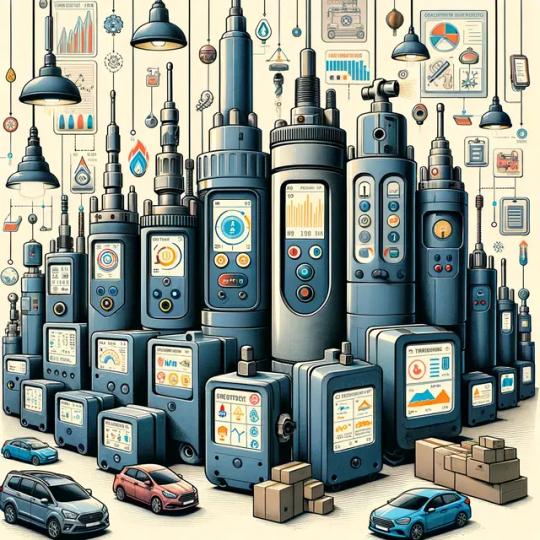

#Tank Level Monitoring System Market

Text

Tank Level Monitoring System Market Size and Forecasts - Trends and Growth Opportunity Analysis

The Tank Level Monitoring System Market is expected to grow from USD 757 million in 2020 to USD 1,057 million by 2025, at a CAGR of 6.9%. Growing demand from process industries and growing demand for IoT-based tank level monitoring systems are the key factors driving the growth of the tank level monitoring system market.

TE Connectivity (Switzerland), Emerson Electricl (US), Graco Inc (US), Piusi (Italy), Tank Scan (US), Gauging Systems (US), Varec Inc (US), Digi International (US), Dunraven Systems (Ireleand), Schneider Electric (France), Pneumercator (US), The Southern Company (US), Skybitz (US), AIUT (US), AXSensor (Sweden), HMS Networks (Switzerland), Kingspan (Ireland), Schmitt Industries Inc (Germany), Oriel Systems (UK) and Powelectrics (UK) are a few major companies dominating the Tank level monitoring system market.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=78964849

Market oil & fuel to dominate in 2020

The market for oil & fuel accounted for the largest size in 2019. The levels of oil and fuel in storage tanks must be continuously monitored because of strict safety and environmental requirements. Overfilling or product discharge on deck and into the sea could have devastating consequences for human life and the environment. The charging and discharging procedures have to be carefully supervised. Advancements in technology have allowed the level sensing technology to measure oil and fuel levels in storage tanks. IoT-based solutions are also gaining traction in the oil & gas industry.

Radar-based technology to grow at a higher CAGR during the forecast period

The market for oil & fuel accounted for the largest size in 2019. The levels of oil and fuel in storage tanks must be continuously monitored because of strict safety and environmental requirements. Overfilling or product discharge on deck and into the sea could have devastating consequences for human life and the environment. The charging and discharging procedures have to be carefully supervised. Advancements in technology have allowed the level sensing technology to measure oil and fuel levels in storage tanks. IoT-based solutions are also gaining traction in the oil & gas industry.

APAC to grow at highest CAGR during the forecast period

In terms of value, APAC to grow at the highest CAGR during the forecast period. Among all applications, the oil & fuel segment is the most dominant application in the APAC tank level monitoring system market. APAC is expected to show significant growth in the oil & gas industry. India is expected to be one of the largest contributors to non-OECD petroleum consumption growth globally.

0 notes

Text

Ad It Up

You only thought it was difficult to escape the marketer’s voice. From traditional media like outdoor, print, and broadcast, to a variety of ads littering our social media feeds, web pages, and search results, marketers have been seemingly everywhere trying to get our attention. And the more they tried, the louder they had to shout, because it’s crowded out there, and the decibel level—whether audible or visual—is increasing.

Except perhaps in stores and at the gas pump, where we felt like we at least had a few minutes of quiet. That, too, is changing rapidly, as in-store advertising has gone digital, to the point of it being called “broadcast-level scale.” Gas pumps too are now coming equipped with video screens to sell to us while we are filling our tank.

It’s all a mixed bag right now of ads, with gas stations able to deliver hyper-local advertising for third-party advertisers nearby. Inside the store, the campaigns are aimed at the masses instead of using an audience-of-one approach.

I see the day coming, though, in which advertising at the pump will be increasingly one-to-one (remember, you have to insert or tap your card first, which could then quickly allow them to access a profile of you).

And the same goes for inside the store, especially once retail formats like Amazon’s “Just Walk Out” technology are deployed widespread. Your presence and unique data would be detected wherever you go in the store as the system monitors your shopping basket, and messages could be directed straight to you when you ponder the pasta sauces or wherever you go.

We’ve come a long way when it comes to in-store advertising. The majority of what we have seen usually involves massive stacks of soft drinks, the red, white, and green packages from Coca-Cola cleverly arranged to spell words or form images. The same goes for snack foods and beer leading up to the Super Bowl. Otherwise, maybe some small shelf hangers might try to whisper a marketing message.

Now, though, there is the possibility of smart screens attached to the clear refrigerator doors, behind which beverages of all kinds reside. Stand-alone screens can also welcome customers as they walk in. The possibilities are limitless, because LCD screens are cheap, and can all be managed remotely.

All of which speaks to this emerging truth: the retail store and gas stations are now viable platforms for advertising, a rentable space little different from billboards, TV, and the internet. The battle for our attention just found a new place to stage that fight. It allows retailers to boost their revenues and bottom lines above and beyond just selling things.

It’s happening in the online arena as well. Have you noticed how many sponsored spots there are on any Amazon results page? Amazon scored $12 billion in ad revenues in Q3 2023 alone. That’s impressive, especially when you consider that Amazon’s total revenue that quarter was $143 billion. In other words, advertising made up one in every 12 dollars of its revenues.

I predict a similar such cascade of revenues for any retailer willing to parse out its interior—and exterior—space for advertising purposes. After all, why not? If you can hit people right when they are coming to spend money anyway, this is pretty simple.

Truthfully, I do not mind the ads, especially if they point me to things I might be interested in. Elevate it to audience-of-one capability, and it is even better. I know…some people will be creeped out by this, just like they have been with all the targeted advertising we see online. I would much rather hear and see ads for things I am likely to buy, as opposed to things I will never buy. Every time I hear that Tampax ad on one of my podcasts, I think about how they’re foolishly wasting half of their ad spend on men like me.

Others may see such ubiquitous advertising as further invasion of their private space, a harbinger of a dystopian society to come. Or maybe it has already arrived. To each their own, but there is no ad blocker yet for the brick and mortar world, and the best you can do is shut your eyes and ears, and walk on by.

Or out.

