#Steel BIM Modeling Services

Text

Get the Best Steel Detailing Services in Glasgow, United Kingdom

Steel Detailing Services are provided by Silicon EC UK Limited in Glasgow, United Kingdom. Our engineering company offers comprehensive steel detailing solutions tailored to meet your exact needs. With years of experience and a dedicated team of professionals, we guarantee high-quality results that exceed your expectations. Our team consists of highly skilled and experienced steel detailers who are proficient in using the latest software and technologies to produce precise and detailed drawings. We prioritize accuracy in every aspect of our work. From initial concept drawings to final fabrication drawings, we ensure that all dimensions, connections, and details are meticulously checked to eliminate errors and avoid costly rework. Our cost-effective solutions help you save both time and money without compromising on quality. By optimizing resources and leveraging our expertise, we strive to provide maximum value for your investment. Contact us today to discuss your project requirements and discover how our premium Steel Erection Drawing Services can add value to your project. We look forward to partnering with you for success!

Supports and software facility:

Our dedicated workforce comprises steadfast QC heads, proficient Team Leads and experienced Steel Detailers who possess extensive expertise. Our Tekla Steel Detailing Services adeptly utilize cutting-edge software, including Tekla Structure showcasing a commitment to staying at the forefront of technological advancements.

Silicon EC UK Limited is a leading provider of Miscellaneous Steel Detailing Services in Glasgow, UK, offering a comprehensive suite of solutions designed to optimize the efficiency and performance of steel engineering projects. With a focus on accuracy, innovation, and client satisfaction, Silicon EC UK Limited continues to set the benchmark for excellence in the steel detailing industry.

For More Details Visit our Website:

#Steel Detailing Services#Tekla Steel Detailing Services#Structural Steel Detailing Services#Structural Steel Shop Drawing Services#Steel BIM Modeling Services#Steel Assembly Drawing Services#Steel Shop Drawing Services#Steel Shop Drawing Company#Joist Steel Detailing Services#Miscellaneous Steel Detailing Services#Tekla Steel Detailing Company#Joist Steel Detailing Services#Steel Erection Drawing Services#Assembly Shop Drawing Services#AutoCAD Steel Detailing Services#Steel Detailing Services in UK#Engineering Services#Engineering Company#CAD Design#CAD Drafting#CAD Drawing#CAD#CADD

0 notes

Text

Structural Engineering Services by S E C D Technical Services LLC in Abu Dhabi, UAE

S E C D Technical Services LLC in Abu Dhabi, UAE, offers a comprehensive range of Structural Engineering Services to support your construction projects. Our expert team of engineers can create innovative and cost-effective structural designs for buildings of all sizes and complexities. We use the latest technology and software to ensure accuracy and efficiency in every project. We provide comprehensive structural analysis services to ensure that your building is safe and structurally sound. Our team can identify potential issues and provide solutions to prevent any problems before they arise. Our Structural CAD Drafting Services utilize the latest CAD software to create detailed and accurate drawings for your project. We can help you visualize your structure and make necessary changes before construction begins. We offer comprehensive project management services to ensure that your project is completed on time and within budget. Our team can handle all aspects of your project, from planning and design to construction and completion.

Supports and software facility:

Our Structural Engineering Services adeptly utilize cutting-edge software, including AutoCAD, Tekla Structure and Revit Structure showcasing a commitment to staying at the forefront of technological advancements.

Contact S E C D Technical Services LLC today to learn more about our Structural Engineering Services and how we can help you achieve your project goals.

For More Details Visit our Website:

#Structural Engineering Services#Structural Engineering Company#CAD Structural Services Abu Dhabi#Structural Engineering Services Abu Dhabi#Structural Engineering CAD Design Services Abu Dhabi#Structural Engineering Consultant Abu Dhabi#Structural Engineering Company Abu Dhabi#Structural Steel Detailing Services Abu Dhabi#Structural Consultancy Services#Structural BIM 3D Modeling Services#Structural CAD Design Services#Structural CAD Drafting Services#Structural CAD Drawing Services#Structural Steel Detailing Services

0 notes

Text

Steel Detailing Services

Steel detailing services involve the creation of detailed drawings and plans that specify the requirements for fabricating and erecting steel structures. These intricate designs encompass precise information on dimensions, connections, materials, and other essential elements crucial for construction. Steel detailing services play a pivotal role in ensuring accuracy and compliance with industry standards, aiding fabricators, erectors, and engineers in executing the structural steelwork efficiently. These drawings serve as a blueprint for constructing buildings, bridges, industrial plants, and various steel-based structures.

