#medicine manufacturing pharma company

Text

#tuttsan pharma#Pharmacists#medications.#pharmacy technicians#pharmaceutical care#drugsmedicinemanufacturingcompanyinindia#pharmacompany#pharmaceuticalcompany#pcdpharmacompany#medicine manufacturing pharma company#What Does a Pharmacist Do

0 notes

Text

From Lab to Patient – The Evolution of Medicine Production

The journey of a medicine from a research laboratory to a patient’s bedside is a complex and intricate process. It involves rigorous scientific research, extensive clinical trials, stringent regulatory approvals, and sophisticated manufacturing processes. This blog will explore the evolution of medicine production, highlighting the role of leading pharmaceutical companies in India, including Centurion Healthcare, in bringing life-saving medications to the market.

The Genesis of Medicine: Research and Development

The Role of Pharma Companies in India

The development of new medications begins with a deep understanding of diseases and the biological mechanisms that drive them. Pharmaceutical companies in India, renowned for their robust R&D capabilities, play a pivotal role in this phase. Researchers at these companies work tirelessly to identify potential therapeutic targets and develop compounds that can modulate these targets effectively.

Preclinical Research

Before a new drug can be tested in humans, it must undergo extensive preclinical research. This involves laboratory and animal studies to assess the safety and efficacy of the compound. The goal is to gather enough data to support the initiation of clinical trials. This stage is crucial for ensuring that only the most promising and safe candidates move forward.

Clinical Trials: Testing in Humans

Phase I Trials

Once a compound has shown promise in preclinical studies, it enters Phase I clinical trials. These trials involve a small number of healthy volunteers and aim to evaluate the safety, tolerability, and pharmacokinetics of the drug. For a medicine manufacturing company in India like Centurion Healthcare, this phase is critical for determining the initial safety profile of the drug.

Phase II Trials

If Phase I trials are successful, the drug progresses to Phase II trials, which involve a larger group of patients who have the condition the drug is intended to treat. The focus here is on assessing the drug’s efficacy and further evaluating its safety. Pharmaceutical companies in India invest heavily in this phase to gather robust data that can support the drug’s potential therapeutic benefits.

Phase III Trials

Phase III trials are the most extensive and involve a large number of patients across multiple locations. These trials are designed to confirm the drug’s efficacy, monitor side effects, and compare it to standard treatments. For a medicine manufacturing company, this phase is critical for obtaining the data needed for regulatory approval.

Regulatory Approval

After successful Phase III trials, the data is submitted to regulatory authorities for approval. In India, the Central Drugs Standard Control Organization (CDSCO) is responsible for evaluating the safety and efficacy of new drugs. Obtaining regulatory approval is a significant milestone for any medicine company in India, allowing the drug to be marketed and made available to patients.

Manufacturing: From Lab Bench to Production Line

Scaling Up Production

Once a drug receives regulatory approval, the focus shifts to manufacturing. Scaling up production from laboratory scale to commercial scale is a complex process that requires significant expertise and investment. Medicine manufacturing companies in India, such as Centurion Healthcare, employ state-of-the-art technologies and adhere to stringent quality control measures to ensure that every batch of medicine meets the highest standards.

Quality Assurance and Control

Quality assurance and control are paramount in medicine manufacturing. Companies implement rigorous testing protocols to ensure that each batch of the drug is consistent in terms of potency, purity, and safety. This involves testing raw materials, in-process materials, and finished products. Pharmaceutical companies in India are known for their stringent quality control measures, which are essential for maintaining the trust of healthcare providers and patients.

Packaging and Distribution

Once manufactured, the medicines are packaged in a manner that ensures their stability and safety during transportation and storage. Packaging must protect the drug from environmental factors such as light, moisture, and temperature fluctuations. After packaging, the medicines are distributed to pharmacies, hospitals, and clinics, ensuring that they are readily available to patients.

