#paper egg tray making machine

Text

youtube

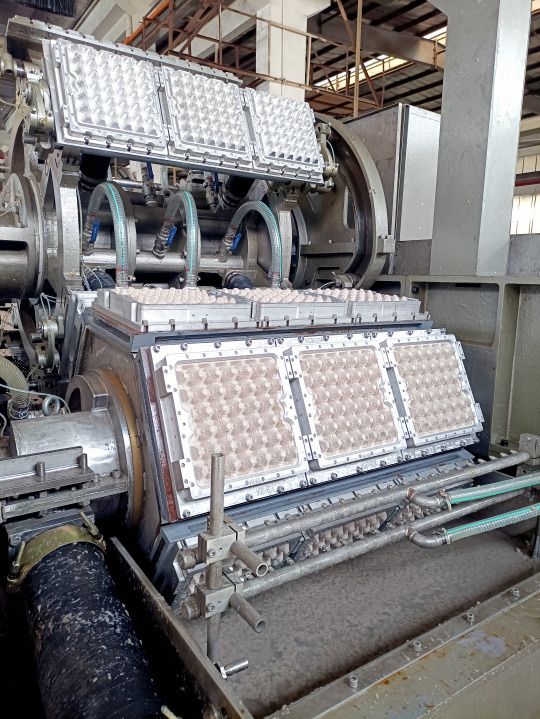

Brick Drayer Egg Tray Making Machine Production 4000/hr

#egg tray packing machine#egg tray manufacture#egg tray manufactures#Paper Pulp egg tray manufactures#Egg tray machine#paper egg tray machine#small egg tray machine#egg tray production line#egg tray machine price#laxmienterprises#laxmi enterprises#egg tray machine in india#egg tray machine for sale1000pcs/h egg tray machine#paper egg tray making machine#Youtube

0 notes

Text

The Rise of Paper Egg Tray Making Machines

0 notes

Text

A Guide to Making Paper Egg Trays for Sustainability

In today’s world, where environmental sustainability is paramount, the need for eco-friendly packaging solutions is more critical than ever. Paper egg trays offer a sustainable alternative to traditional plastic or foam packaging, providing a biodegradable and recyclable option for protecting eggs during transportation and storage. This post serves as a comprehensive guide how to make paper egg…

View On WordPress

0 notes

Photo

Tony Stark’s Cheeseburger Bloody Mary

because what sometimes a genius billionaire playboy philanthropists needs a cheese burger and the hair of a dog.

Recipes under the cut:

Bloody Mary:

large handful of ice

100ml vodka

500ml tomato juice

1 tbsp lemon juice, plus 2 slices to serve

few shakes Worcestershire sauce (I used a vegan brand)

few shakes Tabasco

pinch celery salt

pinch black pepper

2 celery sticks

Olives

One mini-cheeseburger

Place the ice in a large jug. Measure the vodka, tomato juice and lemon juice and pour it straight onto the ice.

Add 3 shakes of Worcestershire sauce and Tabasco (or more if you like it very spicy) and a pinch of celery salt and pepper. Stir until the outside of the jug feels cold, then strain the cocktail into 2 tall glasses.

Top up with fresh ice, add a celery stick, skewers of olives (one with the tiny cheese burger) lemon slice to both glasses and enjoy.

Cheese Burger:

Mini Hamburger Buns (I baked my own)

sliced cheese

one sliced pickle

Hamburger patty (I used Future Farm Plant Based, but you can use whatever you want, or even make mini patties from scratch)

Use a small glass to cut burger patties into small rounds and grill for a few minutes on one side. Flip and add 1/4 of a slice of cheese to the top of the patty. Continue grilling to taste.

Cut bun in half and add one slice of pickle, patty with cheese, and ketchup.

Mini Buns:

1 (1/4-ounce) package (2 1/4 teaspoons) active dry yeast or bread machine yeast

1/2 cup water, warm, about 110 F

2/3 cup whole milk, room temperature

1 large egg

3 tablespoons butter, melted and cooled slightly

2 1/2 tablespoons sugar

1 1/4 teaspoons salt

3 cups all-purpose flour

Butter or oil, for greasing the bowl

1 large egg white

1 tablespoon water

1/4 cup sesame seeds

Combine the yeast and warm water in a large bowl or the bowl of a stand mixer. Let the mixture stand for about 10 minutes, until foamy.

In a small bowl, whisk the milk, egg, and melted butter together to blend.

Add the milk mixture to the yeast mixture along with the sugar, salt, and flour.

