#hdpesheets

Text

How to identify the Right HDPE Sheets ?

#hdpesheet#hdpesheets#hdpesheetsmanufacturer#hdpesheetssupplier#hdpe#sheets#sheetsupplier#india#delhi#manufacturer#trend#trending#post#newpost#tumblr#google

1 note

·

View note

Text

HDPE Sheets - HDPE Sheets Manufacturer in India | Mono Industries

#hdpesheet#hdpesheets#hdpesheetsmanufacturer#hdpesheetssupplier#hdpe#sheets#sheetsupplier#india#delhi#manufacturer#trend#trending#post#newpost#tumblr#google

0 notes

Text

Properties Of Hdpe That Make It Ideal For Food Containers

This article discusses the many benefits of HDPE, which makes it a popular choice for a variety of products and applications.

HDPE is a polyethylene terephthalate (PET) plastic, meaning it is composed of two different polymers chains. This unique combination makes HDPE Sheets perfect for applications that require both a lower average thickness and higher average thickness, such as food containers. HDPE also has a higher tensile strength than other plastics, making it capable of holding its shape under pressure or stress. Additionally, the high density of HDPE makes it ideal for products applications and packaging solutions due to its durability and ability to resist damage from environmental factors

0 notes

Text

Buy & Sell HDPE Product Online - Plastic4trade

Buy & Sell various HDPE Products Online including Grinding, Scrap, Rolls, HDPE Granules, Prime Granules, Reprocess Granules, Lumps and much more with Plastic4trade App

Download Free Android App: https://play.google.com/store/apps/details?id=com.p4t.plastic4trade

0 notes

Text

High-Density Polyethylene Sheet

High-Density Polyethylene (HDPE) Sheets are known for their remarkable strength and chemical resistance. They are made from a flexible, long-lasting plastic resin. These sheets are used in many different industries, such as packaging, construction, agriculture manufacturing, outdoor furniture, playground equipment and more. Discover the lightweight nature of HDPE sheets that doesn't compromise on durability, making them an ideal choice for various projects. With a smooth surface and excellent impact resistance, HDPE sheets offer a reliable solution for both indoor and outdoor applications.

For more information, contact us : +91- 9081802800, e-mail : [email protected]

#hdpesheet#hdpesheetmanufacturer#hdpesheetsupplier#pp#polypropylene#plasticsheet#plastic#polyethylene#sheets#sheetmanufacturer#ecommerce#marketing#artwork#ppbag#branding#sales#commercial

1 note

·

View note

Text

Yash Enterprises- Ldpe sheets and Hdpe Sheets Manufacturer

With more than 30 years of experience, Yash Enterprises deals as a manufacturer and supplier of Water Liners, HDPE Sheets/Liners/Films, LDPE Sheets/Liners/Films, Separation Membrane, Pond Liner, Canal Liners, Geotextile etc. To fulfil all of the demands of our treasured clients, we've constructed an advanced infrastructural unit. On the way to increase the producing ability, our infrastructural unit is furnished with all the advanced machines and equipment.

#HdpeLiners#SeparationMembrane#polythenesheet#LdpeLiners#LdpeFilms#HdpeSheets#HdpeFilms#DowelBarSleeves#PlasticGranules

2 notes

·

View notes

Text

Best Industrial Polymer Supplier Dubai

Veechem Global is the best supplier of industrial polymer In Dubai. We are specialised in marketing and distributing of high quality of raw material for polymers.

