#commodity polymers

Text

Sun Polymer: Shaping the Future of Chennai's Polymer Industry! Discover how this local gem is revolutionizing the sector with innovation, quality, and sustainability. Dive into the journey of excellence that's putting Chennai on the global polymer map.

0 notes

Link

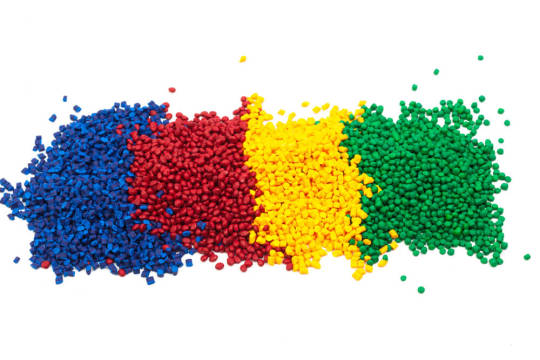

The complete range of commodity polymers in PP, PE & PVC grades is readily available at Kapoor Sales Corporation. The top-ranking Commodity Polymers distributor has a complete variety of LLDPE, LDPE, HDPE, Random copolymer, Homopolymer etc.

0 notes

Text

Understanding Commodity Plastic: Basics and Applications

Commodity plastic is a term frequently used in the plastics industry to refer to a group of plastics that are produced on a large scale and used in a wide range of applications. Understanding the basics of commodity plastic, including its properties and applications, is essential for anyone involved in the manufacturing or use of plastic products.

Exploring the Basics of Commodity Plastic:

Definition and Characteristics: Commodity Plastic refers to a category of plastics that are produced in high volumes and have relatively low costs compared to engineering plastics or specialty plastics. These plastics are characterized by their versatility, durability, and ease of processing, making them ideal for a variety of applications.

Common Types of Commodity Plastics: Some of the most common types of commodity plastics include polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), and polyethylene terephthalate (PET). Each type of commodity plastic has its own unique properties and applications, ranging from packaging materials to consumer goods.

Applications of Commodity Plastic:

Packaging: One of the largest applications of commodity plastic is in packaging materials. Polyethylene and polypropylene, in particular, are widely used for manufacturing plastic bags, bottles, containers, and packaging films due to their excellent barrier properties and flexibility.

Consumer Goods: Commodity plastic is also commonly found in a wide range of consumer goods, including household items, toys, kitchenware, and electronics. Polystyrene, for example, is used to make disposable cups, plates, and food containers, while polyvinyl chloride is used in the production of vinyl flooring and window frames.

Construction Materials: In the construction industry, commodity plastic is used for manufacturing a variety of materials, such as pipes, fittings, insulation, and siding. PVC, in particular, is a popular choice for plumbing and drainage systems due to its corrosion resistance and affordability.

Automotive Components: Commodity plastics play a vital role in the automotive industry, where they are used for manufacturing interior and exterior components, such as dashboards, bumpers, trim panels, and seating. Polypropylene, with its lightweight and impact-resistant properties, is a common choice for automotive applications.

Commodity plastic is a versatile and widely used material that plays a crucial role in various industries and applications. Understanding the basics of commodity plastic, including its properties and applications, is essential for manufacturers, designers, and consumers alike. By recognizing the versatility and value of commodity plastic, we can continue to innovate and create sustainable solutions for the future.

Get More Insights On This Topic: Commodity Plastic

#Commodity Plastic#Polymer#Petrochemical#Packaging Material#Plastic Production#Consumer Goods#Thermoplastic#Industrial Applications

0 notes

Text

Drilling Starch Ahmedabad | PHPA Chemical Ahmedabad - Chem Fert Chemicals

Drilling starch exporter Ahmedabad, Gujarat, India - Searching for the PHPA chemical & PAC LV Importer and Traders? Chemfert Chemicals is leading Water Treatment chemicals Suppliers Ahmedabad, Gujarat, Polymer for pilling india, PHPA chemical exporter and Drilling Starch suppliers in Ahmedabad, Gujarat, India. Organphilic clay Supplier, Construction Chemicals Supplier Ahmedabad, Gujarat, india, Cloud point glycol Supplier, Commodity Chemicals Supplier in Ahmedabad, Gujarat, Best water treatment chemicals suppliers near me in Ahmedabad.

Drilling Starch, PHPA chemical & PAC LV Importer and Trader india, Polymer for pilling Supplier, Organphilic clay Supplier, Construction Chemicals Supplier Ahmedabad, Gujarat, Cloud point glycol Supplier India, Commodity Chemicals Supplier, Water treatment chemicals Suppliers Ahmedabad, Gujarat, India, www.chemfertchemicals.com, Chem Fert Chemicals

#Drilling Starch#PHPA chemical & PAC LV Importer and Trader india#Polymer for pilling Supplier#Organphilic clay SupplierConstruction Chemicals Supplier Ahmedabad#Gujarat#Cloud point glycol Supplier India#Commodity Chemicals Supplier#Water treatment chemicals Suppliers Ahmedabad#India#www.chemfertchemicals.com#Chem Fert Chemicals

0 notes

Note

���!

aw yeah more

True plastic is actually super uncommon and is a rare commodity in The Murderbot Diaries universe. This is because plastic proper is made from petroleum oil, which only exists due to a specific millions-of-years-long history of life and death and decomposition on Earth. It's not at all common throughout the galaxy.