Dr “Talk To Me” Gerlich

Audio Blog

3 notes

·

View notes

Text

⬐ @seeasunset ⬎

“whoa you’re a hot mess, there, what happened getting here?”

Stepping over one of the mercs she’d just shot down, Alisa was pretty sure she was going to regret this entire day. Everything about it was beyond absurd, and she was used to varying levels of absurd. But this? Someone trying to steal her identity? Being shot so she fell through a fish tank, and having to fight her way through the markets in the Wards? Unbelievable. She could swear she still smelled like fish, for crying out loud.

“We’ll talk about it later.” God, she didn’t even want to think about it. It was too ridiculous. Far too ridiculous. A fish tank, really? Of all the thing she’d got herself into, this wasn’t what she was expecting. She was soaked to the bone, hair stuck to her face and her shoulders, and worst of all, she was freezing from having to run through the markets. Saying she was a hot mess was putting it mildly.

Huffing as she looked around, she pulled up her omni-tool, checking the monitoring systems on her biotic amp. She hadn’t overstressed things too much, but that was always a worry for her; if she overstressed them too much, then she put herself at risk for other issues… issues that she didn’t want to repeat. Issues that would be critical given the state the galaxy was in and the role she played in it.

Brushing her soaked bangs off of her forehead, Alisa huffed at the pistol she’d picked up, the weight of it throwing her off. It was difficult to coordinate her biotics with, but it was better than nothing; even if she could primarily rely on her biotics, it was better to at least have one. Not to mention, it seemed to be unique in some way; there might be some clue as to who was coming after her that Brooks had talked about.

“Were you or any of the others able to figure out who the hell these guys are? Or what it is they even want? You know, besides the obvious: me, dead. As if they can accomplish that.”

#me3. ❖﹙ struggle succeed ⋄ rewind and repeat. ﹚#i couldn’t not give vasco the chance at being the rescuer in citadel dlc lmaooo#with the classic “we’ll talk about it LATER” lmao

2 notes

·

View notes

Text

Iranian ultrasonic level sensors

Iranian ultrasonic level sensors represent a locally developed solution for non-contact measurement of fluid levels in diverse industrial and commercial settings. These sensors are designed and manufactured in Iran, catering to the specific needs and requirements of various sectors within the country. Here's an overview of Iranian ultrasonic level sensors:

Design and Development:

Iranian ultrasonic level sensors are engineered and produced by Iranian companies, utilizing advanced technologies and expertise in the field of sensor manufacturing. These sensors are designed to meet the standards of quality, accuracy, and reliability required for a wide range of applications across different industries.

Features:

High Accuracy: Iranian ultrasonic level sensors offer precise measurement capabilities, ensuring accurate monitoring of fluid levels in tanks, reservoirs, and other containers.

Non-contact Measurement: Like their international counterparts, Iranian ultrasonic sensors employ non-contact ultrasonic technology, eliminating the need for physical contact with the fluid being measured. This feature minimizes the risk of contamination and interference, enhancing reliability.

Durability and Reliability: Iranian ultrasonic level sensors are built to withstand harsh environmental conditions, including temperature variations, humidity, and dust. Their robust construction ensures long-term reliability and performance stability.

Adaptability: These sensors are designed to be versatile and adaptable to different applications and industries, including water and wastewater management, oil and gas, chemical processing, agriculture, and more.

Ease of Installation and Use: Iranian ultrasonic level sensors are designed for ease of installation and operation, with user-friendly interfaces and intuitive controls.

Applications:

Industrial Automation: Used in industrial processes for level monitoring and control in tanks, silos, and other containers.

Water Management: Deployed in water treatment plants, reservoirs, and distribution networks for monitoring water levels and ensuring efficient water management.

Agriculture: Utilized in irrigation systems for monitoring water levels in reservoirs and controlling water distribution to fields.

Environmental Monitoring: Employed in open-channel flow measurement systems for monitoring river and stream levels, contributing to flood control and environmental protection efforts.

Advantages:

Localization: Iranian ultrasonic level sensors are developed to meet the specific requirements and standards of the Iranian market, offering tailored solutions for local industries and applications.

Support and Service: Local manufacturers provide technical support, maintenance, and after-sales service, ensuring customer satisfaction and operational efficiency.

Contribution to Local Economy: The development and production of Iranian ultrasonic level sensors contribute to the growth of the domestic sensor industry and the economy as a whole.

In summary, Iranian ultrasonic level sensors represent a domestically developed solution for fluid level measurement, offering high accuracy, reliability, and adaptability to meet the needs of various industries and applications within Iran. Their localization, along with robust performance and local support, makes them a valuable asset in industrial automation and water management systems across the country.

0 notes

Text

Precision Aquaculture Market Exhibits Higher Growth Prospects During 2024-2033

Precision aquaculture is a new approach to fish farming that uses advanced technologies to monitor and optimize conditions in fish tanks or ponds in order to maximize growth and yield. This approach can help farmers to reduce costs and increase profits while also ensuring that fish are raised in a healthy and sustainable manner.

Some of the technologies used in precision aquaculture include sensors that measure water temperature, pH, and dissolved oxygen levels; automated feeders that dispense food at precise intervals; and computerized systems that track and record data on the health and growth of individual fish. This information can be used to adjust conditions in the tanks or ponds in real time, ensuring that the fish are always raised in optimal conditions.

To Know More: https://www.globalinsightservices.com/reports/precision-aquaculture-market/?utm_id=Snehalkast

Market Outlook

Aquaculture is the cultivation of aquatic organisms in controlled environments for food production. Precision aquaculture is a subfield of aquaculture that uses advanced technologies to optimize production.

Precision aquaculture technologies include sensors, data analytics, and automation. These technologies are used to monitor and optimize water quality, feeding, and other factors that affect fish growth and health.

Precision aquaculture has been shown to improve production efficiency and yield, while reducing labor costs and environmental impact. In the future, precision aquaculture is expected to play a major role in meeting the worlds demand for seafood.

Precision aquaculture is a rapidly growing industry that is driven by the need for more efficient and sustainable methods of fish production. The key drivers of precision aquaculture are the increasing demand for fish and seafood, the need for more efficient production methods, and the desire to create a more sustainable industry.

Request Sample: https://www.globalinsightservices.com/request-sample/GIS24570/?utm_id=Snehalkast

Major Players

The global market report includes players like AKVA Group, Nutreco, Steinsvik, Aquabyte, Inc., InnovaSea Systems, Deep Trekker, Lifegard Aquatics, Imenco AS, MonitorFish, and Aqualine AS.

0 notes

Text

Understanding Float Switch Sensors: Applications, Prices, and Varieties in UAE

Float switch sensors are critical components used in various industries and applications to monitor liquid levels effectively. Whether it's water, sewage, sump, wastewater, or diesel fuel, these sensors play a pivotal role in automation and control systems. In this article, we'll delve into the functionality, prices, and varieties of float switch sensors available in the UAE market, particularly in Sharjah and Dubai.

