#digital transformation in manufacturing

Text

Sensors and connectivity: A trend for 2024

Data is the new oil. It's valuable, but if unrefined it cannot really be used. — Clive Humby

In today's rapidly evolving manufacturing landscape, the integration of sensors and connectivity has become indispensable. Just like Clive Humby's analogy of data being akin to oil, sensors serve as the drill, extracting valuable insights from the manufacturing process, while connectivity acts as the pipeline, efficiently transporting this data to where it can be refined and utilized.

But what exactly are sensors and connectivity in the context of manufacturing? Sensors are devices that detect and respond to physical inputs from the environment. These inputs could range from temperature and pressure to motion and light. They are strategically placed throughout the manufacturing process to collect real-time data on various parameters. Connectivity refers to the ability of these sensors to communicate this data to other systems, typically through networks such as Wi-Fi, Bluetooth, or even the Internet of Things (IoT) platforms.

The integration of sensors and connectivity happens at various stages of manufacturing, from the raw material procurement to the final product assembly. Sensors are embedded in machines, equipment, and even products themselves, continuously monitoring and transmitting data. This data is then analyzed using advanced algorithms and machine learning techniques to optimize processes, improve product quality, and enhance overall efficiency.

The benefits of sensor and connectivity integration are manifold. Firstly, it enables predictive maintenance, allowing manufacturers to identify and address potential equipment failures before they occur, thereby minimizing downtime and reducing maintenance costs. According to a study by Deloitte, predictive maintenance can result in up to a 40% reduction in maintenance costs and a 25% increase in productivity.

Moreover, real-time monitoring provided by sensors helps manufacturers gain deeper insights into their processes, leading to better decision-making and optimization. This not only improves operational efficiency but also enhances product quality, resulting in higher customer satisfaction and reduced wastage. In fact, a report by McKinsey suggests that implementing IoT-enabled predictive maintenance can increase equipment uptime by up to 10-20% and reduce maintenance costs by 10-40%.

Additionally, the integration of sensors and connectivity facilitates the transition towards Industry 4.0, where smart factories leverage data-driven insights to drive automation and innovation. This not only improves competitiveness but also paves the way for new business models and revenue streams. According to a forecast by MarketsandMarkets, the global smart manufacturing market is expected to reach $314.7 billion by 2026, growing at a CAGR of 12.4%.

In terms of technology, advancements in sensor miniaturization, wireless communication protocols, and cloud computing have been instrumental in driving the adoption of sensor and connectivity solutions in manufacturing. For instance, the emergence of edge computing enables real-time processing of data at the source, reducing latency and enhancing responsiveness.

In conclusion, the integration of sensors and connectivity represents a paradigm shift in modern manufacturing, unlocking unprecedented levels of efficiency, productivity, and innovation. By harnessing the power of data, manufacturers can not only stay competitive in today's dynamic market but also pave the way for a more sustainable and resilient future. As the Fourth Industrial Revolution continues to unfold, the role of sensors and connectivity will only become more central in shaping the factories of tomorrow. These technologies are not just tools for optimization; they are the cornerstone of digital transformation solutions that will define the future of industry.

#digital transformation solutions#digital transformation in manufacturing#digital transformation company

0 notes

Text

The Digital Revolution Brings Sustainability to Manufacturing

Manufacturers are choosing to embrace digital transformation to enhance their own operations sustainably, thanks to an increased focus on environmental, social and governance (ESG) metrics and shifting customer and market preferences.

While it can be a daunting task to digitally transform in ways that also meet sustainability goals, the potential benefits are virtually unlimited.

Today, manufacturing companies are partnering with digital technology experts like Hitachi, who has over 110 years of industrial experience, to drive sustainability and achieve digital transformation success. This will ultimately help companies gain more market share, retain top talent, improve their brand reputation, and achieve many other benefits beyond operational efficiency, increased profitability, and improved productivity and safety.

Digital innovation requires substantial change, though. To improve sustainability, manufacturers must look for ways to increase efficiency, reduce their energy consumption, integrate alternative energy sources and energy management systems, and reduce their carbon footprint from end to end.

