#piston ring manufacturers

Link

#Piston ring manufacturers in India#Custom piston rings#piston ring suppliers#piston ring#piston ring manufacturers

0 notes

Link

Piston ring manufacturing is an essential process in India, and many piston ring manufacturers have made a name for themselves in the business. However, there is an excellent scope for improvement in the piston ring-making process, which can be achieved through advanced technology and creative processes.

0 notes

Photo

TVR Tuscan 2S

First released in 1999 and manufactured up until 2006 the TVR Tuscan was available in various specifications with varying performance. Being a 2S the car is fitted with the 4 liter Speed-Six TVR engine and revised suspension for increased handling performance. A full engine rebuild was completed resulting in a reliable smooth engine that produces just north of 400BHP. The completed work includes -Syvecs engine management system -Aluminium radiator -FFF EVO2 cylinder head -Billet crankshaft -H section conrods -Up-rated cylinder block -Simplex timing sprockets and chain -Modified half time bearing -New piston rings and bearings -Lightened flywheel -New clutch -Race proven clutch slave cylinder -De-cat exhaust -SC engine mounts -AST suspension -Suspension poly bush kit -Silicone hoses This work completed ensures that this TVR is not only fabulous to drive but most importantly reliable.

199 notes

·

View notes

Text

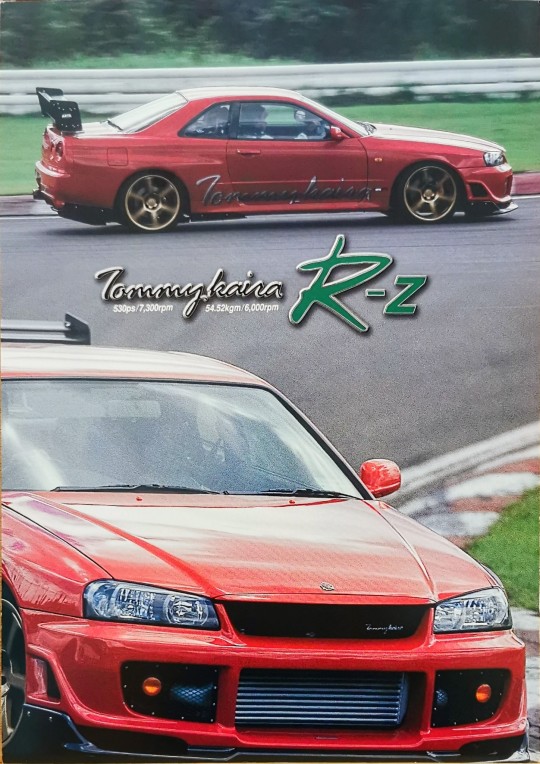

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

17 notes

·

View notes

Photo

1939 Cotton-JAP 500cc Special

Gloucester-based Cotton established its reputation with a string of racing successes in the 1920s thanks to an innovative frame patented by Frank Willoughby Cotton. Cotton's design featured four straight tubes running from the steering head to the rear wheel spindle, augmented by straight stays supporting the gearbox and engine. The result was a stiff, lightweight chassis vastly superior to the bicycle-derived frame used by the majority of manufacturers. Cotton relied on proprietary engines, but such was the advantage conferred by its frame that the Cotton had little trouble seeing off similarly powered rivals.

We are advised that this machine's previous owner was Les Martin of Douglas, Isle of Man, a regular TT competitor from 1933 to 1949 mostly riding Cotton's in the Lightweight races, his best result was 4th place in the 1939 Lightweight race riding an Excelsior. The machine was described as 'restored' when purchased in 1985, since when it has been stored and used only for a solitary Vintage run in which it performed faultlessly. Noteworthy features include a Wal Phillips fuel injector, 'sports' camshaft, and 'The Celestrial Express' script to the fuel tank. The engine number pre/suffixes suggest this 490cc ohv dry-sump unit (manufactured some time between 1 Sep 1937 and 31 August 1938) was a special 'customer order' as indicated by the 'S' suffix and would have benefited from either a 'Modified inlet port 500cc' or 'Piston ring thickness altered', as indicated by the 'J' suffix. Last run in March 2019, the machine is offered with an old-style continuation logbook (issued 1969) for the VRN DFG 687 (no longer assigned to the motorcycle) and assorted photocopies of Cotton-related literature.

