#polyvinylidene chloride

Text

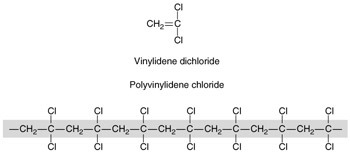

Polymers: Polyvinylidene chloride

A lesser known polymer than its cousin, PVC, polyvinylidene chloride (or PVDC) was first discovered in the 1930s at Dow Chemical. It has a higher chlorine content than PVC and is relatively non-reactive: it has high chemical resistance and can act as a barrier to water, oxygen, mold, bacteria, etc. As such, the main application of PVDC is in coatings and packaging.

The trademark product Saran was originally made with PVDC, though it was phased out of use in the US in the early 2000s due to environmental and health concerns with the high-chlorine content polymer. However, as PVDC remains superior to potential replacements it is still used in some food packaging applications to prevent spoilage.

Sources/Further Reading: (Image source - GlobalSpec) (Wikipedia) (TAPPI Conference) (ThisvsThat) (Material Properties) (PSLC)

12 notes

·

View notes

Text

Market Demand For Barrier Materials Is Growing Big Opportunity 2019-2028

Barrier materials are plastic coatings or multilayer combinations intended to minimize the diffusion of water and gas into and out of a flexible or rigid package. The EVOH, PVDC, PEN, PP, and PE are some of the examples of the barrier materials. These materials are effective against nitrogen, water vapors, oxygen, carbon dioxide, light and aroma compounds, and preserve the quality of the packaged products. Also, these materials are transparent and flexible and can be used in packaging applications in industries such as the food and beverage, pharmaceutical, and cosmetic industry. The market for barrier materials is on the rise as they have been widely adopted in numerous applications on account of their unique properties such as thermal stability, long shelf life, and high-performance levels. Moreover, barrier materials finds its applications in individual moisture barrier packing, air barrier packing, and vapor barrier packing applications. Thus increased adoption of barrier materials in applications such as food ingredients, dried food, resins, pharmaceuticals and cosmetics, automotive coatings, pigments and animal feed is further improving the market growth at rapid pace.

Get Sample PDF Copy of Report (Use Your Business Email for Quick Response): https://www.axiommrc.com/request-for-sample/10289-barrier-materials-market-report

Barrier Materials Market Dynamics

A surge in the demand for packaged food products increases the demand for barrier materials for food packaging applications. Food is an integral part of daily life. Sustainability, counterfeit protection, efficiency, convenience, traceability, and flexibility are some of the main parameters associated with packaging solutions. For consumers, sustainable and easy-to-use packaging is becoming a priority now than ever before. Thus, factors such as growing demand of the consumer for packaged food owing to changing eating habits and improving lifestyle, high disposable income of the consumers, increasing population, demand for high quality and natural food with increased shelf life are propelling the growth of the market. Moreover, factors such as a surge in the demand for blister packaging and drug delivery systems, growing technological advancements, adoption of new regulatory standards and increased health awareness, and increasing demand for primary pharmaceutical packaging are again impelling the growth of the market.

Covid 19 Impact on Barrier Materials Market

Covid19, drastically affects the world supply chain and industrial sector growth. At the initial stages of the pandemic, the world experienced, ‘supply shocks’. China who plays a major role in the world’s supply chain was severely affected. There were disruptions to the availability of goods supplied from China. Supply of both finished and unfinished goods reduced. Day by day as the situation worsened, quarantines, social distance practices were imposed and nations begun instituting lockdowns. Following this the supply chains experienced demand shocks. The shutdown of economic activities affected all the sectors. Manufacturing and mining industry’s sluggish growth in turn affected the barrier materials market.

Barrier Materials Market Segmental Overview

The report analyses the Barrier Materials market based on category, type, industry, and geography

Barrier Materials Market By Category

By category, the global barrier material market is segmented into high barriers and moderate to low barrier depending on the level to which they restrict the passage of gases. The difference between these segmentations are indicatively based on the outcome of the barrier properties on the shelf life of the packaged products. The factors such as increased use of these high, moderate and low barrier materials in various end-use industries for applications such as flexible packaging, barrier coating and lamination, surge in the demand for high barrier packaging materials and increasing production of these materials are attributed to the growth of market.

Barrier Materials by Type

Aluminum, ethylene vinyl alcohol, polyvinylidene chloride, polyethylene naphthalate, and others are the types of barrier materials covered in this market study. The aluminium segment held the largest market share in 2020 and is expected to grow at a CAGR of 5.60% during the forecast period. Increasing application of aluminium in packaging applications mostly in food, pharmaceutical, and cosmetics, and surge in the use of aluminium as a barrier material owing to its several benefiting properties are major contributing factors behind the market growth.

Barrier Materials Market by Industry

The global barrier materials by end use industry is classified into pharmaceutical, food and beverage, agriculture, cosmetics, automotive and others etc. Food & beverage sector dominates the market. Increased production and consumption of various food products such as dairy products, meat products, fruits and vegetable, and many other beverages, a surge in the demand for healthy, processed, and packaged food products, rising adoption of food products by online shopping method during COVID-19 pandemic, and growing awareness of the consumers regarding health are key benefiting factors behind the growth of the market.