#Qatar based polymer industry#polymer supplier dubai#Industrial polymers#polycarbonate sheet#hdpe#hdpesheet#LDPE

1 note

·

View note

Photo

#HDPE#HDPEfabricmanufacturer#hdpesheet#hdpebags#hdpefabric#rustpreventivepackaging#vcipackaging#vcimanufacturer#Seaworthypacking#vcipackagingmanufacturer#Rustprevention#VapourCorrosionInhibitors#Packagingmaterial

0 notes

Photo

INSOL PP ROD

52-A Rama Road, near Mercedes Silver arrow service center, Kirti Nagar, New Delhi, 110015

1748 BHAGIRATH PALACE

4105 AJMERI GATE

Delivering pan world now

Request a Quote Today

Call:- +9196676 69776

+91-9891829822

Mail:- [email protected]

#insulationsolutions #ppsheet #pprod #Polypropylenerod #rubbersheet #PolypropylenePPSheet #pusheet #purod #pesheet #perod #polyurethanesheet #pusheet #purod #pusheet #pumetal #metalworking #pvcstripcurtain #rubbersheet #polyurethanesheet #Polyurethane #hdpesheet #arcylic #arcylicsheet #construction #buildingmaterials #teflonsheets #derlinrod

1 note

·

View note

Text

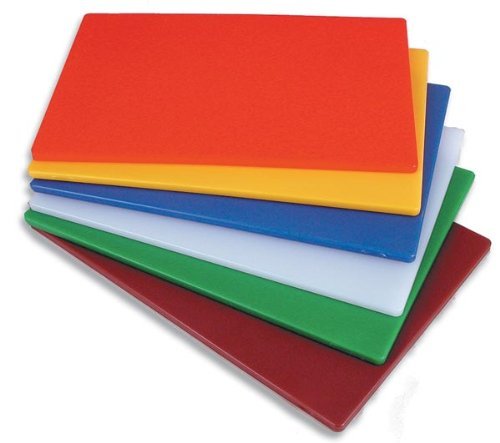

HD Polyethylene as a FDA approved cutting board

During your next time you'll be cutting fresh vegetables upon your chopping board, take a moment and check out it, the material most likely to be used as a High Density Polyethylene Cutting Board Material - Sheets cutting board is Polyethylene. Simply because it is normally FDA and National Sanitation Foundation approved as well as stain, moisture and odor resistant, Polyethylene is an ideal choice for cutting boards.

Other sorts of cutting boards cut from wood are susceptible to bacteria and odors because they lack the sought afterproperties that Polyethylene sheets offer, which include its non porous work surface, chemical substance resistance and approval for food contact. The Polyethylene certainly a durable and lightweight material that comes in a great many forms and is designed for a wide selection of applications. There are a few kinds of Polyethylene commercially accessible. The most widespread are HDPE (High Density Polyethylene), LDPE, and UHMW (Ultra High Molecular Weight Polyethylene). The the main difference has to do with the molecular weight and branching; which happens when a monomer or atom is replaced by a longer chain of polymers (a long repeating chain of atoms).

High Density Polyethylene is often used for milk jugs and Tupperware style food containers. Low Density is typically used for food containers and plastic sandwich bags. UHMW, which has higher molecular weight (2-6 million) that allows for an even transfer over the length of material which makes it stronger, which make it useful for bearing usages due to its great wear resistance. Commonly used in the food processing and dairy industry, UHMW is a nice replacement for a great many other industrial materials in addition to a great method for fixing many wear issues. All of these polymers are derived from the same polyolefin plastics family, but all have certain properties that make them a little different. HDPE provides great chemical resistance, has higher impact strength and great energy absorption. LD Polyethylene has many of the same properties as High Density but it is not as dense at 9.15, instead of HDPE which is 9.34, and it is a softer material ( the one gallon coffee can lids). Additionally, it provides a lower tensile strength along with far better, less complicated formability.

UHMW is really a strong material containing great durability and low co-efficient of friction rendering it an ideal for sliding applications. One of the only plastic material with a lower co-efficient of friction is Teflon - PTFE; which has a higher temperature and chemical resistance. Ultra High Molecular Weight Polyethylene comes with a great deal of material options and properties, and these kinds of products have got outstanding durability that could be properly suited for a variety of applications. From the food industry to automotive, your kitchen or the warehouse, whatever your Polyethylene needs are - High Density, Low Density or UHMW, Polyethylene is a popular option. Call us for additional information on these as well as other plastic material.

plasticsheet

0 notes

Text

HD Polyethylene as a nsf approved cutting board

During your next time you're slicing produce on your own cutting board, take the opportunity and check out it, the material most likely to be used as a HDPE Polyethylene Cutting Board Material - Sheets cutting board is Polyethylene. Simply because it is normally FDA and National Sanitation Foundation approved not to mention stain, moisture and odor resistant, Polyethylene is the ideal choice for cutting boards.