What is a Float Switch Sensor?

A float switch sensor is a simple yet efficient device used to detect liquid levels in tanks or reservoirs. It consists of a buoyant float attached to a switch mechanism. As the liquid level rises or falls, the float moves accordingly, activating or deactivating the switch to signal the level change. This signal can be utilized to control pumps, valves, alarms, or other automated processes.

Applications of Float Switch Sensors

Water Management: Float switches are commonly employed in water tanks for residential, commercial, and industrial purposes. They ensure timely refilling or draining of tanks, preventing overflow or dry running of pumps.

Sewage and Wastewater Systems: In sewage treatment plants and wastewater management systems, float switches monitor levels in collection tanks, facilitating efficient pumping and preventing overflow incidents.

Sump Pump Control: Sump pumps equipped with float switches automatically activate when water levels rise in basements or underground spaces, safeguarding against flooding.

Fuel Tanks: Float switches are utilized in diesel fuel tanks to monitor fuel levels in generators, vehicles, or industrial machinery, ensuring uninterrupted operation.

Industrial Processes: Various industrial applications, including chemical processing, food and beverage production, and manufacturing, rely on float switches for liquid level monitoring and control.

Types of Float Switches

Vertical Float Switches: These switches feature a vertically mounted float that moves up and down with liquid levels.

Horizontal Float Switches: Horizontal float switches have a float that moves horizontally along a guide rod, making them suitable for narrow tanks or limited space installations.

Multi-Level Float Switches: Designed with multiple floats at different levels, these switches provide precise level control and versatility for complex applications.

Reed Switch vs. Mechanical Switch: Float switches employ either reed switch technology or mechanical switches. Reed switches offer high reliability and are suitable for corrosive or hazardous environments, while mechanical switches are cost-effective and suitable for standard applications.

Where to Find Float Switches in Sharjah and Dubai

Float switches are readily available in hardware stores, industrial suppliers, and online marketplaces in Sharjah and Dubai. Popular brands such as Creative Automation offer a wide range of options to suit different requirements and budgets.

In conclusion, float switch sensors are indispensable devices for liquid level monitoring and control across various industries and applications in the UAE. Understanding their functionality, types, and prices can help businesses make informed decisions when selecting the appropriate float switch for their specific needs.

#Wastewater Float Switch#Diesel Fuel Float Switch#Multi-Level Float Switch#Sump Float Switch#Water Level Float Switch#Industrial Float Switch#Float Switch Sensor#Float Switch Price

0 notes

Text

Understanding Manifolds inside the Oil and Gas Industry

In the complicated international of oil and gasoline exploration and production, manifold systems play an important position in facilitating the glide of fluids inside wellheads and production centers. These complicated systems are critical additives of the oil and gas infrastructure, serving numerous functions to make certain efficient operations and maximize manufacturing output.

In this article, we will delve into the concept of manifolds, their uses, and their significance in the oil and fuel company.

What is a Manifold?

A manifold, in the context of the oil and gas industry, refers to a gadget of interconnected pipes or channels designed to accumulate, distribute, and control the flow of fluids alongside crude oil, natural gas, and water inside a production facility. Manifolds are generally crafted from long lasting substances along with metallic or alloy, capable of withstanding immoderate pressures and corrosive environments normally encountered in oil and gas operations.

Uses of Manifolds inside the Oil and Gas Industry:

1. Wellhead Manifolds:

One of the number one programs of manifolds is on the wellhead, in which multiple manufacturing wells are interconnected to a major manifold system. Wellhead manifolds gather crude oil, natural gasoline, and other fluids constituted of personal wells and channel them to downstream processing centers or storage tanks. By consolidating the go with the flow from more than one wells, wellhead manifolds streamline production operations and reduce the need for large ground infrastructure.

2. Production Manifolds:

In large oil and gas fields, manufacturing manifolds are mounted at strategic places to gather and distribute fluids from multiple wellheads inside a designated location. These manifolds serve as primary hubs for managing the go together with the go with the flow of manufacturing fluids, permitting operators to manipulate and optimize production quotes primarily based totally on reservoir overall performance and market call for. Production manifolds might also additionally consist of valves, chokes, and instrumentation to modify the flow prices and monitor process parameters.

3. Injection Manifolds:

In higher oil recovery (EOR) operations, injection manifolds are employed to supply fluids which incorporate water, steam, or chemical components into reservoirs to decorate oil healing costs. These manifolds obtain injection fluids from surface centers and distribute them to injection wells strategically located at some stage in the world. Injection manifolds play an essential function in retaining reservoir stress, displacing oil toward production wells, and maximizing hydrocarbon extraction performance.

4. Separator Manifolds:

Separator manifolds are applied in downstream processing centers to gather and segregate manufacturing fluids into their respective levels, together with oil, gasoline, and water. These manifolds get hold of multiphase fluids from production separators and direct them to similarly processing devices for remedy, separation, and storage. Separator manifolds help optimize the separation manner, lower fluid managing fees, and make sure compliance with environmental recommendations.

Significance of Manifolds in the Oil and Gas Industry:

Manifolds are vital additives of oil and fuel production systems, supplying essential infrastructure for fluid coping with, distribution, and manipulation. Their strategic placement and robust layout permit operators to correctly control production operations, optimize reservoir overall performance, and maximize hydrocarbon restoration charges. By consolidating drift streams from more than one wells and directing them to processing facilities, manifolds contribute to the overall productiveness, profitability, and sustainability of oil and gas duties.

Manifolds play a pivotal function within the oil and gas business enterprise, serving as essential conduits for the float of production fluids from wellheads to processing facilities. Their flexible layout, coupled with advanced automation and control structures, permits operators to streamline manufacturing operations, beautify reservoir performance, and optimize useful resource utilization. As the oil and gasoline industry keeps evolving, manifolds will live vital additives of upstream and midstream infrastructure, helping the continuing quest for strength protection and sustainability.

0 notes

Text

The Ultimate Guide to Shopping for a Pressure Transmitter: Everything You Need to Know

Introduction to pressure transmitters

Pressure transmitters play a crucial role in various industries, from manufacturing to oil and gas. These devices are used to measure and transmit pressure readings, allowing operators to monitor and control processes effectively. Whether you are looking to replace an old pressure transmitter or buying one for the first time, this guide will provide you with everything you need to know to make an informed decision.