Barrier Materials by Geography

Geographically, the barrier materials market is studied across the countries of key regions such as, North America, Europe, Asia Pacific and rest of the world regions which includes Latin America, and Middle East & Africa. Asia Pacific is likely to hold the dominant position and is also expected to be the fastest growing regional market in global barrier materials market during the forecast period owing to improving lifestyle of the people, rising industrialization and urbanization, rising expenditure on nutritious and healthy products, increasing population, rapid growth in the automotive industry in economies such as China and India in the region.

Barrier Materials Key Players

Some of the major players operating in this market include 3M (United States), Kuraray Co., Ltd (Japan), The Dow Chemical Company (United States), Solvay S.A (Belgium), Chang Chun Petrochemical Co., Ltd (Taiwan), DuPont de Nemours, Inc. (United States), Kureha Corporation (Japan), Asahi Kasei Corporation (Japan), Teijin Limited (Japan), Nippon Synthetic Chem Industry Co., Ltd. (Japan), Zhejiang Juhua Co., Ltd (China), Mondi Group plc (UK), Coexpan (Spain), Arkema (France), Toppan Printing CO. Ltd (Japan) among others.

Buy now, this Research Report at https://www.axiommrc.com/buy_now/10289-barrier-materials-market-report

About Us:

Axiom Market Research & Consulting™ is a full-service market research and data analytics company providing key market intelligence to global companies to take informed business decisions pertaining to their marketing strategy, investments, new product launches, market competition, consumer or end users, social media trends etc.

Axiom Market Research & Consulting™ offers market research services such as syndicated market research, custom market research, business consulting, and consumer/end user surveys. Under Business to Consumer (B2C) market research offerings, Axiom MRC assists its clients in finding quantitative information/preferences of its brands and services such as, awareness, usages, satisfaction, tracking, ethnicity etc. Axiom MRC offers data collection services through online surveys, social media, data processing and interpretation.

Axiom MRC with its experienced team of research and data analysts, has delivered more than 5000+ Market Research Projects, 3800+ Data Analytics Projects, 1200+ Business Support Projects and has a 800+ Global Client Base. Axiom Market Research & Consulting™ aims to become the preferred market research and data analytics company by providing key market intelligence solutions for client’s business growth.

Contact Us:

Axiom Market Research & Consulting™

3 Germay Dr. Ste 4 - 4666

Wilmington DE 19804

U.S.:- + 1 (845) 875-9786

U.K.:- + 44 (0) 20 3286 9707

Email: [email protected]

Website: https://www.axiommrc.com/

Follow On

LinkedIn: https://www.linkedin.com/company/axiom-market-research-and-consulting/

Twitter: https://twitter.com/AxiommrcCom

0 notes

Text

Cling Film Market Trends, Segmentation, Outlook, Industry Report to 2031

The cling film market is anticipated to grow at a CAGR of 5.2% during the anticipated time frame and reach USD 8.72 billion by 2027. Food items are routinely wrapped and preserved with cling film, a thin plastic sheet also known as plastic wrap or food wrap.

The sector is developing mainly due to rising customer demand for packaged and handy items as well as increased consumer education on food safety and storage. Cling film is frequently used in homes, restaurants, and the food processing and packaging industries to preserve food for a longer period of time.

Low-density polyethylene (LDPE), polyvinyl chloride (PVC), and linear low-density polyethylene (LLDPE) are the three material kinds that make up the market. Because of its exceptional clarity, strength, and flexibility, PVC is the cling film material that is used the most frequently.

For More Insights on this Market, Get A Sample Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-2654

The effects of cling film on the environment, however, are also a worry. In landfills, plastic cling film takes hundreds of years to decompose, which can contribute to environmental contamination. Due to this, there is an increasing need for cling film substitutes like silicone food covers and beeswax wraps.

Overall, it is anticipated that the cling film market will expand over the next few years due to the rising demand for practical and secure food packaging solutions. To fulfil the changing expectations of consumers, the industry will also need to address worries about the environmental impact of plastic cling film and investigate sustainable alternatives.

Market Benefits

The study provides an in-depth analysis of the global Cling Film market along with the current trends and future estimations to elucidate the imminent investment pockets.

The key market players along with their strategies are thoroughly analyzed to understand the competitive outlook of the industry.

An extensive analysis of the market based on application assists in understanding the trends in the industry.

The report presents a quantitative analysis of the market from 2021 to 2031 to enable stakeholders to capitalize on the prevailing market opportunities.

Key Takeaways from the Cling Film Market Study

Polyvinyl chloride is expected to create incremental opportunity of US$ 508.3 million by 2031. It is cost-effective and suitable for recycling processes.

Cling film products up to 9 microns in thickness is estimated to increase 1.7 times by the end of 2031, attributed to clear and transparent packaging for food product displays.

Canada is expected to reflect faster growth in North America, with a 6.5% CAGR due to the presence of key players and the availability of technological advancements.

Germany leads Western Europe accounting for 26% of the value share by 2031, owing to relatively higher production capacity.

China will continue to dominate APEJ holding over 40% of the market through 2031, supported by a large base of end users and manufacturers.

