#peb building cost

Text

Smith Structure | Innovative Solutions for Engineering Projects

Smith Structure provides innovative engineering solutions, specializing in design & execution, delivering quality results tailored to your needs & services

#emerging company in india#pre engineered metal buildings prices#pre engineered building Construction#pre engineered building layout#best Peb Construction#pre engineered steel buildings#pre engineered building structure#modern pre engineered metal building#peb company#peb building cost#peb office building#engineered building#steel peb

0 notes

Text

PEB Construction and Sustainable Material | NRequipments

PEB Construction and Sustainable Material have been pioneers in sustainable building methods with creative ideas around it that emphasize environmental responsibility

In the face of today’s constantly changing construction climate, builders and developers are increasingly concerned about sustainability. Pre-engineered buildings (PEBs) have been pioneers in sustainable building methods with creative ideas around it that emphasize environmental responsibility. This paper discusses sustainable materials used in PEB construction and how they contribute to making structures greener and more resilient.

Eco-Friendly Material Selection: The use of eco-friendly materials is given great emphasis when constructing PEBs as a way of minimizing their ecological footprints without compromising on structural integrity. From recovered steel to green wood alternatives or efficient insulation, PEBs focus on resources conserving materials that decrease carbon emissions.

Energy-Efficient Design Strategies: An energy saving approach must be at the core of any sustainable PEB design if one wants to decrease the cost of energy consumption and maintenance. This involves optimizing daylighting techniques, incorporating photovoltaic panels for renewable power generation, as well as installation systems that facilitate thermal capabilities and reduce heating/cooling loads.

Manufacturing with a Low Carbon Footprint: PEB parts are manufactured through eco-friendly processes, which employ efficient production methodologies that minimize wastage and energy requirements. Besides, the use of pre-fabricated elements reduces waste in construction as well as on-site pollution which means other forms of building.

Sustainability and Longevity: On the other hand appropriate materials utilized in PEB framework will ensure strength and durability for a long time, hence allowing for less maintenance and replacement activities. By choosing high-quality environmentally friendly materials, these structures become an example of lasting value and adaptability to changing conditions.

Read more: https://nrequipments.in/the-relationship-between-peb-construction-and-sustainable-materials/

#Peb manufacturing near me#Peb manufacturing cost#Safety Standards in Building Manufacturing#peb Steel Building Manufacturing

0 notes

Text

#pre engineered steel buildersintirupur#peb structure cost per sq ft in tirupur#industrial steel structure building manufacturers in tirupur

0 notes

Text

Cost Efficiency In Construction: How PEB Can Save Time And Money

Pre-engineered buildings (PEB) refer to structures that are manufactured off-site using standard designs and components, and then assembled on-site.

2 notes

·

View notes

Text

Warehouse Manufacturer In Uttar Pradesh

Creative Building Solutions: The Best Pre-Engineered Steel Building Manufacturer in Uttar Pradesh

Pre-engineered steel buildings (PEBs) are a popular choice for a variety of applications, including factories, warehouses, , retail stores, and even homes. PEBs offer large number of advantages over traditional building methods, including speed of construction, energy efficiency.and durability

If you are looking for a pre engineered steel building manufacturer in Uttar Pradesh, Creative Building Solutions is the best option for you. Creative Building Solutions has been in the business of manufacturing PEBs for over 12 years, and they have a proven track record of quality and customer satisfaction.

Why Choose Creative Building Solutions?

There are many reasons why you should choose Creative Building Solutions for your next PEB project. Here are just a few reasons

Quality

: Creative Building Solutions uses only the highest quality materials in their PEBs. Their steel is sourced from reputable suppliers, and their manufacturing process is strictly controlled to ensure that every building meets their exacting standards.

Durability

PEBs are built to last. They are designed to withstand even the harshest weather conditions, and they are virtually maintenance-free.

Energy Efficiency

PEBs are very energy efficient. Their steel construction helps to keep them cool in the summer and warm in the winter, and they can be easily insulated to further improve their energy efficiency.

Speed of Construction

: PEBs can be constructed much faster than traditional buildings. This is because they are prefabricated in a factory, and they can be assembled on-site in a matter of weeks.

Affordability:

PEBs are a very affordable option for many businesses and homeowners. The initial cost of a PEB may be higher than a traditional building, but the long-term savings on energy costs can make them a very cost-effective choice.

Creative Building Solutions' Services

Creative Building Solutions offers a wide range of PEB services, including:

Design:

Creative Building Solutions' engineers can help you design the perfect PEB for your needs. They will work with you to determine the size, layout, and features of your building.

