#innomaint cmms

Text

Enterprise Asset Management Market by Application, Component, Organization Size, Deployment Model, Vertical (Energy and Utilities, Government and Public Sector, Manufacturing, Transportation and Logistics), and Region - Global Forecast to 2026 published on

https://www.sandlerresearch.org/enterprise-asset-management-market-by-application-component-organization-size-deployment-model-vertical-energy-and-utilities-government-and-public-sector-manufacturing-transportation-and-logis.html

Enterprise Asset Management Market by Application, Component, Organization Size, Deployment Model, Vertical (Energy and Utilities, Government and Public Sector, Manufacturing, Transportation and Logistics), and Region - Global Forecast to 2026

Increasing shift from legacy asset management methods to modern asset management by enterprises drive the growth of EAM market

The global Enterprise Asset Management (EAM) market size is expected to grow at a Compound Annual Growth Rate (CAGR) of 8.7% during the forecast period, to reach USD 5.5 billion by 2026 from USD 3.3 billion in 2020. Digital business transformation has entered a more challenging and urgency-driven phase due to the COVID-19 pandemic. Global giants are providing customers with cost-effective and productive digital solutions as every industry is economically hard-hit from the pandemic. The sudden shutdowns of organizations and institutions increased the demand for cloud solutions and other online services. In current times, the EAM market is profitable for EAM vendors as several companies from diverse verticals are progressively adopting cloud-based solutions and services. This market is expected to grow further in North America and Europe, whereas it is expected to hold a significant growth rate in APAC, Latin America, and MEA. Factors such as the increased adoption of cloud among SMEs and the Work From Home (WFH) business model due to COVID–19 are expected to drive the market growth.

Need for extending the life span of assets with the help of advanced technologies

Digitization across different verticals is creating new opportunities for organizations to optimize their relationships with customers. Many asset–intensive organizations are focusing on investing in new and ground–breaking technologies to radically transform and improve their operational processes. In today’s highly competitive business environment, asset–intensive businesses succeed and fail based on how they manage complexities in the face of increased competition. Best–in–class organizations are embracing emerging technologies, such as AR, IoT, AI, predictive maintenance, digital twin, and telematics, as the next big thing in industrial services would be to accurately forecast the future of physical assets. The impact of EAM solutions is more than just boosting the bottom line. According to a few primary respondents and industry experts, organizations readily adopt modern EAM solutions to increase the longevity of assets.

The Manufacturing vertical expected to hold largest market share in 2020.

The manufacturing vertical includes automotive, aerospace, heavy machinery, chemicals, and electronics and semiconductors. It is transforming its business functions, such as integration of supply chains, product designing, inventory management, and product deliveries. Manufacturing organizations have disconnected systems and departments working through information silos, making it complex for the EAM system to work with other IT systems. This information isolation prevents the efficient management of assets throughout their lifecycle. Inventory and asset management is considered as the most critical aspect of manufacturing businesses. In case inventory runs out of stock, or there is an unplanned breakdown, the production output would decrease, deliveries would get delayed, and work would be interrupted. This would cost a hefty amount to manufacturers.

North America to hold the largest market size and Asia Pacific (APAC) to grow at a higher rate during the forecast period

APAC is one of the fastest-growing regions in terms of technology adoption, and the demand for digitization is driven by various initiatives carried out by different governments and large enterprises in the region. Countries such as China, Japan, Australia, Singapore, India, and Indonesia are leading this technology adoption, which includes embracing new-age technologies such as AI, edge, IoT, analytics, and cloud. The region houses a large number of enterprises related to manufacturing, energy and utilities, transportation and logistics, chemicals, and aerospace, which is further expected to drive the demand for EAM. Rapid advancements in telecommunications, cloud computing, and IoT have led several organizations to adopt cloud-based strategies.