Pressure transmitters are essential because they provide accurate and reliable pressure measurements. They are used in industries such as chemical processing, pharmaceuticals, food and beverage, and many more. خرید ترانسمیتر فشار ویکا These devices help ensure the safety and efficiency of processes by monitoring pressure levels and alerting operators to any anomalies. By understanding the importance of pressure transmitters, you can appreciate why choosing the right one is crucial for your specific application.

Understanding the importance of pressure transmitters in various industries

In many industries, maintaining the right pressure levels is critical for the success of production processes. Pressure transmitters are used to monitor and control pressure in systems such as pipelines, tanks, and machinery. For example, in the oil and gas industry, pressure transmitters are used to monitor the pressure in pipelines to prevent leaks and ensure the safe transportation of oil and gas. In the pharmaceutical industry, pressure transmitters are used to monitor pressure levels in reactors to ensure the quality of the final product.

The accuracy and reliability of pressure transmitters are vital in these industries. A faulty or inaccurate pressure transmitter can lead to costly downtime, safety hazards, and poor product quality. Therefore, investing in a high-quality pressure transmitter is essential to ensure the smooth operation of your processes and the safety of your employees.

Factors to consider when buying a pressure transmitter

When shopping for a pressure transmitter, there are several factors to consider to ensure you make the right choice for your specific application. Here are some key factors to keep in mind:

Pressure range: Determine the pressure range you need the transmitter to measure. Consider both the minimum and maximum pressure levels you will encounter in your application.

Accuracy: Look for a pressure transmitter with a high level of accuracy. This will ensure that you receive precise pressure readings, allowing you to make informed decisions based on reliable data.

Output signal: Pressure transmitters can have different types of output signals, such as analog or digital. Consider the compatibility of the output signal with your existing monitoring or control systems.

Environmental conditions: Assess the environmental conditions in which the pressure transmitter will be installed. Consider factors such as temperature, humidity, and presence of corrosive substances. Choose a transmitter that can withstand these conditions to ensure its longevity.

Maintenance requirements: Consider the maintenance requirements of the pressure transmitter. Some models may require frequent calibration or replacement of parts. Choose a transmitter that aligns with your maintenance capabilities and resources.

By considering these factors, you can narrow down your options and choose a pressure transmitter that meets your specific requirements.

Types of pressure transmitters available in the market

Pressure transmitters come in different types, each designed for specific applications. Here are the most common types of pressure transmitters available in the market:

Absolute pressure transmitters: These transmitters measure pressure relative to a perfect vacuum. They are typically used in applications where the pressure reference point is absolute zero.

Gauge pressure transmitters: These transmitters measure pressure relative to atmospheric pressure. They are commonly used in applications where the pressure reference point is the surrounding atmospheric pressure.

Differential pressure transmitters: These transmitters measure the difference in pressure between two points. They are used in applications where the pressure difference is more critical than the absolute pressure value.

Sealed pressure transmitters: These transmitters are designed to measure pressure in a sealed or closed system. They are commonly used in applications where the process fluid should not come into contact with the internal components of the transmitter.

Vacuum pressure transmitters: These transmitters are used to measure pressure below atmospheric pressure. They are commonly used in applications such as vacuum chambers and vacuum pump systems.

Understanding the different types of pressure transmitters will help you choose the right one for your specific application. Consider the pressure range, accuracy requirements, and environmental conditions when selecting the type of transmitter that best suits your needs.

Key specifications to look for in a pressure transmitter

When shopping for a pressure transmitter, it's important to consider the key specifications that will determine its performance and suitability for your application. Here are some key specifications to look for:

Pressure range: Ensure that the pressure transmitter can measure the range of pressures required for your application. It should have a high enough maximum pressure rating to accommodate any potential pressure spikes.

Accuracy: Look for a pressure transmitter with a high level of accuracy. The accuracy is usually expressed as a percentage of the full-scale range. The lower the percentage, the more accurate the transmitter.

Output signal: Consider the type of output signal that the pressure transmitter provides. Common output signals include 4-20 mA, 0-10 V, and digital protocols such as Modbus or HART. Choose a transmitter with an output signal compatible with your existing monitoring or control systems.

Response time: The response time of a pressure transmitter refers to how quickly it can detect and transmit changes in pressure. A faster response time is desirable in applications where rapid pressure changes occur.

Environmental ratings: Check the environmental ratings of the pressure transmitter, such as temperature range, humidity tolerance, and ingress protection (IP) rating. Ensure that the transmitter can withstand the environmental conditions in which it will be installed.

By paying attention to these key specifications, you can select a pressure transmitter that meets your performance requirements and is compatible with your existing systems.

How to choose the right pressure transmitter for your specific application

Choosing the right pressure transmitter for your specific application is crucial to ensure accurate and reliable pressure measurements. Here are some steps to help you make the right choice:

Identify your application requirements: Determine the pressure range, accuracy, and environmental conditions of your application. Consider factors such as temperature, humidity, and presence of corrosive substances.

Research available options: Research different brands and models of pressure transmitters that meet your application requirements. Read customer reviews and testimonials to get insights into the performance and reliability of each option.

Consult with experts: If you are unsure about which pressure transmitter to choose, consult with experts in the field. They can provide valuable advice and recommend the most suitable transmitter for your specific application.

Consider long-term costs: Take into account the long-term costs associated with the pressure transmitter, such as maintenance, calibration, and replacement parts. Choose a transmitter that aligns with your budget and resources.

Make a decision: Based on your research and consultations, make an informed decision on which pressure transmitter to purchase. Ensure that it meets all your requirements and is compatible with your existing systems.

By following these steps, you can choose the right pressure transmitter that will provide accurate and reliable pressure measurements for your specific application.

Comparing different brands and models of pressure transmitters

When shopping for a pressure transmitter, it's essential to compare different brands and models to find the one that best suits your needs. Here are some factors to consider when comparing pressure transmitters:

Reputation: Research the reputation of different brands in the industry. Look for brands that are known for producing high-quality and reliable pressure transmitters.

Features and specifications: Compare the features and specifications of different models. Look for the ones that have the key specifications you identified as important for your application.

Price: Compare the prices of different pressure transmitters. Consider both the initial purchase cost and the long-term costs associated with maintenance and calibration.

Customer reviews: Read customer reviews and testimonials to get insights into the performance and reliability of different pressure transmitters. Look for patterns or recurring issues mentioned by multiple customers.

Warranty and support: Consider the warranty and support offered by different brands. A longer warranty period and responsive customer support can provide peace of mind in case any issues arise.

By comparing different brands and models based on these factors, you can make an informed decision and choose the pressure transmitter that offers the best value for your investment.

Where to buy pressure transmitters

There are several options for purchasing pressure transmitters. Here are some common places where you can buy pressure transmitters:

Manufacturers: Many pressure transmitter manufacturers sell their products directly to customers. Buying from the manufacturer ensures that you are getting a genuine product and may provide access to manufacturer support and warranty.