Knead the dough by hand (or using a stand mixer with the dough hook) for 8 to 10 minutes, adding a little more flour if necessary to keep the dough from sticking to your hands, the countertop, or the sides of the bowl. The dough should be smooth and elastic at this point. (do the window pane test - if you can stretch it to the point it’s see through, it’s ready).

Generously grease a large bowl with butter or oil. Gather the dough into a ball and place it into the greased bowl. Turn it over a few times to coat the dough thoroughly.

Cover the bowl with plastic wrap and let the dough rise for 1 to 1 1/2 hours, or until it has doubled in bulk.

Line 2 large baking sheets with parchment paper or lightly grease the pans.

Punch down and pat the dough into a rectangle.

Use a small glass or egg cup to cut out buns and put on tray 2 inches apart.

Preheat the oven to 375 ° F

Whisk the egg white with 1 tablespoon of water until blended and brush over buns. Sprinkle on sesame seeds.

Bake for around 10 minutes. Keep a close eye on them. They are very small and cook very quickly and can go from undercooked to burnt very fast. To check if they’re baked through, tap on the bottom of the bun. If it sounds hollow it’s done. Should be golden in color.

#marvel#avengers#bloody mary#cocktail#tony stark#iron man#cheese burger#food#drink#recipe#tony stark cocktail#iron man cocktail#geeky cocktail#geeky drinks#avengers cocktail#marvel cocktail

29 notes

·

View notes

Text

Tornado Recipe UltraJune

(Symphony Futility in Z major)

Unstageable play

Regiondirect→Camereye stood parallel

A kitchen in an upper middle class home. It’s a dim noon. The counters+sink are lit by adjustable lamps on two aluminum racks overhead. In the middle of the room there is one center island; marbletopped, with two wood doors that open for access to inner-cabinet storage. The sink is in the back at stage right. There is a window above the sink. The Readers can see on the outside that there’s a dreary dusk sky, plus a cloud above. All the cabinet doors are white, the sinkfaucet is gold color, the cabinet doors are gold color. A rack of silver soupladles+spatula+tongs+whisks+tablespoons is mounted on the wall over a blender and beside a black air fryer. Right side: Out of the refrigerator come both hum and icerumble sounds. A windchime sings in parallel with nearing thunder.

(egg timer, stove, junk drawer full of rubberbands, unused tools, a tape measure, whole drawerfull of clean knives+forks+spoons, a dishwasher, a spice rack with one hundred flavors, a microwave, )

Flying soup ladles calmly stir a pot of boiled tin foil. The air fryer cheerfully pops its door open. A gantry crane lowers its chain from the ceiling, on the hook is a red wicker basket full of leather wallets. Two big bowls spin slowly like tops on the center island, one full of ice cream and the other full of fresh soup. The airfryer drops its door open and slides out its metal rack. A forklift made out of an exercise machine takes the basket and dumps the wallets on the airfryer’s rack, which is stuck out like a tongue. A flying pair of tongs with biplane wings serves rolls of bread from a tray out of the oven. The air fryer timerknob is now switched on and the timer is making its quick chatter sound. Icecream and Soup bowls drift and bounce together a bit like careening tops, and now the leather bakes.

Regiondirect→Stage right (Begin ruination of a birthday lunch)

A cardboard box full of embarassing memories is spilled down the stairs: Thousands of ruled paper sheets with awful poems written on them go wafting into the kitchen where they float around and fold into paper airplanes, then they land on the center island in perfect rows like jets on a battleship.

Poemjets: We’re here to attack your confidence with this cringey reminisence.

A stolen medalion flies through the air and crashes into the stained glass sconce of an antique wall lamp which is mounted in the living room: Sconce is shattered when it hits it. Shard after shard of red and blue crystal-cracked glass falls into a steel cauldron on a wheeled cart on a line of railroad tracks sitting on the carpet: The cart drives and the cauldron is taken to a forge by the fireplace where the glass is melted down and poured into a mold that shapes it into a skull: This forms the skull of a clueless fool, this is the first and most important skull.

Blue+Red Glass Shards

Blae+rued Gless Sharides

Blaew+Rueld Gleessh Shparides

jBlaw+Ruelld Gleetssh Sparidens

jblaw+rulled Gleethss Spaidens

Jblaw+krulled tGleeths Spidens

Jlaw skulled tleeth Spienes

Jaw skulled Tleeth Spines

Jaw Skull Teeth Spine

Jaw, Skull, Teeth, Spine

Regiondirect→Stage middle; from mouth of humanactor one

(activate buffoon here)

Foollessclue:

I am going to get this job. Before they mock me and I evaporate. I am going to get my job. j’andob→And keep my job once I have it; I will have a job: this job I am applying for, I will not be mocked or evaporate→ I am applying for a lifetime career→My choices are God’s design→I am not a deadbeat+/or wastrel ‘l ‘el ‘l ‘rel ‘l

Regionpoint: High up at stage middle:

Four cabinets above a stove open and reveal a long television screen behind them, the screen plays a panorama video of the inside of a grocery store on a time lapse, rapidly showing shoppers moving around and down aisles through a full day. So the commerce source of groceries plays inside the storage destination of groceries.