Hitachi recommends 3 key areas to focus on to achieve manufacturing sustainability goals:

Production Processes: Streamlined and energy-saving processes ensure waste reduction and boost visibility to build smart factories that are more sustainable.

Workforce training: Smart manufacturing ensures manufacturers maintain sustainability-based work practices by using digital information-sharing tools to reduce the knowledge drain as skilled workers retire.

Supply Chain: Efficient supply chains can save energy, reduce warehouse storage and streamline logistics, thereby helping lower carbon footprints and foster sustainable manufacturing.

Data-driven smart manufacturing

Data is the key enabler to the sustainability challenge. An unprecedented amount of data is available to organizations, and digitization is vital to derive insights from that data efficiently. Data-driven solutions, in turn, ensure operational benefits and boost efficiencies.

Hitachi, a climate change innovator, is fostering sustainability in manufacturing with its cutting-edge digital technologies. Hitachi Lumada Manufacturing Insights helps manufacturers to develop data-driven operations, increase supply chain visibility, run predictive models, and enable smart factory solutions, thereby fostering waste reduction and optimal utilization of resources.

Explore how Hitachi can help you embrace manufacturing sustainability by utilizing digital solutions to achieve digital transformation success.

Discover how Hitachi is unlocking value for society with Sustainable Innovation in Manufacturing:

#digital technology#digital innovation#digital solutions#sustainable manufacturing / sustainability in manufacturing#smart manufacturing#smart factories#digital transformation in manufacturing#data driven smart manufacturing#digital transformation#sustainability

0 notes

Text

youtube

Watch the 2024 American Climate Leadership Awards for High School Students now: https://youtu.be/5C-bb9PoRLc

The recording is now available on ecoAmerica's YouTube channel for viewers to be inspired by student climate leaders! Join Aishah-Nyeta Brown & Jerome Foster II and be inspired by student climate leaders as we recognize the High School Student finalists. Watch now to find out which student received the $25,000 grand prize and top recognition!

#ACLA24#ACLA24HighSchoolStudents#youtube#youtube video#climate leaders#climate solutions#climate action#climate and environment#climate#climate change#climate and health#climate blog#climate justice#climate news#weather and climate#environmental news#environment#environmental awareness#environment and health#environmental#environmental issues#environmental education#environmental justice#environmental protection#environmental health#high school students#high school#youth#youth of america#school

16K notes

·

View notes

Text

Why should manufacturers in Australia invest in Digital Transformation for effective production?

Digital transformation is expanding in the entire manufacturing sector. If manufacturing firms are unable to understand what's best for them it will result in unproductive employees, and outdated processes in the coming future.

Many businesses have started to experience the long-term advantages of manufacturing automation in Australia. If you, too, wish to go digital, you can gain a lot from higher productivity, optimised data use, increased scope of innovation, and overall cost reduction.

But how to bring a digital transformation to your manufacturing business? What are some typical pitfalls you should be aware of? Let's take a look at it.

Why Should Manufacturing Companies Invest in Digital Transformation?

Innovation

You won't ever regret investing in the digitalisation of your manufacturing company. Investing in the appropriate digital infrastructure, tools, and software will be worthwhile because it will provide your staff with cutting-edge equipment that will help your company move forward.

Reduce costs

You can improve your understanding of problems like delivery status, inventory levels and demand cycles with the help of digital manufacturing. By having more information, you can be in a better position to handle supply and demand fluctuations. The risks and expenses associated with items like excess inventory and materials will be reduced.

Resiliency

Resilience is essential to thriving in challenging business situations. In order to stay ahead of the competition, manufacturers must be able to predict and respond to problems. Digital technologies benefit manufacturing by utilising flexible automation, connecting the supply chain effectively, and allowing remote operation.

Improved process and equipment reliability

Unplanned downtime is estimated to cost manufacturers $50 billion yearly. Predictive maintenance, enabled by digital technology, might hold the key to addressing this heavy price tag.

Predictive maintenance is an approach that seeks to boost reliability by taking corrective measures before a breakdown event happens. By employing this strategy, firms may ensure that their assets are effectively maintained while saving their own companies' internal resources from unnecessary maintenance work.