Common creating materials instead include paper, glass, bamboo, metal, clay, and from-the-ground-up molecularly synthesized polymers.

#asks#anonymous#The Murderbot Diaries#recyclers print things by mixing molecules from pre-loaded stores into patterns#It always feels very synthetic#check out all the other hc's I wrote last night at midnight also

54 notes

·

View notes

Text

New technique can capture or reuse CO2 as a chemical source for the production of sustainable plastics

A team led by chemists at the University of Liège has developed a new polyurethane production technique using CO2 to create new types of easily recyclable plastics. The study, published in the Journal of the American Chemistry Society, could provide a solution for the development of truly sustainable plastics.

Commodity plastics have transformed global industry. Whether in construction, clothing, vehicles or food packaging, these plastics are everywhere in our daily lives, so much so that their global use has been estimated at around 460 million tons in 2019.

"This number is staggering, but not surprising, because plastics, also known as synthetic polymers, have met a large success thanks to their irreplaceable characteristics: they are light, cheap and incredibly versatile," explains Christophe Detrembleur, chemist at the Center for Education and Research on Macromolecules (CERM) of the University of Liège. "However, the fact that they are difficult to recycle, or even impossible to recycle in the case of thermosets, has serious consequences."

Read more.

#Materials Science#Science#Carbon dioxide#Plastics#Polymers#Materials processing#Recycling#University of Liege

15 notes

·

View notes

Text

How Drag Reducing Agent Chemicals Improve Pipeline Efficiency and Save Costs

Pipelines are of utmost importance in the realm of oil and gas transportation as they facilitate the movement of substantial amounts of these valuable commodities from producing sites to refineries and end-users. Nevertheless, the transportation of these fluids over extended distances presents various obstacles, such as the occurrence of frictional losses, heightened energy consumption, and escalated operational expenses. In order to address these difficulties and enhance the efficiency of pipelines, the industry has resorted to the utilisation of drag reduction agent (DRA) chemicals. Experience seamless flow with advanced solutions offered by Imperial Oilfield Chemicals – one of the leading Drag reducing agent chemical manufacturers in India.

This blog post aims to examine the mechanisms of action of DRA compounds, elucidate their advantages, and analyse their role in generating substantial financial savings.

Understanding Drag in Pipelines:

When a fluid traverses a pipeline, it encounters friction with the inner surface of the pipe, resulting in resistance and subsequent pressure reductions. The phenomenon of resistance, sometimes referred to as "drag," is responsible for a reduction in the velocity of fluid flow, an increase in the energy required for pumping, and an elevation in overall energy consumption. The magnitude of drag is contingent upon the characteristics of the fluid, the dimensions of the pipeline, and the velocity of the flow. In the context of hydrocarbon transportation pipes, the phenomenon of drag can result in a reduction in pressure, necessitating the allocation of additional pumping energy to sustain the required flow rate.

Enter Drag Reducing Agents (DRA):

Drag Reducing Agents (DRA) refer to a specific category of chemical compounds that are intentionally introduced into the fluid stream in order to reduce the drag experienced within pipelines. Drag reduction agents (DRAs) have been found to be remarkably efficient in mitigating frictional losses, hence facilitating enhanced fluid flow within pipelines. These devices function through the manipulation of fluid dynamics, resulting in a favourable flow condition characterised by reduced turbulence and diminished presence of eddies and swirls within the fluid flow.

How Drag Reducing Agents Work?

DRA molecules operate at the molecular scale and are commonly characterised by their elongated polymer structure. Upon introduction into the pipeline fluid, these polymers undergo alignment in the direction of flow, resulting in the formation of a protective layer that minimises the interaction between the fluid and the inner surface of the pipe. This phenomenon leads to a decrease in wall shear stress and turbulence, leading to a corresponding reduction in frictional and pressure losses. Consequently, the fluid is able to traverse the pipeline with diminished resistance, thereby sustaining an elevated flow rate and necessitating a reduced amount of pumping power.

Benefits of Using Drag Reducing Agents:

Enhanced Pipeline Efficiency: Through the reduction of drag and frictional losses, the utilisation of Drag Reducing Agents (DRAs) substantially enhances the overall efficiency of the pipeline. The augmented flow rate results in enhanced throughput and decreased transit durations for the conveyed fluids. Maximize flow capacity, trust expertly formulated Drag reducing agent chemical in Vadodara offered by Imperial Oilfield Chemicals!

Energy Savings: By minimising resistance, the pumping demands are decreased, leading to significant energy conservation. The use of energy-efficient practices in operations has a beneficial effect on the environment by contributing to the mitigation of greenhouse gas emissions.

Extended Pipeline Lifespan: The extension of the pipeline lifespan can be attributed to the reduction in friction and turbulence, which subsequently results in less stress on the inner walls of the pipeline. This reduction in stress contributes to the prolonged operational life of the pipeline and then leads to a reduction in associated maintenance costs.

Cost Savings: Cost savings can be achieved through the combined advantages of enhanced efficiency and energy conservation, resulting in direct reductions in expenses. Operators have the ability to enhance the cost-effectiveness of hydrocarbon and fluid transportation by employing Drag Reducing Agents (DRAs).

Enhanced Safety: DRAs also contribute to improved safety through the mitigation of pressure variations and the reduction of the potential for pipeline instability, hence mitigating the danger of accidents or failures.

