#Vedantaaluminium

Photo

Mr. Varun Chopra, Executive Chairman of GEAR - Gemini Equipment And Rentals Pvt. Ltd., speaks about our partnership with GEAR to deploy one of India's largest lithium-ion (electric) forklift fleets at our largest aluminium smelter in Jharsuguda, Odisha. This electric 'green' fleet is equipped with the latest Smart Fleet Management technology to step-change productivity and safety at site, while reducing GHG emissions and fossil fuel (diesel) consumption significantly.

#vedantaaluminium#aluminiumsmelter#aluminarefinery#aluminiumsupplierinindia#aluminiumbilletmanufacturer

0 notes

Photo

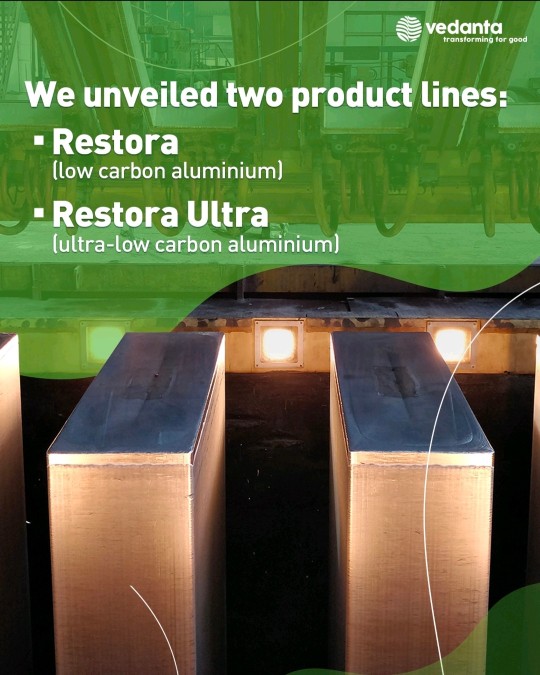

Restora is being manufactured at our world-class aluminium smelters using renewable energy. Restora has a GHG emission intensity that is well below 4 tonnes of CO2 equivalent (tCO2e) per tonne of aluminium manufactured – the global threshold for aluminium to be considered as low carbon aluminium.

Click Here: https://vedantaaluminium.com/products/restora-low-carbon-aluminium/

0 notes

Link

We strive to aid in preservation of local and indigenous traditions and cultures in the areas where we operate. From promoting Dhokra craft, an ancient art form from the times of the Indus Valley civilization, to mural arts, archery and folk theatre, developing sports infrastructure and supporting grassroot sporting culture, our social interventions seek to foster and help sustain community heritage.

0 notes

Link

Vedanta’s goal of facilitating sustainable development among rural communities is closely linked to the enhancement of rural infrastructure. We have taken up critical infrastructural work in the regions where we operate, building approach roads and bridges, drinking water amenities, irrigation support and watershed development, community toilets and sanitation facilities, schools and hospitals, community halls, sports and recreation centres, gardens and many more, changing the contours of rural hinterlands.

Read More: https://vedantaaluminium.com/sustainability/social-impact/building-community-infrastructure/

0 notes

Text

Aluminium, Flying You Around The Earth & Beyond

Aluminium has long sparked the imagination of humankind’s quest to explore the space beyond Earth. In fact, Jules Gabriel Verne, the renowned French novelist credited with stories like ‘Around the World in Eighty Days’, ‘20,000 Leagues Under the Sea’ and ‘Journey to the Centre of the Earth’, wrote of man setting sail to the moon in an aluminium spaceship.

The Wright brothers’ ‘Flyer I’, the first steerable flying apparatus flew with a strong but lightweight 13HP engine whose components were made of aluminium. They chose aluminium for the cylinder block and other engine parts on their first manned flight in 1903. It was also the first time an aluminium alloy had been heat-strengthened, a discovery that positioned aluminium’s dominance in aerospace engineering. As far back as the 19th century, Count Ferdinand Zeppelin used it to make the frames of his iconic airships, demonstrating aluminium’s light weight, strength, and high resistance to corrosion. More than a century later, it is the most-used metal in the air.

Throughout the years, with evolution in the aviation and aerospace industries, the demand for high-performance materials has become more exacting. The advancement of aircraft and rocket technology is directly tied to the advancement and production of aluminium alloys. The first component of the International Space Station was launched in 1998, and today the ISS is a stellar example of our capability to test the limits of human genius. From Flyer I to ISS, aluminium has indeed given wings to humankind’s aspirations to explore the undiscovered.

0 notes

Video

Despite ancestral orientation in Dhokra craftsmanship, Butra Kansari was almost forced to give up on his dreams of pursuing the beautiful artform due to poverty. In a village like Kankeri, with no basic amenities, creating livelihood from art was simply not an option. Discovering the village of Dhokra craftsmen nestled in the forests of Kalahandi, Vedanta initiated a project to revive the 4000-year-old dying artform and in the process, give the artisans a thriving livelihood. Supported with raw materials, training in contemporary designs, market linkage, etc. Butra, and others like him worked hard to build a name for themselves in Dhokra art. Like his story? Help us spread the word far and wide!

Visit To Know More: https://vedantaaluminium.com/

0 notes

Video

Growing up in Jharsuguda, poverty never left Basanti’s side. A young widow with three kids, she decided to fight it out and turn the wheels of destiny in favour of her children. Looking for work, she chanced upon Vedanta’s Subhlalaxmi Co-operative, an all-women co-op society working towards women’s financial inclusion, skill development and enterprise development. Joining Subhalaxmi, Basanti availed loans to set up her shop, and with sheer determination grew her business to what it is today. Once upon a time, she didn’t know what to feed her kids the next day, today, she is a successful entrepreneur and a role model for many. Like her inspiring story? Help us spread the word far and wide!

Visit Us: https://vedantaaluminium.com/

0 notes

Text

Aluminium, Guarding The Nation’s Final Frontiers

As India commemorates the 21st anniversary of Kargil Vijay Diwas today, it is worth dwelling on the critical role of aluminium in bolstering India’s national security. Aluminium, popularly known as the ‘Metal of the Future’, finds critical usage in the military and defence industry as a key component in fighter aircrafts, battle tanks, frigates, ammunition, ground vehicles, armor plating, paneling, electrical systems, and many more.

When it comes to material selection, aluminium is a preferred choice because of its phenomenal properties like high strength-to-weight ratio, ability to alloy for myriad specialized applications, high tolerance for various climactic conditions, exceptional design flexibility, high fatigue strength, fracture toughness and corrosion resistance.

There is a burgeoning demand for quality aluminium alloys in the defence sector, in the form of sheets, forgings and extrusions. Military applications demand high-quality materials in precise specifications, for consistent performance, as national security is not a matter to be trifled with. Military equipment are not only supposed to protect one’s own country, but also keep our armed forces safe to the extent possible.

With significant advancements made in military applications world over, there is immense potential in India to build downstream capabilities for defence applications. Us and the Indian Aluminium Industry, are well-resourced to cater to current and emerging needs of the defence industry. After all, when it comes to protecting our people and our motherland, we are avowed to fulfill our responsibilities as the nation’s partner in progress.

0 notes