#Top Stainless Steel Heat Exchanger Tubes Manufacturer

Text

Understanding the Physical Properties of Stainless Steel Plates

Corrosion Resistance: Stainless steel plates exhibit remarkable resistance to corrosion, making them ideal for applications in harsh environments such as marine and chemical industries.

High Temperature Resistance: These plates maintain their strength and integrity even at elevated temperatures, making them suitable for use in heat exchangers, boilers, and other high-temperature applications.

Strength and Durability: Stainless steel plates boast high strength-to-weight ratios, providing excellent structural integrity and durability, crucial for applications in construction and manufacturing.

Hygienic Properties: Stainless steel plates are non-porous and easy to clean, making them ideal for use in food processing, pharmaceuticals, and medical equipment where hygiene is paramount.

Aesthetic Appeal: With its sleek and modern appearance, stainless steel adds an aesthetic touch to architectural designs, interior decorations, and consumer products.

Magnetic Properties: Depending on the grade, stainless steel plates may exhibit magnetic properties, which can be advantageous for certain applications such as in magnetic resonance imaging (MRI) machines.

In conclusion, stainless steel plates offer a myriad of benefits, including corrosion resistance, high-temperature resistance, strength, durability, hygienic properties, aesthetic appeal, magnetic properties, ease of fabrication, and recyclability. For top-quality stainless steel plates and tubes, consider Om Steel as your trusted supplier. With its extensive range of products and commitment to customer satisfaction, Om Steel ensures reliability and excellence in every purchase. Choose Om Steel for all your stainless steel plate and tube needs and experience unparalleled quality and service.

0 notes

Text

Duplex Steel UNS S32205 Seamless Pipes & Tubes Manufacturers In India

In the industrial and construction sectors, the choice of material is pivotal for ensuring durability, reliability, and efficiency. Duplex Steel UNS S32205 has become a preferred choice due to its exceptional mechanical properties and corrosion resistance. Among the leading manufacturers of Duplex Steel UNS S32205 seamless pipes and tubes in India is Kamal Piping, a company renowned for its commitment to quality and innovation.

Understanding Duplex Steel UNS S32205

Duplex Steel UNS S32205, often referred to simply as S32205, is a grade of stainless steel that combines the beneficial properties of both austenitic and ferritic stainless steels. This unique composition results in a material with superior strength, excellent corrosion resistance, and high durability. S32205 is particularly known for its resistance to stress corrosion cracking, pitting, and crevice corrosion, making it an ideal choice for harsh environments.

Key Features and Benefits of Duplex Steel UNS S32205

High Strength: Duplex Steel S32205 offers significantly higher strength compared to standard austenitic stainless steels, allowing for the use of thinner and lighter sections without sacrificing performance.

Excellent Corrosion Resistance: This grade is highly resistant to various types of corrosion, including chloride-induced stress corrosion cracking, pitting, and general corrosion. This makes it suitable for use in environments where exposure to corrosive substances is common.

Enhanced Durability: The mechanical properties of S32205 ensure long-lasting performance, even in challenging conditions. Its toughness and resistance to wear make it a reliable choice for demanding applications.

Cost-Effectiveness: Due to its high strength-to-weight ratio, using Duplex Steel S32205 can lead to material savings and increased efficiency in fabrication and installation processes.

Applications of Duplex Steel UNS S32205 Seamless Pipes & Tubes

The versatility of Duplex Steel S32205 makes it suitable for a wide range of applications, including:

Oil and Gas Industry: Ideal for pipelines, offshore platforms, and processing facilities where resistance to harsh environments is critical.

Chemical Processing: Used in equipment and piping for chemical plants due to its ability to withstand corrosive chemicals and high temperatures.

Marine Industry: Suitable for shipbuilding and marine environments, offering resistance to seawater and marine atmospheres.

Power Generation: Utilized in power plants for components such as heat exchangers and boiler parts that require high strength and corrosion resistance.

Why Choose Kamal Piping?

Kamal Piping has established itself as a premier manufacturer of Duplex Steel UNS S32205 seamless pipes and tubes in India. Here are some reasons why they are a preferred choice:

Uncompromising Quality: Kamal Piping ensures that all their products meet stringent quality standards. Their seamless pipes and tubes undergo rigorous testing and inspection to guarantee superior performance and reliability.

Advanced Manufacturing Facilities: Equipped with state-of-the-art manufacturing units, Kamal Piping leverages the latest technology to produce high-precision seamless pipes and tubes.

Expertise and Experience: With a team of seasoned professionals, Kamal Piping brings extensive expertise and experience to every project, ensuring that their products meet the highest standards of excellence.

Customer-Centric Approach: Kamal Piping is committed to understanding and meeting the unique needs of their clients. They offer customized solutions, timely delivery, and exceptional customer service, ensuring complete satisfaction.

Duplex Steel UNS S32205 seamless pipes and tubes are indispensable in industries that demand high strength and superior corrosion resistance. Kamal Piping stands out as a leading manufacturer in India, providing top-quality products that meet the stringent requirements of various sectors. Whether you are in the oil and gas industry, chemical processing, marine industry, or power generation, Kamal Piping offers reliable and durable solutions with their exceptional range of Duplex Steel UNS S32205 seamless pipes and tubes.

For more information on their products and services, visit Kamal Piping’s website and discover how they can meet your specific requirements with their outstanding range of Duplex Steel UNS S32205 seamless pipes and tubes.

Email : [email protected]

Call Us : +91-8879048749

Website: https://www.kamalpiping.com/duplex-steel-uns-s32205-pipes-tubes-manufacturers-suppliers-stockists-exporters.html

0 notes

Text

Top Hydraulic Tubes Manufacturer in Mumbai

KRYSTAL GLOBAL ENGINEERING LIMITED (Formally Known as Krystal Steel Manufacturing Private Limited) is a Stainless Steel company with the vision to be the Leader from INDIA in Stainless and Nickel Alloy Tubes with success based on Operational Excellence and Superlative Services.