Regiondirect→Stage left+downstage

Foolllessclue walks like a desk, heavily skulking: A Huge wooden desk in the office room walks like a heavily skulking crab from its place in the office into the doorway of the kitchen. The desk Stomps and sprouts two claws made of stationary: Protractor joints, fountain pen fingers plus inky venom in nibs and two eyeballs on stalks that are webcams.

Deskrab: I make my next shell out of your hard work and notes. If you ever do any hard work again.

Foollessclue stands in the doorway and contemplates going back to bed. Then an idea comes to him:

Foollessclue: Eureka! Wow! Golly! Lord Almighty! The truth has arrived!

A wrecking ball made out of a soccer ball weighing six tonnes falls from the ceiling and crushes the center island: obliterated the bad poems, marble landing strip, and cabinets, instantly.

Chunks of marble fall into a plexiglass gutter and the camereye view changes

Regiondirect→ Camera is now low and pointed upwards: the reader can see through the stage floor to where a plexiglass gutter runs from stage right to left, with cold green water thrashing through it toward a previously hidden now→revealed underground room where a cashregister with bulldozer tracks and an abacus with centipede feet are seen watching the deluge of marble chunks and water fall from a sewer pipe above them into a trough before them.

Hot water spinning in a blender elsewhere.

Rock and Water dropping top right to bottom left.

Cash register bell ding sounds when the drawer pops→slides.

The cash register reaches out with a thin alu-wire appendage, picks pieces of marble out of the wet junk, and carefully organizes them into its drawer compartments. The abacus keeps record while a gooseneck lamp uses square chalk to write mathematical figures on the wall.

Two haggard bowls spin slowly like tops on the plot of the destroyed center island: Now one is filled with pinecones+dry ice and the other full of burning coals+dominos.

A bookshelf gets into a fistfight with the front door. The front door comes unhinged and walks backwards into the stage right of the set while the bookshell follows it and throws punches with arms made out of desk lamps. Sound: of bulbs shattering on punch-contact. The door topples against the fridge: KO. The Shelf keeps punching with lampfists until the door is busted full of holes, then the door breaks almost in half and crumples on the floor up against the fridge.

Regiondirect→ Camera cuts back up to oblique angle of Foollessclue frantically scribbling ideas in a big leather planner

Foollllessclue: I will invent a way to cure all diseases: I will socialize with the society. I will take pictures of every single thing that has ever existed. I will get a job making Christmas cards.

Foolllllessclue gets on his moped and rushes down to the job office. Each of his pockets is jammed with crumpled social security cards, resumes, a half eaten highschool diploma, and a computer eyeball.

A framed photo falls from the kitchen wall and lands face-down: Nothing breaks. The framephoto begins to crawl around on the floor like a bug and bites at the ankles of a chair which kicks and stomps back. Both of them go in circles around the left side of the kitchen.

The leftover marblewater swirling in the trough that couldn’t be fit in the cash register’s abdomen was scooped up by a bucket held by the abacus and laid out on a table. The gooseneck lamp sprouts a tungsten arm and starts using epoxy and bolts to connect the pieces of marble together, end to end, particle by bit, until the dusty chunks are two long bars. The cash register now takes out a chisel and rapidly sculpts the repaired marble bars into two legs, this makes the first pair of legs.

Marble Chunks Bolts

Mairble Chaunkes Beoelts

Mahirble Caunkes feBoelts

Mahigrbles Cankes febelt

mathigrbles Cankves febet

maThigbles Caves feet

aThighles Calves feet

Thighles Calves Feet

Thighs Calves Feet

Foollllllessclue uses his two marble legs to walk into the job store. But his foot gets caught on the doorway and he trips→and his pockets spill their garbage contents everywhere. ←↑→

A suitcase with eight thick-tired wheels (The front two bigger than the rear six) drives like a semi onto the middle kitchen tile at stage middle: and parks. And honks a horn.

Now there’s a sound of two numberlock clasp unclinching, the hinged clasps pop up: then it’s door-like top half opens on the hinge, it drives back/steers to readjust a bit: top half all open: A water fountain sprays out, cubes of ice and a layer of sleet float in the cold, cold water inside this case. A rope net with many small buckets hung on loops at the knots of its threads, is lowered by a golfclub seesaw, gently, into the case, from where it snatches a small portion of water.

