#carbon steel

Video

CARBON STEEL is a dark Sci-Fi horror puzzle adventure where you drag up mysterious creatures from the depths and experiment on them!

Read More & Play The Full Game, Free (Windows)

Gameplay Video:

youtube

#Gaming#indie games#CARBON STEEL#CARBON STEEL game#pc games#pc gaming#indie gaming#indie game#horror#horror games

1K notes

·

View notes

Text

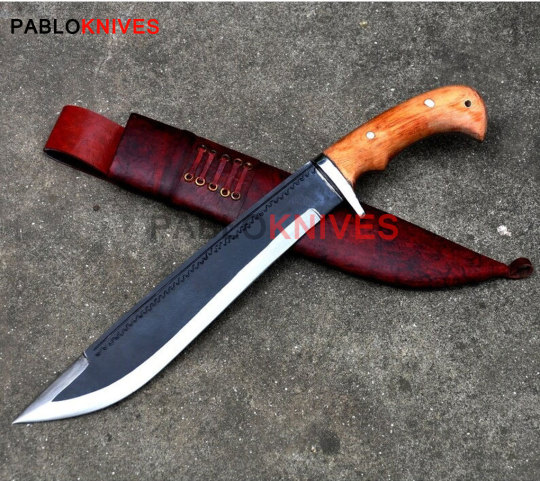

#handmade knife#avatar: the last airbender#etsy#handcrafted#pattern#crafts#dagger#handmade earrings#handmade jewelry#Viking#vintage#Hunting#Skinner#Bowie#Full Tang#Christmas#Handmade#Carbon Steel#Damascus Steel#camp damascus#Outdoor Knife#Jungle Knife

9 notes

·

View notes

Photo

Carbon Steel

#carbon steel#mike klubnika#indie games#horror games#simulation games#puzzle games#gif#screenshots#itch.io

71 notes

·

View notes

Text

Remember to season cookware

4 notes

·

View notes

Photo

(via Blacksmith Premium T-Shirt by djomla88)

#findyourthing#redbubble#blacksmithing#bladesmithing#anvil#roots#hammer#tongs#metalwork#metalsmith#iron#steel#carbon steel#tempering#heat treatment#quenching#annealing

8 notes

·

View notes

Text

5 Latest Manufacturing Process of Heavy Wall Thickness CS Seamless Pipes

Heavy wall thickness CS seamless pipes are used in various applications, from oil and gas to construction and infrastructure. These pipes are known for their high strength, durability, and resistance to corrosion, making them an ideal choice for harsh environments.

The manufacturing process for heavy wall thickness CS seamless pipes involves several steps, each critical to the final product's quality.

Raw Material Selection: The first step in the manufacturing process is the selection of high-quality raw materials. Heavy wall thickness CS seamless pipes are typically made from carbon steel, which is known for its strength and durability. The steel is selected based on its chemical composition, mechanical properties, and other factors to meet the required specifications.

Billet Production: The next step is the production of billets and cylindrical steel pieces that serve as the starting point for the pipe-making process. The steel is heated to a high temperature and then rolled into a cylindrical shape. The resulting billet is cut to the desired length using a saw or other tool.

Piercing and Rolling: Once the billets have been cut to the desired length, they are ready for piercing and rolling. The billets are heated to a high temperature and then pierced with a mandrel, which creates a hollow tube. The tube is then rolled using a series of rollers to reduce its diameter and increase its length.

Heat Treatment and Finishing: After the piercing and rolling process, the tube is heat treated to improve its mechanical properties. The tube is heated to a high temperature and then quenched in water or oil to harden the steel. This process helps to improve the pipe's strength and durability. Once the heat treatment process is complete, the pipe undergoes finishing. This involves cutting the pipe to the desired length and removing excess material or burrs. The pipe is then inspected for quality control to ensure it meets the required specifications.

Testing and Certification: Before the heavy wall thickness CS seamless pipes are shipped to the customer, they undergo testing and certification. The pipes are subjected to various tests, including hydrostatic testing, ultrasonic testing, and visual inspection, to ensure they meet the required quality standards. Once the pipes have passed all required tests, they are certified and shipped to the customer.

In addition to the steps mentioned above, several other important factors must be considered in manufacturing heavy wall-thickness CS seamless pipes.