Are you looking for customized information related to the latest trends, drivers, and challenges? @ https://www.futuremarketinsights.com/customization-available/rep-gb-2654

Competitive Landscape

Berry Global Group, Inc.

Intertape Polymer Group (IPG)

Gruppo Fabbri Vignola S.p.A

Kalan SAS

Fine Vantage Limited

Rotofresh – Rotochef s.r.l.

Manuli Stretch S.p.A.

Cling Film Market by Category

By Material type:

Polyethylene

Low Density Polyethylene (LDPE)

High Density Polyethylene (HDPE)

Linear Low Density Polyethylene (LLDPE)

Bi-axially Oriented Polypropylene (BOPP)

Polyvinyl Chloride

Polyvinylidene Chloride

Others

Speak to Our Analyst @ https://www.futuremarketinsights.com/ask-the-analyst/rep-gb-2654

By Thickness:

Up to 9 micron

9 to 12 micron

Above 12 micron

By End Use:

Food

Meat

Seafood

Baked Foods

Dairy Products

Fruits & Vegetables

2 notes

·

View notes

Text

Europe Medical Tubing Market Analysis, Strategic Assessment, Trend Outlook and Business Opportunities 2021-2028

Business Market Insights latest offering, titled “Europe Medical Tubing Market Size and Share Analysis to 2028,” provides comprehensive insights for startups and big market players. The report covers industry performance, risk factors, growth determinants, economics of cost, and ROI streams. It combines qualitative and primary research methods, making it an essential product for companies, investors, and business strategists aiming to excel in the Europe Medical Tubing market in a projected timeframe.

Market Overview

Europe Medical Tubing market has experienced dynamic transformations in recent years, anticipated to remain an investible domain for investors in the projected time. The market is propelled by consumer preferences, regulatory parameters, and advancements in technology. Concurrently, the surge in automation has favored Europe Medical Tubing market share expansion. Advancements in manufacturing technologies have made the Europe Medical Tubing market viable and accessible, which is further expected to contribute to market growth.

In confluence with the aforementioned growth drivers, the Europe Medical Tubing market is also gauged for restraints and trends. The emerging trends in the market are analyzed in this chapter to assist market players in trying to retain their competitive edge. Strategic insights on key players and their tactics are perks of this research. This section brings forward different organic business strategies, strategic partnerships, and collaborations in the Europe Medical Tubing market.

Market Segmentation

To adequately aid their customers in a competitive Europe Medical Tubing market, enterprises must educate themselves on key segments. Streamlining market approaches is an effective application of market research. The market segmentation section focuses on product, application, and regional categories. Understanding demographics and high-ROI geographical regions helps entrepreneurs optimize their products.

Regional Insights

The report attempts to explore both global and regional market aspects through authorized sources. Regional share, trends, key market players, and future scope are perks under this section.

Report Attributes

Details

Segmental Coverage

Material

Polyvinyl Chloride (PVC)

Polyimide/Nylons

PTFE/Thermoplastic Elastomers (TPES)

Thermoplastic Polyurethanes (TPUS)

Polyvinylidene Fluoride (PVDF)

Polypropylene and Polyethylene

Silicon

and Other

Structure

Single-Lumen

Multi-Lumen

Multi-Layer Extruded Tubing

Tapered or Bump Tubing

Braided Tubing

Balloon Tubing

Corrugated Tubing

Heat Shrink Tubing

and Others

Application

Bulk Disposable Tubing

Catheter & Cannula

Drug Delivery System

and Others

End User

Hospitals and Clinics

Ambulatory Care Centres

Medical Device Companies

Laboratories

and Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Compagnie de Saint Gobain SA

Nordson Corp

Optinova AB

Spectrum Plastics Group Inc

TE Connectivity Ltd

Trelleborg AB

Other key companies

Need a Customized Market Research Report?

You can always share any specific requirements that you have, and our team will adjust the scope of research offerings as per your needs. the following are some customizations our clients ask for:

The report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

Key Questions Addressed in the Europe Medical Tubing Market Research Include:

What are present Europe Medical Tubing market values, and what can be expected in the upcoming decade?

What are the key segments in the Europe Medical Tubing market?

What is the regional distribution of the Europe Medical Tubing market report?

What are the key players and their recent strategies?

What are the key factors driving Europe Medical Tubing market growth?

What are regulatory concerns and requirements businesses have to compel?

Our Unique Research Methods at Business Market Insights

We offer syndicated market research solutions and consultation services that provide complete coverage of global markets. This report includes a snapshot of global and regional insights. We pay attention to business growth and partner preferences, that why we offer customization on all our reports to meet individual scope and regional requirements.

Our team of researchers utilizes exhaustive primary research and secondary methods to gather precise and reliable information. Our analysts cross-verify facts to ensure validity. We are committed to offering actionable insights based on our vast research databases.

Author’s Bio:

Bhavesh Shinde

Senior Market Research Expert at Business Market Insights

0 notes

Text

0 notes

Text

Premium Wrap vs Ordinary Cling Wrap: Which Should You Choose for Food Storage?