The common pitfalls of scaling digital transformations in manufacturing

Failure to adapt: Employing a one-size-fits-all strategy, manufacturers miss the chance to incorporate the adaptability and customisation required to take advantage of the distinct conditions, cultures, and values of various industrial sites.

Analysis paralysis: Conducting a thorough and in-depth analysis of the whole network can leave a manufacturer out of steam before a change can get off the ground. Instead, accurate, robust insights can provide an accurate extrapolation methodology.

Technology-driven rather than value-driven: When solutions are implemented using a technology-first approach, there is no clear connection between them and real value possibilities, business difficulties, or… Continue Reading about Digital Transformation for effective production capability

#manufacturing automation in Australia#Industry 4.0 solutions#Digital transformation in manufacturing

0 notes

Text

Digital Transformation in Manufacturing Market Research Report 2022 to 2028: Industry Trends, Regional Wise Outlook, Growth Projections and Opportunities

This report provides a comprehensive analysis of current Global Digital Transformation in Manufacturing Market based on segmented types and downstream applications. Major product development trends are discussed under major downstream segment scenario.This report also focuses on major driving factors and inhibitors that affect the market and competitive landscape. Global and regional leading players in the Digital Transformation in Manufacturing industry are profiled in a detailed way, with sales data and market share info. This report also includes global and regional market size and forecast, drill-down to top 20 economies.

According to this survey, the global Digital Transformation in Manufacturing market is estimated to have reached $ xx million in 2020, and projected to grow at a CAGR of xx% to $ xx million by 2028.

Get Download Request Sample Report @ https://martresearch.com/contact/request-sample/3/16952

Covid-19 pandemic has impacted the supply and demand status for many industries along the supply chain. Global Digital Transformation in Manufacturing Market Status and Forecast 2022-2028 report makes a brilliant attempt to unveil key opportunities available in the global Digital Transformation in Manufacturing market under the covid-19 impact to help readers in achieving a better market position. No matter the client is industry insider, potential entrant or investor, the report will provide useful data and information.

The Global Digital Transformation in Manufacturing Market has been exhibited in detail in the following chapters

Chapter 1 displays the basic product introduction and market overview.

Chapter 2 provides the competition landscape of global Digital Transformation in Manufacturing industry.

Chapter 3 provides the market analysis by type and by region

Chapter 4 provides the market analysis by application and by region

Chapter 5-10 presents regional and country market size and forecast, under the context of market drivers and inhibitors analysis.

Chapter 11 analyses the supply chain, including process chart introduction, upstream key raw material and cost analysis, distributor and downstream buyer analysis.

Chapter 12 provides the market forecast by type and by application

Chapter 13 provides the market forecast by region

Chapter 14 profies global leading players with their revenue, market share, profit margin, major product portfolio and SWOT analysis.

Chapter 15 conclusions

Get Enquiry Report @ https://martresearch.com/contact/enquiry/3/16952

Segmented by Type

l Robotics

l IoT

l 3D Printing and Additive Manufacturing

l Cybersecurity

l Other

Segmented by Application

l Upstream

l Midstream

l Downstream

Get Discount Report @ https://martresearch.com/contact/discount/3/16952

Key manufacturers included in this survey

l Symantec Corporation

l Siemens AG

l Schneider Electric SE

l SAP SE

l Oracle Corporation

l Mitsubishi Electric Corporation

l Microsoft Corporation

l Intel Corporation

l IBM Corporation

l General Electric Co.

l Cisco Systems Inc.

l ABB Ltd

Contact Us:-

+1-857-300-1122

1 note

·

View note

Link

The market for all of these solutions is projected to elevate for the next decade. time is just right to embrace advanced solutions for taking your manufacturing company to a new level.

0 notes

Text

Enhance Efficiency and Flexibility with DIN Rail Mounted Terminal Blocks in India

Introduction:

In today's rapidly evolving industrial landscape, efficient and reliable electrical connections are crucial for ensuring smooth operations. DIN rail mounted terminal blocks have emerged as a preferred solution for creating secure and organized electrical connections in a wide range of applications. With their versatility, durability, and ease of installation, these terminal blocks have gained immense popularity among professionals in India. In this blog post, we will explore the benefits and applications of rail mounted terminal blocks and highlight their importance in the Indian industrial sector.