A variety of other cutting boards manufactured from wood are vulnerable to bacteria and residual odors simply because they lack the desiredproperties that Polyethylene sheets offer, including its non porous surface, chemical substance resistance and approval for food contact. The Polyethylene is certainly a durable and lightweight material that comes in several forms and is perfect for a range of applications. There are lots of kinds of Polyethylene commercially available. The commonest are HDPE (High Density Polyethylene), Low Density Polyethylene, and UHMW (Ultra High Molecular Weight Polyethylene). The the main difference has to do with the molecular weight and branching; which is when a monomer or atom is replaced by a longer chain of polymers (an excessively long repeating chain of atoms).

High Density Polyethylene is often used for gallon sized milk jugs and common food containers. Low Density happens to be used for food containers or perhaps plastic baggies. UHMW, which has higher molecular weight (2-6 million) which allows for an even transfer over the length of material which makes it stronger, making it able to be used with regard to bearing purposes because of great wear resistance. Very popularly used in the food processing and dairy industry, UHMW is really a good replacement for a great many other industrial materials and also a wonderful strategy to many wear issues. Most of these polymers are made from the same polyolefin plastics family, but all have certain properties that make them just a little different. HDPE provides great chemical resistance, has exceptional impact strength and great energy absorption. LD Polyethylene has many of the same properties as High Density yet it's not as dense at 9.15, whereas HDPE which is 9.34, and it's a softer material ( one gallon coffee can lids). Additionally provides a lower tensile strength as well as better, quite a bit easier forming.

UHMW is known as a strong material with which has great durability and low co-efficient of friction allowing it to be an ideal for sliding applications. The best known material plastic material with a lower co-efficient of friction is Polytetrafluoroethylene - PTFE; which has a higher temperature and chemical resistance. Ultra High Molecular Weight Polyethylene provides a great deal of material alternatives and properties, and these types of materials possess extraordinary toughness which can be worthwhile for several applications. From the food industry to automotive, your kitchen or perhaps the warehouse, whatever your Polyethylene needs are - High Density, Low Denseness as well as UHMW, Polyethylene is really a superb choice. Phone us for more information on these and other plastic raw material.

0 notes

Text

How to choose the Best HDPE Sheets manufacturer in India

#hdpesheet#hdpesheets#hdpesheetsmanufacturer#hdpesheetssupplier#hdpe#sheets#sheetsupplier#india#delhi#manufacturer#trend#trending#post#newpost#tumblr#google

0 notes

Text

BEST PLASTIC SHEETS IN INDIA (प्लास्टिक शीट, दिल्ली)

#hdpesheet#hdpesheets#hdpesheetsmanufacturer#hdpesheetssupplier#hdpe#sheets#sheetsupplier#india#delhi#manufacturer#trend#trending#post#newpost#tumblr#google

0 notes

Text

Everything About HDPE Sheets

HDPE sheets is a kind of clear plastic sheet. It should be recycled by a professional company because of its dangerous to store. Although HDPE sheet is not widely used, it is an interesting material to make products by many companies. The first HDPE sheet was created by the Dow chemical company in 1930s. Since its birth, a lot of companies use HDPE sheet to make a lot of products. For example, some of them use HDPE sheet to make food packaging. It is because HDPE sheet has a good barrier. HDPE sheets is also used to make plastic bottle. Because of its good barrier and chemical stability, HDPE sheet is used to make many household products. Some of them are: food containers, bottles, office supplies, greeting cards, and toys.

