#concreteblocks

Text

Interlocking Blocks Machine in Odisha

Interlocking Blocks Machine in Odisha:

Akshar Precast Industries:

We "Akshar Precast Industries" are a leading Manufacturer of Semi Automatic Fly Ash Brick machines, Manual Bricks Making Machines, Block Making Machines, Paver Block Vibrating tables, Cement Brick Making machines, and other products.

An interlocking blocks machine serves the purpose of creating interlocking blocks, which find application in construction, landscaping, and various other uses. The machine works by pouring concrete into a mold, vibrating the mold to compact the concrete, and then cutting the blocks to size. Subsequently, the blocks are allowed to cure before utilization.

Interlocking block machines come in a variety of sizes and capacities. The smallest machines can make a few blocks per hour, while the largest machines can make thousands of blocks per hour. The machines can be either automated or manual as well. Automated machines are more expensive, but they can produce blocks more quickly and with less labor.

Interlocking block machines are versatile tools that can be used to create a variety of structures. They are a popular choice for building retaining walls, patios, and walkways. They also find usage in landscaping for crafting borders, flower beds, and other features.

Here are some of the benefits of using interlocking blocks machines:

Fast and efficient. A machine can produce a lot of blocks in a short amount of time.

Accurate. The machine can cut the blocks to the exact specifications.

Consistent. The blocks produced by the machine are all the same size and shape.

Strong. Manufacturers create interlocking blocks from concrete, a robust and durable material.

Versatile. Interlocking blocks have the potential for use in a variety of applications.

We provide Interlocking Blocks machine in Odisha Including Bhubaneswar, Cuttack, Rourkela, Berhampur, Sambalpur, Puri, Balasore, Bhadrak, and Baripada. #AksharPrecastIndustries #InterlockingBlocksMachine #Odisha #ConstructionEquipment #LandscapingSolutions #ConcreteBlocks #EfficientMachines #AutomatedTechnology #VersatileApplications #DurableMaterial #BuildingInnovations #PreciseBlockProduction #EnhanceLandscapes #StrongAndAccurate #QuickBlockMaking #BuildingWithConcrete #ReliableManufacturer #BuildingSolutions #OdishaCities

Read the full article

#Balasore#Bhubaneswar#ConcreteBlocks#InterlockingBlocksMachine#Manufacturer#Odisha#Pourkela#Puri#Supplier

0 notes

Text

Unveiling the True Cost of QT4-18 Brick Machine: Raytone Machinery

Dive into the cost breakdown of Raytone Machinery's QT4-18 brick machine in China and understand the value proposition it offers. Explore the features, performance, and maintenance cost of the machine to help make informed decisions about investing in it for your brick-making needs.

#ChinaBlockMachine#BlockMachine#ConstructionMachinery#ConcreteBlocks#BrickMakingMachine#QT425#QT420#QT4-18#HydraulicMachine#BuildingMaterials#BlockMaking#ConstructionIndustry#ChinaManufacturing#IndustrialEquipment#Productivity#Efficiency#Innovation#RaytoneMachinery#BuildingABetterFuture

0 notes

Text

Best Concrete Block Suppliers Manufacturers Wholesaler in Rajasthan - Swastik Dynamic

Find the best Concrete Block Manufacturers Suppliers Wholesaler exporters in Rajasthan. Swastik Dynamic provides latest Concrete Blocks at wholesale price in Rajasthan.

0 notes

Text

Diverse types of Cement Blocks for Construction in India

In this contemporary era, buildings are sprawling in all the places even the remotest places of every town. Commercial buildings, schools, health care centres, apartments and so on. In such a scenario construction business is in high demand, to cater and fulfil to such demands.

The basic construction materials required are cement, steel, bricks, sand, ready mix and so on. Any material employed in building construction has to be selected cautiously to ensure the security and longevity of the building. SD conmix is the best in quality when it comes to concrete blocks.

Cement blocks are concrete blocks that are prefabricated materials mainly used to build walls. Like bricks, the blocks are stacked together and joined with a mortar, consisting of cement, sand and water.

Most of the cement blocks are used in the construction of the walls which protect from strong winds, they can also be used for garden walls, planters, foundations of the building and firepits.