Implementing DRA Solutions:

The process of incorporating DRA solutions into pre-existing pipeline systems is a very uncomplicated endeavour. Chemical substances are introduced into the pipeline at designated locations, and their quantity can be modified according to the flow rates and specific attributes of the pipeline. The flexibility provided enables operators to customise the DRA treatment according to the specific requirements of each pipeline, hence optimising the advantages derived from it.

Final Thoughts:

The implementation of Drag Reducing Agent (DRA) chemicals proves to be a viable strategy for enhancing pipeline efficiency, mitigating operational expenses, and bolstering safety measures during the transit of hydrocarbons and various fluids. Through the process of minimising drag and frictional losses, Drag Reducing Agents (DRAs) effectively optimise flow rates, minimise energy consumption, and enhance the longevity of pipelines.

The execution of this strategy has a mutually beneficial outcome for both pipeline operators and the environment, as it effectively encourages the adoption of sustainable practices and responsible transportation of resources. With the continuous advancement of technology, it is anticipated that the oil and gas industry will witness the emergence of increasingly inventive approaches to enhance pipeline operations and further mitigate the environmental impact associated with carbon emissions. To enhance your pipeline lifespan, get innovative Drag Reducing Agents manufactured and supplied by Imperial Oilfield Chemicals - one of the best Drag reducing agent manufacturers in Vadodara for long-term performance!

#Drag Reducing Agent Chemical Manufacturers India#Drag Reducing Agent Chemical in Vadodara#drag reducing agent manufacturers Vadodara

6 notes

·

View notes

Text

BALDUR’S GATE THREE RELEVANT CANON FOR THIS BLOG from the DESCENT TO AVERNUS MODULE!

first and foremost. baldur’s gate is ruled of a council of four—three dukes and one grandduke. the frandduke has two votes, as opposed to the other dukes one. the dukes are all ELECTED officials, that have to campaign. ulder became grand duke seven years ago, when wyll was seventeen, shortly before wyll was banished after hearing the voice of zariel telling him to go fight the tiamut cultists. more on tiamut later.

dukes can start out in poverty and labor their whole life to get where they are, this is true of both vanthampur AND ulder.

the dukes are: ulder. he was elected as grand duke bc of idealism, both from the nobility and the common people. he would be tough on crime, good for business, good for PEOPLE. he genuinely seems to believe in baldurs gate and see the good in it despite it being incredibly shitty, and he passed that down to his son.

vanthampur, who is evil n the reason duke ravengard got sent to hell n came back hellstouched. they have three weird kids who all suck. she is part of the reason zariel is about to take over bg, she used to work on the sewers. vanthampur is actually the one funding the dead three cultists to make everyone lose faith in the flaming fists. which leads to the events of this game p well tbh

stelmane, who dies before the events of the game but after elturel fell. she was fucking the emperor.

and polymer, who is a useless ineffiecent kind of lazy old man.

there are FIFTY members of the parliment of peers, these are all members of noble families called “patriars”. some noble families are rich, some noble families are poor, all the noble families have manors, each of them has a dozen servants. real estate is a heavy commodity and a marker of power and status. some families sell al their furniture, just to keep their family manor.

the ONLY patriar family that is non-human is a swarven family that goesss allll the way back to them BUILDING the gate, they are incredibly human centric despite having a hugely diverse population. they sayin the book theres no discrimination against you for your fantasy race—but also, you are just? not going to have power?

the watch protects the upper city, they act in the interests of the nobles and their capital. the nobles are all corrupt or expected to be corrupt publically—they go to ballrooms, they go to theater, they go to bathhouses with sex workers, they do shady dealings. the best of them hire vigilantes and “arrange for things to be stolen from them to give to charity without losing face as that is actively dangerous.” the best of them also end up dead in the lower city.

common people have to pay tolls to get into the upper city and theres a curfew just to humilaite them, its enforced with violence and shaming. there are select nobles, weirdos, who like to keep commonfolk therempast curfew just to toy with them sadistically at bdsm horror parties and the like under the guise of “potentially helping their station in politics.”

the flaming fist are fucking AWFUL, they “protect” the lower city, but theyre all corrupt, they will BEAT PEOPLE IN THE STREETS, they all take bribes, they are completely incompetent and distracted and useless without ulder. anyone cam be a flaming fist as long as they have a sword, no bg checks really

ulder is a good a dude ad a guy in charge of these people can be, but between you and me, he’s entirely delusional, he actually believes baldur’s gate is a good place and balduran was a hero. baldur’s gate was NEVER good, it was started by balduran tossing coin at a bunch of thieves and pirates who would pretend to be lighthouses just to crash ships on the shore and then STEAL FROM THEM. then it became a shitty little pieate town full of corrupt bastards and murderers.

and yet there is still so much magic here!

theres the many different religions, hospitals, cultists, a cemeteary like a labyrinth, a park run by a druid. the elfsong tavern actually has a disembodied voice of an elf si ging there and everyone will stoo and listen to this elf si g n no one knows what its about! the shar cultists give food to the needy!

but also every profession imaginable has a union, from “the reputable guild of moneylenders” to the “wonderous weavers.”

theres everything u can imagine can be bought and sold

animals arent allowed in bg if theyre “bigger than a peacock” but that just means now people are OBSESSED WITH THE ILLEGAL TRADE OF PEACOCKS!

bg is in direct opposition with amnh, another city=/area on the coastal council, but everyone has bg’s back every time amnh says they should get rid of them.

elturel is a lawful good holy city, so of course they hate the rotten chaotic evil city for bastards

the paper is called baldur’s mouth and it accepts bribes but it really gets into the city’s darker underdealings

the favorite game of everyone in the city is called baldur’s bones and it’s just dice lol u throw dice

zariel took over elturel n baldurs gate is next unless beave people descend to avernus and stop her with the sword of zariel. the high overseer who sold elturel out is probably still hiding at vanthampur’s villa whole their HUNDREDS of victims wait outside

more on that some other time, perhaps

1 note

·

View note

Text

In Saint-Léon close to Bordeaux is located a “laboratory” that gives new life to plastic waste

At the crossroads of contemporary design and the circular economy, the Plastiquerie manufactures sustainable furniture from recycled plastic.