Distributors: Pressure transmitter distributors often carry a wide range of brands and models. They can provide expert advice and recommendations based on your application requirements.

Online retailers: Many online retailers specialize in selling industrial equipment, including pressure transmitters. Online shopping offers convenience and the ability to compare prices and models from different brands.

Local suppliers: Local suppliers of industrial equipment may have pressure transmitters in stock. Visiting a local supplier allows you to see and touch the products before making a purchase.

Consider your specific requirements, budget, and preferences when choosing where to buy your pressure transmitter. It's also a good idea to compare prices and services offered by different sellers to ensure you get the best deal.

Tips for a successful shopping experience when buying a pressure transmitter

Shopping for a pressure transmitter can be overwhelming, given the wide range of options available in the market. Here are some tips to ensure a successful shopping experience:

Do your research: Before starting your shopping journey, conduct thorough research on pressure transmitters, their specifications, and their applications. This will help you make an informed decision and avoid unnecessary confusion.

Seek expert advice: If you are unsure about which pressure transmitter to choose, seek advice from experts in the field. They can provide valuable insights and help you select the most suitable transmitter for your application.

Read customer reviews: Customer reviews and testimonials can provide valuable insights into the performance and reliability of different pressure transmitters. Read reviews from trusted sources to get an idea of the user experience.

Consider your budget: Set a budget for your pressure transmitter purchase and stick to it. Consider not only the initial purchase cost but also the long-term costs associated with maintenance and calibration.

Check warranty and support: Ensure that the pressure transmitter comes with a warranty and responsive customer support. This will give you peace of mind in case any issues arise after the purchase.

By following these tips, you can have a successful shopping experience and choose a pressure transmitter that meets your requirements and provides reliable performance.

Conclusion and final thoughts

Shopping for a pressure transmitter requires careful consideration of various factors, including accuracy, pressure range, environmental conditions, and budget. By understanding the importance of pressure transmitters in various industries and considering key specifications, you can make an informed decision and choose the right pressure transmitter for your specific application.

Remember to compare different brands and models, read customer reviews, and seek expert advice to ensure you choose a pressure transmitter that meets your requirements and offers reliable performance. Whether you purchase from the manufacturer, a distributor, or an online retailer, consider factors such as reputation, features, price, and warranty.

1 note

·

View note

Text

Understanding Fish Farming: Exploring Saltwater Systems and Freshwater Complete for Aquariums

In the vast expanse of aquaculture, the realms of fish farms salt water systems and freshwater complete for aquariums stand as vital pillars, supporting the delicate balance of aquatic life. Diving into the intricacies of each system unveils the nuances and challenges inherent in nurturing thriving aquatic ecosystems.

Saltwater Systems: Navigating the Depths

Saltwater systems present a captivating yet demanding landscape for aquarists and professionals alike. The complexity of these environments mirrors the diverse ecosystems found in natural marine habitats. Fish farms salt water systems require meticulous attention to detail, from monitoring water chemistry to regulating salinity levels and maintaining optimal temperatures. The allure of saltwater setups lies not only in their vibrant marine life, including exotic fish species and intricate coral formations but also in the economic opportunities they offer. From cultivating high-value species like shrimp and salmon to sustaining thriving reef ecosystems, saltwater aquaculture serves as a cornerstone of the seafood industry. However, the challenges inherent in fish farms salt water systems cannot be understated. Disease outbreaks, environmental degradation, and market fluctuations pose significant threats to the sustainability and profitability of saltwater aquaculture ventures.

Freshwater Complete for Aquariums: A Serene Haven

In contrast to the complexity of saltwater systems, freshwater aquariums offer a serene and accessible entry point for hobbyists and enthusiasts. Freshwater complete for aquariums embraces a diverse array of aquatic life, from colorful tropical fish to lush aquatic plants, creating dynamic and engaging ecosystems within the confines of a glass tank. The versatility of freshwater setups allows for greater customization and experimentation, empowering enthusiasts to design habitats tailored to their preferences and the needs of their aquatic inhabitants. Beyond their aesthetic appeal, freshwater aquariums play a vital role in sustainability and conservation efforts. By promoting responsible fishkeeping practices and supporting captive breeding programs, freshwater complete for aquariums helps alleviate pressure on wild populations and fragile ecosystems. Moreover, the accessibility of freshwater setups makes them valuable educational tools, fostering a deeper understanding and appreciation of aquatic life among hobbyists of all ages.

Conclusion: Harmonizing Aquatic Environments

In the dynamic world of aquaculture, the coexistence of fish farms, salt water systems and freshwater complete for aquariums underscores the intricate relationship between human intervention and aquatic ecosystems. By embracing innovation, education, and conservation, we can navigate the complexities of fish farming while safeguarding the health and vitality of our planet's oceans, lakes, and rivers. Whether cultivating marine marvels or freshwater gems, enthusiasts and professionals alike share a common goal: to nurture thriving and sustainable aquatic environments for generations to come. As stewards of the aquatic realm, it is our collective responsibility to chart a course towards a more harmonious coexistence with the diverse and wondrous world beneath the waves.

0 notes

Text

0 notes

Text

Biofloc Fish Farming In Nepal

Introduction

Biofloc fish farming is gaining popularity in Nepal as an effective and long-lasting technique for growing fish. This innovative technique involves creating an environment where microorganisms, such as bacteria and algae, form a bio floc to enhance water quality and provide a nutrient-rich environment for fish. In Nepal, where traditional aquaculture faces water scarcity and environmental concerns, bio floc fish farming offers a promising solution.

Biofloc fish farming is a kind of aquaculture that uses microbial communities to turn fish waste into a naturally occurring food source, enabling high-density, sustainable fish farming.

With its diverse topography and varying climate, Nepal presents opportunities and challenges for aquaculture. Implementing bio floc technology allows fish farmers to overcome some of these challenges. One of the critical advantages of bio floc fish farming in Nepal is its water-saving feature.

Traditional aquaculture often requires large amounts of water, which can be a limitation in regions with water scarcity. Biofloc systems significantly reduce water consumption, making it a sustainable option for farmers in Nepal.

Moreover, biofloc fish farming contributes to increased biosecurity. The closed and controlled environment minimizes the risk of diseases, providing a healthier and more secure environment for fish growth. This is particularly important in Nepal, where disease outbreaks can devastate aquaculture.

Also, Read: Depths of Sustainable Fish Farming Investigated

Is Biofloc Fish Farming Profitable?

Biofloc fish farming can be very profitable, but it’s not a guaranteed path to riches. Several factors influence its potential for success.

The microbial flocs in biofloc systems provide a natural and cost-effective feed source for the fish.