#Structural Steel Detailing#Steel Detailing and Metallic BIM Modeling Services#Steel Detailing Services

0 notes

Text

Steel Structure Modeling for a Large-Scale Commercial Building

UniquesCADD successfully delivered and completed a project of structural modeling from a client based in Nantes, France. The client required a highly detailed 3D structural model of a commercial complex that took six long months. The team incorporated all necessary details from planning and shop drawings. We provided clients with detailed 3D models that streamline the execution process, reducing errors and rework during construction. Here's a curated case study of a structural modeling project based in France to understand and know more about the project.

#structural bim services#structural 3d modeling#structural drafting services#structural steel detailing#steel shop drawings#3d modeling services#bim services#outsource bim services

0 notes

Text

Structural Drafting Services | Structural Detailing Services

For the United States, the United Kingdom, Australia, the United Arab Emirates, and India, Struc Vision provides structural detailing, CAD, steel detailing, engineering services, Rebar Shop drawing, Revit 3D & 2D Model.

#structural bim services#structural bim modeling services#Steel drafting services#Structural steel drafting services#Retaining wall rebar detail services#Rebar shop drawing services#Precast panel detailing services

0 notes

Text

7 Reasons Why Rebar Detailing Is Key To The Construction Process

Rebar is a basic steel bar or block that's frequently used in reinforced concrete and reinforced masonry structures. These rebars are usually made from carbon steel which enable it to be recounted as reinforcing steel or simply just reinforcement. Under Structural BIM Services Rebar detailing is a discipline of making fabrication or shop drawings of steel reinforcement for the construction process. The site fabrication drawings which can be generated depending on design drawings for reinforcing steel are Rebar Detailed drawings. Engineers and Architects make design drawings to bring about the mandatory strengths based on the rebar detailing providing you with diameter, bar shapes, quantities, length of bars to facilitate your website for avoiding delays and wastage thereby speeding your entire construction process.

Each rebar is detailed representing a shape, length, and diameter based on the requirements in the design drawing. The Rebar placement will then be shown at length which indicates the concrete cover, exact location, and special technique of placement if required. The rebar details and bar bending schedules will demonstrate bar diameter, bar notation, the quantity of bars, weight of the bars, and period of each bar in addition to mentioning the overall weight for the entire group of bars placed inside the drawing. During the preparation of rebar details, the stock lengths of bars are held in view so that there is no wastage in the material.

Rebar Detailing and Reinforcement concrete detailing can be modeled and designed in 3-dimension with the 3D Modelling technology like BIM Modelling Services. The specialized rebar detailing software like Rebar CAD and AutoCAD used for this purpose may help every member in the structural engineering to organize designs, document, track, and overall control.

Having understood the fundamental concept of rebar detailing a section of structural BIM modeling, let's try and understand the significance of it in the overall construction process is. Some in the reasons are:

Importance of Rebar detailing in Structural BIM Modeling

While 2D drawings and bending schedules are often created and given, the 3D model is additionally issued to all or any they members beginning from the consulting engineer and contractor departments right down to the steel fixers which are with the ground level on-site. The combination of those two become especially a good choice for site personnel where site restrictions or congestion of reinforcements remain unidentified until you can find reinforcement and fixation on site. For every single bar, the exact position of fixing is shown inside the 3D model as well as any hindrances or obstructions.

Creating detailing reinforcements in 3D on the 2D process is not only faster but modeling rebar in a 3-dimensional environment helps remove clashes. While modeling one can visualize if any of the bars don't fix at the decided area, thereby identify these kinds of clashes within the rebar drawings. There is perhaps the facility to check the reinforcement in complete detail being a precise detail representation before it's being ordered in the fabricator and complex cages are assembled off-site.

When there is the right rebar detailing solution available, a powerful and accurate reinforcement model can be produced by importing structural calculations in the structural analysis program. With Automation involved the alterations can be reflected inside the 3D rebar detailing as well as necessary updates to drawings and schedules swiftly when changes are manufactured elsewhere unlike having to complete manual changes to 2D sections and views.