In the process of determining and verifying the market size for several segments and sub segments gathered through secondary research, extensive primary interviews were conducted with the key people. The breakup of the profiles of the primary participants as follows:

By Company Type: Tier I: 37%, Tier II: 25%, and Tier III: 38%

By Designation: C-Level: 22%, D-Level: 33%, and Others: 45%

By Region: North America: 42%, Europe: 25%, APAC: 18%, and RoW: 15%

The report profiles the following key vendors:

IBM (US)

SAP (Germany)

Oracle (US)

Infor (US)

IFS (Sweden)

ABB (Switzerland)

Intelligent Process Solutions (Germany)

Maintenance Connection (US)

Aveva (UK)

Aptean (US)

Emanit (US)

CGI (Canada)

Rfgen Software (US)

Assetworks (US)

Ultimo Software Solutions (UK)

UpKeep (US)

Asset Panda (US)

EZOfficeInventory (US)

Pazo (India)

EZMaintain.com (US)

InnoMaint Software (India)

Asset Infinity (India)

Fracttal (Chile)

Aladinme (UAE)

KloudGin (US)

MaintainX (US)

Limble CMMS (US)

TrackX (US)

Cheqroom (Blegium)

The Asset Guardian (Canada)

Fleetio (US)

Gocodes (US)

Redlist (US)

Research Coverage

The report segments the global EAM market by Application, the EAM market has been segmented into asset lifecycle management, inventory management, work order management, labor management, predictive maintenance, facility management, and other applications. By the deployment model, the EAM market has been segmented into public cloud and private cloud. Based on organization size, the market has been classified into Small and Medium-sized Enterprises (SMEs) and large enterprises. By vertical, the EAM market has been classified into Manufacturing; energy and utilities; healthcare and life sciences; government and public sector; transportation and logistics; IT and telecommunications; and others. By region, the market has been segmented into North America, Europe, APAC, MEA, and Latin America.

Key Benefits of Buying the Report

The report will help the market leaders/new entrants in the EAM market with information on the closest approximations of the revenue numbers for the overall EAM market and the sub segments. The report will help stakeholders understand the competitive landscape and gain more insights to better position their businesses and to plan suitable go-to-market strategies. The report also helps stakeholders understand the pulse of the market and provides them with information on key market drivers, restraints, challenges, and opportunities.

0 notes

Link

0 notes

Text

Enhancing Hospital Ambiance & Efficiency: Streamlining Maintenance Management through Digital Work Orders - InnoMaint Case Study

Discover how InnoMaint revolutionized hospital maintenance management with digital work orders, ensuring a seamless ambiance and operational efficiency. Read about the successful implementation that streamlined processes and enhanced patient care. https://www.innomaint.com/case-study/read-about-providing-a-perfect-ambiance-for-hospitals-making-maintenance-management-smooth-via-digital-work-orders/

#innomaint case study#customer success story#customer success journey#healthcare cmms software#hospital asset management software#hospital facility maintenance software

0 notes

Text

6 Effective Tips to Reduce Equipment Maintenance Costs | Innomaint

Learn six valuable tips to effectively reduce equipment maintenance costs and optimize your business operations. Discover how to eliminate repetitive tasks, use high-quality spare parts, reduce labor and travel costs, optimize asset lifecycle, train your team, and standardize maintenance procedures.

#innomaint#cmms software#tips to reduce maintenance costs#how to reduce equipment maintenance costs#asset management software#asset maintenance software#maintenance management software#facility maintenance software#facility management software

0 notes

Text

The Power of Digital Work Order Management: Enhancing Efficiency and Maximizing Profits

Discover the essential reasons why effective work order management is crucial for your facility.

From standardizing templates to optimizing preventive and corrective maintenance, this blog highlights how digital solutions can enhance efficiency, build a connected workplace, gather valuable analytics, and ultimately maximize profits.

Read now https://www.innomaint.com/blog/7-reasons-why-work-order-management-is-important/ and unlock the full potential of your maintenance operations.

#work order management software#work order software#innomaint#cmms software#cmms#maintenance management software

0 notes

Text

Smart Work Order Management Strategies for Businesses on a Budget | Innomaint CMMS

Looking to improve your work order management system? Check out our blog post for the best strategies to save you time and money. Learn how to streamline processes, automate tasks, and optimize your workflow for maximum efficiency.