We are dedicated to help our customers gain a competitive advantage by supplying a wide range of products such as Tubes, Pipes, U Tubes, Coil Formed Tubes.

KRYSTAL has well established “State of Art” facilitates with continuous enhancement of the product and services to serve the customers across the globe.

We have customers from a wide range of Industries such as – Power Plants, Oil & Gas, Chemical Plants, Fertilizers, Pharmaceuticals, Textile, Railways, Defence, Automobiles, Desalination and more. Our products are used in Engineering Applications such as – Pressure Vessels, Heat Exchanger, Condenser, Heat Recovery System and more. Our Products, Technology and Services are used worldwide with complete peace of mind.

Tap here to know more about:

#kgel#krystalglobalengineeringlimited#krystalgeltd#tophydraulictubesmanufacturerinmumbai#topqualityhydraulictubesmanufacturerinmumbai#steels#tubes#metals#mining#pipes#stainlesssteels#seamlesssteels#steelmanufacturer#metalmanufacturer#tubesmanufacturer#pipemanufacturer#steelcompany#steelexporter#steelsupplier#worldwide

0 notes

Text

Stainless Steel 317/317L Heat Exchanger Tubes Exporters

Introduction:

Metinoxoverseas emerges as a reliable name in this domain, Stainless Steel 317/317L Heat Exchanger Tubes, offering a qualitative range designed in adherence to both national and international standards. Our commitment lies in providing top-notch products crafted from superior quality raw materials, ensuring resistance to corrosion and an extended service life.

Description:

specifically designed to withstand extreme temperatures, corrosion, and pressure, making them ideal for a wide range of industrial applications. Stainless Steel 317L Heat Exchanger Tubes find frequent applications in various industries, notably in the cooling systems of hydraulic fluid and oil within engines, transmissions, and hydraulic power packs. Metinox Overseas prioritizes the utilization of high-grade raw materials to ensure optimal performance and longevity of SS 317L Seamless Heat Exchanger Tubes.

Benefits:

Corrosion Resistance: Stainless Steel 317/317L exhibits exceptional corrosion resistance, ensuring longevity and reliability even in harsh environments.

High Temperature Resistance: These heat exchanger tubes are capable of withstanding high temperatures, making them suitable for demanding industrial processes.

Enhanced Durability: Metinoxoverseas ensures superior quality and durability, offering heat exchanger tubes that require minimal maintenance and deliver long-term performance.

Versatility: Stainless Steel 317/317L Heat Exchanger Tubes are versatile and can be customized to meet specific application requirements, making them suitable for various industries including chemical, petrochemical, pharmaceutical, and more.

317/317L Stainless Steel Heat Exchanger Tubes Standard Specifications :

Specifications : ASTM A249 / ASME SA 249

Size Range : 10 mm OD to 50.8 mm OD

Outer Diameter : 6.00 mm to 101.60 mm

Wall Thickness : 0.70 mm to 8.00 mm

Length : up to 20 m (65.62 ft) Length & Customed Required Length

Form : Seamless, Welded, Round, U Bent Tube, Shell and Tube

Ends : Plain End, Beveled End, Treaded

Processing Service : Bending, Welding, Decoiling, Punching, Cutting, Moulding

Technique : Cold drawn, Cold rolled, Hot rolled, Extrusion Tube manufacturer in India

Conclusion:

In conclusion, Metinoxoverseas stands as a trusted provider of Stainless Steel 317/317L Heat Exchanger Tubes, offering unparalleled quality, durability, and performance. With a focus on customer satisfaction and continuous improvement, the company strives to exceed expectations and set new standards in the industry.

For inquiries or orders, reach out to Metinoxoverseas via call at +91-98199 80997 / +91-70212 61928.

0 notes

Text

Stainless Steel Pipe and Tube Supplier in Thane

Luvana Metal Corporation is a Manufacturer, Exporter, and Stainless Steel Pipe and Tube Supplier in Thane, Maharashtra.

Luvana Metal Corporation is an ISO 9001:2015 Certified Company, in Ankleshwar and Pune, India.

We specialize in crafting top-tier stainless steel products, ranging from coils, sheets, plates, bars, rods, wires, valves, pipes, fittings, channels, angles, butt weld fittings,

and flanges, to fasteners.

Our offerings span various forms, material grades, wall thicknesses, types, dimensions, and specifications to cater to diverse needs.

Adhering to both Indian and international standards such as ASME, ASTM, ANSI, and AISI, our stainless steel pipes and tubes are synonymous with quality and reliability.

Our range encompasses a wide variety of SS Pipes and Tubes, including Carbon Steel Pipes, Alloy Steel Pipes, Mild Steel Pipes, Nickel Alloy Pipes, and Non-Ferrous Pipes, offering comprehensive solutions to meet every requirement.

Testing:

Our testing facilities include Tensile Testing Machines, Hardness Tests, IGC Tests, and Positive Material Identification Tests.

Application:

Oil & Gas

Power

Fertilizers

Heat-Exchangers

Paper & Pulp

Pharmaceuticals

Chemicals

Water Treatment

Dairy

Sugar & Food Processing

Luvana Metal Corporation is a Stainless Steel Pipe and Tube Supplier in Thane, Maharashtra covering locations like Aurangabad, Kolhapur, Mahabaleshwar, Malegaon, Matheran, Mumbai, Nagpur, Nanded, Nashik, Osmanabad, Pandharpur, Parbhani, Pune, Ratnagiri, Sangli, Satara, Sevagram, Solapur, Thane, Ulhasnagar, Vasai-Virar, Wardha, Yavatmal.