Instead of determined by official source from paper schedules, the rebar fabricator can extract data directly in the model on the machinery. The concrete pours might be well-defined inside the model with details like quantities and volumes to be sure more accuracy in managing material deliveries. This will allow greater control and lead to less wastage and decrease in overall costs.

Having 3D detailed digital models won't restrict the power to your single-phase that way from the engineering and detailing phase but might be used in the phases. Having reinforcement fully modeled in 3D, the contractor is assured that it'll fit in areas when the time comes for it to be fixed on-site. The data from your model can be used in the field to permit contractors to conduct a model-based layout through the use of robotic total station devices along with tracking rebar and materials and identifying location are going to required.

Fixers present on-site look within the model environment for that rebar detailing to accurately understand its application, i.e. what is required where and when as opposed to counting on their interpretation of traditional 2D drawings.

The structural engineers can certainly and much more quickly generate design reports, schedules, and drawings through the 3D model as compared to 2D designs, thereby enhancing design efficiency. There is more accuracy on price projection based on the rebar quantities produced through the 3D model as is also more reliable compared to 2D drawing take-offs. Not just this the quantities are completely traceable, allowing comparisons and checks to become conducted effortlessly.

With these reasons, we could conclude that Rebar Detailing a discipline of Structural BIM Modelling Services is a with the crucial criteria for the overall success of the project life cycle. To summarize, having Rebar Detailing the rebar contractor can target producing rebars there will be no have to estimate reinforcement requirements for procurements at the web page as a result of efficient 3D models. The model will depict the necessity for anchors and laps inside the drawings thereby ensuring design adequacy as well as reducing wastage. The overall waste and time delays are decreased at your website because every one of the shape drawings are easily available. Based on this info the bars may be easily fabricated based on the shapes and number of bars required.

#steel rebar suppliers Wollongong#reo accessories Wollongong#reo steel Wollongong#reo mesh Wollongong#steel reo suppliers Wollongong#galvanised rebar supplier Wollongong#reinforcement suppliers Wollongong#reinforcing steel suppliers Wollongong#steel reinforcement mesh Wollongong#trench mesh Wollongong#galvanised Reo Mesh Wollongong#pool steel supplier Wollongong

0 notes

Text

The Role Of Steel In Modern Infrastructures

Steel stands as an indispensable pillar of modern infrastructure, strengthening the buildings and bridges that define our urban landscapes. It stands not only as a material of construction but as a symbol of endurance, innovation, and progress. This article will help you understand the role of steel and its significance in the contemporary world and we will also explore what the future predictions of steel in modern infrastructures are.

The Role & Importance of Steel in Modern Infrastructures;

Structural and Infrastructure Development

Structural section makes up 25% of the steel used in buildings, and provides strong and rigid foundations for structures. On the other hand, reinforcing bars, which make up 44% of the steel used in structures, improving the tensile strength and stiffness to concrete. Furthermore, 60% of the steel is used as reinforcing bars in transportation networks and constructing buildings while the remainder comprises sections, plates, and rail tracks, and over 50% of the steel is utilized for underground pipelines, facilitating water distribution for residential use and gas transportation.Top of FormTop of Form

Top of FormTop of FormNow, let’s take a look at the significance of steel in modern infrastructure. It offers strength, durability, and versatility in design, in addition to being a sustainable choice and cost-efficient. Here are key points highlighting the significance of steel in infrastructure development.

Strength, Durability, and Versatility

One of the primary factors attributing to steel's association with modern infrastructure is its remarkable strength, durability, and versatility in design. It serves as the backbone of structures capable of withstanding seismic tremors, hurricane winds, and heavy snow loads. When combined with concrete, steel reinforcement forms an unconquerable shield for prolonging the lifespan of buildings and bridges.

From a durability point of view, the steel service lives averaging between 75 to 100 years, steel bridges stand as enduring testaments to the material's longevity, surpassing alternative materials like timber or concrete. When it comes to steel, the higher the quality, the longer it lasts. Moreover, steel-framed buildings provide earthquake resistance up to five times higher than that of concrete structures.

In the realm of design versatility, steel's versatility knows no bounds. Leveraging cutting-edge technologies such as computer-aided design (CAD) and Building Information Modeling (BIM), architects and engineers harness the material's inherent flexibility to craft structures that push the boundaries of innovation.

Sustainability and Cost Efficiency

In an era marked by increasing environmental consciousness, steel emerges as an ideal of sustainability. With its ability to be recycled indefinitely without compromising its structural integrity, steel embodies the principles of a circular economy, minimizing waste and conserving resources.