(Certain parts of the rear set walls are actually transparent television screens with translucent texture applied to them to give the illusion of tile and drywall. To give readers in the audience the ability to see scenes in the backyard, the screens are turned off, and are looked through.)

Regionmention: Dry ice smoke still looms around in levels, the whole set has developed it’s own climatology with clouds in layers of various hot smogs. The stormcloud aboutside the windows is now flinging billiard balls onto the roof, and into the windchimes and birdfeeders. The windchimes panic and take flight in an instant, the chime goes off stroking through the sky like a squid, hanger upwards, decorations and metal pipes flexing like thick kite streamers beneath. One of the square metal birdfeeders falls from its hanger and starts spinning aggressively on the grass like a top, then starts cutting the soil like a tornado, then shoots off like a flying saucer, and crashes through the window: slowed by the exploding glass: drops into the sink with a bang-loud clang.

Birdfeeder: I was made to feed dinosaurs, but now I’m run aground.

The hail is destructive: Little bombastic billiard balls coated with razor blades and ice start to punch like bullets through the ceiling of the set, fall down on the floor, and shatter out as colored dust and airborne metal while the kitchen tiles start sliding left like a conveyorbelt.

Regiondirect: → (Pathetic here)

Foolllllllessclue: I need a new pair of arms. See? These two limbs are a fool’s impliments.

The kitchen tiles start to undulate aggressively like a solid white ocean.

Kitchentiles: Out! GET OUT! No more of this nonsense. I am meant to be walked on, I am not a landfill.

The Air Fryer’s door falls open and the ExerMach Forklift grasps and moves the tray of melted, smoking, burning leather-walletpile up into ↑ the air. A sentient cloud of smog floats down like a jellyfish and mingles with the rising fumes of fired leather. The sinkfaucet tries to spray the wallet tray with water to put the flames out but only succeeds at waterboarding the birdfeeder in the sink.

A huge pair of hands both wearing motorcycle gloves descends from the ceiling; fingers pointed at the back of the stage, one hand at stage right+one at left, they descend on the rack of burnt leather. A cabinet door above bangs excitedly. The blender swirls hot water. The ExerciseForklift bows and condescends→moves to stage left→into the shadow a bit. Readers see the gloved hands scoop up the leather and stretch it: Outward streetching burnt, charred moneywallet, streeetching out a whole rectangular platterworth. Down below, hot coals and smokey dry ice are getting flung everywhere when the two bowls get mad and attack each other. Up above the GlovedHands form the hot wallet material into two arms→starting at the elbows and strexpanding outward toward the hand and shoulders. A flying pair of tongs with helicopter rotors hovers over and helps be blacksmith→it pulls and sculpts out the leather to form two palms and ten fingers. A third hand holding a bottle of wood glue descends between and squirts it in the folds of the leather and a serpent made out of thick twine with a blowdryer for a head is charmed by a tornado siren to rise out of a low cabinet. The blowdryer snake sprays heat onto the glue to dry it: This is the first pair of arms.

Wallet Leather Ash

Wallcet Leathear Ansh

Wallicet fLeatohearm Andsh

bwallicep florhearm hAndsh

ballicep forhearm handsh

bllicep forearm hands

Blicep forearm Hand

Bicep Forearm Hand

Foollllllllessclue: I will use my arms to get a job making Christmas cards. I will mail my Christmas cards to every person on Earth. Everyone will love me. I’m going to make a lot of money. Money will be given to me out of love. People will pitty me. I will make money from love.

Stage right side of the kitchen implodes in a shower of blasted apart ceramic plates, tossed around silverware, twigs + leaves off tree branches, atomized drywall; flung up tiles. The whole upper floor comes down

Regiondirect→

A set of bedroom furniture is dropped into the destruction. a king size bed plummets with sheets+blanket flapping.

The Cash Register, Abacus, and Lamp respond with alarm to the sound of destruction above. A dark storm cloud, floating not more than 15 feet above the ground, coasts through the exposed hole in the house and then starts to rapidly pour floodsurge levels of water into the kitchen scene. Eventually the water reaches the translucent gutter and starts to pour from high right to low left into the secret room belonging to the Abacus, Lamp, and Register.

Abacus: We’re going to drown. I guess I can count the water by volume.

Lamp: This downpour is erasing my chalk. I can’t work in a flood.

Register: I will rust and jam shut. The marble will be lost within me.

A huge billboard with the words “Too Bad So Sad" and "I Don’t Feel Bad” written in bright blue on a yellow background crashes through the stage wall from right to left like a battering→ram: tosses bedsheets, wood and tree chunks around while swinging across the set.