So what do the big yellow and blue bags from Ikea or the construction helmets from the manufacturer Vinci have in common? They are made of a plastic material that can be recycled to make new objects. “Recycled plastic is a material with endless possibilities that I want to make known to designers. It’s a bit like the marble of the Anthropocene”, explains Julie Robert, co-founder of La Plastiquerie [1] based in Saint-Léon[2], about thirty kilometres south-east of Bordeaux.

Shelves, furniture or floor tiles

Since 2021, the independent artistic director has been passionate about this raw material, she has learned the properties of in order to manufacture designer objects and furniture. The association recovers plastic waste in polypropylene (PP)[3], polyethylene (PE)[4] or polystyrene (PS)[5] to give them a second life. “PET[6] waste such as plastic bottles already benefit from recycling solutions. I focus on families of plastics that are still poorly revalued”, she specifies. Protective films, water tubes from construction sites or industry off-cuts from yoghurt pots are thus treated in a 100 m² workshop housed in the premises of the Syndicate of the Entre-deux-Mers-West-region for the Collection and Treatment of Household Waste[7].

There, under a sheet metal shed, a shredder and a hot press transform the collected waste into confetti and then into large recycled plastic plates that will be used to make shelves, furniture or floor tiles. “La Plastiquerie is a laboratory where we develop prototypes of objects resulting from the recovery of plastic. From cans and flowerpots, for example, I imagined a wall light that saves 980 grams of plastic from landfill and incineration,” explains the entrepreneur.

"Companies want to recycle their own waste"

Although the Plastiquerie was co-founded with another woman, Amandine Boutang, Julie Robert now works alone, sometimes helped by an intern and supported by a board of directors, on her experiments with furniture designed in recycled and recyclable plastic. She is thinking about a waste sorting cabinet for the canteen of the Suez[8] headquarters in Occitanie-Nouvelle Aquitaine[9]. For the Bordeaux start-up Arits[10], she is working on the design of a lamp. A bank has also just approached her for an interior design project…

"Companies come naturally to the association because they want to recover their own waste or participate in the circular economy", rejoices the forty-year-old who wants to sharpen her expertise on recycled plastic to convince designers to adopt it. Two years after the launch of her project, Julie Robert draws a positive balance sheet: “I discovered the world of the circular economy where the actors are positive, imaginative people, full of energy and solutions. A world in which a great breath of optimism is sweeping in which I find myself.”

Source

Florence Donnarel, A Saint-Léon, un «laboratoire» pour donner une nouvelle vie aux déchets plastiques, in : Libération, 9-01-2023, https://www.liberation.fr/forums/a-saint-leon-un-laboratoire-pour-donner-une-nouvelle-vie-aux-dechets-plastiques-20230109_72VUV54KQJBBJGALYJ2C2FTORQ/

[1] Plastic is far from fantastic when it comes to recycling. At La Plastiquerie, we collect non-recycled deposits to revalorize them and produce small and medium design series. Its objective: to transform plastic waste into highly desirable objects and furniture! http://www.laplastiquerie.com

[2] Saint-Léon is a commune in the French department of Gironde (Nouvelle-Aquitaine region) and has 242 inhabitants (1999). The place is part of the arrondissement of Bordeaux.

[3] Polypropylene is the second-most widely produced commodity plastic (after polyethylene). In 2019, the global market for polypropylene was worth $126.03 billion.

[4] Polyethylene (generic acronym PE), or polyethene, refers to ethylene polymers. Simple and inexpensive to manufacture, PEs are the most common plastic material, representing with 100 million tonnes, approximately one third of all plastics produced in 20186 and half of packaging.

[5] Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a poor barrier to oxygen and water vapour and has a relatively low melting point.[6] Polystyrene is one of the most widely used plastics, the scale of its production being several million tonnes per year.[7] Polystyrene can be naturally transparent, but can be coloured with colorants. Uses include protective packaging (such as packing peanuts and in the jewel cases used for storage of optical discs such as CDs and occasionally DVDs), containers, lids, bottles, trays, tumblers, disposable cutlery,[6] in the making of models, and as an alternative material for phonograph records.

[6] Polyethylene terephthalate (or poly(ethylene terephthalate), PET, PETE, or the obsolete PETP or PET-P), is the most common thermoplastic polymer resin of the polyester family and is used in fibres for clothing, containers for liquids and foods, and thermoforming for manufacturing, and in combination with glass fibre for engineering resins.