11 notes

·

View notes

Text

Engine Cylinder Liner Manufacturer in India

Engine Cylinder liner Manufacturer in India is a type a part of auto parts manufacturing that is used by various industry like automotive, agriculture and construction machinery.

The reason for using the cylinder liner is their exclusive feature. Cylinder liner used for Piston rings need a surface against which they may move with the least amount of friction and the maximum amount of sealing in order to prevent combustion gases from leaking into the crankcase. Cylinder liners are generally made of cast iron, but can also be made from steel, aluminum, or composite materials.

With 36 years of industry experience, Nasrin Auto Private Limited (NAPL) offers services like engine cylinder liners manufacturer in India, serving as an OEM supplier of sleeves and air-cooled blocks or auto parts contract manufacturing and exporter. Nasrin Auto Private Limited is a market leader in contract manufacturing and OEM (Original equipment manufacturer) supply of engine cylinder liners, Wet and Dry Sleeves of Cylinders, and Air-Cooled Blocks that may be effectively used for different engine applications. Nasrin Auto Private Limited (NAPL) bears a good reputation in the market as an Engine cylinder liner manufacturer in India. We have setup our strong connection with our customers by offering state of the art products for more than 3500+ engine models for Automobiles, Marine, Diesel Engine, Truck Engine, generator, Agriculture and other Heavy Equipment Machinery items

We have been manufacturing these products from many times and our products are known to give good performance. our company has a good infrastructure and our products are tested for quality before they are dispatched. We have a team of highly skilled and experienced professionals who are always ready to meet the challenges of the market. We are committed to provide our customers with the best possible products and services. So, we are the best Engine cylinder liner manufacturer in India.

2 notes

·

View notes

Text

NAME. montgomery mcqueen.

ALSO KNOWN AS. lightning, monty.

MANUFACTURE YEAR. 2004.

SPECIES. robot, human-resembling.

OCCUPATION. entertainer, professional racer. coach.

LOCATION. travels often for work; home base is in radiator springs, arizona, USA.

HEIGHT. 185cm / 6′1″.

HAIR. brown.

EYES. blue.

BUILD. athletic.

PLAY-BY. harrison ford.

CHEATSHEET.

lightning’s an entertainment android, and as the name implies he was created to entertain humanity.

he’s a first generation robot of the fast track line: a set of androids created to do professional race car driving.

he’s not invincible, with his design trading in overall hardware durability and life expectancy for enhanced performance.

lightning can run on several kinds of energy: gasoline, most alternative fuels, and electricity. he’s had a recent upgrade that converts solar power too, but only when he has a specific panel built in his chest exposed to the sun.

his racing vehicle of choice is a 2006 custom built piston cup racing stock car. originally painted red, he repainted it in 2017 to be a dark blue.

lightning’s most notably won seven piston cups, but has also won several other championships for races inside and outside the US.

ABILITIES.

computer interfacing - when hooked up to any technological device (lightning is USB 3.0 capable!), lightning can navigate it much faster than a human. he can use devices normally (i.e. typing and using a mouse and looking at a monitor and all), but it’s a lot quicker if he’s plugged in. his USB port is at the tip of his left ring finger behind a sliding panel.

perpetual power - lightning doesn’t need to rest or sleep to recharge, technically. he may occasionally need to rest to cool down his internal temperatures and prevent overload if he’s strained himself physically, but sleep itself is unnecessary. lightning only goes into sleep mode to do daily diagnostics and routine file checking of his system.

superhuman capabilities - lightning is stronger, faster, and can take in more input than a normal human, more or less giving him “superhearing” and “supersight”. he can even see in the dark, but his optics glow when he activates it. his processing power also allows him to perform logical operations faster than the human brain, which helps a lot with racing.

scanning - as he’s built to entertain humans, lightning has rudimentary scanning functions that allow him to gauge the basic state of any human he’s talking to. temperature, heartrate, and an acute perception of their body language fall under this sphere.

multilingual - lightning can speak any language currently being used in the world as long as he has the language packs downloaded.

waterproofing - he’s waterproof, but cannot withstand extreme temperatures, whether hot or cold.

car interfacing - lightning is optimised to work best when he’s inside his designated race car and hooked up to it, with all his senses ramped up to maximum capacity as he borrows the car’s processing power. through his car and its satellite and wireless capabilities, he’s able to update himself with the latest fast track firmware available whenever he’s hooked up, and can also be reprogrammed using the computer built into it.