For further details, please feel free to contact us.

Read the full article

0 notes

Text

SS Pipe and Tubes Supplier in Kanpur

Simplex Steels is a Manufacturer, Exporter, and SS Pipe and Tubes Supplier in Kanpur, Uttar Pradesh.

We Specialize in offering a wide range of stainless steel products, including SS Products and MS Products like SS Sheet, Plate, Coils, Pipes, Tubes, Bar, Wires, Rods, Angles, Channels, Flats, SS Fittings, Pipe, Tubes, Industrial Flanges, SS Fasteners, SS Dairy Valves.

We offer a range of SS pipes and tubes tailored to suit varying needs, sizes, and standards.

Our ISO certification underscores our dedication to providing top-notch solutions.

With an extensive selection of materials, we cater to diverse industry requirements.

Customer satisfaction is our priority, and we strive to deliver outstanding service while maintaining superior quality standards.

Service Offerings by Simplex Steels:

High-quality products

On-time delivery

Job transparency

Features:

Durability: Withstand the test of time.

Corrosion Protection: Guarded against corrosive elements.

Dimensional Precision: Crafted with accuracy.

High-Temperature Resistance: Perform under extreme conditions.

Strong Finish: Exhibiting robustness.

Simplex Steels offers wide SS pipes and tubes for use in a diverse range of industries including Oil & Gas, Power, Fertilizers, heat exchangers, Paper & Pulp, Pharmaceuticals, Chemicals, Water Treatment, Dairy, Sugar & Food Processing.

Simplex Steels is an SS Pipe and Tubes Supplier in Kanpur, Uttar Pradesh including

locations like Ghaziabad, Ghazipur, Gonda, Gorakhpur, Hamirpur, Hardoi, Hathras, Jalaun, Jaunpur, Jhansi, Kannauj, Kanpur, Lakhimpur, Lalitpur, Lucknow, Mainpuri, Mathura, Meerut, Mirzapur-Vindhyachal, Moradabad, Muzaffarnagar, Partapgarh, Pilibhit, Prayagraj, Varanasi.

For further information, feel free to contact us.

Read the full article

0 notes

Text

Supplier SS Plates in Uttar Pradesh

Overview: Krystal Steels

Krystal Steel is leading Manufacturer, Exporter and Supplier SS Plates in Uttar Pradesh.

Krystal Steel is located in Ahmedabad, Gujarat, India.

We offer a wide range of stainless steel products, including sheets, plates, coils, fasteners, pipes, tubes, bars, wires, rods, strip coils, angles, channels, flats, industrial valves, flanges, fittings, and dairy valves.

Our plates meet industry standards like ASTM, ASME, AISI, DIN, BS, EN IS, JIS, ensuring top-notch quality.

Customer satisfaction is our priority, backed by superior service and cutting-edge technology ensuring premium quality products.

Stainless Steel Plates are available in various grades, thicknesses, widths, lengths, surfaces, and finishes, meeting both national and international standards for corrosion resistance and durability.

Features:

High Tensile Strength

Corrosion Resistance

Temperature Resistance

Environmentally Friendly Accuracy

Formability of a Strong and Tough Construction

Simple Formability and Fabrication

Specifications:

Grades: 304, 304L, 316, 316L, 321, 309, 310, 347, 409, 410, 420, 430, 904L, etc.

Types: Foils, Shims, Chequered Plate, Perforated Sheet, Strips, etc.

Finish: HR, CR, 2D, 2B, BA, SATIN, MATT, PVC coated, etc.

Thickness: 0.1 mm to 125 mm

Size: Customizable, up to 2500 mm width

Brands: JINDAL, SAIL, IMPORTED

Nickel Alloys: Inconel, Hast Alloy, Nickel, Cupro Nickel, Titanium, Duplex, Super Duplex, etc.

Application:

Oil & gas

Petrochemicals

Power Generation

Pharmaceuticals

Heat exchangers

Condensers

Pulp and Paper Industry

Krystal Steel serves as a Manufacturer and Supplier SS Plates in Uttar Pradesh, catering to locations like Agra, Aligarh, Amroha, Ayodhya, Azamgarh, Bahraich, Ballia, Banda, Bara Banki, Bareilly, Basti, Bijnor, Bithur, Budaun, Bulandshahr, Deoria, Etah, Etawah, Faizabad, Farrukhabad-cum-Fatehgarh, Fatehpur, Fatehpur Sikri, Ghaziabad, Ghazipur, Gonda, Gorakhpur, Hamirpur, Hardoi, Hathras, Jalaun, Jaunpur, Jhansi, Kannauj, Kanpur, Lakhimpur, Lalitpur, Lucknow, Mainpuri, Mathura, Meerut, Mirzapur-Vindhyachal, Moradabad, Muzaffarnagar, Partapgarh, Pilibhit, Prayagraj, Rae Bareli, Rampur, Saharanpur, Sambhal, Shahjahanpur, Sitapur, Sultanpur, Tehri, Varanasi.

For further details, please feel free to contact us.

Read the full article

0 notes

Text

A comprehensive guide on Stainless Steel Round Bar

Stainless steel round bars have become indispensable in various industries due to their exceptional strength, corrosion resistance, and versatility. As a leading SS round bars Manufacturer, Supplier, Stockist, and Exporter on a global scale, Bullion Pipes & Tubes LLP takes pride in offering an extensive range of stainless steel round bars tailored to meet diverse project requirements.

In this comprehensive guide, we'll delve into the world of stainless steel round bars, exploring their composition, properties, applications, and key factors to consider when selecting the right round bar for your specific needs.

Stainless Steel Round Bars

Stainless steel round bars are solid cylindrical bars made from stainless steel, an alloy of iron, chromium, nickel, and other elements. The combination of these elements imparts unique properties to stainless steel, making it a preferred choice in diverse applications.

