#hastelloy c276 pipe

Text

0 notes

Text

Hastelloy C2000 Pipe Fittings Exporters In India

Pipe fittings are utilised in different industries for various present-day and business applications. One of the most remarkable sorts of pipe fittings is Hastelloy C2000 pipe fittings, which have been getting notoriety because of their unmatched strength and deterioration impediment. Hastelloy C2000 pipe fittings are made using a nickel-based alloy anticipated for normal use in terms of obstruction and strength. This alloy has grand protection from an impressive number of heartbreaking media, including oxidising acids, diminishing acids, hot, dirtied seawater, and cruel water plans. Its phenomenal mechanical properties make it the ideal choice for applications involving high temperatures or strains. Hastelloy C2000 pipe fittings are generally utilised in chemical handling, thermal energy stations, oil and gas creation, food handling, and different industries where deterioration deterrents are major.

Hastelloy C2000 pipe fittings show up in several obvious shapes and sizes, including elbows, tees, reducers, couplings, and affiliations. They also come in different wall thicknesses ranging from Schedule 5 to Schedule XXS. This makes them reasonable for certain errands. Hastelloy C2000 pipe fittings can be utilised in applications including high temperatures and strains. They are commonly used in oil and gas production working environments, petrochemical plants, power plants, chemical handling plants, drug manufacturing working environments, water treatment frameworks, food handling plants, cooling designs, and more. Hastelloy B3 pipe fittings, Hastelloy C2000 pipe fittings, and essentially more grades are similarly accessible.

The fundamental advantage of using C-2000 hastelloy pipe fittings is that they are incredibly invulnerable to breaking down from different chemicals, including sulfuric disastrous, hydrochloric horrendous, and nitric damaging. In this way, they have astounding mechanical strength, which makes them reasonable for use in high-pressure structures. Moreover, they are not difficult to introduce and require less upkeep than different sorts of pipe-fitting materials, like treated steel or metal. Various types of things are accessible, such as mind-blowing bars, SMO 254 UNS S31254 pipe fittings, and so forth. UNS N06200 Nickel Alloy Pipe Fitting is a remarkable decision for applications that require huge, strong regions for a breaking-down-safe material. Its best opposition over harming media makes it reasonable for countless industries, including chemical handling, thermal energy stations, oil and gas creation, food processing, and more. Its phenomenal mechanical properties make it ideal for applications including high temperatures or tensions.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

#Hastelloy C276 Pipe Fittings Exporters In India#Hastelloy C2000 Pipe Fittings Exporters In India#Alloy 20 Pipe Fittings Exporters In India#Titanium Gr 1 Pipe Fittings Exporters In India#Titanium Gr 2 Pipe Fittings Exporters In India#Titanium Gr 5 Pipe Fittings Exporters In India

0 notes

Text

0 notes

Text

Hastelloy C276 pipes and tubes are integral components in various industrial applications, particularly in chemical processing, owing to their exceptional properties and reliability. Understanding the advantages of these materials is crucial for optimizing their utilization in demanding environments.

Chemical Composition: Hastelloy C276 is a nickel-molybdenum-chromium alloy renowned for its superior corrosion resistance. Comprising nickel, molybdenum, chromium, and other elements, this alloy offers excellent resistance to a wide range of corrosive substances encountered in chemical processing environments.

Corrosion Resistance: The hallmark feature of Hastelloy C276 pipes and tubes lies in their exceptional resistance to corrosion. They can withstand attacks from aggressive chemicals, including acids, alkalis, chlorides, and organic solvents, ensuring prolonged service life and minimal maintenance requirements.

Weldability: Hastelloy C276 pipes and tubes exhibit excellent weldability, attributed to their low carbon content, which minimizes carbide precipitation during welding. This characteristic ensures that the material retains its corrosion resistance even in welded conditions, making it suitable for various fabrication processes.

High Temperature Performance: Another significant advantage of Hastelloy C276 pipes and tubes is their outstanding performance at high temperatures. They maintain their mechanical properties and corrosion resistance even when subjected to elevated temperatures, making them ideal for applications where thermal stability is critical.

Applications: Hastelloy C276 pipes and tubes find extensive applications across diverse industries, including chemical processing, petrochemicals, pharmaceuticals, oil and gas, pulp and paper, and power generation. They serve crucial roles in conveying corrosive fluids and gases within processing plants and industrial facilities, ensuring operational efficiency and safety.

Conclusion: In conclusion, Hastelloy C276 pipes and tubes offer unparalleled benefits in chemical processing applications, where corrosion resistance, reliability, and performance are paramount. Their unique combination of properties makes them indispensable assets in various industries, enabling efficient and safe operation in challenging environments. Embracing the advantages of Hastelloy C276 pipes and tubes is essential for maximizing productivity and ensuring the longevity of industrial infrastructure.