In the world of food storage, one product has become a kitchen staple for households worldwide: cling wrap. Also known as cling wrap, cling film, or food wrap, this thin, transparent sheet has long been used to cover and preserve various food items. However, as the demand for improved food storage solutions has grown, so too has the range of available options. Among these, Asahi Kasei’s Premium Wrap stands out as a formidable contender, challenging the conventional notion of cling wrap. In this blog, we’ll delve into the debate of Premium Wrap vs. Ordinary Cling Wrap to help you make an informed choice for your food storage needs.

https://jpcdn.it/img/2acf3670bd7a25558f41a0bd1a1a5b93.jpg

Understanding Cling Wrap: The Kitchen Classic

Before we jump into the comparison, let’s take a moment to understand what ordinary cling wrap brings to the table. This ubiquitous kitchen essential is typically made from polyvinyl chloride (PVC) or low-density polyethylene (LDPE). Its primary function is to cover and seal food items, protecting them from moisture, air, and contaminants. Cling wrap is prized for its transparency, allowing you to see the contents without unwrapping. It’s a versatile option used for everything from wrapping sandwiches and leftovers to covering bowls of dough during the rising process.

Introducing Asahi Kasei Premium Wrap: Redefining Food Storage

On the other side of the spectrum stands Asahi Kasei Premium Wrap, a revolutionary product that redefines food storage. Unlike ordinary cling wrap, Premium Wrap is made from a special material known as polyvinylidene chloride (PVDC). This unique material provides several advantages that set it apart from its conventional counterpart.

Enhanced Freshness and Food Safety

One of the most significant differences between Premium Wrap and ordinary cling wrap is their approach to preserving food freshness and safety. Ordinary cling wrap, while effective to some extent, allows a degree of oxygen and moisture permeability. This means that over time, your food items are exposed to air, which can lead to oxidation and spoilage. In contrast, Asahi Kasei Premium Wrap boasts superior barrier properties. It forms an airtight seal that effectively locks out oxygen and moisture, ensuring your food remains fresher for longer.

This enhanced freshness preservation has several advantages:

Extended Shelf Life: Premium Wrap helps prolong the shelf life of your food items, reducing the need for frequent replacements and curbing food waste.

Improved Food Safety: By preventing external contaminants from reaching your food, Premium Wrap enhances food safety and reduces the risk of cross-contamination.

Better Flavor Retention: Foods wrapped in Premium Wrap maintain their original flavors, textures, and aromas, delivering a more enjoyable dining experience.

Heat Resistance and Versatility

Another notable distinction is the heat resistance of Asahi Kasei Premium Wrap. While ordinary cling wrap can be prone to melting when exposed to heat, Premium Wrap can withstand temperatures of up to 140°C (284°F). This heat resistance makes it suitable for a wide range of applications:

Microwave-Safe: Premium Wrap is safe to use in the microwave, allowing you to reheat food without removing the wrap. This convenience saves you time and minimizes dishwashing.

Freezer-Friendly: Whether you’re storing soups, stews, or pre-prepared meals, Premium Wrap maintains its integrity in the freezer. Say goodbye to freezer burn and food degradation.

Versatile Cooking Companion: Use Premium Wrap to steam vegetables, poach fish, or create sealed pouches for flavorful oven-baked dishes. Its heat resistance opens up a world of culinary possibilities.

Odor and Flavor Protection

Have you ever experienced the frustration of finding your leftover pizza or sandwich has absorbed unwanted odors from the refrigerator? Ordinary cling wrap provides limited protection against odor transfer. Premium Wrap, however, acts as a reliable barrier against external odors. Whether you’re storing pungent cheeses, aromatic spices, or delicate pastries, you can trust Premium Wrap to preserve the original flavors and scents of your food.

Sustainability and Environmental Considerations

In today’s eco-conscious world, sustainability is a crucial factor in choosing food storage solutions. Asahi Kasei Premium Wrap takes a step in the right direction by using PVDC, a material that can be more environmentally friendly compared to traditional cling wrap materials like PVC. PVDC is known for its high barrier properties, which means less material is needed to achieve the same level of protection. This reduction in material usage contributes to a more sustainable and eco-friendly product.

Premium Wrap vs. Ordinary Cling Wrap: Making the Choice

Now that we’ve examined the key differences between Premium Wrap and ordinary cling wrap, how do you decide which one is right for you? The choice ultimately depends on your specific needs and priorities in the kitchen.

Choose Premium Wrap if:

You prioritize food freshness: If keeping your food fresher for longer is a top concern, Premium Wrap’s superior barrier properties make it an excellent choice.

You frequently use the microwave: Premium Wrap’s heat resistance makes it a convenient option for microwave reheating without the need to remove the wrap.

You want a versatile cooking companion: Premium Wrap’s ability to withstand high temperatures opens up a world of culinary possibilities, making it suitable for a wide range of cooking methods.

You’re environmentally conscious: Premium Wrap’s potential for reduced material usage contributes to a more sustainable and eco-friendly food storage solution.

Stick with Ordinary Cling Wrap if:

You have basic food storage needs: If you primarily use cling wrap for simple tasks like covering leftovers or sandwiches, ordinary cling wrap may suffice.

You don’t require high-heat resistance: If you rarely use cling wrap in the microwave or for cooking, heat resistance may not be a significant factor for you.