Composition and Grades:

Stainless steel round bars come in various grades, each with its own set of properties and applications. Common grades include Stainless Steel 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 904L and 446 Round Bars. The grade you choose depends on factors such as corrosion resistance, temperature resistance, and mechanical properties required for your specific application.

Properties that Set Stainless Steel Round Bars Apart:

Corrosion Resistance: Stainless steel round bars are known for their excellent corrosion resistance, making them ideal for applications in harsh environments, such as marine and chemical industries.

High-Temperature Resistance: The alloy's ability to withstand high temperatures without losing its structural integrity is a crucial factor in applications like heat exchangers and exhaust systems.

Strength and Durability: Stainless steel round bars exhibit high tensile strength and durability, ensuring a long lifespan and minimal maintenance requirements.

Specifications of Stainless Steel Round Bars

Standard

ASTM, ASME, AISI A 276, SA 276, A 479, SA 479, ASTM, ASME A276/SA 479

Dimensions

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size

18mm – 47mm (11/16″ to 1-3/4″)

Range

3.17 MM TO 350 MM DIA

Stainless Steel Round Bars

SS 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 904L and 446 Round Bars

Length

1 to 6 Meters, Custom Cut Lengths

Condition

Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished

Finish

Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Form

Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc

Applications of Stainless Steel Round Bars Across Industries:

Stainless steel round bars find extensive applications across various industries due to their unique properties, making them a versatile and popular choice for different purposes. Here are some key applications across industries:

Construction and Architecture

Automotive Industry

Oil and Gas Industry

Chemical Processing

Food and Beverage Industry

Medical and Pharmaceutical

Aerospace Industry

Power Generation

Marine Industry

General Manufacturing

Other Applications

Choosing the Right Stainless Steel Round Bar:

When selecting a stainless steel round bar, consider factors such as:

Grade: Choose a grade based on the specific requirements of your application.

Diameter and Length: The size of the round bar should align with your project specifications.

Surface Finish: Depending on the application, you may need a polished or rough surface finish.

Final Words!

Bullion Pipes & Tubes LLP stands as the industry leader in providing top-notch stainless steel round bars exporters globally in various countries like Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia, and many other regions. Our commitment to quality, extensive product range, and customization options make us the preferred choice for customers across diverse industries. Contact us today at [email protected] or [email protected] and experience the excellence of stainless steel round bars that elevate your projects to new heights.

0 notes

Text

Optimizing Industrial Heat Transfer: The Power of Duplex Heat Exchanger Tubes

Duplex heat exchanger tubes are widely used in industry, with many advantages. These tubes, a combination of austenitic and ferritic stainless steels in one compound, offer excellent corrosion resistance accompanied by superior strength. This gives duplex tubes a special property that allows them to handle some of the coldest and hottest environments imaginable, making them an ideal tube for transferring heat.

Superior Corrosion Resistance

A high-performance heat exchanger Duplex tube excels at everything, including corrosion resistance. The fact that the compositions of austenitic and ferritic stainless steels are different from those found in normal steel, coupled with the special measures taken when manufacturing them together makes for an especially strong material. This is able not only to combat highly corrosive environments but also resist attack from chloride-containing substances as well. This feature makes tubes last much longer, and in turn, reduces maintenance costs.

Enhanced Mechanical Strength

Duplex tubes have outstanding mechanical strength, so they weather the most demanding industrial operations. Because their strength is superior, they are able to take high pressure and temperature variations without performance reduction. This strength factor makes them reliable and long-lasting in heat exchange applications.

Versatility Across Industries

Its versatility makes duplex heat exchanger tubes essential across a broad sweep of industries. Because of their adaptability to different environments, they have a competitive edge in applications from chemical processing plants to oil and gas refineries, desalination plants, or otherwise. That efficacy across so many types of environments is what makes them key to the most important heat transfer operations.

Efficient Heat Transfer

Heat exchanger Duplex 2205 pipe is great at promoting effective transfer of heat. Their design and composition allow for the maximum-possible heat conductivity so that they can handle transferring heat from one medium to another very well. This efficiency results in less energy consumption and lower operational costs, which only add to their attractiveness for industrial applications.

Cost-Efficiency and Longevity

Over the long term, investment in duplex heat exchanger tubes makes sound economic sense. These resist corrosion and strong mechanical properties reduce the need for frequent replacements or maintenance work, reducing downtime and costs. This longer life means big savings for industries that utilize heat exchange systems.

Key Considerations in Selection

When choosing a heat exchanger Super duplex tube, several key considerations play a pivotal role in ensuring their effectiveness:

Operating Conditions: According to their working environment, evaluate temperature and pressure factors as well as corrosive conditions for the tubes.

Material Compatibility: Also be sure they're compatible with the fluids or substances that will flow through them to avoid degradation and corrosion.

Maintenance Requirements: Minimize upkeep, and determine needs and frequency of maintenance to optimize operational efficiency.

Longevity and Durability: Reduce replacement costs by choosing tubes with high mechanical strength and a record of long service life.

Cost-Efficiency: Compare initial investment costs against long-term benefits to make an economically sound decision for your application.

Examining these factors carefully enables you to choose a course of action in keeping with your own operational needs, and one that will provide the greatest performance from duplex heat exchanger tubes.

Conclusion

For industries that insist on reliable and efficient heat transfer, the duplex heat exchanger tubes are certainly a top choice. Their combination of corrosion resistance, mechanical strength, and versatility makes them an indispensable component on all sides. With so many advantages, investing in duplex heat exchanger tubes is a wise choice for long-term operating efficiency and quality.