For more Information

Visit website: https://www.deepsteelalloys.com

Email: [email protected]

Contact: 9930466755

#Hastelloy C276 Pipes & Tubes Manufacturers#Hastelloy C276 Pipes & Tubes Suppliers#Hastelloy C276 Pipes & Tubes Stockists#steel#manufacturers#metal#suppliers

0 notes

Text

Hastelloy C276 Pipe Fittings Exporters

Pipe fittings are made of different alloys and metals. Nickel, chromium, inconel, and hastelloy are some of those. Hastelloy C276 pipe fittings ought to be reannealed and cold-worked. It helps in demolishing resistance to corrosion. Hastelloy pipe fittings are impenetrable to diminishing and oxidizing conditions. Hastelloy fittings should be used in serious, strong regions for experiences like chemical and oil. Hastelloy forged fittings are used in high-corrosion, slanted, and high-temperature applications. Hastelloy Tube Fittings are open in buttweld and seamless turn of events. Instrumental applications use seamless pipe fittings rather than buttweld.

ASTM B366 UNS N10276 Material joins nickel and chromium close by tungsten in follow sums. Alloy C276 pipe Bends could have a long or short degree. They are by and large open at a 90- or 45-degree point. The Hastelloy C276 Fittings size ranges from ½ inch to 48 inches. It assists with changing the width of the pipeline and making it a really genuine evaluation. Alloy C-276 fittings have a dissolving point of 1375 degrees C. Their staggering versatility and yield strength are other than said. Hastelloy C276 buttweld fittings, known as tees, are used to interact with three pipes.

#Hastelloy C276 Pipe Fittings Manufacturers in Mumbai#Hastelloy C276 Pipe Fittings Suppliers in Mumbai#Hastelloy C276 Pipe Fittings Stockists in Mumbai#Hastelloy C276 Pipe Fittings Exporters in Mumbai

0 notes

Text

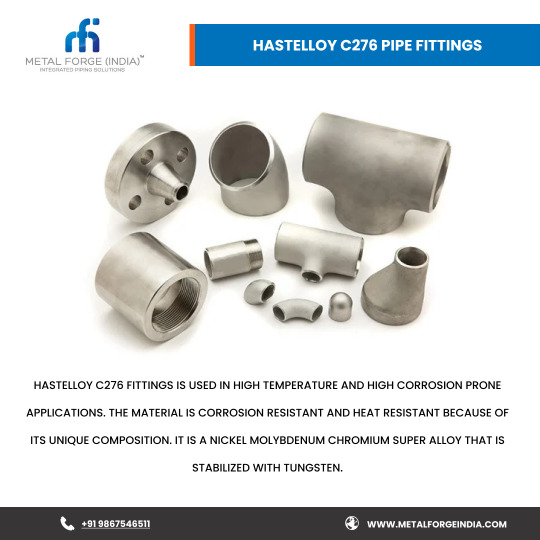

Hastelloy C276 Fittings Manufactures

Hastelloy c276 is used in high temperature and high corrosion prone applications. The material is corrosion resistant and heat because of its unique composition.

0 notes

Text

Hastelloy C276 Pipes & Tubes Suppliers in India

Hastelloy C276 Line is a titanium-settled chromium nickel molybdenum compound. This mix offers a wide assortment of mechanical properties and has a few advantages. Hastelloy Compound C276 Lines items offer great consumption obstruction. These lines’ protection from pitting and fissure consumption makes them interesting.

Hastelloy Amalgam C276 Lines which are appropriate for seawater applications. These Hastelloy C276 Consistent Lines can work in destructive circumstances, for example, those in squander the board and contamination control. Hastelloy C276 Welded Lines have been demonstrated over an extensive stretch to deal with these conditions. These Hastelloy C276 EFW Lines can be effectively turned, profound drawn, press shaped, or punched with their capability to work solidify. Hastelloy C276 ERW Lines require more energy during cold framing since they are stiffer than most of austenitic treated steels. Various cold and hot working strategies can be utilized to make these Hastelloy C276 tubes. Numerous strategies can effectively manufacture Hastelloy C276 Consistent Cylinders.

Nicrofer® 5621 Funneling and Tubing, Hastelloy C-276 Empty Area, C276 Hastelloy® Amalgam Water driven Tubing Exporters, Hastelloy C-276 Instrumentation Lines, Hastelloy C-276 Empty Line and Cylinders Dealers, Hastelloy Combination C-276 Hairlike Funneling, Hastelloy C276 Loop Cylinder Providers in Mumbai, Grade C276 Hastelloy® Amalgam Intensity Exchanger and Condenser Tubing, Nickel Amalgam C276 Cold Drawn Consistent Lines, Noise 2.4819 Hastelloy® Hexagonal Line Stockyards.