[7] The Syndicat de l'Entre-deux-Mers-Ouest pour la Collecte et le Traitement des Ordures Ménagères (S.E.M.O.C.T.O.M.) (Syndicate of the Entre-deux-Mers-West-region for the Collection and Treatment of Household Waste was created by prefectural decree of January 28, 1980. It is a closed mixed syndicate governed by the General Code of Territorial Communities and therefore a public service. Bordered to the north and south by two rivers (the Garonne and the Dordogne) which gave the name to the territory of "Entre-deux-Mers", it is located to the south-east of the Urban Community of Bordeaux and is covers an area of 666 km². It partially or totally brings together 7 communities of municipalities as well as part of the Libournais urban community (CALI). It brings together 85 municipalities and more than 110,000 inhabitants. https://www.semoctom.com/web/fr/11-semoctom.php#:~:text=Le%20Syndicat%20de%20l%27Entre,et%20donc%20un%20service%20public.

[8] Suez a Belgian-French company known as GDF SUEZ after 2008. The company was split up, and as of 2008, the 1858-created company's spun-off environmental business continued as a separate company under the Suez name.

[9] https://www.suez.fr/fr-fr/nous-connaitre/notre-presence-en-france/occitanie

[10]The Bordeaux-based startup Arits, which manufactures sun, has imagined a brilliant lamp, which illuminates interiors with an unprecedented technology. The company aims to reproduce the entire cycle of the sun at home. From sunrise to sunset, passing through the Zenith or the Golden Hour..https://arits.fr/

2 notes

·

View notes

Text

SAP B1 for Trading & Distribution Industries.

Open a new world of revenue by integrating SAP Business One as your primary trading ERP software. SAP ERP Solutions will help you track and manage inventories in a simplified approach. SAP Business One for the trading company will help you deliver goods on time, enhance customer retention and make optimal use of your inventory.

SAP Business One offers a simple & affordable way to manage your entire trading business from sales and customer relationships to financials and operations. SAP B1 ERP solutions and implementation methods are designed specifically for high-growth companies & help you streamline processes, act on timely information, and accelerate profitable growth.

ERP for Trading Industry

– A Solution for All Trading Businesses

Steel Trading – ERP software for trading companies allows complete business automation when it comes to steel trading businesses. From procurement to import and logistics to dispatch, everything can be managed on one single platform with SAP B1.

Coal Trading & Import – SAP B1 ERP helps the coal trading and import industry automate its operations. Improve Your Cash Flow with real-time business visibility, tracking import and export, as well as procurement of coal from washeries via auction, is made more efficient.

Commodity Trading – ERP for Commodity Trading Industry (Minerals, Paper, Polymers, Plastics, Petroleum, etc.) enables comprehensive product categorization and dynamic inventory controls leading to sustainable business growth and helping to gain greater control over your business.

Exim and International Trade – ERP Provide the latest financial market data to manage timely deliveries, streamline operations, track material handling and optimize logistics.

Agro Commodities Trading – Manage all aspects of your agribusiness industry involving perishable commodities, and hence every business function has a short turnaround time. To support operations and enhance productivity, ERP for trading companies plays an important role.

Heavy Equipment & General Trade – SAP Business One ERP for heavy equipment trading business is designed to digitize core processes such as shipment loading, warehouse management, transportation, and delivery ERP software for trading companies allows complete business automation when it comes to steel trading businesses. From procurement to import and logistics to dispatch, everything can be managed on one single platform from anytime, anywhere.

FEATURES

Financial Management

Sales Management

Customer Relationship Management

Compliance Management

Multi-Currency Management

Warehouse Management

Inventory Management

Net Profit Analysis

Procurement Management

Import and Export Operations

WHY SAP B1 ERP FOR THE TRADING & DISTRIBUTION INDUSTRY

Increased Agility

Real-Time Resources Monitoring

Automated Invoicing And Billing

Synchronized Demand And Supply

Ensured Compliance

Easy Information & Forecasting Analysis

Accurate Analysis And Reports

Improved Return Over Investment

Reduced Inventory Management Costs

Expedited Time To Value

WHY ITOSS SOLUTIONS INDIA PVT LTD

ITOSS Solutions understands the dynamic challenges that companies in the trading and distribution industry face, especially in the areas of sourcing, warehouse management, and multi-currency management, because we have comprehensive knowledge of the industry’s workings. As a result, we’ve taken advantage of SAP Business One’s unrivaled functionality to create solutions that simplify and streamline operations for trading companies, speed up processes, and improve customer satisfaction.

Trading industries deal with selling and purchasing goods in exchange for goods and money. The main practices of trading are inventory management and the sale of inventory to retail stores and consumers. The era’s rationally growing industry needs a software pattern to automate the process. Find out how ITOSS Solutions is enabling trading companies to manage their business functions seamlessly with ERP software for trading business.

#SAP Business One partner#sap business one#SAP Business One Partner in India#SAP Business One ERP Solution#SAP Business One for Manufacturers#ERP Software#best erp software#best erp software in india#erp software for construction#top erp software#erp for trading

2 notes

·

View notes

Text

Sun Polymers: Illuminating the Polymer Industry in India

Introduction:

In the vast landscape of the Indian polymer industry, Sun Polymers stands as a beacon of innovation and excellence. As a prominent player in this dynamic sector, Sun Polymers has been instrumental in shaping the landscape of polymer manufacturing in India. This article delves into the key aspects of the polymer industry in India, highlighting Sun Polymers' contributions and impact.

The Polymer Industry in India:

The polymer industry in India has witnessed remarkable growth in recent years, driven by factors such as increasing urbanization, a burgeoning middle class, and the rise of various end-use industries. Polymer products find extensive applications in packaging, automotive, construction, healthcare, and more. India's polymer market has become a crucial component of the country's economic development.