0 notes

Text

Tips for Selecting the Best Source for Duplex Pipes

We have followed our quality assurance procedures since the beginning of our business. They were created to meet the most exacting requirements of our clients in vital sectors where our goods can be applied successfully. To protect both the material qualities and the overall quality of the product, we use the best raw materials, cutting-edge technology, and the necessary post-processing techniques, all of which are followed by stringent quality tests. In terms of quality assurance, we have many years of experience. Furthermore, we have made it our goal to build a strong basis for our quality assurance system inside our already-existing and growing production system.

Types of duplex steel and pipes

One of our manufacturers, duplex steel suppliers in Mumbai, is employed in many different technical and industrial applications. For a variety of applications, we manufacture these sheets and plates in a range of standard and custom dimensions. In order to manufacture sheets and pipes that satisfy our customers' needs, we have also embraced the newest machinery and technology.

As a leading stainless steel pipes supplier, we ensure product quality by utilising the highest quality raw materials and cutting-edge technologies. One tool used to modify the system's flow direction is the stainless steel elbow. Customisation is possible for these elbows, however they are typically offered in 45 and 90-degree twists.

Being a top duplex pipe supplier,we offer superior strength and resistance to corrosion. The Duplex ERW Pipe from our company is machined with a better finish thanks to the most latest machining technology. However, DSS Welded Pipe has far better tensile strength characteristics. Although they are not easily welded, they are well-suited for welding using any common welding technique.

Under demanding circumstances, these tubes have the ability to retain and handle harmful liquids and media. A versatile grade used to transmit heat from two or more fluids is the Duplex Heat Exchanger tube. These tubes have good internal dependability and can be used to combine both hot and cold fluids. Duplex Coiled Tubing is a continuous, small-diameter pipe used in oilfield technologies and remediation procedures. We are India's top duplex tubes supplier.

The Duplex 2205 Pipe is composed of the chemical elements these pipes offer outstanding resistance to oxidation and corrosion under a range of environmental conditions. These pipes are more resistant to corrosion from crevices, erosion, and pitting. They are more thermally conductive and have less thermal expansion. A stainless steel pipe made with 2205 has exceptional mechanical qualities.

Super Duplex 2507 pipestake into account reliable vendors who offer quality control and certificates. Attend trade shows, look at internet directories, and ask for referrals to trustworthy sources. Before choosing, confirm the details, costs, and delivery alternatives.

Conclusion

Our duplex steel and pipes are dedicated to strict quality assurance and meet a wide range of industrial demands. With the use of cutting-edge technology and excellent raw materials, we offer a wide range of products, including duplex pipes and heat exchanger tubes. You can count on us to provide you with strength, durability, and corrosion resistance as your go-to supplier for duplex steel and pipes.

0 notes

Text

Significance Of Both Tube Expander & Grooving Tools!

In the world of manufacturing and machining, precision is the cornerstone of success. Tube expanders and grooving tools are essential components in achieving precision in machining processes. Tube Expander manufacturer in India and Grooving tool manufacturer in India play pivotal roles in providing industries with the necessary tools for accurate and efficient machining operations. In this article, we will delve into the significance of both these tools, their applications, and the key aspects of their manufacturing.

Significance of Tube Expanders:

Tube expanders are essential instruments found in industries like power generation, petrochemicals, HVAC, and manufacturing, particularly where heat exchangers and boilers are frequently used.

Tube expanders are utilized in various industrial applications, including boilers, heat exchangers, and condensers, to enhance and facilitate seamless operations.

Correct tube expansion guarantees firm connections between tubes and tube sheets, effectively preventing leaks and system failures

Significance of Grooving Tools:

Grooving tools excel in precision machining, delivering high precision, repeatability, and superior surface finishes, thereby guaranteeing that components adhere to rigorous specifications.

These tools are versatile and find application across diverse industries like automotive, aerospace, and electronics, where they craft slots and intricate features in crucial components.

Grooving tool manufacturers frequently provide customization possibilities to address precise application needs.

Key Aspects of Manufacturing Grooving Tools and Tube Expanders:

Choosing the Appropriate Materials: Selecting the right materials is a pivotal decision in the manufacturing process of both grooving tools and tube expanders. The choice revolves around opting for top-tier materials like stainless steel, alloy steel, carbide, or specialized alloys. This selection is contingent on the specific applications and challenges these tools will encounter across diverse industries.

Highly Accurate Engineering: The production of these tools necessitates advanced machining methods, notably Computer Numerical Control (CNC) machining. Precision engineering is crucial as it guarantees precise tolerances and reliable performance, meeting the demanding criteria of machining procedures.

Customization: Reputable manufacturers provide customization services, allowing them to adapt grooving tools and tube expanders to the distinct requirements of their clientele.

Support: Well-established manufacturers offer extensive technical assistance to aid customers in choosing the ideal tools for their specific applications.

Quality Assurance: The manufacturing process incorporates rigorous quality control procedures at every stage. Thorough testing, inspections, and stringent quality checks are carried out to guarantee that each tool adheres to the most exacting quality benchmarks.

Innovation: Innovation in materials, design, and manufacturing processes allows these manufacturers to continuously improve the performance and capabilities of their tools.

Sustainability: As the global focus on sustainability grows, manufacturers are also considering environmentally friendly practices in their processes.

About NIGASU

NIGASU is one of the reputed names for making engineering tools and we have the right set of experience for making these tools. To know more about other tools we offer, you can visit our website.

Source: https://penzu.com/p/972c981a2c71e468

0 notes

Text

Understanding the Physical Properties of Stainless Steel Plates

Corrosion Resistance: Stainless steel plates exhibit remarkable resistance to corrosion, making them ideal for applications in harsh environments such as marine and chemical industries.

High Temperature Resistance: These plates maintain their strength and integrity even at elevated temperatures, making them suitable for use in heat exchangers, boilers, and other high-temperature applications.