HISTORY.

montgomery mcqueen, then called “monty” by his creators, was one of the last few models created in his generation.

he was first owned by a nothing scent company named smell swell both to revitalise their sales and to introduce android tech to the racing scene.

as smell swell failed to improve, monty was later purchased by rust-eze, a company for rust and other decay-related removal substances, after a driver for the company first saw him race.

at mack’s-- the aforementioned truck driver’s-- suggestion, monty decided to go by “lightning” from then on, especially since rust-eze gave him full creative control over his image.

after winning plenty of races on small time circuits throughout 2005, lightning became the first android of the fast track line racing among humans in the nationwide piston cup of 2006.

an accident just before his last race of ‘06 had him getting lost on route 66, however, which led him to a small town named radiator springs.

in radiator springs, lightning had his first taste of freedom-- life beyond his programmed purpose to win races. he met a mix of humans and androids, most notably another android named hudson hornet: the first android ever to race on a track with humans and win three consecutive cups.

hudson, after much trials and tribulations, eventually ended up becoming his mentor in racing, as well as the chief of his pit crew.

lightning lost the piston cup of ‘06 after going back to help legendary racing champion, strip “the king” weathers, when the human got caught in a wreck. unbeknownst to him, this improved android acceptance among humans significantly.

following the piston cup of ‘06, rust-eze wrote in an addendum to lightning’s contract, allowing him to live in radiator springs off-season. between racing, his time in radiator springs allowed him to better understand humans and their customs.

after participating in the piston cup of ‘07, lightning finally emerged at the end of the season as champion. his groundbreaking victory thus started a trend of other companies creating racing androids to send in place of humans.

hudson hornet’s systems shut down beyond repair shortly after lightning’s championship win, leaving lightning devastated at the loss of his mentor. though he raced in the piston cup of ‘08-- renamed the hudson hornet memorial piston cup thereafter-- his performance suffered greatly.

his performance in the piston cup of ‘09 was much better in comparison.

in 2010, lightning had his first international competition in the first world grand prix. this launched his career further, allowing him to participate in other international races when he had time outside the american circuits.

for the next ten years, lightning continued racing annually, until the 2016 generation of machine racers left him struggling with his outdated technology. lightning found it near impossible to win against state of the art androids created to have symbiotic relationships with their cars; not only were he and his car separate entities, but his operating software was old, too.

during the piston cup of 2017, lightning eventually passed his torch to cruz ramirez, a newer generation android with much better performance than his. he also became her coach and chief of her crew pit.

though he continued to race in smaller circuits for a few more years after, he announced his official retirement in 2021.

these days, lightning occasionally joins local races throughout arizona, but for the most part the “bigger” parts of his career are over. lightning’s only intentions with huge racing circuits forevermore are in a coaching capacity for cruz-- at least until he shuts down beyond repair one day, too.

lightning mcqueen’s wiki page is here, for reference.

3 notes

·

View notes

Text

French-type valves manufacturer | Svarrnim Forgings

French-type valves offer versatility in their application, catering to a diverse range of fluid handling requirements. This valve is fitted with a Double o-ring piston that prevents leakage. Whether it's controlling the flow of liquids, gases, or steam, these valves excel in providing seamless regulation and shut-off capabilities.

visit source url : https://www.svarrnimforgings.com/handwheel-type-valves.html

0 notes

Text

China offer Thrust disk DLD320-20X2 for turbine generator

China offer Thrust disk DLD320-20X2 for turbine generator

Is YOYIK for the use of turbine units of the power plant supporting professional models of products. YOYIK main generator accessories, generator sets of accessories. For decades, the company relies on advanced technology, technology, materials and scientific management to improve the stability and reliability of the pump, for hundreds of thermal power plants, hydropower stations, cement plants, coal gangue power plants, metallurgical companies, steel and other overhaul , Technical transformation to provide a reasonable and excellent equipment selection, construction planning, installation commissioning, after-sales service, such as perfect complete service, won the power industry industry wide acclaim.