Manufacturing

: Creative Building Solutions' factory uses state-of-the-art equipment to manufacture your PEB to the highest standards.

Construction:

Creative Building Solutions' team of experienced construction professionals will assemble your PEB on-site in a matter of weeks.

Maintenance:

Creative Building Solutions offers a comprehensive maintenance program for your PEB. This program will help to ensure that your building remains in good condition for many years to come

.

Here are some additional benefits of choosing Creative Building Solutions:

Expertise:

Creative Building Solutions has a team of experienced engineers and construction professionals who are experts in the design and construction of PEBs.

Flexibility

: Creative Building Solutions can customize your PEB to meet your specific needs. They offer a wide range of sizes, layouts, and features to choose from.

Warranty

: Creative Building Solutions offers a comprehensive warranty on their PEBs. This warranty will protect you against defects in materials and workmanship.

If you are looking for a quality, affordable, and reliable pre engineered steel building manufacturer in Uttar Pradesh, then Creative Building Solutions is the clear choice. Contact them today to get started on your next project.

2 notes

·

View notes

Text

PEB in industrial projects.

Prefabricated Engineered Buildings (PEBs) are crucial in industrial projects for their cost-effectiveness, reduced construction time, and design flexibility. They enhance efficiency by using standardized components, ensuring quality control, and allowing for easy expansion or modification, thus meeting diverse industrial needs.

0 notes

Text

Prefabricated Warehouse Manufacturers

Prithvi PEB Building System is one of the top Prefabricated Warehouse Manufacturers in India. We offer the best warehouse solutions for industrial and commercial industries. These warehouses are constructed using lightweight and durable materials, making them an ideal choice for small and large industries. Our quality experts ensure that these prefabricated structures are available at the most cost-effective prices. If you are interested, you can visit our website.

Add : BL 86, L-Block Hari Nagar, New Delhi-110064

Email : [email protected]

Ph : +91-7999993434

1 note

·

View note

Text

Industrial Shed Construction Cost: Key Factors and Insights

Constructing an industrial shed involves meticulous planning and understanding various cost factors to ensure that the project stays within budget while meeting all functional requirements. In this blog post, we'll explore the key factors influencing industrial shed construction costs and highlight why EPACK Prefab is the top manufacturer and supplier you should consider for your project.

Understanding Industrial Shed Construction Costs

1. Materials

The choice of materials significantly impacts the overall cost of constructing an industrial shed. Common materials include steel, concrete, and prefabricated components. Steel is often preferred for its strength and durability, while prefabricated panels, like those from EPACK Prefab, offer a cost-effective and efficient solution.

2. Design and Size

The design complexity and size of the shed are critical determinants of the cost. A simple, single-story structure will be less expensive than a multi-story shed with intricate designs. The larger the shed, the more materials and labor are required, thus increasing the cost.

3. Labor

Labor costs vary depending on the location and the complexity of the construction. Skilled labor for specialized tasks, such as electrical work and plumbing, will add to the overall expense. Prefabricated solutions from EPACK Prefab can reduce labor costs due to their ease of assembly and faster installation times.

4. Location

The construction site’s location affects the cost in several ways. Remote areas might incur higher transportation costs for materials and labor, while urban areas could have higher land costs and regulatory fees.

5. Foundation and Site Preparation

The type of soil and the condition of the construction site influence foundation costs. A stable, well-prepared site reduces the need for extensive groundwork, lowering the overall expense. Conversely, a site with poor soil conditions or requiring significant grading will increase costs.

Also Read: PEB Industrial Sheds – Are They Better Than Traditional?

Why Choose EPACK Prefab?

Quality and Reliability

EPACK Prefab is renowned for its high-quality prefabricated solutions that meet stringent industry standards. Their products ensure durability, safety, and efficiency, making them a trusted choice for industrial shed construction.

Cost-Effectiveness

Prefabricated components from EPACK Prefab are designed for quick and easy installation, significantly reducing labor costs and construction time. This cost efficiency does not come at the expense of quality, ensuring that you get the best value for your investment.

Customization

EPACK Prefab offers a range of customizable options to meet specific project requirements. Whether you need a simple storage shed or a complex manufacturing facility, their solutions can be tailored to fit your exact needs.

Sustainability

EPACK Prefab is committed to sustainable building practices. Their prefabricated panels and components are designed to minimize waste and reduce environmental impact, aligning with modern sustainability goals.

Conclusion

Understanding the various factors that influence industrial shed construction costs is crucial for effective budgeting and planning. Materials, design, labor, location, and site preparation all play significant roles in determining the final cost. By choosing a reputable manufacturer and supplier like EPACK Prefab, you can ensure a cost-effective, high-quality construction process that meets your specific needs.

