#multi-axislinearstages

Text

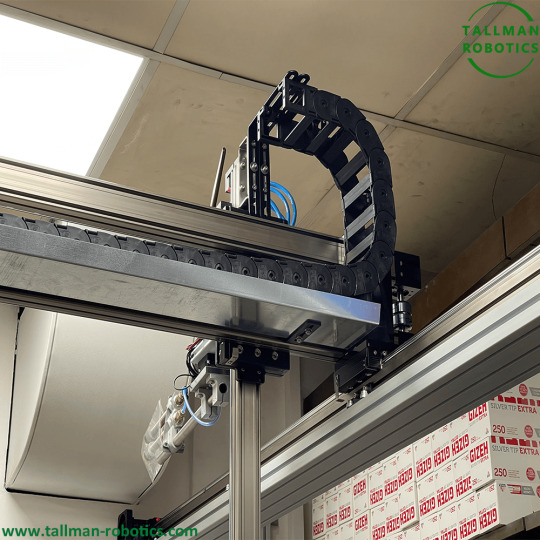

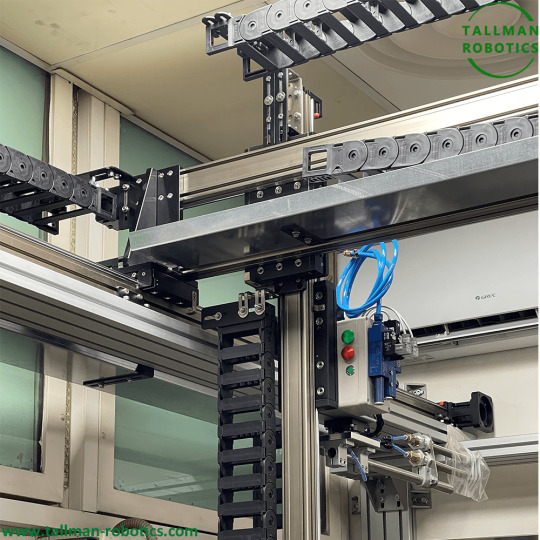

Multi Axis Linear Systems Are Working in Italy Client's Stores

Multi-axis linear systems, also known as multi-axis linear stages or multi-axis positioning systems, are mechanical systems designed to provide precise and controlled movement in multiple linear directions. These systems are commonly used in various applications where precise positioning and motion control are required, such as industrial automation, manufacturing, semiconductor manufacturing, microscopy, and research.

A multi-axis linear module typically consists of multiple linear stages or actuators that are combined and coordinated to enable movement in two or more linear axes. These axes can be orthogonal (perpendicular) to each other or arranged in any other desired configuration. The number of axes can vary depending on the specific application requirements.

Each linear stage in a multi-axis system is equipped with a motor or actuator that generates the necessary force to move the stage along its linear path. The stages are usually guided by precision linear bearings or linear guides to ensure smooth and accurate motion. The stages may also incorporate position feedback sensors, such as encoders, to provide feedback on the position and enable closed-loop control.

To achieve coordinated motion in multiple axes, a multi-axis linear modules relies on a control system. The control system coordinates the movement of each stage, ensuring synchronized motion and accurate positioning. It receives input commands or trajectories and translates them into appropriate control signals for each axis. The control system may include a motion controller, servo drives, and software algorithms for trajectory planning and motion synchronization.

Multi-axis linear systems offer several advantages, including:

1. Precise positioning: These systems provide high-precision positioning capability, allowing for accurate alignment and motion control.

2. Flexibility: Multi-axis systems can be customized and configured to meet specific application requirements, such as the number of axes, travel range, load capacity, and motion profiles.

3. Compact design: The integration of multiple axes into a single system results in a compact and space-saving design, making them suitable for applications with limited space.

4. Increased throughput: By enabling simultaneous motion in multiple axes, multi-axis systems can improve overall productivity and throughput in automated processes.

5. Versatility: These systems can be used in various applications, including pick-and-place operations, assembly, inspection, testing, and scanning.

It's important to note that the specific characteristics and capabilities of multi-axis linear modules can vary depending on the manufacturer, design, and intended application. Therefore, it's recommended to consult with system suppliers or experts to determine the most suitable system for a particular use case.

You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data.

Read the full article

#Cartesianmulti-axissystems#linearsystems#MiniatureMulti-AxisSystems#Multi-Axis(XY)LinearActuator#multi-axislinearstages#Multi-AxisPositioningSystems#Multi-AxisSystems#Multi-axissystemswithlinearmotors

0 notes