You’re looking for an economical option: Ordinary cling wrap tends to be more budget-friendly compared to Premium Wrap, making it a cost-effective choice for basic food storage.

Asahi Kasei Premium Wrap offers enhanced freshness, heat resistance, odor protection, and potential sustainability benefits, making it a versatile and innovative option for those seeking a superior food storage solution. Consider your priorities and cooking habits to determine which product aligns best with your needs. Ultimately, the choice is yours, and both options aim to help you preserve and enjoy your food to the fullest.

0 notes

Text

Learn How BOPP Bags are Made: Explore the Manufacturing Process Today

BOPP (Biaxially Oriented Polypropylene) bags are widely used in various industries for packaging due to their excellent properties such as high clarity, strength, and moisture resistance. Understanding the manufacturing process of BOPP bags provides insights into the intricate steps involved in producing these versatile packaging solutions. In this comprehensive guide, we delve into the manufacturing process of BOPP bags, exploring each stage from raw material preparation to the final product assembly.

What is Bopp bags?

The manufacturing process of BOPP (Biaxially Oriented Polypropylene) bags involves several intricate steps to produce versatile packaging solutions. It begins with the preparation of polypropylene resin, sourced from reputable suppliers and mixed with additives and masterbatches to enhance specific properties. The resin is then extruded into a thin film through a process called film extrusion, where it undergoes biaxial orientation to improve mechanical properties.

After orientation, the BOPP film may undergo coating processes to add functionalities like heat sealability or barrier properties, followed by printing with customized designs using advanced printing techniques. Some films undergo lamination with other substrates to enhance performance or aesthetics. Finally, the film is converted into bags through cutting, folding, sealing, and adding features such as handles or closures.

Throughout the manufacturing process, stringent quality control measures are implemented to ensure consistency and meet industry standards. The finished BOPP bags are inspected, packaged, and prepared for distribution, ensuring they provide superior clarity, strength, and protection for a wide range of products. Overall, the manufacturing process of BOPP bags combines precision engineering with advanced technologies to deliver high-quality packaging solutions for various industries.

Raw Material Preparation:

Polypropylene Resin: The primary raw material used in BOPP bag manufacturing is polypropylene resin, a thermoplastic polymer derived from propylene gas. The resin is sourced from reputable suppliers and undergoes quality testing to ensure consistency and purity.

Additives and Masterbatches: Depending on the desired properties of the Bopp bags manufacturers in india, various additives such as antioxidants, slip agents, and UV stabilizers may be incorporated into the polypropylene resin. Additionally, masterbatches containing colorants or other functional additives are mixed with the resin to achieve specific color or performance requirements.

Extrusion:

Film Extrusion: The manufacturing process begins with the extrusion of polypropylene resin pellets into a thin film through a process called film extrusion. In this stage, the resin pellets are melted and formed into a continuous flat sheet using an extruder machine equipped with a flat die.

Orientation: The extruded film is then stretched in both the machine direction (MD) and transverse direction (TD) using specialized rollers or tenter frames. This biaxial orientation process enhances the mechanical properties of the film, including tensile strength, clarity, and barrier properties.

Coating and Printing:

Coating: After orientation, the BOPP film may undergo additional coating processes to impart specific functionalities such as heat sealability, barrier properties, or surface treatment for printing. Coating materials such as acrylics, PVdC (Polyvinylidene Chloride), or EVOH (Ethylene Vinyl Alcohol) are applied using coating machines equipped with precision applicators.

Printing: BOPP films can be printed with customized designs, logos, or product information using various printing techniques such as flexography, gravure, or digital printing. Printing is typically done on one side of the film using specialized printing presses capable of high-resolution graphics and vibrant colors.

Lamination and Conversion:

Lamination: In some cases, BOPP films may undergo lamination with other substrates such as LDPE (Low-Density Polyethylene) or metallized films to enhance barrier properties, moisture resistance, or aesthetic appeal. Lamination is achieved by bonding multiple layers together using heat and pressure in a lamination machine.

Conversion: The laminated BOPP film is then converted into bags through a process called bag making. This involves cutting the film into appropriate sizes, folding and sealing the edges, and adding features such as handles, gussets, or resealable closures using specialized bag making machines.

Quality Control and Packaging:

Quality Control: Throughout the manufacturing process, stringent quality control measures are implemented to ensure that BOPP bags meet industry standards and customer specifications. This includes monitoring key parameters such as film thickness, seal strength, print registration, and visual appearance.

Packaging: Once manufactured, Bopp bags manufacturing process are carefully inspected, stacked, and packaged for storage or distribution. Proper packaging techniques such as shrink wrapping or palletizing are employed to protect the bags from damage during transportation and storage.

Conclusion

The manufacturing process of BOPP bags is a sophisticated and highly controlled operation that involves multiple stages from raw material preparation to final product assembly. By understanding the intricate steps involved in producing BOPP bags, manufacturers can ensure consistent quality, performance, and functionality to meet the diverse packaging needs of various industries. From extrusion and coating to printing, lamination, and conversion, each stage of the process plays a critical role in delivering high-quality BOPP bags that offer superior clarity, strength, and protection for a wide range of products.