Cement blocks or the concrete blocks are of many types eg

1 Cement bricks

2 Aerated autoclaved concrete blocks

3 Hollow concrete blocks

4 solid concrete blocks

5 Lintel blocks

6 Jamb concrete blocks

7 Concrete pillar blocks

8 Concrete stretcher blocks

The full cement bricks look like grey bricks but are typically large they are used to build walls. Aerated autoclaved blocks are preferable because of their light weight and resistance of high degree of sound and temperature resistance. Hollow bricks are usually manufactured using lightweight aggregates with a certain design load depending on where it is used. Solid concrete blocks are denser and bigger than concrete bricks, they are strong and load-bearing in nature. Lintel blocks are used in the preparation of the lintel frameworks. Jamb concrete is made with a shallow groove across the two holes and a deeper groove at one end. They are often used specifically in double-hung windows. Concrete pillar blocks as the name imply are used to build pillars or piers. Concrete stretcher blocks are used to combine masonry units in construction concerning its look. Their faces are laid parallel to the walls face.

Different types of concrete blocks are designed for different places in structure, SD conmix is the best when it comes to concrete blocks.

0 notes

Link

Do you need to buy concrete blocks for a construction project?DBS Ghana is a leading manufacturer of concrete blocks in Ghana. We have high-quality hollow blocks at reasonable prices. Call us to speak with a construction expert.

0 notes

Text

2 notes

·

View notes

Text

PRS1200 Concrete Block Machine Installation Process

⚙️ High-capacity machine

⚙️ Fully automatic batching system

⚙️ Fully automatic machine with easy maintenance

📲 +90 549 325 6670

#startupbusiness#PRS#concrete#concreteblock#concreteblockmachine#blockmachine#construction#africa#turkish#turkishgoods#madeinturkey

0 notes

Text

#concrete#concreteblock#concreteblockmachine#blockmakingmachine#concretebatching#concretebatchingplant#batchingplant#concreteplant#hollowblock#BurkinaFaso#turkishmade#turkish#turkey#africa

0 notes

Text

Make your new home strong and sustainable with Brikolite AAC Blocks. We provide you with the best materials for your construction needs. Whether you’re looking for a modern look or an eco-friendly option, our AAC blocks are perfect for any project. With their strength and durability, they’ll last for years to come! Get started on the journey to your dream home today!

0 notes

Photo

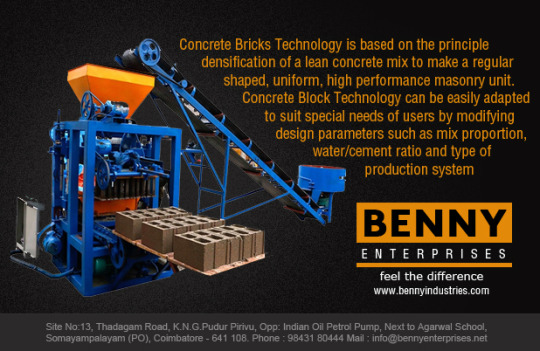

Concrete Bricks Technology is based on the principle of densification of a lean concrete mix to make a regular shaped, uniform, high performance masonry unit. Concrete Block Technology can be easily adapted to suit special needs of users by modifying design parameters such as mix proportion, water/cement ratio and type of production system.

For more details:-

Contact: 9843180444

Visit: https://www.bennyindustries.com/

0 notes

Text

🚀 Say Goodbye to Slow Setting and Poor Workability! 🏗️

Are you tired of dealing with concrete mixes that take forever to set? 😩 Struggling with low workability that makes it a nightmare to work with?

Presenting CERA Plast CT 20 - The Ultimate Solution for All Your Concrete Woes! 💯

This high-performance admixture is a game-changer for concrete block production. 🌟 It combines the power of an accelerator and superplasticizer, delivering unparalleled results.

⚡ Advantages at a Glance:

✅ Ideal for early de-molding, saving you time and effort

✅ Excellent reduction in permeability for durable structures

✅ Superior plasticizing for improved workability

✅ Produces dense and homogeneous concrete

✅ Accelerates setting time for faster production

✅ Perfect for cement concrete block manufacturing

Don't settle for subpar admixture products any longer! 🚫 Elevate your construction game with CERA Plast CT 20. 🏆

Call us at: 98404 80307

Email: [email protected]

#CERAPLastCT20 #AcceleratingAdmixture #SuperplasticizedConcrete #CementMortar #ConcreteBlocks #EarlyDemolding #ImprovedWorkability #DurableConcrete #ConstructionChemicals #CERACHEM #pavarblocks #admixtures #tileadhesive #constructionchemicals #constructioncompany #buildingmaterials

0 notes

Text

The ACC Concrete bricks are built to make your home stand firm in all weather conditions

✅ Highly Durable and sustainable

We are authorised manufacturers for ACC's Green Building Centre for Ludhiana, Nawanshahr, Phagwara, Jalandhar and Kapurthala.