Post-Market Surveillance

The journey of a medicine does not end with its launch in the market. Post-market surveillance is crucial for monitoring the drug’s performance in the real world. This involves collecting and analyzing data on the drug’s safety and efficacy from patients and healthcare providers. Pharmaceutical companies in India are actively involved in post-market surveillance to ensure that any potential issues are identified and addressed promptly.

Pharmacovigilance

Pharmacovigilance is a key component of post-market surveillance. It involves the detection, assessment, understanding, and prevention of adverse effects or any other drug-related problems. Medicine manufacturing companies in India have dedicated pharmacovigilance teams that monitor and report any adverse events associated with their drugs, ensuring patient safety.

The Role of Technology in Medicine Production

Advanced Manufacturing Technologies

The pharmaceutical industry has embraced advanced manufacturing technologies to enhance efficiency and product quality. Techniques such as continuous manufacturing, automation, and advanced analytics are revolutionizing the way medicines are produced. These technologies enable medicine manufacturing companies to produce drugs more efficiently, reduce waste, and ensure consistent product quality.

Digital Transformation

Digital transformation is playing a significant role in the evolution of medicine production. Pharmaceutical companies in India are leveraging digital technologies such as artificial intelligence (AI), machine learning, and big data analytics to streamline their operations. These technologies are used in various stages of drug development and manufacturing, from identifying new drug targets to optimizing production processes and ensuring quality control.

Sustainability in Medicine Production

Sustainability is becoming increasingly important in the pharmaceutical industry. Companies are adopting environmentally friendly practices and technologies to minimize their environmental footprint. This includes using renewable energy sources, reducing waste, and implementing green chemistry principles. Medicine manufacturing companies in India are at the forefront of this movement, striving to make their production processes more sustainable.

Centurion Healthcare: Leading the Way

As a leading medicine manufacturing company in India, Centurion Healthcare is dedicated to advancing the field of medicine production. Our commitment to quality, innovation, and sustainability sets us apart in the industry. Here is how we are contributing to the evolution of medicine production:

Cutting-Edge Research and Development

Our R&D team is at the heart of our success. We invest heavily in research to discover and develop new therapeutic agents that address unmet medical needs. Our state-of-the-art facilities and collaboration with leading research institutions enable us to stay at the forefront of medical innovation.

Advanced Manufacturing Capabilities

At Centurion Healthcare, we utilize advanced manufacturing technologies to produce high-quality medicines efficiently. Our manufacturing facilities are equipped with the latest equipment and adhere to international standards of quality and safety. We are committed to continuous improvement and innovation in our production processes.

Comprehensive Quality Control

Quality is our top priority. We have established rigorous quality control measures to ensure that every product we manufacture meets the highest standards. From raw material testing to final product release, our quality assurance team meticulously monitors every step of the production process.

Commitment to Sustainability

We are committed to making our production processes more sustainable. We have implemented various initiatives to reduce our environmental impact, including energy-efficient practices, waste reduction programs, and sustainable sourcing of raw materials. Our goal is to contribute to a healthier planet while providing high-quality medicines to patients.

Conclusion

The evolution of medicine production is a testament to the dedication and innovation of pharmaceutical companies in India. From the initial stages of research and development to the manufacturing and distribution of life-saving medications, every step in this journey is crucial. At Centurion Healthcare, we are proud to be a part of this dynamic industry, contributing to the health and well-being of patients worldwide.

As a leading medicine company in India, we remain committed to advancing the field of medicine production through cutting-edge research, advanced manufacturing technologies, and a steadfast commitment to quality and sustainability. Our journey from the lab to the patient’s bedside is driven by a passion for excellence and a desire to make a meaningful impact on global health.

#Medicine manufacturing company in India#Pharma companies in India#Medicine company in India#Pharmaceutical companies in India#Medicine manufacturing company

2 notes

·

View notes

Text

Pioneering excellence in Indian pharma | centurionhealthcare

Centurion Healthcare stands at the forefront of pharmaceutical innovation in India, renowned among the top medicine manufacturing companies in the nation. As a leading medicine company, we are committed to delivering high-quality pharmaceutical products that improve lives. Join the ranks of healthcare professionals and patients who trust Centurion Healthcare for safe, effective, and reliable medications.

