what-to-note-regarding-the-floating-suctions-and-skimmer-systems/

0 notes

Link

The rotational vitality is realized by the electric or motor mortar. FRANCESCO DI GIORGIO MARTINI, an Italian architect in 1475, built up a mud-lifting machine, which was viewed as the primary sort of centrifugal pump. These pumps can be purchased from Centrifugal Pumps manufacturer India.

We should investigate a portion of the normal centrifugal pumps utilized today. Since they are utilized for various occupations, it’s critical to know which one to utilize when.

AXIAL FLOW PUMPS

It utilizes a propeller in a funnel, which is driven by an engine inside the cylinder, joined outside the channel or utilizing a correct edge drive shaft, which penetrates the funnel. The propeller persistently squeezes the liquid or gas driving their stream corresponding to the pivot of revolution. The force required increments as the stream diminishes. The most noteworthy force is accomplished at a zero stream rate. Consequently, the force required increments with the expansion inflow.

Advantages

It has a high stream rate at moderately low force.

It is effectively movable to run at top productivity by changing the pitch of the propeller.

The most well-known use of the Vertical Turbine Pump is the sewage specialty running from business, mechanical, and metropolitan administrations. They are likewise utilized in move pumps to cruise stabilizer. They can be utilized to lift water utilized for the water system and pumping water from stores.

MIXED/RADIAL FLOW PUMPS

This is a centrifugal pump with a blended impeller. The impellers for rapid pumps are fitted with a diffuser and a cylindrical packaging while those of generally low speed is fitted with a volute packaging. Liquids or gasses enter through the pivotal plane, and afterward it is moved by the impeller and ways out at the correct edge to the pole radially. This sort of pump works in higher weights than the Horizontal Splits Pumps and offers higher release than the outspread stream pumps.

Advantages

They are profoundly dependable and are not arduous.

They are most appropriate for modern use since they are financially savvy and require less capacity to move enormous volumes of liquid.

This kind of centrifugal pump is strong along these lines will be of incredible monetary significance for an extended period.

This sort of pump is utilized in circumstances that require an elevated level of stream with low weight applied. They are energetically recommended for modern use because of the minimal effort of activity and toughness.

PERIPHERAL PUMPS

For this situation, the fringe impeller pivots in an enormous concentric packaging channel with both a delta and outlet. As the liquid more than once flows between the impeller and the channel surface, high vitality is made. The vitality made powers the liquid to move from the focal point of revolution to the outlet point. This sort of pump can pump liquids with high gas content better than some other kind of End Suction Pumps.

Advantages

They are not complex and subsequently can be utilized in little scope pumping of water.

They don’t utilize a lot of vitality as they use the force of the liquid.

Fringe pumps are likewise utilized in pumping uncontaminated water or other uncontaminated liquids. They are for the most part utilized for vehicle wash pumps or for pressure boosting purposes.

0 notes