These Hastelloy C276 Welded Cylinders are utilized for Latches, Forgings, Sulfuric corrosive reactors, and that's just the beginning. Hastelloy C276 EFW Cylinders are frequently utilized for Mash and paper creation, Squander treatment, etc. These Hastelloy C276 ERW Cylinders are likewise utilized for Parts around sharp gas, Fade plants, and digesters for assembling paper and mash, and so on. Fashioned types of Hastelloy UNS N10276 Lines are outfitted in the arrangement heat-treated condition except if generally determined. Brushing with a hardened steel wire brush in the wake of welding these Hastelloy Clamor 2.4819 Cylinders will eliminate the intensity color and produce a surface region that doesn't need extra pickling.

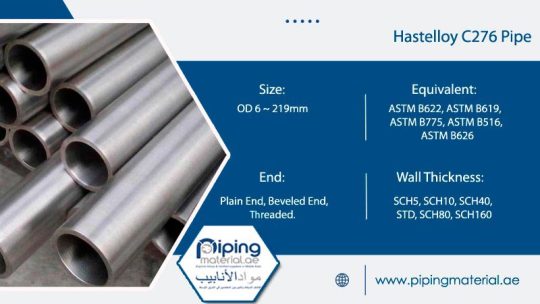

Hastelloy C276 Pipes & Tubes Specification

Specifications : ASTM B622, B619, B626 / ASME SB622, SB619, SB626

Standard : ASTM, ASME and API

Size Range : 15"NB – 150"NB

Outer Diameter : 1.250″ – 6.000″ (30-150mm)

Wall Range : 0.095″ – 1.000″ (.2.5-25mm)

Schedule : SCH 10, SCH20, SCH30, SCH40, STD, SCH60, XS, SCH80, SCH120, SCH140, SCH160, XXS

Type : Seamless / ERW / Welded / Fabricated / LSAW Pipes

Length : Single Random, Double Random & Cut Length

Form : Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, "U" Shape, Pan Cake Coils, Hydraulic Tube

Grade Hastelloy C276 Pipes & Tubes UNS (N10276), DIN (2.4819)

For More Information :

Visit Our Website: https://sankalpalloys.com

Contact No: 91-8828369483

E-Mail ID: [email protected]

0 notes

Text

The top 5 benefits of using Hastelloy C276 round bars

This medium nickel-molybdenum-chromium alloy is developed to withstand the severest of conditions and as such possesses corrosion resistance, high strength, and very good durability. In this write-up, we will show the 5 top advantages of the use of Hastelloy C276 Round Bar and why it is the preferred material for chemical processing, oil and gas, and the marine market.

1. Exceptional Corrosion Resistance

Aside from being the material with excellent corrosion resistance properties, resisting attacks by different kinds of chemicals, this is the most important feature of Hastelloy C276 round bar. These alloys are mostly composed of molybdenite and the oxide layer it forms on the exterior of the alloys protects it from oxidation. Thus, it protect the corrosion even in the most aggressive environments. Hastelloy c276 pipe is subject to the action of a variety of chemicals like hydrochloric acid, sulfuric acid and chlorine or what are widely used in chemical processing plants and in other corrosive places.

2. Resistance to Tear and Wear

Hastelloy C276 CB Round Bar owns top-notch mechanical properties which are strength and ductility simultaneously. It is the proper combination of these materials that makes the material capable of handling heavy loads and stresses without allowing any distortion. The high strength-to-weight ratio of Hastelloy C276 also makes it a first-class question to be answered in those fields where weight is of the essence, including the aerospace industry.

3. Wide Temperature Range

Another advantage of the Hastelloy c276 pipe is that it can keep its mechanical properties over a wide temperature range. The strength and corrosion resistance of this metal alloy remains unchanged irrespective of the cryogenic temperatures or temperatures as high as 1000°C (1832°F). The multiple options associated with the material make it an ideal choice for different high temperature applications like heating components/furnace parts, exchangers and turbine parts.

4. Excellent Weldability

Thanks to superb weldability of the Hastelloy C276 Round Bar, you are capable to do the fabricating and welding processes easily. This alloy has weldedness through various processes using TIG, MIG, and SAW, not compromising its corrosion resistance or stress point. Weldability of Hastelloy C276 is good and it is possible to construct equipment of different configurations. These properties make it to be useful in the wider industrial field.

5. Cost-Effectiveness

Even though C276 Hastelloy has a higher initial price than other alloys, which is its superior performance and long-lasting durability, Hastelloy is a competitive choice when it comes to the costs in the long run. On the other hand, C276 has amazing corrosion resistance and high-strength properties, this helps a lot in terms of not needing to replace or maintain often which in turn saves time and money. When design an asset applying Hastelloy C276 Round Bar will give a reliable performance and long service life, this is a smart economic decision for companies to take long term.

Conclusion

The article concludes that Hastelloy C276 Round Bar’s awesome advantages are the reasons it is so frequently used for almost every industry application. Its outstanding corrosion resistance, high strength, wide temperature range, high weldability, and low production cost outweigh those of the other alloys. While working with Piping Material, we ensure that the sourcing of Hastelloy C276 Round Bar is from a supply partner of great repute and competent experience.