For your next industrial shed project, consider the advantages of prefabricated solutions from EPACK Prefab. Their expertise, quality, and cost-efficiency make them the top choice for industrial shed construction.

Visit EPACK Prefab’s website to learn more about their products and how they can help you achieve your construction goals efficiently and economically.

#IndustrialShed#ConstructionCosts#EPACKPrefab#PrefabConstruction#BuildingMaterials#SteelSheds#IndustrialBuilding#CostEffectiveConstruction#PrefabricatedSolutions#ConstructionPlanning#SustainableBuilding#ConstructionTips#QualityConstruction#LaborCosts#SitePreparation

0 notes

Text

What Is A Pre Engineered Building And Its Components - Everest Industries

The Indian construction industry is rapidly expanding, leading to a steady emergence of smarter methods of construction. As new techniques and methods emerge, the focus shifts to maximising efficiency and minimising costs. These newer methods of construction stand in stark contrast to traditional methods, which have several disadvantages. Some of which are:

• Longer project timelines

• High labour costs

• Excess wastage of materials

• Limited design flexibility

• Higher safety risks

Advantages of pre-engineered buildings

1. Cost-effective

PEBs are designed using tapered sections and manufactured in highly controlled environment of a factory, which means there is less wastage of material compared to traditional construction. They are also faster to erect, which reduces labour costs.

2. Durable

Steel is a highly ductile material that can withstand reversible loads like wind, and earthquakes. Hence, PEBs are designed to withstand the most extreme weather conditions.

3. Flexible

PEBs can be customised to meet the specific requirements of the client. They can be designed to accommodate various building types, including commercial, industrial, and residential.

4. Environmentally friendly

Since steel is a recyclable material, this makes PEBs an environmentally friendly choice. They can also be designed for energy efficiency by maximising natural lighting and providing effective insulation, which reduces the energy requirements of the building.

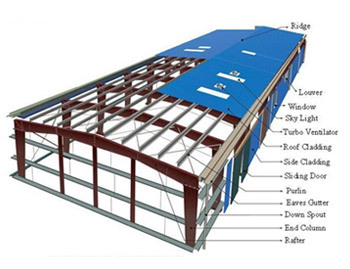

Major components of pre-engineered steel buildings

PEB is made up of several structural and non-structural elements that are connected by bolted joints. Let’s take a closer look at the components of pre-engineered buildings, which include primary components, secondary components, sheeting or cladding, and accessories.

1. Primary components

The primary components of a pre-engineered building are columns and rafters that constitute the mainframe.

1. Mainframe

The mainframe is the skeleton of the building and is made up of built-up steel sections. It is designed to reflect the size and shape of the building. It comprises Columns and Rafters.

2. Columns

The columns are vertical members that support the main frame. They help transfer the load of

the structure to the foundation.

3. Rafters

The rafters are horizontal structures that connect the columns and support the roof.

0 notes

Text

What is metal building?

Metal buildings have become a popular choice for a wide range of construction projects due to their numerous advantages. They are strong, durable, and can be erected quickly and efficiently. Metal buildings are structures where steel acts as the primary framing material for walls and roofs. They are pre-engineered in sections at manufacturing facilities, then transported to the construction site for assembly. This prefabricated approach allows for faster construction times and cost savings compared to traditional building methods.

Types of Metal Buildings

Pre-Engineered Buildings (PEBs) is the most popular type of metal building. They are versatile and can be customized for various uses. PEBs are known for their clear span design, meaning there are no interior support columns, maximizing usable space. Straight-Wall buildings have straight walls with a gabled roof. They are a good option for warehouses, workshops and storage facilities. Arch Buildings is also known as Quonset huts, these feature a curved roof design. They are economical and well-suited for agricultural buildings, storage units, and sports facilities. Lean-To Buildings are attached to an existing structure, lean-to buildings have one vertical wall and a sloping roof. They are ideal for extra storage space or covering walkways.

Benefits of Metal Buildings

Steel is a strong and resilient material that can withstand harsh weather conditions, including heavy rain, snow, and strong winds. Metal buildings are also resistant to fire, termites, and other pests. Metal buildings are generally less expensive to construct than buildings made with other materials like wood or brick. This is due to the efficiency of prefabrication and faster erection times. Metal buildings can be designed to be energy-efficient by using insulated metal panels for walls and roofs. This can significantly reduce heating and cooling costs. Metal buildings require minimal maintenance compared to other structures. The steel frames are resistant to rust and corrosion, and the metal panels are easy to clean. As mentioned earlier, metal buildings are prefabricated, allowing for a quicker construction process. This can be a significant advantage for projects requiring a fast turnaround. Metal buildings can be customized to meet specific needs and preferences. A variety of wall and roof panel options, door and window configurations, and insulation levels are available.