Regiondirect→From stage right (With happiness)

Foollessclue runs into the kitchen waving around a stack of Christmas cards while loudly exclaiming “I have the solution! I have the answer! I will find success and happiness!” Right as the ceiling collapses and buries him under the entire set. The water continues to rise until the whole room is a flooded half-floating landfill. Burnt things and wall studs floating on rain. The lights extinguish. Try again.

5 notes

·

View notes

Video

youtube

Watch How Our Egg Tray Making Machine Transforms Recycled Paper into Qua...

0 notes

Text

Sustainable Packaging Trends: Pulp Molding Machinery Insights

In today's fast-paced worldwide market, the demand for lasting options has never ever been extra pressing. With environmental concerns at the forefront of market discussions, companies are progressively transforming to environment-friendly choices to satisfy customer need and minimize their carbon footprint. One such technology making waves in the packaging market is pulp molding machinery.

Pulp molding equipment includes a variety of equipment made to produce shaped pulp items from materials such as recycled paper or farming waste. These devices supply a sustainable option to typical packaging products like plastic or styrofoam, making them a popular option for services wanting to take on even more eco-friendly practices.

At its core, pulp molding equipment runs by converting pulp material right into a molded type through a series of procedures. The raw material, normally in the form of recycled paper or agricultural waste, is initial gelatinated to produce a slurry.

Pulp molding equipment consists of numerous crucial components, each playing an essential function in the production process. These components consist of the pulper, responsible for breaking down the raw product right into a pulp mix, molding devices used to shape the pulp blend, a drying out system to get rid of dampness and strengthen the pulp product, and ending up devices for extra processes such as cutting or labeling.

The flexibility of pulp molding machinery makes it ideal for a wide variety of applications throughout numerous markets. Some typical applications include egg packaging, food packaging, commercial packaging, and tableware production. Pulp molding equipment is employed in creating egg trays, fruit trays, mug service providers, takeout containers, safety product packaging for delicate items, and disposable tableware.

There are numerous benefits to making use of pulp molding machinery for product packaging and other applications. Sustainability is an essential advantage, as it uses recycled products and agricultural waste, reducing the need for virgin sources and reducing waste sent out to garbage dumps. Furthermore, products made with pulp molding machinery are naturally degradable, versatile, cost-effective, and adjustable to fulfill details needs and branding choices.

As the need for sustainable product packaging continues to expand, the pulp molding industry is poised for continued innovation. Some arising fads and innovations consist of the expedition of sophisticated products to improve product buildings, innovations in automation and robotics to enhance production processes, and the combination of digitalization and information analytics to optimize efficiency and high quality.

In today's busy international market, the need for sustainable remedies has never been more important. With ecological worries at the forefront of industry conversations, services are progressively turning to environment-friendly alternatives to satisfy customer demand and reduce their carbon impact. One such advancement making waves in the packaging sector is pulp molding machinery.

Pulp molding machinery incorporates a range of tools made to create molded pulp items from materials such as recycled paper or farming waste. These machines provide a sustainable option to conventional packaging materials like plastic or styrofoam, making them a popular choice for services looking to embrace more eco-friendly practices.

At egg carton making machine , pulp molding machinery runs by converting pulp material right into a shaped type through a series of procedures. The raw material, commonly in the form of recycled paper or farming waste, is very first gelatinated to create a slurry.

Dive into the world of lasting product packaging options with innovative technology like pulp molding makers. These devices are revolutionizing the method we consider product packaging, supplying eco-friendly choices to standard plastic choices.

Photo this: You walk right into your favorite grocery store, searching the aisles for eggs. As you grab a carton, you might not recognize the intricate procedure behind its development. Enter the egg tray making machine, a marvel of engineering that changes humble pulp right into sturdy packaging.

It's not just about eggs. These machines are functional, efficient in producing a wide range of molded pulp items. From egg containers to tableware, the opportunities are countless.

One of the principals in this market is the paper pulp molding device. With its reliable design and sustainable result, it's no surprise why producers are flocking to purchase this innovation.

Take, as an example, the sugarcane bagasse tableware making device. By making use of farming waste, it not only decreases ecological effect yet additionally develops financial possibilities for farmers.

Let's not ignore the importance of innovation. Business are regularly pressing the borders of what these makers can do. Whether it's enhancing effectiveness or increasing item offerings, the skies's the limit.

Think of a world where every plan you encounter is made from renewable materials. Thanks to improvements in egg tray equipment and paper pulp packaging producers, that vision is coming true.

So, the next time you reach for an egg container or a paper tray, take a minute to appreciate the modern technology behind it. Pulp molding machines are not just devices; they're stimulants for change in the product packaging market.