Strength and Durability: Stainless steel plates boast high strength-to-weight ratios, providing excellent structural integrity and durability, crucial for applications in construction and manufacturing.

Hygienic Properties: Stainless steel plates are non-porous and easy to clean, making them ideal for use in food processing, pharmaceuticals, and medical equipment where hygiene is paramount.

Aesthetic Appeal: With its sleek and modern appearance, stainless steel adds an aesthetic touch to architectural designs, interior decorations, and consumer products.

Magnetic Properties: Depending on the grade, stainless steel plates may exhibit magnetic properties, which can be advantageous for certain applications such as in magnetic resonance imaging (MRI) machines.

In conclusion, stainless steel plates offer a myriad of benefits, including corrosion resistance, high-temperature resistance, strength, durability, hygienic properties, aesthetic appeal, magnetic properties, ease of fabrication, and recyclability. For top-quality stainless steel plates and tubes, consider Om Steel as your trusted supplier. With its extensive range of products and commitment to customer satisfaction, Om Steel ensures reliability and excellence in every purchase. Choose Om Steel for all your stainless steel plate and tube needs and experience unparalleled quality and service.

0 notes

Text

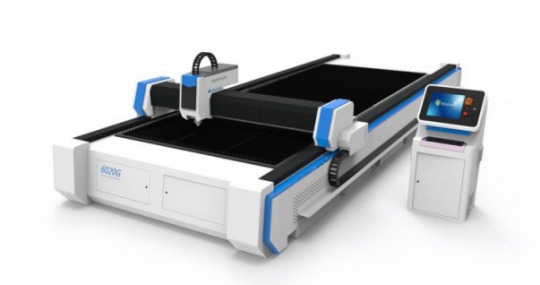

Fiber Laser Cutting Machine Manufacturer in India

We are the best fiber laser cutting machine manufacturer in India, we give you a lot of metal laser cutting machine. As you are aware, industries are benefiting greatly from the one-by-one technological advancements that are occurring nowadays. The task is completed quickly and easily thanks to these technology, and the results are good as well. Currently, we’re talking about the metal sectors, which are leveraging these technologies to increase their output and generate a lot of money. As a result, we have offered you a high-quality laser cutting machine at a reasonable price. When compared to other products on the market, our laser fiber laser cutting machine is more affordable, has better quality, and is made with higher-quality components. We also use the most recent, cutting-edge technologies to ensure that our products last as long as possible. Additionally, all of our items are produced under the guidance of our professionals to prevent future problems.

Pusaan Automation Pvt. Ltd. is a brand-leading business in India, one that consistently earns the confidence of its customers and builds stronger bonds with them. When it comes to our sheet metal laser cutting machine price in India, it is reasonable and of high quality. We are the leading provider and manufacturer of fiber laser cutting machines in India and we supply the top models of laser machines for cutting sheet metal. Our powerful laser cutting machine provides a metal with a high-quality cutting surface. The quality of a product is rising thanks to this technology. Fiber laser machines are employed in numerous industries today, including the automotive, lighting, advertising, fitness equipment, and decoration industries. numerous metal businesses also use this laser cutting machine technology.

Open Type Fiber Laser Cutting Machine

This cutter’s metal body underwent a 600 ° C heat treatment and is kept cool for 24 hours in the chamber. When this is possible, a plano-milling machine and welded carbonic acid gas are used. High power and a twenty-year service life are therefore guaranteed. Maximum acceleration rate of 1.0G, repeated position precision of 0.05mm/1000mm, and maximum running speed of 100 M/min are all high class-leading and high-efficiency. A world first invention, easy integration, and contemporary design with the least amount of space required for a machine of the same level. Each and every feature, including the control arm, LED indication design, and stainless steel border, exudes excellent and supreme elegance.

We create industrial goods with the newest technologies and to the highest standards of luxury. 600 °C heat treatment, 24 hr. of oven cooling We employ high-quality components to ensure 20 years of operation without deformation. Auto collimator: to check the straightness of the guide rails and ensure each machine set’s precision. It features a database of expert cutting parameters, which means that different cutting parameters will be automatically applied for various sheet metal materials at various thicknesses, reducing the need for operator work. has excellent features implemented and uses servo motors that were originally imported. It has excellent MS 0.5–12mm (depending on material) cutting thickness. We offer top-notch Open Type Fiber laser cutting machine with cutting-edge features.

Exchange Table Type Fiber Laser Cutting Machine

Exchange Table Type Fiber Laser Cutting Machine: Buy Now! We give you a fantastic bargain and discount. Every detail is perfect, the suspension lamp style, the console has a chrome steel border, and we are producing industrial goods to meet the demands of high-end goods. Our exbelow shows the machine’s technical specs.perts provide the greatest electrical and driving systems. We only use parts of the highest calibre, and the table.

Sheet and Tube Fiber Laser Cutting Machine

Exchange Table Type Fiber Laser Cutting Machine: Buy Now! We give you a fantastic bargain and discount. Every detail is perfect, the suspension lamp style, the console has a chrome steel border, and we are producing industrial goods to meet the demands of high-end goods. Our exbelow shows the machine’s technical specs. It includes an upper and lower exchangeable table, which greatly reduces standby time. The drawer-type material collection device also allows for a wide variety of practical options, which significantly boosts the effectiveness of the entire five hundredth. It has a highly distinctive and contemporary style and is furnished with a companion interchangeable table. We included high-quality parts in the machine, giving you a wonderful experience and properly increasing your output.

Advantages of Fiber laser cutting Machine

There are several benefits to employing a fiber laser cutting machine. As you may be aware, there are numerous application domains that use this technology to increase production and expand their businesses quickly. The main benefits of a fiber laser cutting machine are five.