0 notes

Text

Nickel Alloy Seamless Pipe: A Full Overview

Shashwat Stainless Inc is a leading Nickel Alloy Seamless Pipe Manufacturer in India. Nickel alloy seamless pipes are vital components in a variety of sectors due to their remarkable qualities. Whether in high-temperature or very corrosive settings, these pipes provide unparalleled performance. We are a top quality Nickel Alloy Seamless Pipe Supplier in India. Our Nickel Alloy Seamless Pipes are manufactured with National and International Quality Standards.

Nickel alloy seamless pipes are created without a weld seam using alloys based on nickel. Compared to welded pipes, they are stronger and more resistant to pressure because of their seamless construction. These pipes are renowned for their superior mechanical qualities, resilience to corrosion, and tolerance to high temperatures.

Nickel alloy seamless pipes manufacturers stand out for their outstanding qualities and applicability across a wide range of applications. Despite the greater initial cost, their longevity, low maintenance requirements, and improved performance make them an excellent investment. As technology progresses and market demand increases, the future looks bright for these extraordinary materials.

For More Detail

Website: shashwatstainless.com

Product: Nickel Alloy Seamless Pipe Suppliers in India

Other Product: Hastelloy C276 Seamless Pipes Manufacturer in India.

#Nickel Alloy Seamless Pipe Manufacturer in India#Nickel Alloy Seamless Pipe Manufacturer#Nickel Alloy Seamless Pipe

0 notes

Text

What is Nickel Alloy C276 Coils?

Nickel Alloy C276, extensively referred to as Hastelloy C276, stands as a hallmark of excellence inside the realm of corrosion-resistant alloys. Among its various bureaucracy, Nickel Alloy C276 coils come to be flexible additives, imparting great overall performance and reliability throughout a spectrum of industries. As a foremost stockist of Hastelloy C276 coils, MV Super Alloys takes pleasure in providing top-first-rate merchandise that cater to the numerous desires of our clients.

Understanding Nickel Alloy C276 Coils:

Nickel Alloy C276 is a nickel-molybdenum-chromium alloy known for its superb corrosion resistance in competitive environments. Hastelloy C276 Coils Suppliers, provide a blend of vital residences that cause them to be crucial in traumatic applications. These coils exhibit brilliant resistance to corrosion, oxidation, and pitting, making them best to be used in harsh chemical environments, high-temperature settings, and corrosive media.

Applications Across Industries:

Hastelloy C276 coils discover considerable application across a myriad of industries due to their advanced overall performance traits. Some super packages include:

Chemical Processing: In chemical processing vegetation, Hastelloy C276 coils are utilized for managing corrosive acids, alkalis, and solvents, ensuring reliability and durability in critical method devices.

Oil and Gas: Offshore and onshore oil and gasoline facilities depend upon Hastelloy C276 coils for piping structures, valves, and additives uncovered to corrosive environments, safeguarding operations in challenging conditions.

Power Generation: In energy technology centers, those coils are hired in boilers, heat exchangers, and condensers, wherein resistance to corrosion and erosion is vital for efficiency and safety.

Pharmaceutical: Within the pharmaceutical industry, Hastelloy C276 coils are applied in equipment for drug production, supplying resistance to competitive chemical compounds and making sure product purity.

Reliable Supply from Trusted Suppliers:

As a main stockist of Hastelloy C276 coils, MV Super Alloys is devoted to assembling the various needs of our clients with top-satisfactory products and reliable carriers. We work closely with authentic producers to supply high-grade Hastelloy C276 coils that adhere to strict excellent requirements. Our considerable inventory and efficient supply chain make sure to spark off transport to our clients, assembling their challenge timelines and necessities with precision and reliability.

Conclusion:

Nickel Alloy C276 coils, embodying the superb houses of Hastelloy C276 Coils Stockist, function as fundamental components throughout a huge variety of industries. As a relied on supplier and stockist of Hastelloy C276 coils, we give premium-nice merchandise that meet the stringent needs of our clients. With our commitment to excellence and patron pride, we stand as your dependable accomplice for sourcing Hastelloy C276 coils, ensuring unequaled overall performance and durability in vital applications. Trust MV Super Alloys for superior Hastelloy C276 coils that exceed expectancies and deliver lasting price.

#Nickel Alloy C276 Coils#Hastelloy C276 Coils Stockist#Hastelloy C276 Coils#Hastelloy C276 Coils Suppliers

0 notes

Text

EXPLORING THE BENEFITS AND APPLICATIONS OF HASTELLOY C276

Hastelloy C276 is a renowned nickel-based superalloy celebrated for its exceptional corrosion resistance and mechanical properties. Widely used across various industries, this alloy offers many benefits and finds extensive applications in challenging environments where conventional materials fail to perform adequately. In this blog, we delve into the advantages and diverse applications of Hastelloy C276.

THE BENEFITS OF HASTELLOY C276:

Outstanding Corrosion Resistance: Hastelloy C276 excels in resisting corrosion from various aggressive chemicals, including chlorides, sulfuric acid, hydrochloric acid, and phosphoric acid. Its superior corrosion resistance makes it suitable for environments prone to corrosion-induced damage.