Pulp molding equipment represents a considerable innovation in the area of sustainable product packaging solutions. Its convenience, efficiency, and green attributes make it an engaging choice for organizations looking for to lower their ecological impact and fulfill customer demand for greener choices. With proceeded development driving the industry ahead, the future of pulp molding machinery looks brilliant, offering limitless opportunities for lasting product packaging services across different industries.

1 note

·

View note

Text

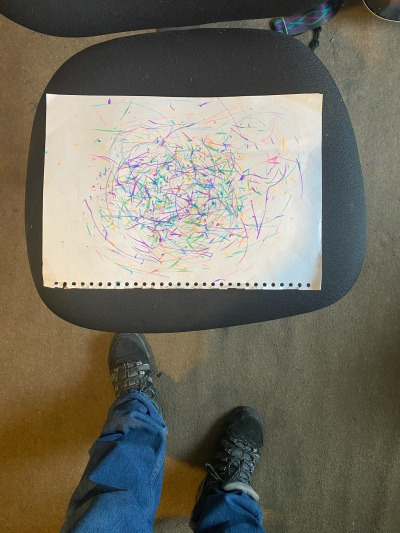

Spinning mechanism of pens .

Creating indexical marks on paper .I made a drawing machine using flat sided highlighter pens, masking taped onto an egg tray, The pen lid clips are a good way to keep the pens stable and all keep the same length . i also used a small box inside to hold everything in place.

The drawing machine worked best when spinning making contact with the paper. It makes a good swirling moving pattern with unpredictability . The index marks show contact and direction of movement . It fills the space well, this would be a good supporting image background to develop.

Wet Paint is being transferred form this spiky rubber toy as the board was tilted the ball rolled through the paint showing indexical marks after travelling through he paint .

Blaze

1 note

1 note

·

View note

Text

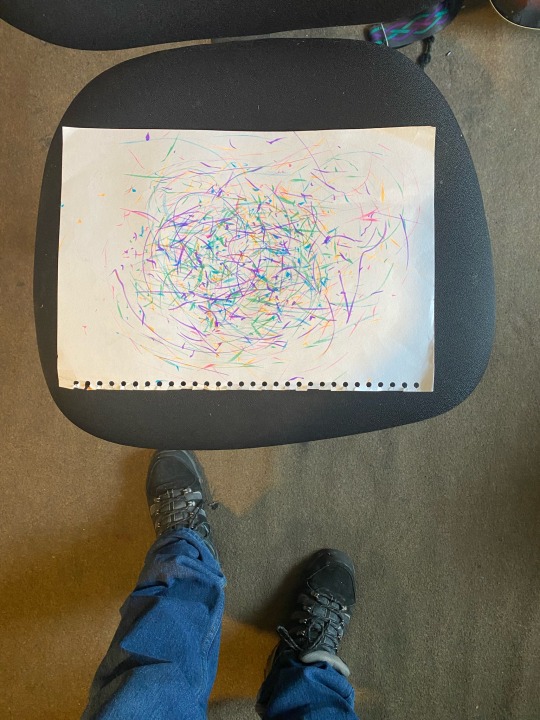

Spinning mechanism of pens .

Creating indexical marks on paper .I made a drawing machine using flat sided highlighter pens, masking taped onto an egg tray, The pen lid clips are a good way to keep the pens stable and all keep the same length . i also used a small box inside to hold everything in place.

The drawing machine worked best when spinning making contact with the paper. It makes a good swirling moving pattern with unpredictability . The index marks show contact and direction of movement . It fills the space well, this would be a good supporting image background to develop.

1 note

·

View note

Text

Elevating Your Egg Business: The Game-Changing Power of Egg Tray Making Machines

In the realm of modern business, adaptability and innovation are key to sustained success.

In the realm of modern business, adaptability and innovation are key to sustained success. The egg tray making machine stands as a testament to this principle, a versatile device that has evolved to meet diverse market demands. Originally designed for crafting egg trays, its applications have expanded to encompass storage solutions for items as varied as shoes, coffee cups, and fruits. As market demands continue to shift, the egg tray making machine China has undergone various iterations to cater to specific investor needs, including automatic, semi-automatic, and manual models. Among these, the automatic model, specifically the mechanical design, has emerged as a game-changer. Let’s delve into the features and benefits of this remarkable innovation that could significantly boost your business.

Efficiency in Operations:

At the forefront of the automatic egg tray machine's advantages lies its self-sufficient operational system. This eliminates the need for additional expenditures on manual labor for overseeing the process, resulting in both enhanced efficiency and reduced operational costs. With the capacity to yield up to 12,000 egg trays per hour, this model caters to high-volume manufacturers, making it a cost-effective choice. Moreover, its optimal speed contributes to lower fuel consumption, a critical factor in a sector often impacted by energy expenses.