Boost in Cutting Speed– Fiber laser cutting machines have good cutting speeds, which enable them to do jobs fast and with the highest quality possible. A fiber-based laser can cut more quickly than a conventional laser while cutting a straight line that is 1 mm thick.

Superior Performance- You’ll discover that fiber lasers perform better than many of their competitors. Fibers offer a high-quality laser beam that may be tightly focused to attain incredibly high levels of accuracy and greater power density.

Cutting Reflective Material– The reflecting material is one of the key issues when utilising a conventional laser. There is a possibility that a laser reflector will strike the substance and cause damage. Because of this, cutting copper, brass, and aluminium with conventional lasers is uncommon. However, this reflective material issue is no longer a problem with fiber optic lasers, allowing cutting of these materials.

No Moving Parts- The absence of moving parts lowers running expenses and raises maintenance requirements. It is not essential to use a moving mirror to generate the required laser because light pulses are transmitted via fiber optic cabling. There is no material loss during cutting since only the cutting material makes contact with the laser.And provide a best finishing cut.

Higher Electrical Efficiency- Each time the fiber optic design is employed, power is saved, and because less energy is needed, the hardware’s lifespan is also increased. A laser cutter can handle any challenge. High powered lasers can be utilised on a very small region of material with hardly any distortion or warping.

Less Expensive- The cost of fiber laser cutting is perhaps its most beneficial advantage. The cost overhead for this method entails a little initial saving and a significant saving over the course of the laser’s lifetime. For one thing, unlike other laser technology, it does not need pricey optical mirrors. Furthermore, the focusing lens is sealed inside the cutting head rather than being exposed. As a result, unlike laser applications where damage and frequent replacement are required over the lifespan of fiber optics, concentrating lenses only need damage when maintained properly.

#best fiber laser cutting machine manufacturer in India#fiber laser cutting machine manufacturer in India#best fiber laser cutting machine in India#fiber laser cutting machine in India#fiber laser cutting machine

0 notes

Text

Top Stainless Steel Seamless Tubes in Mumbai

KRYSTAL GLOBAL ENGINEERING LIMITED (Formally Known as Krystal Steel Manufacturing Private Limited) is a Stainless Steel company with the vision to be the Leader from INDIA in Stainless and Nickel Alloy Tubes with success based on Operational Excellence and Superlative Services.

We are dedicated to help our customers gain a competitive advantage by supplying a wide range of products such as Tubes, Pipes, U Tubes, Coil Formed Tubes.

KRYSTAL has well established “State of Art” facilitates with continuous enhancement of the product and services to serve the customers across the globe.

We have customers from a wide range of Industries such as – Power Plants, Oil & Gas, Chemical Plants, Fertilizers, Pharmaceuticals, Textile, Railways, Defence, Automobiles, Desalination and more. Our products are used in Engineering Applications such as – Pressure Vessels, Heat Exchanger, Condenser, Heat Recovery System and more. Our Products, Technology and Services are used worldwide with complete peace of mind.

Tap here to know more about:

#kgel#krystalglobalengineeringlimited#krystalgeltd#beststainlesssteelseamlesstubesinmumbai#topstainlesssteelseamlesstubesinmumbai#steels#tubes#metals#mining#pipes#stainlesssteels#seamlesssteels#steelmanufacturer#metalmanufacturer#tubesmanufacturer#pipemanufacturer#steelcompany#steelexporter#steelsupplier#worldwide

0 notes

Text

BEST SS TUBE MILL MACHINE MANUFACTURERS IN AHMEDABAD

Are you searching for a top-notch tube mill manufacturer for your production requirements?

You need to go no farther than Ahmedabad, which is home to some of the greatest tube mill manufacturers in Ahmedabad in the business. So how can you pick the best choice for your company when there are so many to select from?

To take the load off your shoulders we “Ashapura Industries” have come up with all the questions you need to know before choosing the best ss tube mill machine manufacturers in Ahmedabad.

What is the SS Tube?

SS Tube is an abbreviation for stainless steel tube. It is a hollow cylindrical construction composed of corrosion-resistant stainless steel, which is a strong material. Several industries, including building, transportation, industry, and decoration employ stainless steel tubes.

There are several grades of stainless-steel tubes, including 304 and 316, each with unique characteristics and uses. To fulfil the unique requirements of diverse industries and applications, they are offered in a variety of diameters, wall thicknesses, and lengths.

Stainless steel tubes are frequently used in heat exchangers, medical devices, food and beverage processing equipment, structural elements, and architectural elements, among other applications. They are widely used in fields that need great strength, resistance to corrosion, and aesthetic appeal.

What is the SS Tube mill?

Stainless steel tubes are made using a machine called a "SS tube mill" from steel coils or strips. Many steps are involved in the process, including cutting, sizing, welding, and forming.

Forming is the initial step in the procedure when a set of rollers is used to shape the steel strip into a cylindrical shape. Afterward, a high-frequency induction welding procedure is used to join the strip's edges together. After being welded, the tube is sent through a series of sizing rolls to get the proper ovality, wall thickness, and outside diameter.

Once the tube is sized, it may be cut to the desired length using a flying saw or a rotary cutting machine. The cut tube is then inspected for defects and may be further processed to achieve specific surface finishes, such as polishing or bead blasting.

Stainless steel tube mills come in different sizes and configurations, depending on the specific requirements of the application. Some mills can produce tubes with a diameter as small as a few millimetres, while others can produce large-diameter tubes used in industrial and structural applications.

Why do we need ss tube mill machine manufacturers in Ahmedabad?

There are several reasons why we need SS tube mill machine manufacturers in Ahmedabad:

Manufacturing Capability:

Ahmedabad has a well-developed industrial infrastructure and a skilled workforce, which makes it an ideal location for SS tube mill machine manufacturing. The manufacturers in Ahmedabad can produce high-quality stainless-steel tubes in various sizes, shapes, and grades to meet the specific needs of different industries.