High-Temperature Stability: Hastelloy C276 retains its mechanical properties withstanding elevated temperatures, ensuring structural integrity even in high-temperature applications. This stability makes it an ideal choice for equipment exposed to extreme heat.

Excellent Mechanical Strength: Hastelloy C276 exhibits impressive mechanical strength, providing robustness and reliability in demanding environments. Its strength allows it to withstand high-pressure conditions and mechanical stress.

Versatility in Applications: Due to its exceptional properties, Hastelloy C276 is indispensable across various sectors. Its versatility makes it indispensable in chemical processing, oil and gas, pharmaceuticals, pulp and paper, and waste treatment.

Resistance to Pitting and Crevice Corrosion: Beyond general corrosion resistance, Hastelloy C276 offers resistance to localized corrosion phenomena like pitting and crevice corrosion, ensuring protection even in areas prone to such damage.

Ease of Fabrication: Hastelloy C276 can be easily fabricated into different forms, including C276 sheets, C276 plates, C276 pipes, and fittings. Its machinability and weldability facilitate the fabrication of complex structures and components.

Longevity and Durability: Components made from Hastelloy C276 are known for their longevity and durability. They require minimal maintenance and offer prolonged service life, reducing downtime and replacement costs.

APPLICATIONS OF HASTELLOY C276:

Chemical Processing: Hastelloy C276 is widely used in chemical processing equipment, such as reactors, vessels, and piping systems, where resistance to corrosive chemicals is crucial.

Oil and Gas Industry: In oil and gas extraction and refining operations, Hastelloy C276 is employed in equipment exposed to corrosive fluids, high temperatures, and aggressive environments.

Pharmaceutical Manufacturing: Pharmaceutical companies utilize Hastelloy C276 for equipment to produce drugs and pharmaceutical products, ensuring product purity and integrity.

Pulp and Paper Production: Hastelloy C276 is used in pulp and paper mills to handle corrosive chemicals used in bleaching and pulping processes, extending equipment lifespan and improving efficiency.

Waste Treatment: Waste treatment facilities utilize Hastelloy C276 to handle corrosive fluids and gases involved in wastewater treatment processes, ensuring reliable performance and longevity of equipment.

Desalination Plants: Hastelloy C276 finds applications in desalination plants for components exposed to seawater and aggressive brines, providing corrosion resistance and longevity in challenging environments.

Power Generation: Hastelloy C276’s corrosion resistance and high-temperature stability benefit components in power generation facilities, such as boilers, heat exchangers, and flue gas desulfurization systems.

In conclusion, Hastelloy C276 is a highly versatile and reliable material offering exceptional corrosion resistance, mechanical strength, and longevity. Its broad range of applications across diverse industries underscores its significance in environments where corrosion and high temperatures pose significant challenges. By leveraging the benefits of Hastelloy C276, industries can ensure the durability, reliability, and efficiency of their equipment and processes, even in the most demanding conditions.

To Know More: https://www.smmindustriesllp.com/exploring-the-benefits-and-applications-of-hastelloy-c276/

0 notes

Text

Maximize Performance with High-Quality Hastelloy C4/C22/C276 Stud & Anchor Bolts

In the vicinity of business programs in which reliability, sturdiness, and resistance to corrosion are paramount, the selection of fasteners plays a important characteristic. Hastelloy C4/C22/C276 fasteners, collectively with nuts, bolts, screws, washers, stud bolts, and anchor bolts, stand out as high examples of immoderate-trendy overall performance substances that make certain finest operation even within the cruelest environments. Let's delve into how these specialised fasteners can maximize usual ordinary performance in various commercial enterprise settings.

Hastelloy C4/C22/C276 Fasteners: Ensuring Superior Performance

Hastelloy C4/C22/C276 fasteners are engineered to face as much as extreme conditions, making them first rate for industries collectively with chemical processing, oil and gas, electricity generation, and marine programs. These fasteners display off incredible resistance to corrosion, oxidation, and high-temperature environments, making them vital in environments in which traditional substances have to fail.

Enhancing Structural Integrity with Hastelloy C4/C22/C276 Nuts and Hastelloy C4/C22/C276 Bolts

Hastelloy C4/C22/C276 Nuts and Hastelloy C4/C22/C276 bolts are the backbone of many structures, maintaining additives together securely. Hastelloy C4/C22/C276 nuts and bolts provide outstanding electricity and durability, ensuring the structural integrity of essential installations. Whether it's miles for offshore structures, chemical reactors, or excessive-strain piping structures, those fasteners offer peace of thoughts through preserving tight connections even in corrosive atmospheres.