One of the key considerations is the quality of the equipment used in the production process. Modern equipment and technology, such as advanced rolling mills and heat treatment furnaces, can significantly improve the efficiency and quality of the process.

Another important consideration is the quality control measures throughout the manufacturing process. Strict quality control measures ensure that the pipes meet the required strength, durability, and corrosion resistance standards.

These measures can include regular inspections and testing throughout the production process and comprehensive final testing and Certification.

It is also worth noting that the manufacturing process for heavy wall thickness CS seamless pipes can vary depending on the specific application and customer requirements.

For example, some applications may require additional steps, such as surface treatment or coating, to enhance the pipe's corrosion resistance.

Overall, the manufacturing process for heavy wall thickness CS seamless pipes requires careful attention to detail and a commitment to quality at every step. By selecting high-quality raw materials, using modern equipment and technology, and implementing strict quality control measures, manufacturers can produce pipes that meet the most stringent requirements for strength, durability, and corrosion resistance.

For more such stories, kindly follow Tumblr.

#metal industrial#construction#stainless steel#architecture#alloy#buildings#carbon steel pipe#seamless pipe#heavy wall pipe#CS Seamless Pipes#Carbon Steel#SEAMLESS CARBON STEEL HEAVY WALL THICKNESS PIPES#ASTM A53 Heavy Wall Thickness Seamless Pipes#ASTM A106 Gr B Steel A53 Heavy Wall Thickness CS Seamless Pipe

2 notes

·

View notes

Photo

Leading Manufacturer & Supplier of Pipes in India

Alloyed Sustainable Manufacturer, Exporter, Supplier & Stockist of Pipe in Mumbai. We offer seamless pipes in all grades and materials. Additionally, we provide pipes made of commercially available metals including Stainless Steel, Duplex Steel, Alloy Steel, Carbon Steel, Low-Temperature Carbon Steel, Copper and Nickel Alloys, Round Pipe, Square Pipe, Rectangle Pipe, Hydraulic Pipe, etc.

4 notes

·

View notes

Text

annealing steel coil application

0 notes

Text

Building Green: Harnessing the Power of Low-Carbon & Mild Steel Sheets for Sustainable Construction

Low-carbon steel sheets, including Mild Steel (MS), are emerging as a favored choice in the realm of steel, offering a multitude of advantages that cater to various industries. Here's a brief exploration of why low-carbon steel sheets are making waves in the world of steel:

Eco-Friendly: Low-carbon steel sheets, including MS Sheets, contribute to sustainability efforts with reduced carbon emissions during manufacturing.

Strength and Flexibility: They offer commendable strength while retaining flexibility for shaping into various structures. Corrosion Resistance: Low-carbon steel sheets, including MS, withstand harsh environments, enhancing longevity with minimal maintenance.

Cost-Effectiveness: Affordable pricing makes them a preferred choice without compromising quality. Ease of Machinability: Machining, welding, and manipulation are simplified, reducing production time and costs.

Versatile Applications: From construction to automotive industries, they serve diverse needs with reliability.

Recyclability: Low-carbon steel sheets, including MS, are recyclable, conserving resources and reducing waste. In essence, low-carbon steel sheets, including MS, offer a sustainable, versatile, and cost-effective solution for various applications.

0 notes

Text

The Essential Applications of Carbon Steel Pipes

Carbon steel pipes are indispensable in various industries, offering unmatched durability and versatility. Let's explore five key applications where these pipes play a crucial role:

1. Infrastructure Construction:

Carbon steel pipes are vital for constructing infrastructure such as buildings, bridges, and roads.

They ensure reliable water supply and drainage systems in urban and rural areas.

2. Oil and Gas Transport:

In the oil and gas industry, carbon steel pipes are used to transport crude oil, natural gas, and refined petroleum products.

Their robust construction withstands high pressures and corrosive environments.

3. Industrial Manufacturing:

Carbon steel pipes are essential for fluid and gas transportation in industrial manufacturing processes.

They facilitate the operation of machinery and equipment in various sectors.

4. Power Generation:

Carbon steel pipes play a crucial role in power plants, transporting water, steam, and other fluids in boiler systems.

Their resilience ensures efficient energy production and distribution.