Yoyik can offer many spare parts for power plants as below:

#DF-Thrust disk DLD320-20X2-DF

piston vacuum pump A10VS0100DR/32R-VPB12N00

centrifugal pump vertical DFB125-80-230

manual vacuum pump P-1259

servo valve SM4-20- (10)38-80/40-50-S10

sealing ring HB4-56J8-79

flange coupling A10VS0100DR/31R-PPA12N00

mechanical shaft seal 021-M43K/125-00

industrial vacuum pump P-1751

pressure hose S100-AC-FA-0320

dc screw pump ACF090N4IRBP

pressure hose SMS-10/20-610mm-C

pump 40YW10-15-1.5

sliding vane pump F3V101S6S1C20

Gland Seal Extractor CQ-95-164-1

HPtrip block HTEHBA6C.0-1

Relief valveDBDS6K1X/315Proportional relief valve AGMZO-TERS-PS-010/210/I

nozzle 19D61-5-0

Coupling elastic block PVH074R01AB10A2500AE01

screw pump diagram 3GR30*4

sealing ring HB4-56J8-26

globe throttle check valve KJC50C-2.5P

axial piston variable pump PVH098R01AD30A250000002001AB010A

servo valve 163.320Z

three screw pump ACG070K7 NVBP

pump screw NM063BT01L06V

Seal oil roots pump KZB707035

electric motor centrifugal water pump YCZ50-250C

unloading valve F3-CV1-25-D16-L-40

liquid ring vacuum pump P-1937A

screw pump manufacturer 3GR70×2W21

sliding vane pump F3V101S7S1020

axial piston pump PV29-2R1D-C02

Solenoid valve FRE.WJA3.044

vacuum pump oil P-2402

O-ring C8689088

Thrust disk DLD320-20X2

mechanical seal types XD108-45

actuator diaphragm KS250ZXNO16BQ12SNOERH

BLADDER NXQAB100/10

oil vacuum pump 30WS

Rotary valve

vacuum oil pump 30-WS-COML

roots vacuum pump PVH141R13AF30A230000002001AB01A

roots vacuum pump P1725B

hydraulic oil pump electric 65AY50*10

Thermostatic water valve avta25

piston pump parts PV292R10C02

vacuum pump 226v 30-WS P-2811

sealing oil re-circulating pump repair kit HSNH-280-43NZ

mechanical seal in pump 24SAP-28

mechanical face seal LTJ-GJ-125A/R

vacum pump air vacuum PACG070K7NVB

hydraulic power 80AYⅡ60A-2

twin screw pump HSNH940-46

relief valve RV5-16-F-0-50

valves hydraulic Vickers SM4-20(20)76-80/40-10-S10

screw pump diagram DLZB820-R65-19

sealing ring HB4-56J8-53

radial piston pump PVH740ICRSF-IS-10-1

vacuum pump oil P-1751

pump screw HSNH-280-43NZ

fuel pump 3G70*2-46W

vacuum pump rotary vane F3V10IS6SIC20

AC lube pump impellersealing ring 125LY-35

fuel pump 3GR42×44

mechanical seal in pump DBF100-80-230

MOOG pump

vacuum pump ac P-1609-1

three screw pump HSNH440-46NZ

hydraulic pump motor 40AY35X11

Accumulator bladder NXQA-40/31.5

vacuum pump ac P-1762

Thrust disk DLD320-20X2

DFYLSYC-2024-4-15-A

0 notes

Text

TOTAL SEAL ACHIEVES ISO CERTFICATION

April, 2024 Phoenix, AZ Total Seal just announced the management system of Total Seal Inc, has been found to conform to the Quality Management System Standard ISO9001:2015 for Design, Machining, Fabrication and Assembly of Piston Rings.

Matt Hartford, CEO of Total Seal, commented, "Congratulations to the team at Total Seal for their hard work and dedication in achieving this significant ISO milestone. It is a testament to their skills and commitment to quality, and it reflects the high standards upheld by the employees, managers, and workers at the company. This accomplishment will surely bring about continued success and growth for Total Seal in the future."