Precision Engineering with Hastelloy C4/C22/C276 Screws and Hastelloy C4/C22/C276 Washers

In applications requiring particular fastening and sealing, Hastelloy C4/C22/C276 screws and washers excel. These fasteners are designed with meticulous attention to element, thinking of dependable overall performance below tough situations. Whether it is sealing joints in chemical processing tool or securing components in aerospace assemblies, Hastelloy C4/C22/C276 screws and Hastelloy C4/C22/C276 washers deliver constant results, making sure leak-proof connections and preventing steeply-priced downtime.

Secure Fixation with Hastelloy C4/C22/C276 Stud Bolts and Hastelloy C4/C22/C276 Anchor Bolts

Hastelloy C4/C22/C276 Stud bolts and Hastelloy C4/C22/C276 anchor bolts play a essential function in anchoring heavy device, device, and structural elements to concrete or metal surfaces. Hastelloy C4/C22/C276 stud bolts and anchor bolts offer unequaled strength and corrosion resistance, ensuring sturdy fixation even in harsh environments. From agency machinery to offshore structures, those fasteners provide peace of thoughts thru stopping loosening or failure because of corrosion.

Why Choose Hastelloy C4/C22/C276 Fasteners?

Corrosion Resistance: Hastelloy C4/C22/C276 alloys are renowned for his or her remarkable resistance to corrosion, making them suitable for use in corrosive environments which include chemical processing flowers and marine packages.

High Temperature Stability: These fasteners keep their mechanical houses even at prolonged temperatures, ensuring dependable regular overall performance in excessive-temperature packages collectively with energy era and aerospace engineering.

Durability: Hastelloy C4/C22/C276 fasteners are designed to resist harsh situations, providing long-term sturdiness and reliability in stressful business environments.

Versatility: From nuts and bolts to screws and washers, Hastelloy C4/C22/C276 fasteners are to be had in a diverse bureaucracy to match a huge variety of programs, presenting versatility and versatility in design and assembly.

Cost-Effectiveness: While initially, the value of Hastelloy C4/C22/C276 fasteners may be higher than conventional materials, their sturdiness and resistance to corrosion provide lengthy-time period fee financial savings by decreasing protection and replacement fees.

Conclusion: Partner with Anand Steel for High-Quality Stainless Steel Solutions

In end, on the subject of maximizing performance in business programs, the choice of fasteners is paramount. Hastelloy C4/C22/C276 fasteners, which include nuts, bolts, screws, washers, stud bolts, and anchor bolts, offer extraordinary overall performance, sturdiness, and corrosion resistance, making sure dependable operation even within the maximum challenging environments. For wonderful Hastelloy fasteners and other chrome steel solutions, appearance no further than Anand Steel. As a main importer and exporter of chrome steel shims, strips, coils, foils, spherical bars, and nickel alloys, Anand Steel is committed to delivering excellence and purchaser satisfaction. With years of revel in and understanding, they've established themselves as a trusted dealer inside the industry, catering to the unique needs of diverse sectors. Contact Anand Steel these days for all your chrome steel requirements and revel in the distinction best made.

#Hastelloy C4/C22/C276 Fasteners#Hastelloy C4/C22/C276 Nuts#Hastelloy C4/C22/C276 Bolts#Hastelloy C4/C22/C276 Screws#Hastelloy C4/C22/C276 Washers#Hastelloy C4/C22/C276 Stud Bolts#Hastelloy C4/C22/C276 Anchor Bolts

0 notes

Text

Advantages of Using Hastelloy Tubes in Offshore Oil and Gas Operations

In the place of offshore oil and gas operations, wherein harsh environments and corrosive conditions are commonplace, the choice of materials for device and infrastructure is vital. Hastelloy tubes, identified for their outstanding corrosion resistance and mechanical homes, have emerged as a preferred answer for severa applications in offshore drilling and manufacturing activities. In this weblog, we're capable of finding out the advantages of the usage of Hastelloy tubes in offshore oil and fuel operations.

Introduction to Hastelloy Tubes:

Hastelloy is a circle of relatives of nickel-based complete alloys acknowledged for their high-quality resistance to corrosion, immoderate temperatures, and stress. Hastelloy tubes, made from the ones alloys, show off superior traditional standard performance in aggressive environments containing acids, chlorides, sulfides, and specific corrosive materials. They are widely implemented in industries together with chemical processing, aerospace, and, appreciably, offshore oil and gas manufacturing.

Advantages of Hastelloy Tubes in Offshore Operations:

1. Corrosion Resistance:

Hastelloy tubes offer first rate corrosion resistance, even in quite corrosive environments encountered in offshore oil and fuel operations. They are proof in the direction of pitting, crevice corrosion, and strain corrosion cracking, making sure lengthy-time period integrity and reliability of the tool.

2. High Temperature Strength:

In offshore drilling and manufacturing environments, where temperatures can vary notably, Hastelloy tubes preserve their mechanical electricity and structural integrity at multiplied temperatures. This property is crucial for maintaining the general common overall performance and protection of crucial components beneath hard conditions.

3. Versatility:

Hastelloy tubes are available in severa grades and compositions, allowing engineers to choose the most suitable alloy for precise offshore programs. Whether it is Hastelloy C276, Hastelloy C22, or one-of-a-type versions, there may be a Hastelloy alloy tailor-made to meet the requirements of numerous on foot conditions.