5. Water Treatment Facilities:

Carbon steel pipes are integral to water treatment facilities, transporting potable water and wastewater.

They resist corrosion, ensuring the integrity of water supply systems.

In your pursuit of reliable carbon steel pipes, consider OM Steel as your trusted supplier. With a commitment to quality and customer satisfaction, OM Steel offers a diverse range of carbon steel pipes to meet your specific needs. Choose OM Steel for unmatched reliability and excellence in carbon steel pipe manufacturing.

0 notes

Text

Jiaxiao MTC specializes in the production of heat-treated steel strips. Relying on the advantages of Baosteel's high-quality hot-rolled raw materials, Jiaxiao MTC independently develops band saw production technology and opens a band saw factory cgoodsaws. This video was shot by jiaxiao MTC in the factory. This narrow carbon steel has a bandwidth of 10-20mm. Steel The model is CK67. After heat treatment, the hardness and toughness have been qualitatively improved. It is very suitable for cutting frozen bones and frozen meat. As you can see from the video, our saw blade is extremely sharp and can cut frozen bones and fish meat into two parts in an instant. Not only that, we also provide the following steel belts with different chemical compositions for you to choose from:

Heat Treated Steel Strip for Band Saw, Saw Blade, and Steel Strip for Stone Frame Saw Blade:

CK50, C67S, CK70, 68CrNiMo, C75Cr1, 75Ni8, SK4, SK5.

Main Applications:Woodwoeking saw, hand saw,marble row saw, diamond sawblade.

Heat Treated Bimetal Backing Steel Strip:

50CrNiMoVA, D6A, X32.

Main Applications:Bimetal band saw.

Heat Treated Steel Strip for Stainless Tools:

SUS420J2/J3/J4.

Main Applications:

Various kinds of cutting tools.

For more information, please visit: https:jiaxiaomtc.com

#saw blade#bandsaw#metalprocessing#hardened and tempered#jiaxiao mtc#heat treatment#carbon steel#cold rolled#steel manufacturer#steel strip#steel#wholesale#sales#saw 2004

1 note

·

View note

Text

Which is better, high carbon steel or aluminum alloy?

High carbon steel and aluminum alloy as two widely used materials in home design, they play a vital role in shaping the home environment and enhancing the living experience. Many people will face a difficult problem when choosing materials: high carbon steel and aluminum alloy, which is more superior? In order to help you better understand the characteristics of these two materials, I will conduct in-depth analysis from multiple dimensions, including their advantages and disadvantages, application occasions and durability, hoping to provide some inspiration for your choice.

First of all, from the basic characteristics of the material, high carbon steel and aluminum alloy have their own advantages. High carbon steel is known for its superior strength and hardness, which makes it excellent at withstanding heavy loads and pressures, so in home improvement design, high carbon steel is often used to create structural and supportive components, such as stair railings, door and window frames. Aluminum alloy is favored for its excellent corrosion resistance and lightweight properties, which make aluminum alloy especially suitable for the production of decorative products such as bathroom facilities and furniture, adding a light and elegant home space.

In the scope of use, high carbon steel is widely used in different home improvement design styles because of its diverse adaptability. Whether used for structural support or decorative products such as furniture and lighting, high carbon steel can bring a modern and solid feeling to home Spaces.

In contrast, although the application of aluminum alloy in home improvement design is relatively limited, its lightweight characteristics make it excellent in the production of bathroom products such as shower rooms, bathtubs, etc., and it is also suitable for the production of furniture such as wardrobes and cabinets, showing its advantages in decoration and practicality.

When it comes to durability, the performance of high carbon steel is undoubtedly better than that of aluminum alloy. Due to its high strength and hardness, high carbon steel can withstand greater pressure and impact, and is not easy to deformation. Although aluminum alloys perform well in corrosion resistance, they are not as strong and hard as high-carbon steel, and are more prone to deformation and scratches. Therefore, in the environment that needs to bear a large load, high carbon steel products are undoubtedly a more stable and durable choice.

High carbon steel and aluminum alloy each have unique advantages and application scenarios. In the process of home improvement design, we should choose the most appropriate materials according to the specific functional requirements and design objectives. If the pursuit of high load capacity and durability, high carbon steel may be a more ideal choice; If you pay attention to lightness and decorative effect, aluminum alloy may be more in line with the requirements. In practical applications, we can also consider the combination of the two, for different functions and requirements to choose the right material, in order to create a beautiful and practical home environment.