Common Uses of Metal Buildings

Industrial Buildings

Commercial Buildings

Agricultural Buildings

Community Buildings

Residential Buildings

Factors to Consider Before Buying a Metal Building

Clearly define the intended use of the building. This will influence the size, design, and features needed. Determine the required length, width, and height to accommodate your needs and comply with local building codes. Building codes and wind load requirements may vary depending on your location. Ensure the chosen metal building meets the necessary specifications. Establish a realistic budget for the project, including the cost of the building, delivery, installation, and any permits required. Research local building permits needed for your specific project. Consider the level of customization required, such as wall and roof panels, doors, windows, and insulation. Choose a reputable metal building manufacturer with a proven track record of quality and customer service.

Metal buildings offer a compelling option for those seeking a strong, durable, and cost-effective building solution. Their versatility, ease of construction, and low maintenance requirements make them a popular choice for various applications. By understanding the different types, benefits and factors to consider, you can make an informed decision to determine if a metal building is the right choice for your project.

0 notes

Text

PEB Structural Fabrication Service in Chennai

MH Infra Project is one of the leading providers of PEB Structural Fabrication Service in Chennai, Tamil Nadu, India.

The company excels in overseeing industrial and commercial fabrication projects, pipeline projects, chain-link fencing fabrication, PEB fabrication, custom fabrication, structure fabrication, and roofing structures.

PEB structural fabrication involves assembling building components in a controlled environment using advanced techniques and machinery.

From primary framing elements to secondary structural elements, each component undergoes meticulous fabrication to maintain high quality standards.

PEB Structural Fabrication enhances efficiency by reducing construction time, ensuring cost-effectiveness through minimized wastage, offering customization for diverse project requirements, and providing exceptional durability and strength against environmental factors.

Embracing this revolutionary approach to building construction, PEB structures continually redefine the landscape of modern architecture.

PEB Structural Fabrication caters to diverse sectors including industrial facilities, commercial buildings, institutional structures, and agricultural buildings. Its swift construction, versatility, and robustness effectively meet various architectural needs.

MH Infra Project is one of the leading providers of PEB Structural Fabrication Service in Chennai and places like Advadi, Kanagam, Ennore, Chetpet, Minjur, Kolathur, Mylapore, Ennore, Adyar, MRC Nagar, Pallikaranai, Egattur, Nesapakkam, Perungalathur, Kottivakkam, Kazhipattur.

For detailed information or inquiries, please feel free to contact us.

0 notes

Text

Pre-Engineered Buildings Cafes & Restaurants | NREquipments

Building Cafés and Restaurants: Exploring Construction Options and Why PEB Takes the Lead

In the dynamic world of café and restaurant construction, choosing the right method is crucial for creating spaces that blend aesthetics, functionality, and efficiency. As you embark on the journey of establishing a café or restaurant, it’s essential to weigh various construction options. In this blog, we’ll delve into the realm of construction possibilities and shed light on why Pre-Engineered Buildings (PEB) stand out as the optimal choice for building your dream café or restaurant

Understanding Construction Options:

Traditional construction: Methods involve on-site assembly of components, which can often be time-consuming and may result in increased costs. The intricate nature of café and restaurant designs and the need for precision demand a construction method that aligns with efficiency without compromising quality

Read more: https://nrequipments.in/pre-engineered-buildings-cafes-and-restaurants-nrequipments/

#Pre-Engineered Buildings Manufacturing#peb Steel Building Manufacturing#Safety Standards in Building Manufacturing#Cost-Effective Construction

0 notes

Text

Pre Engineered Building Fabricators in Chennai

Ritvi Steels Buildings is a leading pre engineered metal building fabricators in Chennai delivering excellent turnkey PEB services to various industries, as well as commercial and residential projects at an affordable price.

#pebcompanyinchennai#peberectors#peb structure cost per sq ft in chennai#pre engineering building manufacturer

0 notes

Text

Peb Buildings - Perfect Metal Structure

Peb buildings, also known as Pre-Engineered Buildings, are considered the perfect metal structure for a variety of applications. These buildings are constructed using steel columns, beams, and other components that are fabricated off-site and then assembled on-site. The use of metal materials ensures that Peb buildings are durable, able to withstand harsh weather conditions, and can be easily customized to meet specific requirements. Additionally, these structures are cost-effective, energy-efficient, and have a quick construction time. Overall, Peb buildings are an ideal choice for industries, warehouses, workshops, and commercial spaces seeking a reliable and high-quality metal structure.