Sun Polymers: Pioneering Excellence

Sun Polymers has emerged as a key player in the Indian polymer industry, contributing significantly to the sector's advancement. The company's commitment to quality, sustainability, and innovation has set it apart in a competitive market.

State-of-the-Art Manufacturing Facilities:

Sun Polymers boasts cutting-edge manufacturing facilities equipped with the latest technology. These facilities adhere to international quality standards, ensuring that the products meet or exceed customer expectations.

Diverse product portfolio:

The company offers a diverse range of polymer products catering to various industries. From high-performance polymers for automotive applications to specialized polymers for the healthcare sector, Sun Polymers' product portfolio is designed to address the evolving needs of different markets.

Research and Development:

Sun Polymers places a strong emphasis on research and development, constantly pushing the boundaries of polymer science. The company's R&D initiatives focus on developing innovative solutions, improving product performance, and addressing environmental concerns through sustainable practices.

Commitment to Sustainability:

In an era where environmental consciousness is paramount, Sun Polymers is dedicated to sustainable practices. The company invests in eco-friendly production processes, recycling initiatives, and the development of bio-based polymers, contributing to a greener and more sustainable polymer industry in India.

Customer-Centric Approach:

Sun Polymers prioritizes customer satisfaction through a customer-centric approach. The company collaborates closely with clients, understanding their unique requirements and providing tailor-made solutions. This customer-focused strategy has solidified Sun Polymers' reputation as a reliable partner in the polymer industry.

Polymer Industry Trends in India:

In the broader context of the Indian polymer industry, several trends are shaping its trajectory:

Increasing Demand for Biodegradable Polymers:

With growing environmental concerns, there is a rising demand for biodegradable polymers. Sun Polymers, aligning with this trend, has been at the forefront of developing sustainable and eco-friendly polymer solutions.

Technological Advancements:

Rapid technological advancements are influencing the polymer industry, leading to the development of high-performance polymers with enhanced properties. Sun Polymers' commitment to staying technologically updated ensures that its products remain at the forefront of innovation.

Focus on Circular Economy:

The concept of a circular economy, where materials are recycled and reused, is gaining prominence. Sun Polymers actively participates in this paradigm shift by implementing recycling initiatives and exploring ways to minimize environmental impact.

Conclusion:

Sun Polymers' role in shaping the polymer industry in India is both significant and commendable. As the industry continues to evolve, Sun Polymers remains a guiding light, leading the way with its commitment to quality, sustainability, and innovation. In a world that demands responsible and forward-thinking practices, Sun Polymers stands as a testament to the bright future of the polymer industry in India.

0 notes

Photo

Commodity Polymers Distributor

The complete range of commodity polymers in PP, PE & PVC grades is readily available at Kapoor Sales Corporation. The top-ranking Commodity Polymers distributor has a complete variety of LLDPE, LDPE, HDPE, Random copolymer, Homopolymer etc.

0 notes

Text

Poly Methyl Methacrylate Prices, Price Trend, Pricing, News, Analysis & Forecast

Poly Methyl Methacrylate (PMMA) prices have witnessed fluctuations in recent years, influenced by various factors within the global market. PMMA, commonly known as acrylic or acrylic glass, is a versatile polymer extensively utilized in a myriad of applications, ranging from automotive parts to construction materials and consumer goods. Understanding the dynamics behind PMMA pricing entails considering several crucial elements.

Firstly, raw material costs significantly impact PMMA prices. PMMA is derived from methyl methacrylate (MMA), a monomer synthesized from petrochemical sources. Fluctuations in crude oil prices directly affect the cost of MMA production, consequently influencing PMMA prices. Global economic conditions, geopolitical tensions, and supply-demand imbalances further contribute to the volatility in raw material costs, leading to price variations in PMMA.

Moreover, market demand plays a pivotal role in determining PMMA prices. The growing demand for lightweight and durable materials across industries such as automotive, electronics, and construction drives the consumption of PMMA. Technological advancements and shifting consumer preferences towards sustainable and eco-friendly alternatives also impact demand dynamics. Consequently, fluctuations in market demand, influenced by factors like economic growth, industrial trends, and regulatory changes, exert pressure on PMMA prices.

Get Real Time Prices of Gum Rosin: https://www.chemanalyst.com/Pricing-data/polymethyl-methacrylate-50Furthermore, production capacity and supply chain dynamics affect PMMA pricing. PMMA manufacturers must balance production capacities with market demand to avoid oversupply or shortages, which can impact pricing stability. Additionally, disruptions in the supply chain, such as transportation challenges, natural disasters, or geopolitical tensions, can lead to temporary shortages or delays, influencing PMMA prices due to supply-demand imbalances.

Global market trends and regional factors also influence PMMA prices. As a globally traded commodity, PMMA prices are influenced by macroeconomic trends, currency fluctuations, and trade policies. Regional factors, including regulatory frameworks, environmental standards, and industry competitiveness, vary across markets and impact the cost structure of PMMA production, thereby influencing prices in different regions.

Moreover, innovations in manufacturing processes and technological advancements impact PMMA prices. Continuous research and development efforts aim to enhance production efficiency, reduce costs, and improve product performance. Breakthroughs in polymerization techniques, recycling technologies, and material design can influence the cost structure of PMMA production, thereby impacting prices in the long term.

Additionally, environmental and sustainability considerations are increasingly shaping PMMA pricing trends. With growing awareness of environmental issues and regulatory pressure to reduce carbon footprint, manufacturers are investing in sustainable practices and eco-friendly alternatives. The adoption of bio-based feedstocks, recycling initiatives, and energy-efficient manufacturing processes can affect the cost dynamics of PMMA production, ultimately influencing prices.