In addition, the material's longer lifespan results in lower maintenance and replacement expenses over time, offsetting initial costs and making it an economically sound option over time.

Steel stands as a foundation of modern infrastructure development due to its strength, durability, sustainability, and cost-effectiveness. Its role in creating resilient and visually appealing structures that withstand the test of time is pivotal for the progress and prosperity of societies worldwide. Lastly, let’s explore the crucial role of steel in shaping the future of the construction route.Top of Form

Future Steel Outlook

We expect that the profitability of steel producers will experience a slight increase or maintain a moderate level, supported by growing demand, a modest uptick in prices in China, India, and Europe, as well as declining raw material costs. Top of Form

Manufacturing is likely to get better first, but steel demand might not grow much because of high interest rates. Next year, most places will see faster growth, but China might not grow as quickly.

As outlined in its latest Short-Range Outlook (SRO) report, the World Steel Association (World Steel) projects a 1.7% increase in global steel demand for 2024.

By the year 2030, there will be a mandate for all new constructions, infrastructure projects, and renovations to possess a minimum of 40% lower embodied carbon emissions, accompanied by substantial upfront reductions in carbon emissions. Additionally, all newly constructed buildings will operate with net zero operational carbon emissions.

By the year 2050, it is envisioned that newly constructed buildings, infrastructure developments, and renovated structures will achieve net zero embodied carbon emissions. Furthermore, all buildings, inclusive of existing structures, will be required to operate with net zero operational carbon emissions.

Conclusion

Steel stands as a foundation of modern infrastructure development due to its strength, durability, sustainability, and cost-effectiveness. Its role in creating resilience against environmental challenges and its ability to endure the test of time make it a vital element in the construction of the progress and prosperity of societies worldwide. As we continue to innovate and evolve, steel will undoubtedly remain at the forefront of infrastructure development, laying the foundation for a more resilient and sustainable future for societies worldwide.

References:

https://utilitiesone.com/steel-construction-ushering-in-a-new-era-of-infrastructure

0 notes

Text

Why Choose Silicon EC UK Limited for Your Steel Detailing Needs?

Discover excellence with Silicon EC UK Limited for your steel detailing needs. Our team of skilled professionals ensures precision, efficiency, and timely delivery. With a commitment to quality and cutting-edge technology, we transform your visions into detailed, accurate steel structures. Choose Silicon EC UK Limited for unparalleled expertise in steel detailing services.

Dive into the world of steel detailing with our blog! Explore expert insights, the latest industry trends, and practical tips for precision in every detail. Whether you're a seasoned professional or just starting, discover valuable knowledge that enhances your skills and keeps you ahead in the dynamic field of steel detailing.

blog:

#Steel Detailing Services#Tekla Steel Detailing Services#Structural Steel Detailing Services#Structural Steel Shop Drawing Services#Steel BIM Modeling Services#Steel Assembly Drawing Services#Steel Shop Drawing Services#Steel Shop Drawing Company#Joist Steel Detailing Services#Miscellaneous Steel Detailing Services#Tekla Steel Detailing Company#Joist Steel Detailing Services#Steel Erection Drawing Services#Assembly Shop Drawing Services#AutoCAD Steel Detailing Services#Steel Detailing Services in UK#Blog#steeldetailingblog#newblog#blogpost

0 notes

Text

Get the Best Structural CAD Design Services in Sharjah, UAE

S E C D Technical Services LLC stands at the forefront of

Get in touch with S E C D Technical Services LLC today! Whether you have questions about our Structural Engineering Services or would like to discuss a specific project, our team is here to assist you every step of the way. Visit our website or give us a call to learn more about how we can bring your vision to life with precision and expertise.