Discover the difference with Centurion Healthcare, your partner in promoting health and wellness across India.

#Pharma companies in India#Medicine company in India#Pharmaceutical companies in India#Medicine manufacturing company#Medicine manufacturing company in India#Healthcare sector#Healthcare industries

4 notes

·

View notes

Text

DISCOVER LUCRATIVE BUSINESS OPPORTUNITIES IN THE PCD PHARMA INDUSTRY

Best PCD (Propaganda cum Distribution) pharmaceutical franchise company in India, Lezaa Biotech is renowned for its dedication to providing high-quality medical supplies and services. Lezaa Biotech has a significant presence in the pharmaceutical sector and provides a variety of cutting-edge and reasonably priced pharmaceutical formulations.

Read more: https://lezaabiotechpharma.blogspot.com/2023/05/discover-lucrative-business.html

#Injectables Manufacturers in India#Softgel Capsules exporter In Karnataka#Pediatric Medicine Manufacturer in India#third party manufacturing in bihar#PCD Pharma franchise company in india#Pharma franchise company

2 notes

·

View notes

Text

For Cardiac Diabetic PCD Pharma Franchise Choose Aplonis Healthcare

With the increased demand for medicines, Aplonis Healthcare is offering cardiac diabetic PCD pharma franchise services to counter this epidemic.

#PCD Pharma Franchise#pcd pharma india#pcd pharma business#pharma franchise#pcd pharma company#pcd pharma franchise#pcd pharma products#pcd pharma distributors#cardiac diabetic PCD pharma#marketing#entrepreneur#branding#top medicine manufacturers

2 notes

·

View notes

Text

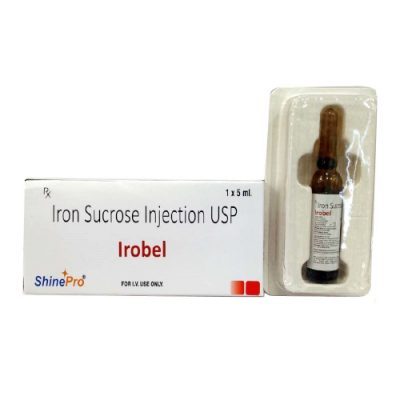

ShinePro Life Sciences Pvt. Ltd. is a leading PCD pharma franchise company in Panchkula and throughout India, is committed to offering best pharmaceutical products. It offers Third Party Manufacturing, PCD Pharma Franchise, Tablets, Syrup, Injection, etc.

#Best PCD Pharma Franchise Company#Pharmaceutical company in India#Pharma company in panchkula#Indian Pharmaceutical company#Leading Pharma Franchise Company#Pharma Medicine Company#Top Quality Pharmaceutical Company in Panchkula#Chandigarh#India#Best Pharma Franchise Company#Pharmaceutical Tablets Manufacturers#Top Medicine Formulation Company

2 notes

·

View notes

Text

#Third Party Pharma Manufacturers#Third Party Manufacturers#Third Party Medicine Manufacturer#Third Party Manufacturing Company

2 notes

·

View notes

Text

Top Pharmaceutical Manufacturers in India | Acinom Healthcare

Acinom Healthcare is one of the top pharmaceutical manufacturers in India, whose focus is provide PCD Pharma Franchise. A fully integrated pharma company, Acinom Healthcare are serving all pharmaceutical products include derma product, dental, eyedrops, injection, cream, gel, mouth wash. we are well known in the market for pharmaceutical manufacturer & supplier. We manufacturer the pharmaceutical medicine & products for many MNC company such as Sun Pharma, Zydus Cadila healthcare , Nectar etc. Also we are known for best PCD Franchise company in Chandigarh, Punjab, Delhi, Himachal Pradesh, Uttar Pradesh etc.