In conclusion, Poly Methyl Methacrylate (PMMA) prices are subject to a multitude of factors, reflecting the complex interplay between raw material costs, market demand, production dynamics, global trends, technological advancements, and sustainability considerations. Understanding these factors is crucial for stakeholders in the PMMA industry to navigate market dynamics, mitigate risks, and make informed decisions in a rapidly evolving landscape.

Get Real Time Prices of Gum Rosin: https://www.chemanalyst.com/Pricing-data/polymethyl-methacrylate-50

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Innovations in Commodity Plastic: Advancements and Trends

Commodity plastic, long a staple of modern manufacturing, continues to evolve with new innovations, advancements, and trends shaping its usage and applications across various industries.

Biodegradable Plastics: One notable innovation in commodity plastic is the development of biodegradable plastics, which offer a more environmentally friendly alternative to traditional plastics. These plastics are designed to break down into harmless substances when exposed to natural conditions, reducing the environmental impact of plastic waste and contributing to efforts to combat plastic pollution.

Recycled Plastics: With growing concerns about plastic waste and environmental sustainability, there has been a significant focus on recycling Commodity Plastic. Innovations in recycling technologies have made it possible to transform used plastics into high-quality recycled materials that can be used to manufacture new products, reducing the need for virgin plastics and minimizing waste.

Advanced Manufacturing Techniques: Advancements in manufacturing techniques, such as 3D printing and injection molding, have revolutionized the production of commodity plastics. These techniques allow for greater precision, customization, and efficiency in the manufacturing process, enabling manufacturers to create complex shapes and designs with ease.

Enhanced Performance Properties: Another trend in commodity plastic innovation is the development of plastics with enhanced performance properties, such as increased strength, durability, and resistance to heat, chemicals, and UV radiation. These advanced plastics are finding applications in industries such as automotive, aerospace, and electronics, where demanding performance requirements must be met.

Get More Insights On This Topic: Commodity Plastic

#Commodity Plastic#Polymer Materials#Plastic Manufacturing#Plastic Industry#Petrochemicals#Plastic Production#Plastic Resins#Synthetic Polymers#Plastic Recycling

0 notes

Text

Examining the possible effects of the EU's new CBAM on Southeast Asian economies, or trading off

Agile Advisors can provide Carbon Border Adjustment Mechanism, The EU ETS the organization's premier emissions trading scheme, will undergo a significant overhaul in 2023. Up until now, the plan has concentrated on reducing carbon emissions from domestic economic activity within the bloc, such as the production of electricity or the operation of carbon-intensive industries. The EU ETS's scope is expanded to include imports of specific items that enter the European Economic Area under the new Carbon Border Adjustment Mechanism, or CBAM. The main instrument for preventing carbon leakage from trade-exposed sectors is the CBAM, which takes the place of free allocation. The initial three-year pilot phase of CBAM requires EU importers to report the greenhouse gases released during the production (direct and indirect) of aluminum, cement, iron and steel, fertilizer, hydrogen, and electricity produced outside of the EU, as per the provisional agreement reached by the Council and the European Parliament.

In Agile Advisors as a Carbon Border Adjustment Mechanism, the scope and coverage of the mechanism were the subject of lengthy talks prior to the interim agreement. The intention is to eventually include all commodities covered by the EU ETS inside the mechanism's scope, as well as additional commodities susceptible to carbon leakage, such as organic compounds and polymers (plastics). Importers will have to obtain and turn in certificates for the greenhouse gases connected to imports from outside the EU when the CBAM goes into effect in 2027.The introduction of the CBAM aimed to create parity between EU and non-EU manufacturers of comparable products with respect to the regulatory cost of climate policy. The deployment of this measure is likely to lower the competitiveness of carbon-intensive items produced outside the region. Many of the first considerations of the CBAM's possible effects center on nations that are directly and quickly implicated as major exporters of the impacted products to the EU.

We consider Agile Advisors to be a Carbon Border Adjustment Mechanism, we examine how vulnerable the major economies of Southeast Asia are to CBAM in its most likely future form (which would cover plastics according to the EU Parliament's proposal) and we use an economic model called CLIMTRADE to evaluate a number of broader issues that might result from disruptions to global trade flows. Producers now have an additional incentive to think about the carbon footprint of their operations, whether they export to the EU now or in the future. Furthermore, the policy may affect trade flows that are not only directed toward the EU. For instance, if CBAM causes a decline in EU demand for imported steel, this could affect the global supply and demand balance and perhaps result in cheaper steel prices being sold to non-EU nations. Exporters from outside the European Union who deal with steel, aluminum, or other CBAM-covered products should be aware of the risks to the value of their goods posed by shifts in pricing, demand, or both.

In our opinion as Carbon Border Adjustment Mechanism, Economic concerns associated with CBAM are challenging to quantify. A nation's likelihood of being impacted by CBAM is mostly determined by its exporting countries' exposure, or the number of impacted exports to the EU, in addition to the EU ETS price and the strictness of CBAM. However, exposure on its own doesn't reveal anything about potential financial hazards. Vulnerability is a risk indicator that is more pertinent. In addition to exposure, vulnerability assesses economic reliance, export concentration, and diversification. This helps identify exporting nations that may bear the majority of the mechanism's costs. A non-EU nation would be particularly susceptible, for instance, if it produced and exported CBAM-relevant goods for the EU market (high concentration) primarily (lack of diversification), and especially if the nation's GDP heavily relied on these exports. Trade patterns will be permanently impacted by the decarbonization of global trade flows.