Contact: 98550-07686

#construction#concreteblocks#concretebricks#manufacturer#builders#constructor#ACCcement#ACCBlock#civilengineering#indianarchitecture#blocks#buildingmaterials#contractor#concrete#architecture

0 notes

Text

Raytone Machinary's QT4-25: Building a Better South Africa with Concrete Bricks Machine

Rayton’s machinery's QT4-25 Concrete Brick Machine is a game-changer for South Africa's construction industry, offering high production capacity and versatile capabilities for various types of blocks. Upgrade your construction capabilities today.

#ChinaBlockMachine#BlockMachine#ConstructionMachinery#ConcreteBlocks#BrickMakingMachine#QT425#QT420#QT240#HydraulicMachine#BuildingMaterials#BlockMaking#ConstructionIndustry#ChinaManufacturing#IndustrialEquipment#Productivity#Efficiency#Innovation#RaytoneMachinery#BuildingABetterFuture

0 notes

Text

Concrete Block Making Machine KAD1500

This movable Concrete Block Making Machines is also capable to produce different kinds of Hollow block, wall block, partition block by using sand, pumice, leca.

This Automatic system has loader and silo. The mould and matrix (shoulder) are moved by jacks. It consist of a loader which can do the action of feeding the moulds automatically.

In silo section, the concrete feeding action is not performed manually. In every feeding time, it can produce 142 blocks. All the process such as filling the mould, feeding action and running around in the production band are done automatically.

The role of human resources is very low and the system is able to do the production process just by one person to change the mould.

This movable machine has also controlling part, eight set of curbstone mould, six set of block mould with one electro-vibration and two hydraulic vibration, which simultaneously carry out the vibrating and hydraulic press. Maximum used surface in moulds is 126*100 cm (20, 30 H).

website: Https://safayimachinery.com

Whatsapp: +989142002834

#hollowblock #concreteblock #cementblock

1 note

·

View note

Text

Various types of Concrete blocks used in Construction

SD Conmix manufactures two types of Concrete blocks used in Construction; namely, Solid and Hollow. These Concrete blocks are usually used in the construction of walls as well as other construction purposes.

Solid concrete blocks are not entirely solid compared to hollow ones. They are frequently used for strong manufacturing. It provides longer structure stability and is bigger when compared to bricks. Solid Concrete appears as solid grey bricks.

One tends to get confused between concrete blocks and cement blocks.

Cement blocks are made of the following materials-

Clay powder, limestone, and other substances mixed with water.

Concrete is made of cement which is an ingredient used in its manufacturing process. Other materials include sand, stone, and gravel.

Various types of Concrete blocks used in Construction

Concrete blocks are classified based on their size, shape, and manufacturing process.

Concrete blocks are mainly classified into 2 types namely,

Solid concrete blocks

Hollow concrete Blocks

Solid Concrete Blocks

Solid concrete blocks also called Concrete Masonry Units are in common use.

They are heavy, manufactured from dense aggregate and are highly strong.

As they provide good stability to the structures, this type of Concrete blocks are used in Construction for large works of masonry such as load-bearing walls.

These solid blocks are most preferable as they are available in large sizes compared to bricks. The advantages of large Solid Concrete Blocks are, it saves time during construction.

Hollow Concrete Blocks

Hollow concrete blocks are formed when the void area is greater than 25% of the gross area, and the solid area is supposed to be more than 50%. Based on the construction requirement the hollow part may be split into several components. These concrete blocks are lightweight and can be easily installed.

The various types of Hollow Concrete Blocks include :

Stretcher block

Bull nose block

Corner block

Frogged brick block

Jamb block

Lintel block

Pillar block

Partition block

SD Conmix has a separate unit that is widely spread and entirely dedicated to manufacturing strong and durable concrete blocks and other substances. It has an automatic batching unit that is well-equipped with accurate weighing scales with minor variations. Our manufacturing unit is fitted with a moisture probe device. This device monitors the water content in batching quantity and ensures the desired water-cement ratio. Every batch quantity at SD Conmix is examined under rigorous compressive strength checks regularly. The manufacturing process is very efficient and always ensures that consistent quality is maintained and raw materials are being checked extensively.

The concrete blocks unit of SD Conmix has a highly-equipped laboratory that is backed by the advanced and latest technology. Our extensive manufacturing process includes raw materials source identification and the concrete block unit is capable of easily manufacturing thousands of blocks daily. This enables us to supply and accomplish the needs of multiple clients; thereby, servicing big projects simultaneously.

SD Conmix offers a wide range of products and services. Our products include Hollow Concrete Block, Ready Mix Concrete (RMC),sealants etc.

0 notes

Photo

Do you need to buy concrete blocks for a construction project? DBS Ghana is a leading manufacturer of concrete blocks in Ghana. We have high-quality hollow blocks at reasonable prices. Call us to speak with a construction expert.

0 notes