What are DIN Rail Mounted Terminal Blocks?

DIN rail mounted terminal blocks are electrical connectors that provide a convenient and standardized method for connecting and distributing power or signals in industrial control systems. These blocks are specifically designed to be mounted on DIN rails, which are widely used for organizing and securing electrical components in control panels, switchgear cabinets, and equipment enclosures.

Benefits of DIN Rail Mounted Terminal Blocks:

Space-saving and Modular Design: DIN rail mounted terminal blocks feature a compact design that allows for optimal use of available space. Their modular construction enables easy customization and expansion as per the specific requirements of an application, making them highly adaptable.

Secure and Reliable Connections: These terminal blocks ensure secure and reliable connections, thanks to their robust construction and advanced connection technologies. They provide a sturdy grip on wires and facilitate excellent contact, minimizing the risk of loose connections and electrical failures.

Easy Installation and Maintenance: With their tool-less and user-friendly design, DIN rail mounted terminal blocks simplify installation and maintenance procedures. The snap-on mounting feature of these blocks allows for quick and hassle-free assembly, reducing overall downtime during system installation or upgrades.

Enhanced Safety: Rail mounted terminal blocks adhere to stringent safety standards and offer features like finger-safe design, which prevents accidental contact with live components. This ensures the safety of both the equipment and the personnel working with them.

Applications of DIN Rail Mounted Terminal Blocks:

Industrial Automation: Rail mounted terminal blocks are extensively used in industrial automation systems, where they serve as a vital component for connecting sensors, actuators, motors, and other devices. These blocks provide a reliable interface for transmitting power and signals between various control elements.

Power Distribution: DIN rail mounted terminal blocks play a crucial role in power distribution systems, allowing for easy and organized connection of power supply lines to different equipment. They enable efficient energy management and facilitate the distribution of power to multiple devices within a control panel.

Building Automation: In building automation systems, DIN rail mounted terminal blocks provide a convenient solution for connecting various electrical components, such as lighting controls, HVAC systems, security systems, and more. Their modular design allows for easy integration and maintenance of these systems.

Rail Mounted Terminal Blocks in India:

The Indian industrial sector is witnessing significant growth, and the demand for reliable electrical connectivity solutions is higher than ever. Rail mounted terminal blocks have gained traction in India due to their versatility and ability to meet the diverse requirements of industries ranging from manufacturing to infrastructure development. Manufacturers and suppliers in India offer a wide range of DIN rail mounted terminal blocks, catering to different voltage and current ratings, wire sizes, and connection types.

Conclusion:

Rail mounted terminal blocks have revolutionized the electrical connectivity landscape in India, providing efficient, secure, and organized solutions for various industrial applications. Their space-saving design, ease of installation, and robust construction make them indispensable for creating reliable connections in control systems and power distribution networks. As the industrial sector continues to thrive in India, the importance of DIN rail mounted terminal blocks as a key component in electrical installations cannot be overstated. By embracing these advanced terminal blocks, Indian industries can enhance efficiency, reduce downtime, and ensure safe and reliable operations.

#Rail Mounted Terminal Blocks India#DIN Rail Mounted Terminal Blocks India#Power BusBar Terminal#Finger Safe Power Terminal blocks#Barrier Terminal Block Manufacturer in India#electrical wire termination technology#manufacturer#terminal block#DIN Rail Mounted Connectors#switchgear industry#solar product#PCB connectors#DIN rails channels#digital voltmeter#digital ammeter#power and signal#current transformer#railway#renewable energy#elmex#electrical company#electrical industry

2 notes

·

View notes

Text

youtube

Watch the American Climate Leadership Awards 2024 now: https://youtu.be/bWiW4Rp8vF0?feature=shared

The American Climate Leadership Awards 2024 broadcast recording is now available on ecoAmerica's YouTube channel for viewers to be inspired by active climate leaders. Watch to find out which finalist received the $50,000 grand prize! Hosted by Vanessa Hauc and featuring Bill McKibben and Katharine Hayhoe!