Meeting the demand for high-quality tube mills:

Tube mills are an essential piece of machinery used in various industries, such as construction, automotive, and aerospace. To meet the growing demand for these machines, we need reliable and efficient manufacturers who can design and manufacture high-quality tube mills.

Customized solutions:

Every business has unique requirements when it comes to tube mills. By working with SS tube mill machine manufacturers in Ahmedabad, businesses can get customized solutions that meet their specific needs. This ensures that they have the right equipment for their operations, which can lead to improved efficiency and productivity.

Local manufacturing:

By working with local manufacturers in Ahmedabad, businesses can benefit from reduced lead times, faster delivery, and better communication. This can help them to better manage their supply chain and respond more quickly to changing market demands.

Cost-effective solutions:

Working with SS tube mill machine manufacturers in Ahmedabad can also be cost-effective compared to importing machines from other countries. This can help businesses to reduce their costs and improve their bottom line.

What is the use of an SS tube mill machine?

An SS tube mill machine produces stainless steel tubes of various sizes and shapes.

It is used in industries such as construction, automotive, and aerospace.

The machine shapes flat strips of stainless steel into seamless tubes through a series of rollers and welders.

The resulting tubes are high-quality and can be used for structural support, fluid transport, and heat exchange.

In summary, the use of an SS tube mill machine is to produce high-quality stainless-steel tubes for various industrial applications.

Benefits of having the Best SS Tube Mill Machine Manufacturers in Ahmedabad:

High-quality production: Advanced technology for durable and reliable stainless steel tubes.

Customized solutions: Tailored solutions for different industries.

Cost-effective production: Affordable tubes from high-quality raw materials.

Timely delivery: Strategically located for reduced transportation costs and faster delivery.

Skilled workforce: Ahmedabad's industrial infrastructure and skilled workforce produce various sizes, shapes, and grades of stainless-steel tubes.

Why choose only the best SS Tube Mill Machine Manufacturer in Ahmedabad?

Quality: The best SS tube mill machine manufacturers in Ahmedabad produce high-quality tubes that meet industry standards.

Customization: They provide customized solutions to meet the specific needs of different industries.

Cost-effective: They have access to high-quality raw materials at competitive prices, which helps in producing cost-effective tubes.

Timely delivery: They are located in a strategically advantageous location, which helps in the timely delivery of the tubes.

Reputation: They have a proven track record of delivering high-quality products and excellent customer service.

Looking for high-quality and reliable stainless-steel tubes? Ashapura Industries use advanced technology and skilled workforce to make us the best tube mill manufacturer in Ahmedabad. With customized solutions, cost-effective production, and timely delivery, we offer a one-stop solution for all your stainless-steel tube needs.

Trust us for durable and dependable stainless-steel tubes that meet industry standards. Contact us now to learn more about our products and services.

#Tube Mill Manufacturer in Ahmedabad#SS Tube Mill Machine Manufacturer in Ahmedabad#SS Tube Mill Machine Manufacturers

0 notes

Text

Which stainless steel pipes are ideal for your needs?

Which metal, carbon steel or stainless steel, is preferable and why? This is a problem that plagues many workplaces and is faced by engineers, designers, and factory workers alike. Stainless steel and carbon steel tubes are both sturdy options, so picking one over the other might be challenging. Understanding steel and its applications can help you choose the best kind for your purposes.

You know that steel looks to be made out of metal. The author informs you that steel is used in many different contexts and can be found in almost every produced item on the market today. Even if steel is something you work with often, you probably haven't given much thought to the material itself. For their steel pipe needs, many choose Cold drawn seamless tube manufacturers in India.

To what does it belong? Steel is a metal, but what makes it unique from other metals? Finally, why are there so many unique steel varieties?

What, exactly, is steel?

Indeed, steel is an alloy, a class of metals that combines properties of many elements. Alloys are created when two or more different types of metal are combined. Suppliers of API 5L X65 Pipe are top-notch. Steel, in any context, refers to an iron-based alloy that often also includes another metal. Stainless Steel Seamless Tube Manufacturers in India have been outstanding.

Many types of steel include many metals, however the amounts might vary widely. The metals and characteristics that make up a steel's classification. You can easily find 304 stainless steel tube manufacturer in India.

A carbon-based steel

To all appearances, carbon steel is just a standard steel made up of iron and carbon. Tiny or undetectable amounts of other chemicals might be present. Carbon steel is classified by the percentage of carbon added to the iron during the manufacturing process. Carbon steel is famously hardy and heat resistant. Stainless Steel Heat Exchanger Tube manufacturers in India are always reliable.

Type 316L Stainless Steel, Certified by the American Iron and Steel Institute

The addition of chromium to an alloy results in stainless steel. Steel with a lower carbon content is called "basic," and although it may include up to 2% carbon, stainless steel contains at least 10% chromium. Stainless Steel Boiler Tube manufacturers in India has the finest quality. Even though carbon steel is not often found in stainless steel, its presence might go undetected in certain alloys. The Stainless Steel Precision Tube manufacturers in India are always ready to assist you.

Because it is resistant to rust and corrosion, stainless steel is perhaps its most desirable quality. Most of the elements in steel are iron, and iron rusts easily. Stainless Steel Capillary Tube manufacturers in India have great prices.

The alloying elements used in steel vary amongst the many distinct types of steel. Steel type and properties are also influenced by the heating and maybe handling of metals during production. In addition to carbon and iron, steel may also include a variety of other elements including tungsten, cobalt, nickel, lead, and molybdenum. Stainless Steel Coiled Tubing manufacturers in India has been fantastic.

0 notes