For More Details Visit our Website:

#Structural BIM 3D Modeling Services#Structural CAD Design Services#Structural CAD Drafting Services#Structural CAD Drawing Services#Structural Steel Detailing Services#Structural Design Services#Structural Engineering Services#Structural Engineering Company#Outsource Structural Engineering Firm#Structural Detailing Services#Structural Engineering Outsourcing Services#Structural CAD Services Provider#Structural Engineering Consultant#Structural Services#Structural Consultancy Services#Structural CAD Services#Structural Engineering Firm

0 notes

Text

7 Reasons Why Rebar Detailing Is Key To The Construction Process

Rebar is really a basic steel bar or block which is popular in reinforced concrete and reinforced masonry structures. These rebars are often created from carbon steel and may be recounted as reinforcing steel or simply just reinforcement. Under Structural BIM Services Rebar detailing is really a discipline of creating fabrication or shop drawings of steel reinforcement for your construction process. The site fabrication drawings that are generated depending on design drawings for reinforcing steel are Rebar Detailed drawings. Engineers and Architects make design drawings to bring about the mandatory strengths based on the rebar detailing that delivers diameter, bar shapes, quantities, length of bars to facilitate the website for avoiding delays and wastage thereby speeding your entire construction process.

Each rebar is detailed representing a shape, length, and diameter determined by the requirements with the design drawing. The Rebar placement might be shown in greater detail which indicates the concrete cover, exact location, and special way of placement if required. The rebar details and bar bending schedules can have bar diameter, bar notation, the amount of bars, weight of the bars, and amount of each bar along with mentioning the complete weight for that entire pair of bars placed inside drawing. During the preparation of rebar details, the stock lengths of bars are kept in view to ensure there isn't any wastage with the material.

Rebar Detailing and Reinforcement concrete detailing is now able to modeled and designed in 3-dimension with all the 3D Modelling technology like BIM Modelling Services. The specialized rebar detailing software like Rebar CAD and AutoCAD used by this purpose will help every member with the structural engineering to get ready designs, document, track, whilst overall control.

Having understood the fundamental thought of rebar detailing a piece of structural BIM modeling, allow us to make an effort to view the significance of it in the overall construction process is. Some with the reasons are:

Importance of Rebar detailing in Structural BIM Modeling

While 2D drawings and bending schedules are likely to be created and given, the 3D model can be issued to all or any they members starting from the consulting engineer and contractor departments into the steel fixers that are on the ground level on-site. The combination of the two become especially useful for site personnel where site restrictions or congestion of reinforcements remain unidentified until there are reinforcement and fixation on location. For every single bar, the actual position of fixing is shown in the 3D model in addition to any hindrances or obstructions.

Creating detailing reinforcements in 3D over the 2D process is not only faster but modeling rebar in a very 3-dimensional environment helps remove clashes. While modeling you can visualize if any of the bars tend not to fix in a decided area, thereby identify all such clashes within the rebar drawings. There is the facility to review the reinforcement in complete detail as a precise detail representation prior to it being being ordered in the fabricator and complicated cages are assembled off-site.

When you have the right rebar detailing solution available, a competent and accurate reinforcement model can be done by importing structural calculations through the structural analysis program. With Automation involved the alterations are typically reflected inside 3D rebar detailing in addition to necessary updates to drawings and schedules swiftly when changes are manufactured elsewhere unlike having to do manual changes to 2D sections and views.

Instead of according to manual input from paper schedules, the rebar fabricator can extract data directly in the model to the machinery. The concrete pours might be well-defined inside model along with other details like quantities and volumes to ensure more accuracy in managing material deliveries. This will allow greater control and cause less wastage and reduction of overall costs.

Having 3D detailed digital models won't restrict the benefit to some single-phase that way from the engineering and detailing phase but could be used in all the phases. Having reinforcement fully modeled in 3D, the contractor is assured that it'll easily fit into areas when the time comes for it to be fixed on-site. The data from the model may be used within the field to allow contractors to conduct a model-based layout by utilizing robotic total station devices along with tracking rebar and materials and identifying when and where they'll be required.

Fixers present on-site will be inside model environment for the rebar detailing to accurately understand its application, i.e. precisely what is required location as an alternative to counting on their interpretation of traditional 2D drawings.

The structural engineers can easily plus much more quickly generate design reports, schedules, and drawings from your 3D model as compared to 2D designs, thereby enhancing design efficiency. There is more accuracy in price projection determined by the rebar quantities produced in the 3D model as is also more reliable compared to the 2D drawing take-offs. Not just this the quantities are completely traceable, allowing comparisons and checks to become conducted effortlessly.

With these reasons, we could conclude that Rebar Detailing a discipline of Structural BIM Modelling Services is one with the crucial criteria for that overall success of the project life cycle. To summarize, having Rebar Detailing the rebar contractor can focus on producing rebars high will be no should estimate reinforcement requirements for procurements at the website on account of efficient 3D models. The model will depict the necessity for anchors and laps inside drawings thereby ensuring design adequacy together with reducing wastage. The overall waste and time delays are decreased at your website because each of the shape drawings are often available. Based on R12,R16,R20,R24,R28 Galvanised Dowel Bar Sydney info the bars could be easily fabricated according to the shapes and amount of bars required.