0 notes

Text

Exploring the Versatility of Carbon Steel in Industrial Applications

I. Introduction to Carbon Steel

Carbon steel is a versatile material that plays a crucial role in various industrial applications. Understanding its properties, types, and uses can provide valuable insights into its significance in different sectors.

A. What is Carbon Steel?

Carbon steel is an alloy of iron and carbon, where carbon content is the key characteristic that distinguishes it from other steel types. Its composition can vary, but typically ranges from 0.05% to 2.5%.

B. Properties of Carbon Steel

Carbon steel exhibits high tensile strength, excellent durability, and good weldability, making it suitable for a wide range of applications. Its hardness and ductility can be adjusted through heat treatment.

C. Types of Carbon Steel Alloys

Different carbon steel alloys include low carbon steel, medium carbon steel, and high carbon steel, each offering unique properties suited for specific industrial needs.

II. Uses of Carbon Steel in Industry

The versatility of carbon steel makes it indispensable in various industrial sectors, serving different purposes with its strength and reliability.

A. Structural Applications

Carbon steel is commonly used in building structures, bridges, and pipelines due to its strength, allowing for the construction of stable and durable frameworks.

B. Machinery and Equipment

The machinery industry relies on carbon steel for components like gears, shafts, and axles, as its robust nature ensures the efficient performance of equipment.

C. Infrastructure and Construction

In the construction sector, carbon steel is utilized in reinforcements, roofing, and beams, contributing to the stability and longevity of buildings and infrastructure projects.

III. Advantages of Carbon Steel

The numerous advantages offered by carbon steel make it a preferred choice for industrial applications, providing reliability and cost-efficiency.

A. Strength and Durability

Carbon steel's high strength-to-weight ratio and durability make it ideal for structures and equipment that require long-term performance under demanding conditions.

B. Cost-Effectiveness

Compared to other materials, carbon steel is relatively inexpensive, making it a cost-effective solution for industries looking to optimize their production processes without compromising quality.

C. Ease of Fabrication and Maintenance

Carbon steel is easy to work with, allowing for seamless fabrication processes, repairs, and maintenance, saving time and resources in industrial operations.

IV. Challenges and Limitations of Carbon Steel

Despite its advantages, carbon steel is not without its limitations, requiring careful consideration of factors like corrosion resistance, environmental impact, and temperature constraints.

A. Corrosion Resistance

One of the main challenges with carbon steel is its susceptibility to corrosion, especially in harsh environments, necessitating protective coatings or alloy modifications.

B. Impact on Environment

The production and disposal of carbon steel can have environmental repercussions, leading to the need for sustainable practices and recycling initiatives to minimize ecological footprint.

C. Temperature Limitations

Carbon steel's performance can be affected by extreme temperatures, with low-temperature brittleness and high-temperature strength reduction posing challenges in certain applications.

V. Innovations and Future Trends in Carbon Steel

The continuous evolution of carbon steel technology is paving the way for innovative solutions and sustainable practices in the industry, ensuring its relevance in the future.

A. Development of High-Strength Alloys

Research and development efforts are focused on creating high-strength carbon steel alloys with enhanced properties, catering to advanced industrial requirements and increasing efficiency.

B. Sustainable Practices in Production

To address environmental concerns, manufacturers are adopting sustainable production methods, recycling processes, and utilizing green energy sources to reduce carbon emissions and waste.

C. Integration with Advanced Technologies

Carbon steel is being integrated with advanced technologies like additive manufacturing and IoT systems to enhance quality control, product customization, and supply chain management in the industry.

0 notes

Text

Carbon Steel Coat Rack

1pc 4/5 Layer 23in Carbon Steel Coat Rack, Multipurpose Coat Hanger And Shoe Shelf, Black/white, Self Assembly Required

👉 -95% off discount+EXTRA 30% OFF❤️

🎉 Flash sale[$5.69] -95% off

👉 item link: https://temu.to/m/ulvsnlgsd9p

⚠️ Every New App User can only enjoy once

0 notes