Expansive Market Opportunities:

Eggs, a staple in diets worldwide, enjoy a consistent demand. This demand has fostered increased poultry production, generating a need for efficient transportation and storage solutions, which the egg tray machine fulfills impeccably. Beyond eggs, the machine's applications extend to other products like fruits, enhancing its versatility and market appeal. Opting for the automatic egg tray machine ensures you stay ahead of competitors by offering superior performance, meeting demand, and capitalizing on a lucrative market niche.

Eco-Friendly Manufacturing:

In an era marked by environmental consciousness, sustainable manufacturing practices are highly valued. The automatic egg tray machine aligns with this trend by recycling waste paper, mitigating the pollution caused by improper disposal. This eco-friendly approach aligns with evolving consumer preferences for products and services that minimize environmental impact. By adopting this model, you not only enhance your business profitability but also contribute to a greener planet.

Investment in the Future:

Choosing the automatic egg tray machine is an investment in the long-term prosperity of your business. While the initial expenditure might be higher compared to other options, the returns in terms of efficiency, production capacity, and market positioning are substantial. Conducting a comprehensive market analysis before investing is crucial to identify the right opportunities and clientele to ensure a thriving business. Take a view at the egg tray manufacturing plant cost.

In conclusion, the automatic egg tray making machine represents a strategic move for entrepreneurs in the manufacturing industry. Its multifaceted benefits, ranging from efficiency gains to environmental sustainability, make it a valuable asset. As the market continues to evolve, this innovation positions your business to thrive and meet the demands of a dynamic consumer landscape. By embracing innovation and adopting eco-friendly practices, you're not only securing business success but also contributing to a brighter, greener future.

0 notes

Text

youtube

Full Automatic Rotary Egg Tray Making Machine- Paper Tray

Waste paper use make so many difrent types of products . One of those products is egg tray. And today we are going to tell you and show you its entire process. We will explain all the processes one by one, give complete information about the machine, how much it costs and how many types there are. Best Egg Trays Making Machine Factory Using Waste Paper | Fully Auto Egg Cartoon Making , EGG Trays Making Machine with Waste Paper ,

#Fully Automatic#Laxmi Enterprises#egg tray packing machine#egg tray manufacture#egg tray manufactures#Paper Pulp egg tray manufactures#Manufacturer#Fully Automatic Egg Tray Machine Metal Multilayer Dryer#Eggs Trays Brick Dryer System#Semi Automatic Egg Tray Machine (Without Dryer)#Paper Pulp Egg Tray Making Machine#Rotary Egg Tray Making Machine#Egg Tray Forming Machine#Egg Tray machine with Brick Dryer#Automatic Egg Tray Plant Video how to make#egg tray making machine price in india#egg tray making machine price in south africa#egg tray making machine price in kolkata#egg tray making machine companies#egg carton making machine#paper egg tray making machine#small egg tray making machine#manual egg tray making machine#egg carton manufacturing machine#pulp egg tray making machine in india#egg tray making machine fully automatic#cheap egg tray making machine#egg tray making machine italy#egg tray making machine manufacturer#egg crate manufacturing machine

1 note

·

View note

Text

Why do more and more people choose pulp molding equipment?

Pulp molding equipment, also known as pulp molding machines, has gained popularity for several reasons, and its adoption is increasing for various applications. Here are some reasons why more and more people choose pulp molding equipment:

Environmentally Friendly: Pulp molding is an environmentally friendly process that uses recycled paper or agricultural fibers as raw materials. This makes it a sustainable and eco-friendly choice, especially when compared to traditional plastic and foam packaging materials.

Biodegradability: Products made with pulp molding equipment are biodegradable and compostable. This addresses concerns about the environmental impact of non-biodegradable materials, particularly in the context of single-use items.

Regulatory Compliance: With increasing regulations and restrictions on single-use plastics in many regions, businesses are seeking alternative packaging solutions to comply with environmental standards. Pulp molding offers a viable and compliant option.

Versatility: Pulp molding equipment can produce a wide range of products, including packaging trays, containers, egg cartons, and more. Its versatility makes it suitable for various industries, including food and beverage, electronics, and consumer goods.

Cost-Effective Production: Pulp molding is often considered a cost-effective manufacturing process. The raw materials, such as waste paper, can be sourced at a lower cost than some traditional packaging materials. Additionally, the production process itself can be efficient and streamlined.

Customization: Pulp molding equipment allows for customization of products to meet specific requirements. Manufacturers can easily adjust molds and parameters to produce different shapes and sizes, providing flexibility in design.