0 notes

Text

The Science of Freshness: How Asahi Kasei Premium Wrap Blocks Oxygen and Moisture to Preserve Food

The Battle Against Oxidation and Moisture

To appreciate the science behind Asahi Kasei Premium Wrap, we need to delve into the enemies of freshness: oxygen and moisture. When food is exposed to air, it undergoes a process called oxidation. This chemical reaction can have detrimental effects on the taste, texture, and nutritional value of your ingredients and dishes. It’s the reason why sliced apples turn brown, and why that once-crispy potato chip becomes disappointingly soggy.

Moisture, on the other hand, can be equally problematic. Excess moisture can lead to the growth of bacteria and molds, causing your food to spoil prematurely. It’s the reason why your bread becomes moldy, and why that leftover lasagna loses its appeal after a day or two in the fridge.

Asahi Kasei Premium Wrap understands these challenges and offers a powerful solution. Crafted from a clear and special PVDC material, this cling film acts as a formidable barrier against both oxygen and moisture, preserving the quality of your food and extending its shelf life.

The Power of PVDC

PVDC, or polyvinylidene chloride, is a synthetic polymer known for its exceptional barrier properties. It’s like a protective shield that stands between your food and the elements that can cause it to deteriorate. When used in Asahi Kasei Premium Wrap, PVDC brings several key advantages to the table.

Oxygen Barrier:

PVDC is impermeable to oxygen, effectively blocking it from coming into contact with your food. This is crucial because many chemical reactions that lead to food spoilage and loss of freshness require the presence of oxygen. By keeping oxygen at bay, Asahi Kasei Premium Wrap ensures that your ingredients and dishes stay fresher for longer.

Moisture Resistance:

PVDC also has excellent moisture resistance. It repels water and prevents it from penetrating the wrap and reaching your food. This is particularly beneficial when you’re dealing with foods that are prone to sogginess or mold growth in the presence of moisture. Asahi Kasei Premium Wrap’s moisture-blocking properties help maintain the desired texture and quality of your food.

Convenience and Versatility

Beyond its scientific prowess, Asahi Kasei Premium Wrap offers convenience and versatility to home cooks and professional chefs alike. Unlike traditional cling wraps that can be cumbersome to use, this wrap is designed with ease in mind.

Built-In Cutter:

One of the standout features of Asahi Kasei Premium Wrap is its built-in cutter. Say goodbye to struggling with sharp-edged cling wrap boxes or hunting for scissors. With a simple tug, you can effortlessly tear off the desired length of wrap, ensuring a smooth and hassle-free experience every time.

Storage Options:

Asahi Kasei Premium Wrap isn’t limited to one storage environment. Whether you need to keep your produce fresh in the fridge, store leftovers in the freezer, or protect your dishes at room temperature, this cling film has you covered. Its versatility makes it a go-to choice for various culinary needs.

Microwave Safe:

In a world where reheating is a common practice, Asahi Kasei Premium Wrap stands out as a microwave-safe option. It can withstand temperatures of up to 140°C, making it suitable for reheating food without the need for transfer to another container. This not only saves time but also reduces the number of dishes to wash.

Freshness at Your Fingertips

The beauty of Asahi Kasei Premium Wrap lies not only in its scientific innovation but also in its ability to put freshness at your fingertips. Whether you’re storing your favorite fruits and vegetables, wrapping sandwiches for a picnic, or preserving that homemade lasagna, this cling wrap is your trusted ally.

Extend Shelf Life:

By effectively blocking oxygen and moisture, Asahi Kasei Premium Wrap extends the shelf life of your groceries and prepared dishes. You can say goodbye to food waste and enjoy your ingredients and meals for longer periods.

Preserve Flavors:

Freshness isn’t just about appearance; it’s about taste too. With this cling wrap, you can preserve the flavors and aromas of your ingredients and dishes, ensuring that every bite is as delightful as the first.

Reduce Environmental Impact:

Asahi Kasei Premium Wrap is also an eco-conscious choice. By helping you reduce food waste, it contributes to a more sustainable kitchen and a greener planet. It’s a small step with significant implications for a healthier environment.

In conclusion, the science of freshness is a precise art, and Asahi Kasei Premium Wrap is a masterpiece in this regard. With its PVDC material, convenience features, and versatile applications, it’s not just a cling film; it’s a guardian of freshness in your kitchen. Say goodbye to food waste, sogginess, and premature spoilage. Say hello to longer-lasting, delicious meals with Asahi Kasei Premium Wrap.

0 notes

Text

The Importance of Material Selection in True Union Ball Valve Manufacturing

In the world of fluid control systems, true union ball valves are essential components. These valves allow precise control over the flow of liquids or gases, making them vital in various industries such as chemical processing, water treatment, and manufacturing. However, what often goes unnoticed is the critical role that material selection plays in the manufacturing of these valves. In this article, we will delve into the significance of material selection in true union ball valve manufacturing and how it affects the performance, durability, and safety of these essential devices.

Understanding True Union Ball Valves

Before we dive into the importance of material selection, let's briefly understand what true union ball valves are and how they work. True union ball valves are a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of fluids. When the valve handle is turned 90 degrees, the ball inside either allows flow or blocks it entirely. This simple yet effective design makes them ideal for a wide range of applications.