The market demand for fish is another crucial factor. In Nepal, where fish is a staple food and demand is consistently high, biofloc fish farming can be lucrative. The controlled environment of biofloc systems ensures a steady supply of quality fish, meeting consumer preferences and fetching more money on the open market.

However, like any business venture, biofloc fish farming success requires careful planning, proper management, and adherence to best practices. Farmers need to invest in training and education to maximize the benefits of biofloc technology and ensure a profitable outcome.

Biofloc Fish Farming Guide

Implementing a successful biofloc fish farming system demands a thorough comprehension of the technology and its principles. Here is a step-by-step guide to help farmers in Nepal establish and manage a biofloc fish farm:

Step 1: Selection of Site: Select a place that has access to water and adequate facilities. Think about things like availability, temperature, and water quality.

Step 2: System Setup: Install a bio-floc system, including tanks or ponds, aeration systems, and a water recirculation system. Ensure proper design and sizing based on the planned fish production.

Step 3: Microbial Inoculation: Introduce beneficial microorganisms like bacteria and algae to initiate bio floc formation. This microbial community will help maintain water quality and provide a nutrient-rich environment for fish.

Step 4: Stocking the Fish: Select appropriate fish species based on market demand and local preferences. Stock the fish in the biofloc system at recommended densities.

Step 5: Water Quality Management: Monitor and manage water parameters such as pH, dissolved oxygen, ammonia, and nitrite levels. Adjust water quality as needed to ensure optimal conditions for fish growth.

Step 6: Feed Management: Implement a feeding strategy based on the nutritional requirements of the selected fish species. Use high-quality, balanced feed and adjust feeding rates based on fish growth.

Step 7: Disease Prevention: Adopt biosecurity measures to prevent disease outbreaks. Implement quarantine protocols for new fish introductions and monitor health regularly.

Step 8: Harvesting: Plan the harvesting process based on the growth rates of the fish. Use proper harvesting techniques to minimize stress and ensure product quality.

Step 9: Marketing: Develop a marketing strategy to sell the harvested fish. Establish partnerships with local markets, restaurants, or distributors to guarantee a consistent item market.

Step 10: Continuous Learning: Stay updated on advancements in biofloc technology and aquaculture best practices. Attend training programs and workshops and engage with the aquaculture community for continuous learning and improvement.

Biofloc Fish Farming Cost

While bio-floc fish farming offers numerous benefits, awareness of the setup and maintenance costs of a bio-floc system is crucial for farmers in Nepal considering this innovative method. The cost of biofloc fish farming can differ based on elements like the size of the operation, system design, and local conditions.

General range of estimated costs for Biofloc fish farming in Nepal:

Small backyard system (around 1000 liters): NPR 20,000 — NPR 50,000

Medium-scale system (around 5000 liters): NPR 50,000 — NPR 1,00,000

Large-scale commercial system (around 10,000 liters or more): NPR 1,00,000 — NPR 5,00,000 or more

Here’s a breakdown of critical expenses:

Infrastructure Costs:

Building bio floc ponds involves expenses such as excavation, pond liners, aeration systems, and other infrastructure components. The size and number of ponds will influence the overall infrastructure cost.

Microbial Inoculation:

Carbon sources, such as molasses, are often added to stimulate microbial growth in biofloc systems.

These additives contribute to developing a healthy microbial community in the pond.

For more details Click Here

0 notes

Text

New break tank package booster sets for fire fighting meet DIN 14462: 2023-07

At the end of 2023 KSB launched a new generation of its HyaDuo break tank package booster sets for fire fighting on the market. The sets meet the revised DIN 14462: 2023-07 standard for fire-fighting systems and break tank package booster sets for wall hydrant systems. The extended standard contains a number of changes that majorly impacted the design details of the fully automatic break tank package booster set for fire fighting.

The redundancy, in particular, that is stipulated for the supply of fire-fighting water means that all control and measuring elements now have to be doubled or redundant. The HyaDuo 2 D FL and HyaDuo 2 D FL Compact sets also feature two inlet devices ensuring the hygienic separation of drinking water and fire-fighting water to EN 1717 type AB.

The effective volume of the break tank is now 600 litres to compensate for any fluctuations in inflow rate and reliably supply the pumps with water for one minute. Newly designed suction elbows allow full use of the tank volume. A ball valve near the bottom of the tank enables the operator to regularly check the function of mains water supply. A window for fill level indication shows the water level at all times.

To facilitate manoeuvring when installing the set, the hydraulic unit can be separated from the tank unit. The master switch is now outside the control cabinet as the new edition of DIN 14462 requires the entire place of installation to be protected against unauthorised access.

In the event of fire, HyaDuo 2 D FL Compact supplies wall hydrant systems with up to 36 cubic metres of fire-fighting water per hour with only one duty pump. The sets have been developed for supplying fire-fighting water to protect multiple dwellings, residential and office buildings, multi-storey car parks and hospitals, for example.

In the event of a lack of water, the new products from KSB now incorporate the option of either stopping the pumps or continuing operation. The default setting is for the pumps to stop if lack of water occurs. The operator can deactivate this function by removing a wire jumper, which means the pumps will keep running even in the event of a lack of water.

The fully automatic break tank package booster set for fire fighting of the type series HyaDuo 2 D FL Compact is fitted with two fully redundant pumps, each of which has got its own power and control circuit. Their redundant control systems continuously monitor pressure switches and limit switches for broken wires and short circuits.

www.ksb.com

Read the full article

0 notes

Text

5 Benefits of Using Tank Level Monitoring Systems

Tank level monitoring systems have been gaining popularity in various industries in recent years. This technology has been designed to help business owners monitor and manage fuel levels in their tanks remotely. With this system in place, it becomes easy to track fuel usage, predict when a refill is needed, and prevent fuel theft. There are many tank level monitoring systems on the market, but Otodata Tank Monitors are the best accurate tank monitors in Canada. In this post, we'll look at the top five benefits of using tank level monitoring systems.

1. Avoid fuel runouts

One of the most significant benefits of using tank level monitoring systems is that they prevent fuel runouts. When a tank runs out of fuel, it can cause a lot of problems. Not only will it lead to downtime, but it can also cause inconvenience to your customers and damage to your business reputation. With a reliable tank monitor for fuel, you'll be able to see when the tank is getting low and schedule a refill before it's too late.

2. Cost savings

Another significant benefit of using tank level monitoring systems is cost savings. With accurate tank monitoring, you can prevent over filling or under filling your tanks, which usually results in expensive fuel wastage. By minimizing fuel loss, you can save money in the long run.

3. Increased efficiency

Tank level monitoring systems also help to increase operational efficiency. When your fuel usage is tracked and monitored, you'll be able to optimize your fuel delivery schedule. This way, you can avoid unnecessary fuel deliveries and reduce your carbon footprint. Doing so not only saves you money but also helps the environment.