About the ISO Process

The International Organization for Standardization (ISO) certification establishes credibility and trust among consumers, clients and other business partners. In today's international marketplace, such a designation validates that an organization adheres to global standards of quality assurance, manufacturing and business. For enterprise organizations, understanding what ISO certification entails can help to optimize business practices and inspire confidence in their interested parties.

About Total Seal Piston Rings

For more than 50 years, Total Seal has been known as the “Home Of The Gapless Piston Ring”, but today Total Seal® provides much more than Gapless rings. From our patented Gas Ported piston rings to industry leading Diamond Finish rings, no other manufacturer offers as broad a selection of piston rings as Total Seal®. Based in Phoenix, AZ, Total Seal manufactures innovative and advanced piston rings, tools and ring sealing solutions right here in the USA. Whether it’s an engine or an air compressor, if it takes a piston ring, Total Seal can make a better ring that improves the performance and durability of any internal combustion engine or air compressor.

SIDE NOTE FROM RPM MAGAZINE - ISO9001:2015 or any ISO system is difficult to achieve and requires a great deal of teamwork and dedication from Management and Staff of any organization. Having been a Quality Manager in my last position prior to working with RPM Magazine, I understand how difficult this task is to document from raw material through to completion to be able to track a product start to finish and be able to replicate the process producing an TOP QUALITY Product each and every time and when it isn't, being able to find the reason why through use of the tracking done throughout the build process. Congratulations to Total Seal on this amazing achievement!

#rpmmag #rpmmagazine #totalseal #iso9000 #iso90012015 #QMS

Read the full article

0 notes

Text

The piston ring, a small but mighty guardian, seals the power within, igniting the spirit of every engine's heartbeat.

0 notes

Link

Indiapistonring is leading piston manufacturing company in India. We practice stringent quality control measures for all our products. Send your requirement to us.

0 notes

Text

Applications and Working process of Control Valve

A valve is a device that regulates the fluid flow as well as the pressure within a system or process. Unlike on-off valves, a control valve is used to regulate the fluid flow by stopping and starting the fluid flow as per the direction is given by the controller.

Control Valve

Control valves consist of three main parts: the valve, the actuator, and the controller. Various components of the Actuator include rain cap, eye bolt, diaphragm, spring, actuator stem, diaphragm case, scale plate, stem connector, and yoke.

The components of body part include packing flange, packing follower, yoke claim nut, gland packing, valve stem, bonnet, stud bolt and nut, gasket, guide ring, guide bushing, valve plug, seat ring, valve body, trim set, and positioner.

Though the primary purpose of a control valve is to regulate the fluid flow, there are two main forms of action i.e. the sliding stem and the rotary action. The most common type of control valves in the sliding stem include globe valve, angle body valve, and angle seat piston valve while the rotary action includes a butterfly valve and ball valve.

Why Control Valves are Used?

Control valves are used for various purposes in the industrial, engineering, manufacturing, and scientific communities. The primary purpose of a control valve is to regulate the rate of the fluid flow by varying the size of the flow passage. Control valves are most commonly used for consequential control of process quantities including pressure, temperature, and the liquid level.

How do Control Valves work?

With the help of opening and closing internal passages, control valves regulate the fluid flow. Control valves form a control loop which is then used by a controller to send signals. Control valves respond to these signals and adjust the internal openings accordingly.

Control valves use the actuator to move the valve stem. Usually, it is either air (pneumatically) or electrically driven. The pressure between the inlet and outlet decides the rate of flow through the valve.

In order to reduce the fluid flow, the valve is closed, which results in more back-pressure and increases the difference between the inlet and outlet pressures.

Control valves help in controlling the fluid flow and are used in various industries including pipeline, oil & gas, food & beverage, the biopharma industry, and marine industry.

Sonu Hose is the top Control Valve suppliers and they are also the leading control valve suppliers in India. All their products are tested for resilient durability to provide the best industrial valve to their customers.

Contact Us

Call now: +91-9311288288

G-mail: [email protected]

Visit our Site: https://sonuhose.com

0 notes

Text

Enhancing Engine Performance: Understanding Engine Rebuilding and Boring Services

Introduction:

Engines are the heart of any vehicle, powering its performance and ensuring smooth operation. Over time, engines may experience wear and tear, decreasing efficiency and power. This is where Engine Rebuilding Services and boring services come into play, offering practical solutions to revitalize and optimize engine performance.