The Role of Material Selection

Now, let's explore why material selection is crucial in the manufacturing of true union ball valves.

Chemical Compatibility

One of the primary considerations when selecting materials for these valves is chemical compatibility. Different industries handle various types of fluids, some of which can be highly corrosive or reactive. Using the wrong material can result in chemical degradation, leaks, or even catastrophic failures. Manufacturers must carefully assess the chemicals that will come into contact with the valve and choose materials that can withstand these harsh environments.

Temperature Resistance

Temperature variations can also pose challenges in fluid control systems. Materials used in ball valve manufacturing must have the appropriate temperature resistance properties. Extreme temperatures can cause materials to expand, contract, or become brittle, affecting the valve's performance. Ensuring that the selected material can handle the expected temperature range is crucial to long-term reliability.

Mechanical Strength

Ball valves are subjected to significant mechanical stress during operation. The material used must have the required mechanical strength to endure this stress without deformation or failure. This includes factors like pressure, torque, and wear resistance. Material selection is critical in preventing valve malfunction or leakage under mechanical strain.

Longevity and Durability

True union ball valves are often installed in locations that are not easily accessible for maintenance. Therefore, durability and longevity are paramount. The right material can significantly extend the valve's service life, reducing maintenance costs and downtime. Long-lasting valves also contribute to the overall efficiency of the system.

Common Materials Used

Several materials are commonly used in the manufacturing of true union ball valves, each with its advantages and limitations. Some of these materials include:

PVC (Polyvinyl Chloride): Ideal for applications involving water and mild chemicals due to its corrosion resistance and affordability.

CPVC (Chlorinated Polyvinyl Chloride): Offers improved chemical resistance over PVC and can handle moderately corrosive fluids.

PP (Polypropylene): Known for its excellent chemical resistance and suitable for handling a wide range of acids and bases.

PVDF (Polyvinylidene Fluoride): Resistant to highly corrosive chemicals and capable of withstanding high temperatures.

Stainless Steel: Suitable for applications requiring high mechanical strength and resistance to extreme temperatures.

Conclusion

Material selection is a critical factor in the manufacturing of true union ball valves. The right choice of material ensures chemical compatibility, temperature resistance, mechanical strength, and longevity, all of which contribute to the reliable performance of these essential components in fluid control systems. Manufacturers and engineers must carefully consider the specific requirements of their applications when selecting materials, as the wrong choice can lead to operational issues and safety concerns.

0 notes

Text

Keep Your Fruits & Vegetables Fresh with the Asahi Kasei Premium Wrap

The Asahi Kasei Premium Wrap

The Asahi Kasei Premium Wrap is not your ordinary cling wrap. It’s a high-quality cling film made from PVDC plastic, a food-safe material that ensures your produce remains untainted in taste and texture. This versatile wrap can be applied in seconds, significantly extending the freshness of your fruits and vegetables.

Preventing Ethylene Gas Buildup

One of the key advantages of cling film is its ability to thwart the buildup of ethylene gas. Many fruits and vegetables naturally emit this gas as they ripen, which can accelerate spoilage. Plastic wrap forms a protective barrier that prevents ethylene gas from reaching your produce. This action slows down the ripening process, keeping your fruits and vegetables fresh for a more extended period.

Guarding Against Moisture Loss

Another critical role of cling wrap is to prevent moisture loss. By creating a tight seal around your fruits and vegetables, it locks in moisture and prevents it from evaporating. This is especially beneficial for delicate produce like leafy greens and berries, which can wither and become mushy when they lose moisture.

Versatile and Easy to Use

The Asahi Kasei Premium Wrap is incredibly versatile. Whether you want to keep your strawberries fresh, prevent lettuce wilting, or halt avocados from browning, this cling wrap is up to the task. It’s also perfect for wrapping leftovers or covering dishes in the fridge, making it an indispensable tool for any home cook.

An Eco-Friendly Choice

In addition to its practical benefits, the Asahi Kasei Premium Wrap is environmentally friendly too. It is composed of PVDC (polyvinylidene chloride) plastic. When compared to standard plastics like PE (Poly Ethylene) or PVC (Poly Vinyl Chloride), PVDC is capable of preventing about 2.5 times more moisture and retaining about 200 times more oxygen with the same amount of plastic. It also has a built-in cutter that enables you to only cut the amount needed, reducing the unnecessary use of plastics compared to other cling films. This makes it a great choice for anyone who is looking to reduce their environmental impact.

Simple to Use

Using the Asahi Kasei Premium Wrap couldn’t be easier. Tear off a piece of the wrap using the built-in cutter, place it over your produce, and press down on the edges to create a tight seal. Store your fresh produce in the fridge as usual. When it’s time to enjoy your fruits and vegetables, simply remove the cling wrap and savor the freshness.

In conclusion, the Asahi Kasei Premium Wrap is an indispensable tool for anyone who desires longer-lasting fruits and vegetables. Its capacity to thwart ethylene gas buildup and moisture loss makes it highly effective for preserving produce. Its ease of use and versatility make it a valuable addition to any kitchen, and its eco-friendly design aligns with a commitment to reducing environmental impact. Give it a try and experience the difference it can make in keeping your fruits and vegetables fresher for longer.