#Medicine manufacturers in India#Pharmaceutical manufacturers in India#Top pharmaceutical company in Chandigarh#PCD pharma manufacturing company in India#Best pharmaceutical manufacturer in india

2 notes

·

View notes

Text

Best Third Party Pharma Manufacturers in India

Third Party Manufacturers, a leading B2B Pharma Platform, is renowned as one of the Best Third Party Pharma Manufacturers in India. Specializing in high-quality production services, this platform connects businesses with top-tier manufacturers, ensuring reliable, efficient, and cost-effective pharmaceutical solutions for diverse healthcare needs.

#Third Party Pharma Manufacturing#Third Party Manufacturers#Third Party Manufacturing#Third Party Manufacturing Pharma Company#3rd Party Manufacturing#Third Party Manufacturing Company#Pharma Contract Manufacturing#Top 10 Pharmaceutical Third Party Manufacturing Company in India#Top Third Party Pharma Manufacturers in India#3rd Party Manufacturing Pharmaceuticals#Contract Manufacturing Companies#Third Party Medicine Manufacturer#Pharmaceutical Contract Manufacturing#Top Third Party Manufacturers#Best Third Party Manufacturing Companies in India#3rd Party Pharma Manufacturing#Third Party Manufacturing Products#Pharmaceutical Third Party Manufacturing

0 notes

Text

Comprehensive Pharmaceutical Resources with Chemxpert Database

Discover the extensive generic medicine company list and connect with leading API suppliers in India through Chemxpert Database. Whether you're seeking detailed information on biologics and biosimilars or need to find reputable pharmaceutical labs near me, Chemxpert Database is your go-to resource. It offers valuable insights into the medical pharma industry, ensuring you stay ahead in the ever-evolving pharmaceutical landscape. Explore Chemxpert Database for unparalleled access to top-tier pharmaceutical data.

#best generic medicine company in India#pharmaceutical companies in Austria#drug suppliers#pharma research#pharma equipment manufacturers

1 note

·

View note

Text

Understanding the Implications of Third-Party Manufacturing in Pharma

Navigating the Financial Landscape: Understanding the Implications of Third-Party Manufacturing in Pharma

In the dynamic world of pharmaceuticals, the decision to outsource manufacturing to third-party entities is not merely a strategic choice but a financial one as well. This practice, known as third-party manufacturing, has become increasingly prevalent as companies seek to optimize resources, enhance flexibility, and improve cost-efficiency. However, navigating the financial implications of third-party manufacturing requires a nuanced understanding of various factors that impact the bottom line. In this blog, we delve into the key financial considerations pharmaceutical companies must weigh when outsourcing manufacturing processes.

The Cost Dynamics of Third-Party Manufacturing

At the forefront of any discussion on third-party manufacturing lies the aspect of cost. While outsourcing production can offer significant cost savings, it’s essential to conduct a comprehensive cost analysis to determine the actual financial implications. Factors such as labor costs, material procurement expenses, overhead costs, and transportation expenses must be meticulously evaluated to gauge the overall cost-effectiveness of third-party manufacturing.

Economies of Scale and Cost Optimization

One of the primary drivers behind outsourcing manufacturing is the potential for leveraging economies of scale offered by specialized third-party manufacturers. By consolidating production volumes across multiple clients, these manufacturers can spread fixed costs over a larger output, resulting in lower per-unit production costs. Pharmaceutical companies stand to benefit from this cost optimization strategy, particularly when dealing with high-volume products or specialized processes that require significant capital investment.

Capital Expenditure vs. Operating Expenses

Another critical financial consideration in third-party manufacturing is the distinction between capital expenditure (CapEx) and operating expenses (OpEx). While in-house manufacturing may involve substantial upfront capital investment in infrastructure, equipment, and facilities, outsourcing shifts these costs from CapEx to OpEx. This transition can lead to improved cash flow management and greater financial flexibility, as companies can allocate capital resources to core research and development activities rather than infrastructure development.