#steel rebar suppliers Sydney#reinforcement suppliers Sydney#reinforcing steel suppliers Sydney#steel reinforcement mesh Sydney#reinforcement mesh Sydney#Steel Suppliers near me#galvanized bar#galvanised reo Sydney#galvanised steel Bar#galvanised reinforcing Supply#galvanised rebar supplier Sydney#Galvanised Mesh Sydney#R12#R16#R20#R24#R28 Galvanised Dowel Bar Sydney#S12 Pool steel Sydney#SL72/SL82/SL81/SL102 Galvanised Mesh Sydney#N12#N16#N20#N24#N28#N32 rebar Sydney#SL62/SL72/SL82/SL92 MESH supplier Sydney#SL72 Mesh#Ligature#Bondek Slab Sydney#Dowel Bar

0 notes

Text

Modular Construction Materials Market to Reach US$ 168.2 Bn by 2031

Modular construction materials have emerged as a game-changer in the building and construction sector, offering efficiency, sustainability, and cost-effectiveness. As we delve into the period from 2023 to 2031, the modular construction materials market is poised for substantial growth, driven by urbanization, infrastructure development, and technological advancements. Let’s explore the dynamics shaping this market, its segmentation, regional landscape, key drivers, challenges, trends, and future outlook.

In 2022, the global industry was valued at US$ 101.3 Bn. It is projected to grow at a CAGR of 5.8% from 2023 to 2031, reaching US$ 168.2 Bn by the end of 2031.

The modular construction materials market is witnessing a surge in demand as builders and developers seek innovative solutions to streamline construction processes and address challenges such as time constraints, labor shortages, and cost overruns. Modular construction involves the assembly of prefabricated components in controlled factory settings before being transported to the construction site for final assembly, offering numerous benefits over traditional building methods.

Download Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85577

Market Segmentation:

By service type:

Design and Engineering

Manufacturing and Fabrication

Installation and Assembly

By sourcing type:

In-house Production

Outsourced Components

By application:

Residential Buildings

Commercial Buildings

Industrial Facilities

Infrastructure Projects

Others

By industry vertical:

Construction

Real Estate

Infrastructure

Others

By region:

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Regional Analysis:

North America and Europe are anticipated to lead the modular construction materials market, driven by advanced construction techniques, supportive regulatory frameworks, and increasing demand for sustainable building solutions.

The Asia Pacific region is poised for significant growth, fueled by rapid urbanization, population growth, and government initiatives promoting affordable housing and infrastructure development.

Latin America and the Middle East & Africa are witnessing growing adoption of modular construction methods to address housing shortages, enhance disaster resilience, and accelerate infrastructure projects.

Market Drivers and Challenges:

Drivers:

Growing population and urbanization, increase demand for affordable and sustainable housing solutions.

Rising awareness of environmental concerns and the need for energy-efficient building practices.

Advantages of modular construction, include reduced construction time, cost savings, and improved quality control.

Challenges:

Limited adoption of modular construction methods due to entrenched practices and resistance to change within the industry.

Lack of standardized regulations and certification processes for modular construction materials.

Challenges in logistics, transportation, and site preparation for modular construction projects.

Market Trends:

Integration of advanced technologies such as Building Information Modeling (BIM), prefabrication, and automation to enhance design precision and construction efficiency.

Growing emphasis on sustainable and recyclable materials in modular construction, including wood, steel, recycled plastics, and composite materials.

Adoption of modular construction methods in disaster relief efforts, military applications, and remote construction sites.

Future Outlook:

The future of the modular construction materials market is promising, driven by technological innovation, sustainability goals, and the need for scalable, adaptable building solutions. As stakeholders continue to embrace modular construction methods and invest in research and development, the market is poised to witness significant growth and transformation in the coming years.

Key Market Study Points:

Analysis of market dynamics, including drivers, challenges, and opportunities.

Assessment of regional market trends and growth prospects.

Evaluation of key players, their strategies, and competitive landscape.

Exploration of technological advancements and their impact on market dynamics.