0 notes

Text

Introduction of PP Woven Bags / Sacks

Polypropylene bags were introduced into India in last-sixties and there are more than 500 PP bags manufacturing units in India. Polypropylene Bags are more accurately referred to as PP Bags or PP Woven Bags. PP bags are prepared using various PP Woven fabrics or PP Woven Sheets with variety of qualities, patterns, prints, colors, sizes and different capacities.

Due to its attractive features PP bags have quickly gained popularity in the market and now a days these are extensively adopted by various industries. PP Bags have become an ideal choice for industrial packaging, where it is widely used in packing foods, fertilizer, powders, cements, chemicals in granulated form, etc. Some of the strong features of PP bags/Sheets are noted here:

Protects Products or commodities, ensuring safe storage

Extends the shelf Life

Prevents spoilage

Eco-friendly and pocket-friendly

100% reusable and durable

Light in weight and flexible

Excellent resistance to stress and high resistant to cracking

Humidity and Dust proof

Easy to clean and anti bacterial

Breathable or water proof with a laminated film

Can be colored or printed

Can be stored in an open area

Considering all above we can summarize PP woven Bags/ PP Woven Sheets Manufactured by Bubna Polysack Industries are ideal for Bulk Packaging. Our PP bags / HDPE woven products are suitable for all kind of packaging requirements. We aim to provide our customers with complete packaging solutions in accordance to their requirements and specifications.

#bags#ppbags#hdpesheet#woven#Bulk packaging#cement#chemical#food packaging#food#fertilizer#powder#grains

0 notes

Text

HDPE as a FDA approved cutting board

Next time you may be slicing fresh fruit on your own cutting board, take a moment and look at it, the material most likely to be used as a High Density Polyethylene Cut Grade Material - Sheets cutting board is Polyethylene. Simply because it is generally FDA and high quality guaranteed NSF approved as well as stain, moisture and odor resistant, Polyethylene is an ideal choice for chopping boards.

Many cutting boards created from wood are prone to bacteria and strong odors for the reason that lack the sought afterproperties that Polyethylene sheets offer, which include its non porous work surface, chemical resistance and approval for food contact. HD Polyethylene most certainly a durable and light-weight material that comes in a great many forms and is designed for a range of applications. There are plenty of varieties of Polyethylene commercially accessible. The most common are HDPE (High Density Polyethylene), LDPE, and UHMW (Ultra High Molecular Weight Polyethylene). The the main difference has to do with the molecular weight and branching; this occurs when a monomer or atom is replaced by a longer chain of polymers (an excessively long repeating chain of atoms).

The High Density is often used for the one gallon milk jugs and glad food storage containers. Low Density is often used for bottles and plastic baggies. UHMW, which has higher molecular weight (2-6 million) which enables for an even transfer over the length of material which makes it stronger, so that it is useful for bearing purposes for the great wear resistance. Often employed in the food processing and dairy industry, Ultra High Molecular Weight Polyethylene is a brilliant replacement for a great many other industrial materials and also a great means to many wear issues. These types of polymers are derived from the same polyolefin plastic family, but they all have certain properties that make them just a little different. HDPE provides great chemical resistance, with extreme impact strength and great energy absorption. Low Density has several of the same properties as High Density but it is not as dense at 9.15, the lowest in comparison to HDPE which happens to be 9.34, plus its a softer material ( the soft coffee can lids). On top of that provides a lower tensile strength and better, less complicated heat forming.

UHMW is really a strong material with which has great durability and low co-efficient of friction making it an ideal for sliding applications. Dupont makes the plastic material with a lower co-efficient of friction is Dupont Teflon - PTFE; which has a higher temperature and chemical resistance. Ultra High Molecular Weight Polyethylene comes with a wide range of material alternatives and properties, and these types of materials possess extraordinary durability which could be best with a number of applications. From the food industry to automotive, the kitchen or even the warehouse, whatever your Polyethylene needs are - High Density, Low Denseness or perhaps UHMW, Polyethylene is a nice decision. Contact us for additional information on these and other plastic semi-finished materials.

plasticsheet

0 notes