#molded plastic part

Text

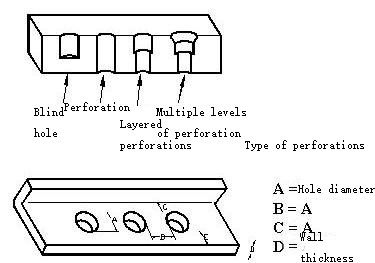

Plastic structure design 5 —hole, thread, and insert design requirements

For previous read, please refer to Plastic structural design 4 —reinforcement ribs and columns. This article mainly introduces requirements for design of holes, formed threads and metal inserts in plastic structure design. See below for details:

1. Hole and recess design

It is a common method to open holes in plastic parts to connect them with other parts or to increase functional combination…

View On WordPress

#core-pulling mechanism#Hole and recess design#in-mold nuts#mechanical engineer#Metal insert design#Metal insert molding#mold structure#molded plastic part#Nut Support Design#plastic parts#Plastic structure design#product design

0 notes

Text

it's cool to have my parts come in and test them out and see the phenomena from my injection molding textbook play out in front of me. look at that! it breaks right at that stress concentration! or when overloaded here, it breaks right at the weld line! there's shrinkage here and here! even stuff like anisotropic strength due to the orientation of the glass fibers and the polymer strands is right there in front of my eyes. yes!! yes!!

#friendly neighborhood mechanical engineer#blorbos (parts 2-10459 and 2-10460) from my shows (Plastic Part Design for Injection Molding: An Introduction#2nd edition. Robert A Malloy)

10 notes

·

View notes

Text

Month 4, day 3

Tonight we did a mossy ground texture :D

I'm going to cause ~problems~ with this >:3 Visorian problems~

#the great artscapade of 2024#art#my art#blender#blender render#procedural textures#blender 3D#cycles render#my roommate has issued me a challenge#or rather a suggestion#plastic!#which should be relatively easy enough to do but he specifically wanted with surface imperfections#like from the molding process on Gunpla parts#(he's the reason I'm doing that untitled Gunpla comic if anyone remembers the character expression sheets I did for that in '22)#so I'll see if I can find a tutorial for something similar and see if I've absorbed enough lessons to make it >:3

3 notes

·

View notes

Text

i love making posts on my rick shades blog that are just me doing my stupid and silly me things, bc i have the smallest chance of people calling ME rick shades, and just that possibility makes me sit there with glee bc i get to imagine rick doing the same stupid shit i do. on the other hand i am scared of ppl assuming im just a rick shades rp blog, which is not the case. like rp blogs are perfectly fine, but im just a silly little guy who relates far too much to a silly little FICTIONAL guy

anyways this started about me getting platonic crushes on people, im sitting here like kicking my legs and twirling my hair like OMGGG WHAT IF WE WERE FRIENDSSS WE SHOULD BE FRIENDSSSS

#wizard.txt#like i loved the gatorlyte post#ill draw myself as rick for a joke#its funny#and i do have many things wrong with me#i have been told to not eat mold#ive eaten plastic#when i was a child i ate a mud pie#ive gotten food poisoning from expired fruit snacks#the funny part about that is while i was eating them#i was w/ my partner#and i was like 'babe.... these fruit snacks kinda taste weird...'#'oh well! they prolly changed recipes its not bad'#the next day i threw up LMAO#ive also eaten expired whip cream#knowing it was expired#i am a very smart man but i lack a lot of common sense

11 notes

·

View notes

Text

hold on i gotta be emo

#txt#drug use/drug abuse mention#man im dissociating so hard right now and i feel like im losing it#i just need my strength to be witnessed#im fitting fangs rn#and the molding stuff comes in little plastic capsuls#and the amount of powder in the capsule#as well as the act of opening the capsule and getting everything out of it#its kind of fuckjng#fucking with me#it looks just like europa#i always forget about this part w fangs#probably for a reason

4 notes

·

View notes

Text

Application of 3+2 CNC Machining in Mold Making Factory

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

Some pics of my Christmas tree this year!

The tree itself is an artificial tree with black leaves. The ornaments are all painted with fluorescent paint and the lights are UV fairy lights. It looks so dang cool all lit up at night.

#christmas#christmas tree#christmas 2022#happy holidays#merry shitscram#fluorescent paint#neon paint#ultraviolet#it doesn't show much#but I also customized the tree topper#it was just gold accent with orange plastic over the lights#but I did a wash with black paint on the gold part#and then painted black lines on some ridges molded into the star#that helped give it a bit more depth#I think I'm gonna try to remove some lights from the star for next year though#because it overpowers the rest

2 notes

·

View notes

Text

About time I did some rework on my 3D printable clamp.

#ooc#and this one's gonna look so much better than the old blue one#eventually might customize it more with unnecessary details just to flex#maybe a diamond plate surface finish or 'mock plastic molding' structural ribs around the holes and edges of the part#it's adapted from a metal stock design#you can mix things up when adapting those metal designs for 3D printing#the process is different so understanding those differences can unlock so many possibilities for a new design#you can print complicated shapes that can't be easily done with a mill or lathe#don't let subtractive techniques hold you back!#💫❤️🌹🌞❤️❤️🌼 I fucking love making things#I'm on legal amphetamine sorry

2 notes

·

View notes

Text

The Influence of Plastic Mold Quality on Injection Molding Production

The purpose of mold design and manufacturing is for the mass production of injection parts with high efficiency and high quality, to produce high-quality plastic parts, the first mold is good, a good set of plastic molds is not just a good look, want to do a set of high-quality, high level, high precision plastic molds, from the following aspects.