0 notes

Text

The Future of Warehousing: Exploring the Benefits of PEB Warehouses - BDS Fabrication

Introduction

In today's fast-paced business environment, efficient and cost-effective storage solutions are paramount. Pre-Engineered Building (PEB) warehouses have emerged as a game-changer, offering numerous advantages over traditional construction methods. In this article, we will delve into what PEB warehouses are, their benefits, and why they are the future of warehousing.

What Are PEB Warehouses?

Pre-Engineered Building (PEB) warehouses are steel structures designed and manufactured in a factory and then assembled on-site. These warehouses are tailored to meet specific requirements, providing a versatile and durable storage solution.

Benefits of PEB Warehouses

1. Cost-Effective

One of the most significant advantages of PEB warehouses is their cost-effectiveness. The pre-engineering process minimizes waste and reduces construction costs, making it an economical choice for businesses.

2. Quick Installation

PEB warehouses can be erected much faster than conventional buildings. The components are fabricated off-site and merely need to be assembled, which significantly speeds up the construction timeline.

3. Durability and Low Maintenance

Constructed from high-quality steel, PEB warehouses are incredibly durable and require minimal maintenance. They are resistant to pests, fire, and harsh weather conditions, ensuring long-term reliability.

4. Versatility

PEB warehouses can be customized to meet specific storage needs. Whether you require additional space, specialized sections, or specific design features, PEB warehouses offer the flexibility to accommodate various requirements.

ConclusionPEB warehouses represent the future of warehousing, providing cost-effective, durable, and versatile storage solutions. Businesses in need of efficient and reliable warehousing should consider the numerous benefits of PEB warehouses. To learn more about how PEB warehouses can transform your storage needs, contact us today.

About Us

Established in 1998, BDS Projects has in-house facilities for designing, fabrication, shot-blasting, painting, powder-coating, supply, and installation of PEB warehouses, steel storage racks, heavy steel structures, roof sheeting, accessories, and EOT cranes, porta cabins. At BDS Projects, our commitment to excellence extends beyond project execution to include stringent Quality and Safety Standards.

We pride ourselves on adopting proper safety protocols throughout every project, ensuring a secure work environment. To achieve this, a dedicated team of highly trained safety officers is appointed for each project, emphasizing our unwavering commitment to safety.

Contact Us

BDS Projects

Address: Sampla, Rohtak, Haryana 124501

Email: [email protected]

Phone: 9814016010 / 9999201713

Website: https://www.bdsfabrications.com/

#PEB Warehouse#PEB manufacturer in India#Portable Cabins#peb steel building manufacturing#EOT Crane Manufacturer in India#Steel Storage Racks#Heavy Steel Structures

0 notes

Text

PEB Structure Fabrication in Gujarat

Kaswala Steel Buildings LLP is a Provider of PEB Structure Fabrication in Gujarat, India.

Our expertise lies in crafting bespoke structures, intricately engineered and constructed to precisely match your distinct needs and desires.

PEB Structure Fabrication marks a revolution in the design, fabrication, and assembly of building structures.

Our PEB structures stand out due to their incredible flexibility in design. Sophisticated software and technology custom-design these buildings to meet specific demands, accommodating unique requirements.

From wide-span hangars to intricate multi-story buildings, the design possibilities are nearly limitless, tailored to withstand local weather conditions and load requirements.

A controlled factory environment manufactures the components of PEBs, ensuring high quality and precision. It fabricates steel frames, roof and wall panels, and other structural elements to exact specifications.

One of the most significant advantages of PEB structure fabrication is the speed of assembly. Since pre-fabricated components merely require assembly at the site.

PEB structures are inherently modular and scalable. Expansions are simplified as new modules can be designed to integrate with existing structures seamlessly.

PEB structures offer efficient fabrication due to standardized components. They find application in warehouses, factories, and commercial buildings, offering cost-effectiveness, rapid construction, and design flexibility.

Kaswala Steel Buildings LLP is a Provider of PEB Structure Fabrication in Gujarat and places like Ahmedabad, Vatva, Naroda, Sanand, Dhandhuka, Dholka, Viramgam, Kathawada, Odhav, Surat, Vadodara, Rajkot, Jamnagar, Bharuh.

Please feel free to contact us with any questions or for additional information.

Read the full article

0 notes