4. Resistance to Hydrogen Sulfide (H2S) Corrosion:

Offshore oil and gasoline fields frequently incorporate high tiers of hydrogen sulfide, a corrosive gasoline that may degrade conventional materials. Hastelloy tubes show remarkable resistance to H2S corrosion, making them great for use in environments in which this compound is present.

5. Durability and Longevity:

Hastelloy tubes have a single record of durability and toughness in offshore packages, contributing to decreased protection prices and prolonged provider life of tools. Their sturdy manufacturing and resistance to degradation ensure dependable everyday universal overall performance over prolonged durations.

6. Ease of Fabrication:

Despite their outstanding homes, Hastelloy tubes are alternatively easy to manufacture, weld, and install, deliberating seamless integration into offshore infrastructure. This ease of fabrication complements overall performance sooner or later of production and installation techniques.

7. Regulatory Compliance:

The use of Hastelloy tubes in offshore oil and fuel operations allows groups to follow stringent employer policies and requirements related to corrosion safety, safety, and environmental sustainability. By using corrosion-resistant substances like Hastelloy, operators can mitigate dangers and ensure regulatory compliance.

Conclusion:

Hastelloy tubes provide a big variety of blessings for offshore oil and gasoline operations, making them essential components inside the business enterprise. Their wonderful corrosion resistance, excessive temperature power, versatility, and durability make them properly-relevant for critical applications in harsh marine environments. By choosing Hastelloy tubes by Bullion Pipes, operators can decorate the overall common universal performance, reliability, and protection of their offshore infrastructure, ultimately contributing to the fulfillment of oil and gasoline exploration and manufacturing activities.

0 notes

Text

Industrial Flanges Supplier in Warangal

Simplex Steels is a Manufacturer, Exporter, and Industrial Flanges Supplier in Warangal,

Telangana.

We specialize in SS Sheet, Plate, Coils, Pipes, Tubes, Bar, Wires, Rods, Angles, and Channels.

Our company produces Stainless Steel Flanges in a variety of shapes, sizes, and specifications to meet diverse customer needs.

Simplex Steel commonly provides an extensive selection of flange types, sizes, and materials to fulfill diverse industry needs.

Why Our Product?

Manufactured from high-quality materials

Durable

Efficient performance

Dimensional accuracy

Faster Delivery

Competitive Price

In-house Testing Facility

Packaging and stock facility

Qualified Technicians

Quality controllers

Available Flanges:

Weld Neck Flanges

Slip-On Flanges

Blind Flanges

Socket Weld Flanges

Threaded Flanges

Lap Joint Flanges

Specifications:

Stainless Steel: ASTM A 182, A 240

Grade: F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L, Duplex stainless steel UNS S31803, 2205, Super duplex stainless steel UNS S32750

Carbon Steel: ASTM A 105, ASTM A 181

Alloy Steel: ASTM A 182, GR F1, F11, F22, F5, F9, F91

Nickel Alloys: Monel 400 & 500, Inconel 600 & 625, Incoloy 800, 825, Hastelloy C22,C276

Copper Alloys: Copper, brass & gunmetal

Size: 1/8" NB TO 48"NB.

Class: 150#, 300#,400 #, 600#, 900#, 1500# & 2500 #.

Application:

Pipeline engineering

Marine industry

Power industry

Oil & gas industry

Waste water management

Aerospace

Chemical industry

Food processing

Simplex Steels is a Industrial Flanges Supplier in Warangal, Telangana, India including locations like Hyderabad, Warangal, Nizamabad, Khammam, Karimnagar, Ramagundam, Mahbubnagar, Nalgonda, Siddipet, Miryalaguda, Suryapet, Jagtial, Bhongir, Kamareddy, Mancherial, Wanaparthy, Jangaon.

For further information, feel free to contact us.

Read the full article

0 notes

Text

Lap Joint Flanges, Lap Joint Flanges Manufacturers, Lap Joint Flanges Suppliers, Lap Joint Flanges Exporters, Lap Joint Flanges Stockists.

Lap Joint Flanges in Mumbai, Lap Joint Flanges Manufacturers in Mumbai, Lap Joint Flanges Suppliers in Mumbai, Lap Joint Flanges Exporters in Mumbai, Lap Joint Flanges Stockists in Mumbai.

Lap Joint Flanges in India, Lap Joint Flanges Manufacturers in India, Lap Joint Flanges Suppliers in India, Lap Joint Flanges Exporters in India, Lap Joint Flanges Stockists in India.