#ACLA24#ACLA24Leaders#youtube#youtube video#climate leaders#climate solutions#climate action#climate and environment#climate#climate change#climate and health#climate blog#climate justice#climate news#weather and climate#environmental news#environment#environmental awareness#environment and health#environmental#environmental issues#environmental justice#environment protection#environmental health#Youtube

16K notes

·

View notes

Text

Advanced NetSuite Manufacturing Revives Production Efficiency

Advanced Manufacturing in NetSuite delivers a single and unified business solution that replaces disparate and disconnected systems and helps modern-day Manufacturers thrive in the evolving landscape with Advanced Automated Capabilities.

For the most part, Advanced Manufacturing NetSuite is orchestrated on native NetSuite ERP. Given these points, it helps ensure that all manufacturing processes are extensively connected to financial reports, inventory management, and outstanding orders in real time.

Some of the highlighting features of Advanced Manufacturing NetSuite covers

Planning and Scheduling

Shop floor capabilities

Resource utilization

Discrete or Assembly Manufacturing Capabilities

Finite Production Scheduling

Work Order Release capabilities

Batch or Process Manufacturing capabilities

Recipe or Formulation capabilities

Raw and Bulk Lot Control

In addition, modern-day manufacturing units can make the most of Advanced Manufacturing NetSuite to gain complete control of all aspects of their manufacturing or production processes including finite capacity, scheduling, and manufacturing execution.

Advanced Inventory NetSuite

In general, the deployment of Advanced Inventory NetSuite helps modern-day production and distribution businesses drive the capability required for robust manufacturing operations management and retain customer engagement in the long run. For the most part, Advanced Inventory Management in NetSuite

Delivers inventive features such as

Demand-based Inventory Replenishment

Inventory Control

Lot Management

Bin Management

Return Merchandize Authorization

Pick, Pack, and Ship Management

In particular, the Advanced Inventory Management NetSuite is a crucial part and function of Advanced Manufacturing NetSuite.

Advanced NetSuite Support

To make the most of NetSuite capabilities, optimize ERP usage, and multiply the business benefits of Advanced Inventory NetSuite or Advanced Manufacturing NetSuite, get Advanced NetSuite Support.

At inoday, #1 ORACLE NetSuite Channel Partner, you can avail of impressive customer services, including Advanced Customer Support NetSuite.

For the most part, businesses relying on our Certified NetSuite Consultants are managing key operations under the aegis of Expertise, Exposure, and Experience.

Undeniably, by offering Advanced NetSuite Support, we help you make the best of global consulting, implementation support, and services with deep knowledge across NetSuite Solutions.

In particular, these subject-matter experts help you scale up with Advanced Customer Support in NetSuite and let you overcome critical issues, without a hitch.

At inoday, thriving manufacturing businesses can avail of Advanced Inventory Management in NetSuite or Advanced Manufacturing in NetSuite and ensure continued operations with Advanced Customer Services in NetSuite.

Explicitly, we leverage our 16+ years of experience in driving Digital Transformation via Cloud Computing Solutions and have excelled in Successful Deliveries of NetSuite Solutions.

We are globally recognized for our proven track records, innovative approach, and commitment to technology enhancements.

For more details, write to us at [email protected] Or Schedule A Demo

#netsuite erp#netsuite manufacturing#Advanced NetSuite Manufacturing#netsuite#Digital Transformation

0 notes

Text

AI in Beverage Manufacturing: Revolutionizing Production with Matt Britton's Expert Insights

In the rapidly evolving landscape of beverage manufacturing, the infusion of artificial intelligence (AI) is not just a trend; it's a revolutionary pathway to enhancing production efficiency and elevating consumer satisfaction. As industries globally embrace digital transformation, understanding the potential and application of AI in this sector becomes crucial. Enter Matt Britton, a renowned AI expert speaker and the visionary Founder & CEO of the consumer research platform, Suzy. With his extensive background consulting for over half of the Fortune 500 companies and his insights into new consumer trends as detailed in his bestselling book "YouthNation," Britton stands out as a top keynote speaker, particularly in the realm of AI applications in various industries.