To help you as Carbon Border Adjustment Mechanism, Traditional production characteristics like land, labor, and capital no longer solely determine how competitive the goods produced by exporting nations are. In areas and industries subject to a carbon pricing scheme, the cost of carbon incurred during the manufacture of goods already constitutes a significant cost factor. Producers and exporters in third countries are also affected by these economics due to carbon border adjustment mechanisms like the EU CBAM.Producers and exporters need to reduce their carbon footprint and related expenses to be competitive as importing nations increasingly price in the cost of carbon to safeguard native industries and guarantee the efficacy of regional climate policies. As their goods become considerably more competitive in carbon-constrained markets, producers and exporters who implement decarbonization at the earliest possible pace are expected to reap substantial returns on their investment. This is an important opportunity.

0 notes

Text

"Diving Deep into the Specialty Polymers Market: Trends, Innovations, and Strategic Insights

Specialty Polymers: Harnessing the Power of Specialty Macromolecules for Next-Generation Technologies

Specialty Polymers Overview

Specialty macromolecules, also known as engineering macromolecules, are a class of macromolecules that are specially engineered to have targeted physical and chemical properties that make them suitable for advanced applications. Though they only represent a small fraction of the total macromolecules market, specialty macromolecules command a significant revenue share due to their higher value and more niche end uses.

Types of Specialty Macromolecules

There are several main types of specialty macromolecules classified based on their monomer makeup and resultant properties. Some of the major types include:

Polyamides (Nylons)

Polyamides, best known by the brand name Nylon, are a class of thermoplastic macromolecules containing amide linkages along their polymer chains. They are known for their high strength, toughness, and relative durability compared to other plastics. Engineering polyamides such as Nylon 46 and Nylon 610 can withstand higher temperatures than commodity nylons.

Fluoromacromolecules

Fluoromacromolecules contain strong carbon-fluorine covalent bonds which give them unique oil, chemical, heat and weather resistance properties. Popular fluoromacromolecules include polytetrafluoroethylene (PTFE or Teflon), fluorinated ethylene propylene (FEP), and polyvinylidene fluoride (PVDF). They are used in applications requiring non-stick, low friction surfaces.

Polyesters

Engineering polyesters such as liquid crystal macromolecules (LCP), polybutylene terephthalate (PBT), and polyethyleneterephthalate (PET) can be formulated with enhanced heat resistance, strength and rigidity over traditional polyesters. They are employed in automotive, electrical/electronic and consumer goods.

Liquid Silicone Rubbers

Liquid silicone rubbers (LSRs) are two-part addition-cure silicone elastomers that vulcanize at room temperature. Their biocompatibility, stability and flexibility make them well-suited for medical, food and microfluidic device applications. Low compression set LSRs retain shape over time.

Polyketones

Polyketones are a family of thermoplastics with high strength, heat resistance and chemical resistance derived from their ketone groups in the polymer backbone. They include comacromolecules like polyetheretherketone (PEEK) used in demanding mechanical and electrical end uses.

Markets and Applications

Specialty macromolecules are developing across diverse markets driven by the need for advanced material performance. Some of the major application areas include:

Automotive

In automotive, specialty macromolecules enable lightweighting through replacement of traditional metals. Nylons, PBT, polycarbonate and liquid silicone aid composites in vehicles. Use in engine components require heat resistance of PEEK and liquid crystal macromolecules.

Electronics

Electronics rely on specialty macromolecules for miniaturization and reliability. PTFE, FEP, PET and PVDF bring dielectric, insulating properties. PBT molding aids housings. Semiconductor uses benefit from high heat resistance of PEKK and LCP.

Medical

Biocompatible and non-leaching properties of silicones, nylons and PEEK suits medical industry. Implants, catheters, sensors and drug delivery use these. PEKK aids orthopedic devices. Silicones serve prosthetics, wound care and contact lenses.

Infrastructure

Resistance to chemical, heat and environmental stress qualifies many macromolecules for infrastructure. PVDF and silicones protect coatings and paints. Dams, tunnels utilize durability of PTFE and polyketones lining.

Other Developments

New technologies foster demand for high performance plastics. Renewable energy harvest requires specialty macromolecules in wind turbines, solar cells. Aerospace gravitates toward sturdy yet lightweight materials like PEKK, PEEK. Microfabrication leverages specialty silicones and fluoromacromolecules. As applications diversify, advanced macromolecules enable novel solutions.

Future Prospects

The specialty macromolecules market is forecast to sustain strong growth over the medium term supported by their rising penetration across major end-use industries. Polyketones, liquid silicone rubbers and high-temperature polyamides will be key winning product types. The Asia Pacific region is expected to lead future demand growth driven by its large manufacturing industries. Robust R&D focus on bio-based and high-tech specialty macromolecules will further fuel new product innovations and market opportunities going forward.

In Summary, specialty polymers represent a fascinating realm of materials science, offering tailored properties and applications beyond traditional macromolecules. These advanced materials are engineered to meet specific performance requirements, such as enhanced durability, conductivity, or biocompatibility. From aerospace components to medical devices, specialty macromolecules play a crucial role in a wide range of industries, driving innovation and pushing the boundaries of what's possible.

0 notes