These lap joint flanges are constantly utilized with either a stub end or taft which is butt welded to the pipe with the flanges loose behind it. This implies the stub end or taft dependably makes the face. The lap joint is favored in low weight applications since it is effectively assembled and adjusted. To lessen cost these stub end lap joint flanges can be supplied without a hub and/or in treated, coated carbon steel.SPECIFICATION

Standards:

ANSI B 16.5 Class 150 lb

ANSI B 16.5 Class 300 lb

ANSI B 16.5 Class 400 lb

ANSI B 16.5 Class 600 lb

ANSI B 16.5 Class 900 lb

ANSI B 16.5 Class 1500 lb

Carbon Steel:

ASTM A 105, ASTM A 181

Alloy Steel:

ASTM A 182, GR F1, F11, F22, F5, F9, F91

Nickel Alloys:

Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276

Copper Alloys:

Copper, Brass & Gunmetal

Size:

1/8" NB TO 48"NB.

Class:

150#, 300#,400 #,600#,900#, 1500# & 2500 #.

ANSI:

ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN:

DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S:

BS4504 , BS4504, BS1560, BS10

0 notes

Text

The Impact of Hastelloy Alloy Materials on High-Tech Industries

Hastelloy alloys are a commonly acknowledged substitute for other materials in industrial settings. At Jay Steel Corporation, we take great satisfaction in locating all varieties of hastelloy alloys. We serve the global industry as exporters with a focus on round bar, fittings, sheets and hastelloy alloy fasteners. As an exporter of hastelloy alloy round bars and sheets, we are a reliable partner because of our experience with grades including C22, C276, B2, and B3. You can count on us to deliver top-notch goods that adhere to industry standards.

We shall examine the significant influence of Hastelloy alloy materials on advanced engineering in this blog post.

Alloy Hastelloy

Apart from the well-known grades like C22, C276, B2, and B3, Hastelloy alloys provide a distinctive combination of molybdenum, chromium, and nickel. These special qualities make these alloys the preferred materials for demanding and high-tech applications because they provide remarkable resistance to oxidation, corrosion, and high temperatures.

Effect of Hastelloy alloys on high mechanical properties

The chemistry made a big difference:

Our Hastelloy alloy product plays an important role in the development of chemical process industries. From reactor vessels to pipe valves, our corrosion-resistant Hastelloy alloys contribute to improved safety, resulting in the development of chemical compounds and cutting-edge chemicals

Advances in aerospace technology:

Hastelloy alloys became a cornerstone in the aerospace industry. Used in aircraft components such as turbine blades, exhaust systems and structural elements, these alloys maintain their integrity at high temperatures, ensuring the safety and performance of aerospace technologies

To ensure the quality of electronics manufacturing:

As electronics decrease in size but increase in power, the need for durable and corrosion-resistant components has never been greater Our Hastelloy alloy provides the essential reliability of, and supports, critical electrical components for the longevity of electronic devices.

Power sector capacity building:

Alloys from these alcohols are important in the energy sector, especially in oil and gas exploration. From downhole machinery to oil refining components, our blends provide resistance to corrosion and moisture, contributing to the efficiency and safety of energy extraction and production wom

Our variety of products

As a leading supplier of Hastelloy alloy products, Jay Steel Corporation offers an extensive inventory to meet the needs of various industries. Our products include:

Wire Mesh; Hastelloy wire mesh is engineered to be durable and resilient ensuring performance, in challenging environments.

Round bars; Our crafted round Hastelloy Round Bars maintain system integrity and resilience under extreme strain.

Strips, Sheets and Plates; Whether for chemical or aerospace applications our Hastelloy strips, sheets and plates offer corrosion resistance and lasting durability.

Tubes & Pipes; Designed to withstand conditions our Hastelloy tubes and pipes are ideal for demanding applications across industries.

Fittings and Flanges; Our Hastelloy fittings and flanges enhance the effectiveness and safety of high tech systems by providing leak connections.

Welding Rods & Fasteners; With a focus on quality and precision our Hastelloy welding rods and fasteners deliver performance, in demanding conditions.

Final Words!

Examples of the important role of Hastelloy alloys in refined manufacturing include Jay Steel Corporation's emergence as the pioneer of Hastelloy alloys Our scope extends to a wide range of grades, including the versatile C22 and C276, a it is also difficult. B2 flexibility and B3 corrosion resistance. Hastelloy Alloy Fasteners Exporter, Hastelloy Alloy Round Bar Exporter, Hastelloy Alloy Fitting Exporter, and Hastelloy Alloy Paper Exporter, we offer a wide range of products such as wire mesh, round bars, strips, paper & plates, tubes & pipes, fittings and more We supply range, Flanges, Welding Rods, and Fasteners and all over the world in different countries like India, Thailand, Singapore, Malaysia, Germany, Russia, France, Nigeria, USA, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, and Jordan, Bahrain. Italy, and the United Kingdom, we continue to support high-technology development and innovation around the world. Choose us for unparalleled quality and reliability in Hastelloy alloy solutions.

#Hastelloy Alloy Product Supplier#Hastelloy Alloy Fasteners Exporters#Hastelloy Alloy Round Bar Exporters#Hastelloy Alloy Fittings Exporters#Hastelloy Alloy Sheets Exporters

0 notes