Competitive Landscape:

The modular construction materials market is characterized by a competitive landscape with key players including:

Laing O’Rourke

Skanska AB

Katerra

Red Sea Housing Services

Lendlease Corporation

Recent Developments:

Investments in research and development to enhance modular construction technologies and materials.

Strategic partnerships and collaborations to expand market presence and access new opportunities.

Adoption of innovative business models, including modular construction as a service (MCaaS) and modular component leasing.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=85577<ype=S

About Transparency Market Research

Transparency Market Research, a global market research company registered in Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyse information.

Our data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll-Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Retaining wall rebar detail services | Structural Detailing Services

For the United States, the United Kingdom, Australia, the United Arab Emirates, and India, Struc Vision provides structural detailing, CAD, steel detailing, engineering services, Rebar Shop drawing, Revit 3D & 2D Model.

#structural bim services#structural bim modeling services#Steel drafting services#Structural steel drafting services#Retaining wall rebar detail services#Rebar shop drawing services#Precast panel detailing services

0 notes

Text

Outsource CAD Design, Drawing, and Drafting Services in Minnesota, USA at very low cost

CAD Outsourcing is a leading provider of CAD Design, CAD Drawing, and CAD Drafting Services. With our expertise in CAD Services, including AutoCAD design, we offer comprehensive solutions to meet the diverse needs of our clients. Our team of skilled CAD designers possesses the knowledge and experience to deliver high-quality designs and precise drawings, adhering to industry standards. We provide end-to-end CAD solutions, from conceptualization to final drafts, ensuring accuracy and attention to detail. Our commitment to quality, accuracy, and customer satisfaction sets us apart as a trusted partner in CAD Services.

Why choose Us CAD Outsourcing Consultant?

- Use of latest software and international standards.

- 16+ years of experience.

- Skilled and experienced team of 250+ engineers, designers, and modelers.

- Cost-effective project delivery.

- An individual project manager assigned to clients for project updates.

- Multiple CAD Services and engineering consultants available on the one-single roof.

- Assurance for data-security and cloud-based server for all project-related information.

We offer our CAD Services Minnesota and covered other cities: California, Florida, Ohio, Texas, Chicago, Georgia, Washington, Los Angeles and New York.

Visit Us

https://www.cadoutsourcing.net/cad-outsourcing-services/why-outsourcing.html

Our Portfolio

https://www.cadoutsourcing.net/architectural-cad-design-drawing/architecture-3d-model.html

https://www.cadoutsourcing.net/building-information-modelling/bim-sample.html

https://www.cadoutsourcing.net/structure-cad-design-drawing/structure-3d-model.html

https://www.cadoutsourcing.net/hvac-engineering-services/hvac-drafting-drawing.html

https://www.cadoutsourcing.net/shop-drawing-services/steel-shop-drawings.html

License User:

AutoDesk AutoCAD, Revit, Tekla Structures, STAAD.Pro, SOLIDWORKS, ZWCAD, AutoDesk Navisworks, 3Ds Max, Inventor, Showcase, ReCap, Infraworks 360, Civil 3D.

Connect with us today to get quotations for the CAD Outsourcing Services.

For more information

Website: https://www.cadoutsourcing.net/cad-design-drafting/cad-services.html

Check Out my Latest Article "Top 10 Benefits of Outsourcing CAD Design, Drawing, and Drafting Services"" is now available on

https://cadoutsourcingblog.weebly.com/blog/top-10-benefits-of-outsourcing-cad-design-drawing-and-drafting-services

#CADServices#CADOutsourcing#CADDrawing#CadOutsourcingCompany#CadOutsourcingServices#TeklaStructure#Revit#AutoCAD#Engineering#Architecture#BIMServices#ShopDrawings#BIM#Structure#MEP#Detailing

3 notes

·

View notes

Text

SteelNine Building Brilliance: The Art and Science of Structural Steel Detailing Services

In the dynamic realm of construction, the intricate dance between artistry and precision is showcased prominently through the services provided by SteelNine. The delicate balance between the artistic vision of architects and the scientific precision required for structural integrity.

This article delves into the unique blend of art and science that defines SteelNine's Structural Steel Detailing Services, exploring how the company has become a beacon of excellence in the field.

The Artistry of Steel Detailing:

At the heart of SteelNine's approach lies a profound appreciation for the artistry inherent in structural steel detailing. The company recognizes that every construction project is a unique canvas, demanding a customized approach to bring architectural visions to life.