1. The smoothness of the injection mold surface

The polishing of the mold surface is very important, which is one of the most important links to determine the success or failure of mold manufacturing. The surface of the mold is not smooth enough, its surface is uneven, and the surface of the plastic parts injected will have skin lines and sand grains. Generally, the polishing surface into a mirror is good, in addition to the choice of mold steel, grinding personnel, time, technology will have an impact on the polishing mirror effect, requiring a professional mold polishing master, experience to be particularly rich in order to accurately grasp the polishing time, to ensure the effect of mold mirror polishing.

2. Accuracy of mold

The precision of the mold determines the dimensional accuracy of the plastic parts, mold manufacturing must first have the conditions of high-precision measurement, such as quadratic detector, three-dimensional detector and other detection instruments, using the object imaging principle to accurately calculate the size and spatial position of the object, can detect the difference of 0.02mm, accurate measurement of product size and injection volume.

3. Fit degree of mold production

Although the mold industry has certain operating standards, the mold and injection molding of different mold manufacturers will have small differences, such as mold opening and injection molding are not the same manufacturer, due to the different mechanical equipment and production methods of various manufacturers, there will be risks in production, affecting product quality and production efficiency, in order to reduce this risk, generally choose to open mold and injection molding in the same manufacturer is better. From mold opening to injection molding manufacturers can control themselves, and problems can be solved in time.

0 notes

Text

#plastic-parts-manufacturing-companies#plastic-components-manufacturers#Best-Plastic-Mold-Companies-in-Canada

0 notes

Text

How Hands Craft Precision: A Journey through Injection Parts and Molding Services by PTMS

PTMS's injection parts and molding services exemplify the pinnacle of precision engineering and craftsmanship. With a steadfast commitment to excellence and a focus on meeting the diverse needs of clients, PTMS continues to set the standard for innovation and quality in the manufacturing industry.

#plastic injection molding#plastic injection molding companies#plastic injection molding company#injection molding companies#injection molding company#injection molding manufacturers#plastic injection molding manufacturer#injection moulding manufacturers#plastic injection mold maker in china#injection mold maker china#injection mold maker#plastic injection parts#injection parts#plastic injection molding parts#plastic molded parts#injection molded parts#plastic injection molded parts#plastic injection molding service#injection molding services#plastic injection mold tooling#injection mold china#plastic injection tooling#injection mold tooling china#injection mould tooling china#custom injection molding#custom plastic injection molding

1 note

·

View note

Text

Relationship between injection molds and injection machines is explained clearly at once

Injection mold is installed on injection machine. When designing an injection mold, in addition to mastering injection molding process, you should also have a comprehensive understanding of relevant technical parameters of selected injection machine to ensure that designed mold is compatible with injection machine used.

1. Classification and models of injection machines

1. Classification of…

View On WordPress

#angle injection machines#Classification of injection machines#double parting surface injection molds#horizontal injection machines#injection machine#injection mold#injection molding process#injection pressure#injection volume#mechanical clamping mechanism#molded plastic part#multi-cavity injection molds#plastic injection molding#Relationship between injection molds and injection machines#single parting surface injection molds#thermoplastic parts#thermosetting plastic parts#vertical injection machines

0 notes

Text

Experience unparalleled performance and productivity with our SHE Series Injection Molding Machines. Designed and manufactured by NINGBO SANSHUN MACHINERY & TECHNOLOGY CO., LTD, our machines are the perfect solution for creating high-quality plastic car parts, chairs, and pipes. With advanced technology and superior engineering, these machines are a game-changer for any plastic molding operation.

#injection moulding machine#plastic auxiliary machine#injection blow molding machine#SHE400 Auto-car Part Injection Molding Machine#SHE800 Plastic Chair Making Injection Molding Machine#SHE538 PVC Pipe Making Injection Molding Machine

0 notes

Text

Dive into the world of injection molding and unravel the challenges and innovations shaping plastic part manufacturing. Explore the nuances of the molding process, from melting pellets to finishing touches. Question how mold features impact material flow and quality. Investigate the art of designing injection-molded parts, emphasizing the role of ribs, bosses, and finishing options. Gain insights into customer decision-making with a deeper understanding of injection molding components. Discover the transformative potential of informed choices in custom injection molding.

#Injection Molding#Plastic Part Quality#Manufacturing Innovations#Mold Features#Design Challenges#Ribs and Bosses#Finishing Options#Transformative Choices#Material Flow#Decision-Making#Customization.

1 note

·

View note

Text

Are you searching for Plastic injection molding companies in china? Then here you are at the right place. Order any kind of mold for all industries with them now. Top quality and cost-effective guarantee. Order now!

#Injection Mold#Machining#Manufacturers#Mold Parts#Plastic Molds#industry#plastic injection molding companies in china

2 notes

·

View notes

Text

Buy Injection Molded Plastic Parts

Are you looking to Buy Injection Molded Plastic Parts? then visit Nagual Precision Limited. We are your one-stop destination for top-tier injection molded components tailored to your needs. Our commitment to quality, innovation, and customer satisfaction has earned a reputation for excellence in the industry. Visit our website now.

0 notes