#innomaint#cmms software#maintenance management software#asset management software#asset maintenance software

0 notes

Text

Unleashing the Power of CMMS Software for Real-time Data Analysis and Reporting | Innomaint CMMS

Discover how CMMS Software is transforming the oil and gas maintenance landscape. Uncover the key benefits and functionalities of CMMS software in enabling real-time data analysis and reporting, leading to improved operational efficiency, reduced downtime, and enhanced asset performance. Read this insightful blog post to stay updated on the latest trends in oil and gas maintenance and leverage CMMS technology for unparalleled success.

0 notes

Text

youtube

Streamline Your Food Manufacturing with Cutting-Edge CMMS Software | Innomaint CMMS

Discover our state-of-the-art cloud-based CMMS software, designed exclusively for the food and beverage industry. Ensure food safety, superior quality, and operational excellence with automated maintenance tasks, HACCP monitoring, and Good Manufacturing Practices integration. Effortlessly manage work orders, track maintenance activities, and gain complete visibility and control of your operations.

Say goodbye to breakdowns and production disruptions.

Book a free demo today via www.innomaint.com/request-for-demo/ and unlock the full potential of your food manufacturing or processing company.

Contact us now for a smoother, more efficient production process at [email protected] | +91 75399 78399.

To know more, visit tinyurl.com/48bkc7sc #FSMS #Innomaint

0 notes

Text

The Role of CMMS in the Food and Beverage Industry | Innomaint FSMS Software

Discover the significant impact of CMMS in the food and beverage industry with our comprehensive article. Learn how CMMS software revolutionizes maintenance management, improves asset performance, minimizes downtime, and ensures regulatory compliance in this vital sector. Uncover the reasons why adopting CMMS solutions is essential for streamlining operations, optimizing productivity, and achieving long-term success in the dynamic world of food and beverage manufacturing. https://www.innomaint.com/blog/why-cmms-for-food-and-beverage-industry/

0 notes

Link

For more information, visit innomaint.com or to become our customer drop a message at [email protected] or else reach us via +91 75399 78399.

#innomaint#pha#automation#paperwork#cmms software#maintenance management software#cmms#asset management software#asset maintenance software

1 note

·

View note

Text

Improve Maintenance Activities through Innomaint CMMS

As maintenance is the best activity to resolve all your work issues, there are many maintenance software available in the market, but Innomaint is the best software, as it has features such as adaptability, flexibility, user-friendly, & cost-effective. Visit https://www.innomaint.com/ to know more.

1 note

·

View note

Link

Here we have elaborated how a long-standing material handling equipment manufacturing company Daifuku used Innomaint to track technicians on-site for best engagement.

#customer success story#customer success journey#case study#daifuku#innomaint#cmms software#maintenance management software

0 notes

Text

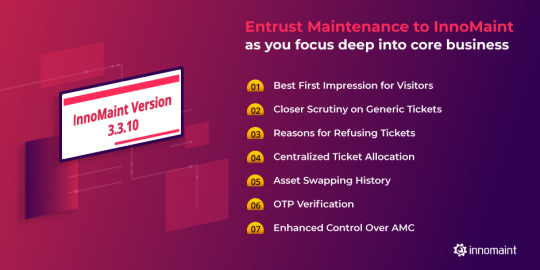

Focus On Core Business While Re-Opening Facilities🏢 Safely

We’re glad to unveil Release Notes V3.3.10 of InnoMaint with features fine tuned for enhancing your financial security and better control over AMC, ease of use of the application and meticulous reports for an even better user experience.

#innomaint#innomaintv3.3.10#releasenotes#versionrelease#cmms#maintenancemanagement#facilitymanagement#assetmanagement#fieldservicemanagement#visitormanagement#cloudcmms

0 notes

Text

5 Key Benefits of Predictive Maintenance in the Manufacturing Industry | Innomaint CMMS

Here you can find out the 5 key benefits of predictive maintenance in the manufacturing industry and how Every industry requires maintenance to retain optimum functionality.

#predictive maintenance software#preventive maintenance software#asset management software#asset maintenance software#maintenance management software#cmms software#innomaint

0 notes