The Expertise of Matt Britton

Matt Britton has carved a niche as one of the top conference speakers, especially on topics related to AI and consumer trends. His experience at Suzy, a platform that harnesses real-time consumer insights to help companies make better, faster decisions, underscores his deep understanding of how data and AI can transform business operations and consumer interactions. Britton's role as a consultant for a vast array of Fortune 500 companies has equipped him with unique perspectives on leveraging technology to drive business success, making him a sought-after AI keynote speaker and innovation speaker.

AI in Beverage Manufacturing: A Game Changer

The integration of AI in beverage manufacturing is not just about automating processes; it’s about transforming them. AI technologies can predict maintenance needs, optimize supply chains, personalize customer experiences, and much more. In his speeches, Britton often emphasizes how AI can significantly reduce downtime and enhance production efficiency, which are critical factors for success in the fast-paced beverage industry. Whether discussing smart sensors that monitor equipment health or AI algorithms that adjust recipes based on real-time consumer feedback, Britton delivers insights that are both actionable and thought-provoking.

Enhancing Production Efficiency

One of the key benefits of AI in beverage manufacturing, as Britton might elaborate in his keynote speeches, is the dramatic improvement in production efficiency. AI systems can analyze vast amounts of data to optimize production schedules and maintenance routines, reducing waste and increasing throughput. For instance, AI can foresee equipment failures before they occur, allowing for preventative maintenance that minimizes unplanned downtime—a major cost in manufacturing.

Boosting Consumer Satisfaction

As a consumer trend expert, Britton is adept at linking technology applications with consumer expectations. In the beverage industry, consumer satisfaction hinges on consistency, quality, and innovation. AI helps brands tailor their products to meet evolving tastes and preferences. Through predictive analytics, manufacturers can anticipate trends and adjust their offerings accordingly. Moreover, AI-enabled personalization allows for creating customized beverages, enhancing the consumer experience and fostering brand loyalty.

Case Studies and Statistics

In his role as an AI expert speaker, Britton often incorporates relevant case studies and statistics that highlight the successes and lessons from AI implementations in the industry. These might include examples of beverage companies that have successfully integrated AI to optimize their supply chains, reduce energy consumption, or enhance product quality. Such real-world examples not only lend credibility to his talks but also provide attendees with a clear vision of what AI can achieve.

Future Trends and Generation Z

Understanding the preferences of younger generations is crucial for the future of any consumer-facing industry. As a Generation Z expert, Britton sheds light on how this demographic's preferences will shape the future of beverage consumption. Sustainability, customization, and health are key trends among these consumers, and AI is pivotal in addressing these areas effectively. By predicting and adapting to these trends, beverage manufacturers can position themselves favorably in a competitive market.

Conclusion

For stakeholders in the beverage manufacturing industry, gaining insights from an AI keynote speaker like Matt Britton can be incredibly beneficial. His unique blend of expertise in AI, consumer trends, and strategic consulting provides a comprehensive overview of how AI can be effectively utilized to not only streamline production but also enhance consumer engagement and satisfaction.

By choosing Matt Britton as a speaker for your next conference, you not only get an expert who can demystify AI and its applications but also a visionary who can inspire your team to embrace these technologies to future-proof your operations. His engaging delivery and profound insights make him one of the top keynote speakers in the field, particularly for industries looking to leverage AI for substantial growth and innovation.

#beverage manufacturing#artificial intelligence#consumer satisfaction#AI applications#digital transformation

0 notes

Text

Innovate and Excel: Unlocking the Potential of ERPNext Manufacturing with Sigzen.

Welcome to ERPNext Manufacturing, where innovation meets excellence in real-time. As an ERPNext expert, I’m excited to guide you through how this solution transforms manufacturing operations. In today’s fast-paced market, businesses need to streamline processes and deliver quality products efficiently. ERPNext Manufacturing offers a comprehensive solution to integrate all aspects of manufacturing…

View On WordPress

#Agile Manufacturing#Automation Solutions#Digital Transformation#ERPNext#Lean Manufacturing#Manufacturing#ProcessOptimization#Quality Control#Technology Integration

0 notes

Text

The Impact of Digital Transformation on Business Consulting in Ahmedabad

D&V Business consulting in Ahmedabad has seen a significant transformation with the rise of digital technologies in recent years. As companies try to stay competitive in today’s quickly changing marketplace, the need for operational excellence consultants has become more crucial than ever before.