4. Prevent theft

Fuel theft is a common problem for many businesses that have fuel tanks. With a tank level monitoring system in place, you can track your fuel levels and detect any unauthorized removal of fuel. This technology helps to prevent fuel theft and improve security.

5. Easy to use

Another great benefit of using tank level monitoring systems is that they are easy to use. With Otodata tank monitors, you can buy online tank monitors and install them with minimal technical knowledge. The system is user-friendly, and the data can be accessed remotely, making it ideal for corporate tank monitoring and remote tank monitoring in Canada.

Conclusion:

In conclusion, using tank level monitoring systems can be of great benefit to your business. Otodata tank monitors offer the best accurate tank monitors in Canada that can help you save costs, prevent fuel runouts, increase operational efficiency, prevent fuel theft, and are user-friendly. Don't wait any longer; get your tank monitor today!

0 notes

Text

Hygienic Point Level Sensor Market Upcoming Trends 2032

The competitive analysis of the Hygienic Point Level Sensor Market offers a comprehensive examination of key market players. It encompasses detailed company profiles, insights into revenue distribution, innovations within their product portfolios, regional market presence, strategic development plans, pricing strategies, identified target markets, and immediate future initiatives of industry leaders. This section serves as a valuable resource for readers to understand the driving forces behind competition and what strategies can set them apart in capturing new target markets.

Market projections and forecasts are underpinned by extensive primary research, further validated through precise secondary research specific to the Hygienic Point Level Sensor Market. Our research analysts have dedicated substantial time and effort to curate essential industry insights from key industry participants, including Original Equipment Manufacturers (OEMs), top-tier suppliers, distributors, and relevant government entities.

Receive the FREE Sample Report of Hygienic Point Level Sensor Market Research Insights @ https://stringentdatalytics.com/sample-request/hygienic-point-level-sensor-market/1968/

The hygienic point level sensor market caters to industries where strict hygiene and sanitation standards are essential, such as food and beverage, pharmaceuticals, and biotechnology. These sensors are used to monitor and control the level of liquids, powders, or granular materials in tanks and vessels while maintaining cleanliness and compliance with industry regulations.

Report Consumption Analysis:

Consumption analysis in a market report for hygienic point level sensors typically includes data on the demand for these sensors across various industries. It may provide insights into factors driving consumption, such as increasing automation in food processing, the need for accurate level measurements, and regulatory requirements for hygiene and safety.

Key Vendors:

Key vendors in the hygienic point level sensor market are companies that manufacture and supply these sensors. Potential key vendors may include:

Endress+Hauser Group

VEGA Grieshaber KG

ABB Ltd.

Emerson Electric Co.

Siemens AG

Anderson-Negele

IFM Electronic GmbH

KROHNE Messtechnik GmbH The report may provide information on their market share, product portfolios, global presence, and strategic initiatives.

Market Segments:

Segmentation in the hygienic point level sensor market can be based on various criteria, including:

Industry Vertical: Different industries have unique requirements for hygienic point level sensors, such as dairy processing, pharmaceutical manufacturing, and brewing.

Type: Segmentation by sensor type, such as capacitive sensors, conductive sensors, or optical sensors.

Application: Different applications, including liquid level monitoring, interface detection, and powder level sensing, may require specialized sensors.

Business Overview:

This section of the report provides an overview of the current state of the hygienic point level sensor market. It may include information on market size, growth trends, competitive landscape, and key players. A SWOT analysis could highlight the strengths, weaknesses, opportunities, and threats in the market. Financial performance, recent developments, and growth strategies of key vendors might also be included.

Upcoming Trends:

The report may forecast or suggest potential upcoming trends in the hygienic point level sensor market. Some trends to watch for may include:

Industry 4.0 Integration: Integration of sensors into Industry 4.0 and smart manufacturing systems for real-time monitoring and data-driven decision-making.

IoT Connectivity: Use of IoT-enabled sensors for remote monitoring, predictive maintenance, and improved efficiency.

Hygienic Materials: Development of sensors made from materials that comply with strict hygiene standards and are resistant to corrosion and contamination.

Increased Automation: Growing adoption of automation in food and pharmaceutical production, driving the demand for precise and reliable level sensors.

Regulatory Compliance: Ongoing focus on compliance with hygiene and safety regulations, leading to the adoption of sensors that meet industry standards.

Customization: Demand for sensors tailored to specific industry requirements, leading to customized sensor solutions.

Key Benefits of Hygienic Point Level Sensors:

Improved Hygiene: Hygienic point level sensors are designed to meet stringent cleanliness standards, ensuring that they can be used in sanitary and sterile environments without introducing contaminants.

Enhanced Product Quality: These sensors help maintain consistent product quality by ensuring that tanks and vessels are filled to the correct level, preventing underfilling or overfilling.

Regulatory Compliance: They assist industries in complying with strict regulatory requirements related to hygiene and safety, reducing the risk of non-compliance fines.

Reduced Product Loss: Accurate level monitoring minimizes product wastage by preventing spills and overflows, leading to cost savings.

Process Efficiency: Automation and real-time monitoring enabled by these sensors improve process efficiency, reducing downtime and optimizing resource utilization.

Remote Monitoring: Many hygienic point level sensors offer remote monitoring capabilities, allowing operators to track levels and receive alerts from a distance, improving operational flexibility and responsiveness.

Market Segmentations:

Global Hygienic Point Level Sensor Market: By Company

• GHM Group

• Siemens

• Anderson-Negele

• SICK Vertriebs

• Petrotek

• Ferret

• Tempcon

• Hidroteka

• Baumer Group

• OMEGA Engineering

Global Hygienic Point Level Sensor Market: By Type

• Contact Type

• Non-contact Type

Global Hygienic Point Level Sensor Market: By Application

• Petrochemical

• Metallurgy

• Electricity

• Pharmaceuticals

• Others

Regional Analysis of Global Hygienic Point Level Sensor Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Hygienic Point Level Sensor market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Hygienic Point Level Sensor Market Research Report @ https://stringentdatalytics.com/purchase/hygienic-point-level-sensor-market/1968/

Report includes Competitor's Landscape:

➊ Major trends and growth projections by region and country

➋ Key winning strategies followed by the competitors

➌ Who are the key competitors in this industry?

➍ What shall be the potential of this industry over the forecast tenure?

➎ What are the factors propelling the demand for the Hygienic Point Level Sensor?

➏ What are the opportunities that shall aid in significant proliferation of the market growth?

➐ What are the regional and country wise regulations that shall either hamper or boost the demand for Hygienic Point Level Sensor?

➑ How has the covid-19 impacted the growth of the market?