Risk Mitigation and Contingency Planning

Despite the potential cost savings, engaging in third-party manufacturing introduces inherent risks that must be addressed from a financial standpoint. Supply chain disruptions, quality control issues, regulatory compliance challenges, and intellectual property concerns are among the key risks that pharmaceutical companies face when outsourcing production. Developing robust risk mitigation strategies and contingency plans is essential to safeguard against potential financial losses and reputational damage arising from unforeseen circumstances.

Read more.....

#health & fitness#health#pharmacy#pharmaceutical#pcd pharma company#pcdpharmafranchise#third party manufacturing#medical#medicine

0 notes

Text

Top 5 PCD Pharma Companies in India: Aingo Pharma

Top 5 PCD Pharma Companies in India is burgeoning, and at the heart of this growth are PCD (Propaganda Cum Distribution) Pharma companies. These companies play a pivotal role in democratizing access to healthcare products across diverse markets within the country. This article aims to highlight the top five PCD Pharma companies in India that have excelled in terms of product innovation, distribution networks, and strategic business models

#Top 5 PCD Pharma Companies in India#pharmaceutical#antibiotics#aingopharma#monopolyrights#quality#medicines#pcdpharmafranchise#manufacturing#pcd pharma franchise#pcd

0 notes

Text

#phama franchise in andhra pradesh#pcd in uttar pradesh#pcd in west bengal#anti diabetic franchisee#anti diabetic pcd#anti-diabetic franchise#pharma franchise in north east#pcd pharma#pcd in assam#Pharmaceutical Manufacturing#Pharmaceutical Manufacturing Companies Near Me#Pcd Pharma Franchise Company in Gujarat#Best Pharma Companies#Best Derma PCD Franchise#Medicine Franchise Company List

0 notes

Text

Doctors prescribe Linezolid Tablet IP manufactured by leading Medicine manufacturing companies in India to treat serious bacterial infections. Effective against resistant strains, these tablets are vital for treating infections such as pneumonia and skin infections, ensuring that patients receive the best care with advanced pharmaceutical technology.

#medicine#medicine seller#pharma companies#third party manufacturing for pharma companies in dehradun#pharmacy

0 notes

Text

Best Pharma Contract Manufacturing in India

Third Party Manufacturers, a leading B2B Pharma Platform, offers the Best Pharma Contract Manufacturing in India. Renowned for its top-notch services, this platform connects businesses with reliable manufacturers, ensuring high-quality production, compliance with industry standards, and efficient delivery, making it a trusted partner for pharmaceutical companies.

#Third Party Pharma Manufacturing#Third Party Manufacturers#Third Party Manufacturing#Third Party Manufacturing Pharma Company#3rd Party Manufacturing#Third Party Manufacturing Company#Pharma Contract Manufacturing#3rd Party Manufacturing Pharmaceuticals#Contract Manufacturing Companies#Third Party Medicine Manufacturer#Pharmaceutical Contract Manufacturing#Top Third Party Manufacturers

0 notes

Text

Easy Way to Reduce Costs in Drug Manufacturing | Chemxpert Database

In the realm of pharmaceuticals, where innovation saves lives and every molecule counts, the cost of drug manufacturing is a critical factor. Drug manufacturing companies are constantly seeking ways to optimize their processes to reduce costs without compromising quality or safety. Moreover, with the ongoing debates surrounding drug pricing, pharmaceutical companies face increasing pressure to find efficient methods of production that translate into affordable medications for consumers. In this blog post, we explore some strategies and technologies that can help reduce costs in drug manufacturing, benefiting both drug manufacturers and consumers alike.

#pharmaceutical compliance#low cost medicine#pharmacy distributor#API meaning pharma#top pharma companies in USA#contract manufacturing pharma

1 note

·

View note