Engine Restoration Services:

Engine rebuilding is a comprehensive process that involves disassembling, inspecting, cleaning, and replacing worn-out components to restore an engine to its optimal condition—this service particularly benefits engines with high mileage, damage, or general wear.

During the engine rebuilding, skilled technicians carefully examine each component, such as pistons, cylinders, crankshafts, and camshafts. To ensure longevity and efficiency, damaged or worn parts are replaced with high-quality components. The goal is to address issues like cylinder misalignment, worn bearings, or piston ring damage that can affect overall engine performance.

Engine rebuilding is a cost-effective alternative to purchasing a new engine and an environmentally friendly option, as it promotes recycling and reduces the need for manufacturing new components.

Services for Engine Boring:

Engine boring is a specialized machining process that involves enlarging the diameter of the cylinders in an engine block. This is done to accommodate larger pistons, which can enhance the engine's overall power and performance. Engine Boring Services is commonly performed when an engine has experienced wear or damage beyond what simple honing can rectify.

Skilled machinists use precision equipment to bore the cylinders to specific tolerances, ensuring a perfect fit for the new pistons. This process can also address issues such as cylinder taper, out-of-round cylinders, or damage caused by overheating.

Engine boring is often paired with engine rebuilding to achieve maximum performance gains. Increasing the cylinder size allows the engine to accommodate larger valves and improve airflow, resulting in increased horsepower and torque.

The Mid-Point Inclusion:

For those seeking to optimize their engine's performance, engine rebuilding and engine boring services offer valuable solutions. Engine rebuilding addresses internal wear and tear, while engine boring enhances the engine's capacity for increased power and efficiency.

Conclusion:

Engine rebuilding and boring services are crucial in maintaining and improving engine performance. Whether your engine requires a comprehensive overhaul or a specific enhancement to its capacity, these services offer practical and sustainable solutions.

For reliable engine rebuilding and boring services, consider contacting ARA Engine Reconditioning. Their team of experienced technicians is dedicated to delivering top-notch services, ensuring your engine operates at its best. Visit their website at araenginereconditioning.com.au to learn more about their offerings and how they can meet your engine reconditioning needs—Trust ARA Engine Reconditioning for quality artistry and expert solutions to keep your engine running smoothly.

0 notes

Text

Are there any known issues with the Range Rover 2.0 engine?

Introduction

Range Rover, renowned for its luxurious design and off-road prowess, introduced the 2.0 engine variant in some of its models to provide a blend of performance and efficiency. However, like any complex mechanical system, this engine has faced its share of issues. We delve into the known problems associated with Range Rover's 2.0 engine, exploring their causes and potential solutions.

Turbocharger Malfunctions

One common issue reported with the Range Rover 2.0 engine is turbocharger malfunctions. Turbochargers, responsible for increasing engine power by forcing extra air into the combustion chamber, can fail due to various reasons such as oil leaks, bearing wear, or compressor damage. Symptoms include loss of power, unusual noises, or excessive exhaust smoke.

Oil Consumption

Owners have also noted significant oil consumption in some Range Rover models equipped with the 2.0 engine. Excessive oil consumption can be attributed to factors like piston ring wear, valve seal degradation, or PCV system malfunctions. Continuous monitoring of oil levels and regular maintenance are essential to mitigate this issue.

Timing Chain Tensioner Failure

Timing chain tensioner failure is another concern that has surfaced among Range Rover owners. The timing chain tensioner is crucial for maintaining proper timing between engine components. When it fails, it can lead to engine misfires, rattling noises, and even engine damage if not addressed promptly. Faulty tensioners may require replacement to prevent further complications.

Cooling System Issues

Cooling system issues have been reported in some Range Rover 2.0 engine variants. Overheating can occur due to factors like coolant leaks, faulty thermostats, or radiator blockages. Inadequate cooling can lead to engine overheating, which may result in severe damage if not rectified in time. Regular inspection of the cooling system is vital to prevent such occurrences.

Electrical Gremlins

Modern vehicles, including those with Range Rover's 2.0 engine, rely heavily on complex electrical systems. Owners have encountered various electrical gremlins, ranging from sensor failures to issues with infotainment systems. These problems can be challenging to diagnose and may require specialized equipment and expertise for resolution.