➒ Has the supply chain disruption caused changes in the entire value chain?

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

Enquiry Before Buying @ https://stringentdatalytics.com/inquiry/hygienic-point-level-sensor-market/1968/

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

6 Steps to Develop an Intelligent Fleet Management Software

It may be challenging to manage various business processes for higher efficiency and simultaneously deliver a favorable customer experience. Therefore, businesses that deal with transportation are always looking for digital solutions to optimize their operations.

The best example of such a solution is fleet management software that manages a company’s work vehicles to enhance productivity, cut costs, and reduce risks. It uses advanced technology like AI, GPS, geofencing, etc., to make operations automatic and smooth.

According to the MARKETSANDMARKETS report, the global fleet management market is expected to grow from USD 20.6 Billion in 2021 to USD 33.9 billion by 2026, at a CAGR of 10.5%.

Whether you run a courier startup or an oil and gas delivery business, a fleet management system helps you effectively administer vehicles for higher productivity.

We’re going to look at various benefits, features, and step-by-step ways to develop robust fleet management software, and the best mobile app company in the UK can help you develop a robust fleet management application for your business.

Benefits of Fleet Management Software

A fleet management system can be computer or cloud-based with the primary purpose of collecting, analyzing, and reporting fleet data. This data is used for various purposes like measuring fleet performance, tracking and managing vehicles, monitoring driver behavior, etc. Here are some of the primary benefits of fleet management software:

● Reduce fuel and maintenance costs

● Reduce risks like vehicle theft

● Increase vehicle uptime

● Improve driver safety

● Enhance customer satisfaction

● Increase operational efficiency and profitability

Essential Features of Fleet Management Software

In this high-tech world, fleet management software is an indispensable need for a company associated with transporting products or services. We take a look at the five must-have features that will meet most of your business goals.

GPS Tracking

GPS vehicle tracking is one of the vital features that allow real-time monitoring of a fleet. It involves a tracking device being installed on the vehicle which then exports data to the managers.

They can identify the accurate vehicle position- where it started the journey, where it stopped, and how long. Additionally, this feature lets the customer track their order progress and arrival date.

Driver Behaviour Monitoring

This feature allows analysis of various driver activities like speed and acceleration, idle time, harsh braking, and other unsafe habits. The managers can analyze these behaviors and share feedback with the drivers to help them avoid harmful practices and ensure productivity and safety. Driver behavior monitoring also helps in reducing maintenance costs and increasing efficiency.

Alerts and Notifications

Alerts and notifications are important features because they allow quick responses to solve any problems in the fleet. For example, you can set alarms to monitor driving speed, driver idle time, the temperature of goods, or sharp vehicle turns to ensure safety and efficiency.

Fuel Management

Fuel costs are one of the significant expenses in transportation businesses. Therefore, this feature allows you to supervise fuel levels in real time and monitor how many times vehicles are refueled. It helps you ensure there are no incidents of theft, fraud, or fuel tank leaks. The sensors alert you whenever there is fuel drainage so that you can solve problems as they arise.

Route Planning

Route planning uses AI technology to calculate the optimized routes for the vehicles and decrease the total distance traveled. Route optimization is necessary for last-mile delivery businesses that serve customers living in densely populated cities with harsh traffic conditions.

Steps to Develop a Fleet Management Software

Now that you know the benefits and essential features of fleet management software, it’s time to get on the steps to build a custom system that will meet all your business requirements. There are numerous companies providing app development services in the UK. Let’s start by taking the basic steps and gradually moving toward the advanced processes.

Define Your Goals

You must first define your software’s goal. Define why you need a fleet management system, what problems you want to solve, and what type of software is best for your requirement.

Your primary goal may be to cut down fuel consumption by 15%, supervise driver activities for higher efficiency or optimize routes for timely delivery.

A definite business goal will help the development team to have a clear vision, understand your specific requirements, and select the best tech stack.

Build a Team

Next, you need to assemble a team of software development engineers. Since developing custom fleet management software is a complex process, you must ensure the team is expert and well-introduced to trending technologies. You have three options for creating a team:

Freelance developers:

Upwork and Freelancer platforms can provide you with software engineers as independent contractors. This is the cheapest solution to get app developers in the UK, but it is unreliable because there can be less transparency and a lack of control.

Not only do you have to ensure freelancers are trustworthy, but you also have to design a work plan and manage the whole process.

In-house team:

The second option is you can build an in-house team by hiring software engineers and get complete control of the process. Developers can create custom software, but you will have to manage and lead your team.

The hiring process is time-consuming because you will need to hire developers for various development roles. Moreover, you may have to pay internal costs and hardware charges.

Software development company:

The third option is outsourcing to an established company that offers mobile app development services in the UK. Although this may be an expensive option, you can rest assured you will have the finest software meeting all your requirements.

A mobile app development company in the UK employs extremely skilled engineers who take care of everything from defining project specifications, releasing MVP, collecting feedback, and making improvements to maintaining the software.

Define Software Features

Now that you have a team, it’s time to list the primary features for designing a Minimum Viable Product (MVP).

An MVP consists of only the critical features, making the product simple and effective to improve business efficiency. Also read: https://www.ficode.co.uk/blog/mvp-software-development-can-save-your-start-up-from-failure-learn-how/

This method will ensure you don’t invest a hefty amount on an idea before testing it on the market. An MVP will allow you to start by taking small steps, validate your idea by generating profits, and take further steps to make the product advanced.

Development

Now comes the most crucial step- developing the fleet management software. Here engineers will code, test and deploy to create software fitting your requirements. Next, a software demo will be created to allow you to evaluate performance.

Launch an MVP

If everything is perfect, you will be ready to launch an MVP to test the product in your company. This will help you find where the software lacks and what extra features need to be added. The team will take the feedback and continue development to upgrade the software and make it advanced.

Maintenance

When the software is completely ready for your business, you have to ensure proper maintenance for long-term functioning. You may have to optimize the code, add new features, or troubleshoot to improve the software’s performance.

Final Words

Fleet management software uses advanced technologies to effectively manage the work vehicles of your company and boost operational productivity. Building custom software to fit your specific business goals can be challenging.

Ficode is a leading bespoke software and app development company in the UK that can be the perfect tech partner for your business.

We have extremely skilled app developers in the UK with years of experience translating the raw idea into fully functional software. From consultation and development to maintenance of your fleet management software, Fiocde will always be there to support you in app development in the UK.

Ready to build robust software that increases your business efficiency?

Contact us now to know more about our services.

This post originally appeared on Ficode website, and we republished with permission from the author. Read the full piece here.

#App developers UK#App development company#Mobile app development company#Mobile app development services UK#ficode technologies#ficode

0 notes