0 notes

Text

0 notes

Text

PVDC Barrier Material Market Forecast 2024 to 2032

PVDC (Polyvinylidene Chloride) is a type of barrier material used in various industries, primarily for its excellent barrier properties against gases, moisture, and odors. It is often used in packaging applications in which maintaining product freshness and extending shelf life is crucial.

The PVDC Barrier Material Market was valued at USD 117.21 Million in 2022 and is expected to register CAGR of 2.35% by 2032.

Consumer preference for fresh and minimally processed foods, along with the need for extended shelf life, has led to the adoption of barrier materials like PVDC in food packaging. This is a key factor expected to drive global market growth during the forecast period.

PVDC Barrier Material Market By Vendors:

Dow

Kureha

Asahi Kasei

Juhua Group

Solvay

Nantong SKT

Keguan Polymer

PVDC Barrier Material Market By Types:

PVDC resins

PVDC latex

PVDC Barrier Material Market By Applications:

Food Packaging and Wrap

Pharmaceuticals Packaging

Unit Packaging for Hygiene and Cosmetic Products

Sterilized Medical Packaging

About Us:

Xcellent Insights is a market intelligence provider and consulting firm. We offer data-driven research services based on multiple analysis frameworks which helps businesses across the globe to understand current market scenario and align their strategic initiatives.

We offer syndicated research reports, customized research reports, consulting services and datasets which are mapped across multiple datapoints.

We provide research reports for all the industry sectors like Consumer Goods, Packaging, Chemicals and Materials, Healthcare, Pharmaceuticals, Medical Devices, Agriculture, Food and Beverages, Automobile and transportation, Electronics and Semiconductors, IT and Communication, Energy and Power, Machinery and Equipment.

Contact Us:

Name: Willie J

Phone: US: +1 4086277717

UK: +44 2086386439

Email: [email protected]

#PVDC Barrier Material Market#PVDC Barrier Material Market size#PVDC Barrier Material Market share#business#starups

0 notes

Text

0 notes

Text

Exploring the Versatility of Tetrahydrofuran (THF) and Cyclohexanone in Various Industries

Tetrahydrofuran (THF) is a crucial component in the production of several polymers. It is a key ingredient in the synthesis of polytetramethylene ether glycol (PTMEG), which is used in the manufacturing of polyurethanes, elastomers, and spandex fibers. Tetrahydrofuran (THF) is also used in the production of polyvinyl chloride (PVC) resins and polyvinylidene fluoride (PVDF). For more details call us at +86-510-83223090.

0 notes

Text

Europe Medical Tubing Market Forecast Size Estimated to Observe Significant Growth by 2028

Business Market Insights recently announced the release of the market research titled Europe Medical Tubing Market Outlook to 2028 | Share, Size, and Growth. The report is a stop solution for companies operating in the Europe Medical Tubing market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. Europe Medical Tubing Market report allows business to reduce their risks by offering a closer picture of consumer behavior, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, Business Market Insights is helping brands unlock revenue opportunities in the Europe Medical Tubing market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated Europe Medical Tubing market research has all that you need.

What are Key Offerings Under this Europe Medical Tubing Market Research?

Global Europe Medical Tubing market summary, current and future Europe Medical Tubing market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Europe Medical Tubing Market Analysis by Application

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global Europe Medical Tubing Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the Europe Medical Tubing Market?

Europe Medical Tubing market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. Europe Medical Tubing market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their Europe Medical Tubing market share.

Report Attributes

Details

Segmental Coverage

Material

Polyvinyl Chloride (PVC)

Polyimide/Nylons

PTFE/Thermoplastic Elastomers (TPES)

Thermoplastic Polyurethanes (TPUS)

Polyvinylidene Fluoride (PVDF)

Polypropylene and Polyethylene

Silicon

and Other

Others

Structure

Single-Lumen

Multi-Lumen

Multi-Layer Extruded Tubing

Tapered or Bump Tubing

Braided Tubing

Balloon Tubing

Corrugated Tubing

Heat Shrink Tubing

and Others

Others

Application

Bulk Disposable Tubing

Catheter & Cannula

Drug Delivery System

and Others

Others

End User

Hospitals and Clinics

Ambulatory Care Centres

Medical Device Companies

Laboratories

and Others

Others

Regional and Country Coverage

North America

US

Canada

Mexico

Europe

UK

Germany

France

Russia

Italy

Rest of Europe

Asia Pacific

China

India

Japan

Australia

Rest of APAC

South / South & Central America

Brazil

Argentina

Rest of South/South & Central America

Middle East & Africa

South Africa

Saudi Arabia

UAE

Rest of MEA

Market Leaders and Key Company Profiles

Compagnie de Saint Gobain SA, Nordson Corp, Optinova AB, Spectrum Plastics Group Inc, TE Connectivity Ltd, Trelleborg AB , and other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective Europe Medical Tubing market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

Business Market Insights offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The Europe Medical Tubing market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

Author’s Bio:

Bhavesh Shinde

Senior Market Research Expert at Business Market Insights

0 notes