Fuel System Concerns

Fuel system concerns have also been reported by some Range Rover owners. Issues such as fuel pump failures, injector malfunctions, or fuel leaks can disrupt engine performance and fuel efficiency. Regular inspection and maintenance of the fuel system components are essential to ensure optimal engine operation and prevent potential hazards.

Transmission Problems

Transmission problems have plagued some Range Rover models equipped with the 2.0 engine. Issues like rough shifting, transmission fluid leaks, or complete transmission failure have been reported. Proper maintenance, including regular fluid changes and inspections, can help prolong the lifespan of the transmission and mitigate potential issues.

Engine Control Module (ECM) Failures

The Engine Control Module (ECM), responsible for managing various engine functions, can experience failures in some Range Rover 2.0 engine variants. ECM failures can result in erratic engine behavior, warning lights on the dashboard, or even engine stalling. Reprogramming or replacing the ECM may be necessary to resolve such issues effectively. More details about the range rover here at https://www.rangeroverengine.co.uk/ .

Conclusion

While the Range Rover 2.0 engine offers a balance of performance and efficiency, it is not immune to certain issues commonly encountered in modern vehicles. From turbocharger malfunctions to ECM failures, owners may face various challenges requiring timely attention and maintenance. Regular inspections, prompt repairs, and adherence to manufacturer-recommended maintenance schedules are crucial for ensuring the longevity and reliability of Range Rover vehicles equipped with the 2.0 engine. By staying informed about potential issues and addressing them proactively, owners can enjoy the driving experience that Range Rover is renowned for, without being hindered by unexpected mechanical setbacks.

Read the full article

0 notes

Text

The Average Lifespan of Diesel Generators

The expected lifespan of the generator is an important factor when purchasing a backup power system. It is worth mentioning that most industrial companies have equipped diesel generators because diesel generators have countless advantages. From our customer feedback, we can see the advantages of diesel generators.

To start a business, you need a generator that can work in any working environment, especially during power outages. Even if there is no electricity, this generator can still ensure your business is running smoothly. Thank goodness, diesel generators are reliable enough to do this.

Significant contributing factors.

The expected life of diesel generators depends on two main factors: the power of the generator and the maintenance method. Additionally, there are:

Product Brand and Quality

Engine power system

Natural environmental conditions

Next, please follow Dingbo Power to discuss in depth the two factors that affect the lifespan of diesel generators:

Power generation

For the efficiency of diesel generators, power is very important. Therefore, you should determine the load size of the machine planned to operate with the generator.

If you use a generator with a load capacity of up to 90%, there is no doubt that its lifespan will be longer. This ensures that the generator can obtain sufficient combustion pressure at all times to secure the piston rings.

However, using small diesel generators to achieve high loads can also shorten their lifespan. In this special case, insufficient load on the generator will affect the lifespan of the system.

Maintenance work

Whether it is a natural gas generator or a diesel generator, a well maintained generator has a longer lifespan than a poorly maintained generator. Regular maintenance is necessary to keep the generator running for several hours. Don't wait for a power outage before developing the motor. Comprehensive maintenance of the generator includes regular oil or air changes, replacement of fuel filters, and checking for any changes in operation.

Expert reminder: Don't forget to check if your generator will make noise, smoke, vibrate, or consume more fuel than before. This may indicate that there are some potential issues that need to be addressed.

Overall life expectancy

The lifespan of diesel generators can be maintained for at least 15000 hours until maintenance is required. Ultimately, the expected lifespan of any generator depends on factors such as generator selection and preventive maintenance methods.

The lifespan of a generator set also depends on how many hours of operation it operates each year. For example, a generator that operates for 650 hours per year can operate for 30 to 20000 hours. Similarly, if a generator works for a longer period of time in a year, its lifespan will also be shortened.

Understand your generator

The lifespan of a motor depends on factors such as movement and maintenance. To extend the service life of the generator, it is crucial to prioritize its operation regardless of power outage. If the generator is used regularly and regularly maintained, you will find that it can greatly improve the lifespan of the generator.

Dingbo Power was founded in 1974 and is one of the earliest manufacturers of generators and diesel generator sets in China. If you want get more information, please feel free to send email to [email protected] we will pay highly attention on your question.

0 notes