One of the key areas where digital transformation has had a profound impact on Business consulting in Ahmedabad is in the field of lean management.

0 notes

Text

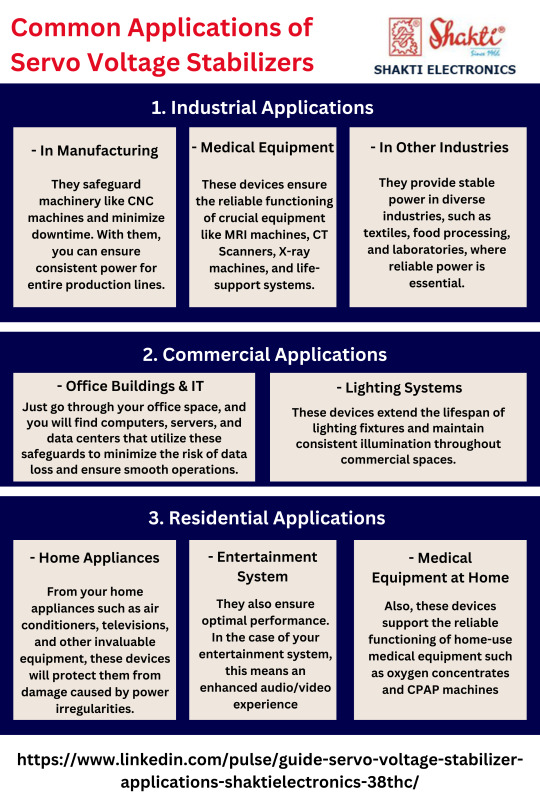

Guide for Servo Voltage Stabilizer Applications

We live in a world that is heavily dependent on electronic appliances. Just look around, and you are sure to find several devices that are hooked to a power supply. You cannot even imagine your life without these appliances.

Source Link: https://www.linkedin.com/pulse/guide-servo-voltage-stabilizer-applications-shaktielectronics-38thc/

#servo voltage stabilizers#isolation transformer#digital stabilizers manufacturer#voltage stabilizer#transformer#voltagestabilizers

0 notes

Text

Why do Manufacturers need a Digital Transformation Strategy?

#Digital transformation company#digital transformation#Digital transformation in manufacturing#digital business transformation#tech solutions#digital transformation solutions

0 notes

Text

how to bring a digital transformation to your manufacturing business? What are some typical pitfalls you should be aware of? Let's take a look at it

#manufacturing automation in Australia#Industry 4.0 solutions#Digital transformation in manufacturing

0 notes

Text

Data-driven assessment is based on the analysis and interpretation of data to guide strategic business decisions that align with the goals, objectives, and initiatives of a company. It is an evidence-based approach that relies on data to make informed decisions. According to IDC, the global data is growing from 45 zettabytes in 2019 to an estimated 175 zettabytes by 2025! Backed by data, everyone in the company can be empowered to innovate and work on new ideas.

#data driven assessments#digital transformation for manufacturing#digital transformation manufacturing industry

0 notes

Text

In the transformative era of Industry 4.0, the Internet of Things (IoT) stands as a crucial catalyst reshaping the manufacturing industry. The implementation of IoT in manufacturing has facilitated the adoption of digital technologies like cloud computing and Big Data, creating a seamless integration that enhances operational efficiency and productivity. IoT has revolutionized data utilization, communication, and operational practices across industries. This evolution has given rise to the Industrial Internet of Things (IIoT), marking a significant shift in manufacturing operations. With a persistent drive to enhance productivity, efficiency, and cost-effectiveness, the manufacturing sector increasingly relies on IoT as a promising solution to address these ongoing challenges.

0 notes

Text

Go digital with GetOnCRM Solutions' expertise and redefine your manufacturing success! Boost sales, customer satisfaction, and innovation with Salesforce's advanced tools.

#crm#salesforce#technology#crm solution#salesforce partner#manufacturing#digital transformation#getoncrm

0 notes