Market Demand: As consumer awareness of environmental issues grows, there is an increasing demand for sustainable and eco-friendly packaging solutions. Businesses are responding to this demand by adopting pulp molding equipment to align with consumer preferences and market trends.

Reduced Dependency on Plastic: Pulp molding provides an alternative to plastic packaging, contributing to efforts to reduce plastic waste and dependency on fossil fuels. This shift aligns with global initiatives to promote a circular economy and reduce the environmental impact of plastic pollution.

In summary, the increasing popularity of pulp molding equipment can be attributed to its environmental benefits, regulatory compliance, versatility, cost-effectiveness, customization options, and alignment with the growing demand for sustainable packaging solutions.

0 notes

Text

Market Consolidation and Mergers in the Global Disposable Egg Trays Industry

The disposable egg trays market is experiencing significant growth, with global revenues expected to increase by nearly 6% year over year in 2021. According to a forecast by FMI (Future Market Insights), the market is projected to almost double in size between 2021 and 2031.

Disposable egg trays are typically made from paper pulp and are used for storing eggs from poultry farms. They are environmentally friendly and sustainable due to their composition. Additionally, these trays offer enhanced durability with a smooth finish, thanks to the use of thick multi-layers of paper pulp for packaging and protecting the eggs.

In addition to their role in storing eggs, disposable egg trays are preferred by manufacturers for egg transportation due to their excellent physical and barrier properties. These trays are lightweight and easy to handle, and their cavities, created by the disposable egg tray forming machine, provide external shock resistance, ensuring the safe transportation of eggs.

A key trend in the disposable egg trays market is the increasing use of recycled paper by manufacturers. This shift contributes to environmental sustainability and reduces costs for consumers, as recycled paper is less expensive than virgin paper for making egg trays. The reusability of recycled paper further drives its extensive use in the manufacturing of disposable egg trays, reducing waste and pollution.

For More Insights on this Market, Get A Sample Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-13658

The demand for storage and transportation solutions in poultry farms is a significant driver for the disposable egg trays market. Moulded fiber, cardboard, and other paper-related materials are commonly used to make these trays. Moulded fiber provides a strong integrated framework, offering suitable stiffness and rigidity to make the trays shock-resistant during transportation. Compared to plastic trays, moulded fiber trays offer good air permeability and hygroscopic ability, which are crucial for egg storage.

Key Takeaways:

The disposable egg trays market is witnessing strong growth, with revenues expected to increase by nearly 6% in 2021.

Recycled paper is increasingly being used in the manufacturing of disposable egg trays, benefiting both the environment and consumers.

The demand for storage and transportation solutions in poultry farms is driving the adoption of disposable egg trays.

Moulded fiber trays offer shock resistance, air permeability, and hygroscopic ability, making them a preferred choice for egg storage and transportation.

Competitive Landscape

The following global key players such as

Henry Molded Products, Inc.

Pacific Pulp Molding LLC

KSP Fiber Products Pvt Ltd

Cosmoplast Ind. Co. LLC

Region Analysis:

The majority of the disposable egg tray manufacturers are present in India which contributes maximum share to the market. Also, India has a huge population which is involved in agriculture and poultry businesses for making money which is expected to uplift the disposable egg trays market in the coming days.

Customize your report by selecting specific countries or regions and save 30% @ https://www.futuremarketinsights.com/customization-available/rep-gb-13658

Key Segments of Disposable Egg Trays Market Covered in the Report

Based on the Cavity:

2 to 6

8 to 12

12 to 24

More than 24

Based on the Material:

Paper egg cartons

Recycled paper

Molded pulp

Plastic egg trays

Polystyrene foam

Clear plastic

Enquire before purchasing this report @ https://www.futuremarketinsights.com/checkout/13658

Based on the Sales Channel:

Online

Offline

Retail shops

Distributors

Supermarket/Hypermarket

Based on the Region:

North America

Latin America

Europe

South Asia

East Asia

Oceania

Middle East & Africa

0 notes

Text

Paper Egg Tray Making Machine with Brick Oven Dryer Egg Box Equipment

By: Hebei Wongs Machinery Equipment Co Ltd

https://youtu.be/YOHd_5r80pY

#EggTray #EggTrayMachine

0 notes

Text

Egg Tray Molding Machine

Egg Tray Molding Machine

An egg tray molding machine uses recycled paper and molds them to make egg cartons, egg trays, and egg boxes.

The interest in eggs and egg products is rising all over the globe. This creates the necessity for better storage facilities and much better transport services. Eggs are very fragile and have to be handled with caution during storage and transportation. This is why the egg tray forming…

View On WordPress

0 notes