SteelNine's team of skilled professionals collaborates closely with architects, understanding their creative intent and translating it into detailed steel structures that seamlessly integrate with the overall design. The result is not just a structure but a work of art that complements the aesthetic vision of the project.

Precision as a Science:

While the artistic aspect sets SteelNine apart, the company's commitment to scientific precision is equally noteworthy. In the world of construction, accuracy is paramount, and SteelNine embraces cutting-edge technologies and methodologies to ensure that every detail is meticulously accounted for. From 3D modeling to advanced analysis tools, SteelNine employs a scientific approach to guarantee structural integrity, safety, and compliance with industry standards. This fusion of art and science creates a solid foundation for construction projects that stand the test of time.

Innovative Technologies Driving Excellence:

SteelNine stays at the forefront of technological advancements, employing state-of-the-art tools and software to enhance the efficiency and accuracy of its detailing services.

The integration of Building Information Modeling (BIM) allows for a comprehensive understanding of the entire project, fostering collaboration and minimizing errors. This commitment to innovation positions SteelNine as a forward-thinking partner for architects and builders, leading the way in embracing new technologies that redefine the landscape of structural steel detailing.

Collaboration and Communication:

Central to SteelNine's success is its emphasis on collaboration and communication. Recognizing that successful projects hinge on effective teamwork, the company fosters an environment where architects, engineers, and detailing experts work seamlessly together.

Regular communication channels ensure that any design adjustments or modifications are addressed promptly, maintaining the delicate balance between artistic vision and engineering precision.

Conclusion:

"SteelNine Building Brilliance: The Art and Science of Structural Steel Detailing Services" showcases how SteelNine has elevated the standard in the industry by seamlessly blending artistry with scientific precision. The company's commitment to creating structural masterpieces goes beyond traditional detailing services, offering a comprehensive solution that is as visually stunning as it is structurally sound.

In a world where construction is an art form, SteelNine stands as a beacon of brilliance, shaping the future of architectural excellence through its innovative and meticulous approach.

1 note

·

View note

Text

Why you need MEP coordination services for your building projects

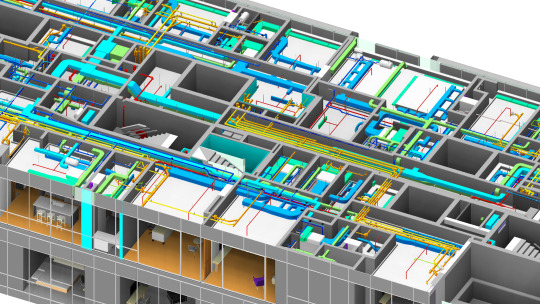

Mechanical, Electrical and Plumbing (MEP) coordination administration is the harmonization of all the building administrations with different disciplines that structure the building texture, construction and outside envelope (steel, concrete, and so forth.). The building administrations incorporate warming, ventilation and cooling (central air).

A MEP group includes a MEP expert, a MEP worker for hire, exchange explicit MEP and putting out fires subcontractors, fabricators, establishment, and support trained professional. The MEP advisors set up the 3D MEP composed drawings and give them to the MEP worker for hire. The MEP worker for hire is answerable for the establishments and creation. This implies that it's the job of the worker for hire to do the specifying, creation, spatial coordination and establishment on the 3D drawings. This is the very thing that achieves the test requiring the requirement for MEP coordination administrations.

Much of the time, however the MEP advisor's drawings have no conflicts, the MEP expert should change the plans somewhat with the goal that they can befit his prerequisites to the extent that simplicity of creation, slacking, protection remittance and establishment effectiveness is concerned. A portion of the progressions that the worker for hire is probably going to make incorporate, channel resizing, pipework rerouting, parting of the electrical stepping stool, change of hardware, and so on.

The requirement for the MEP worker for hire to redraw the advisor's plan drawings influences the undertaking cutoff times and timetables adversely which eventually influences the financial plan. With MEP coordination administrations, there is expanded joining of the different individuals from the MEP group. MEP coordination work is likewise introduced in a 3D climate for every one of the disciplines.

3 Ways MEP Coordination Services Will Save You Time & Money

Mechanical, Electrical, and Plumbing (MEP) coordination administrations incorporate each group's plan to address any contentions during the constructability survey process. Configuration clashes stayed away from or disposed of right off the bat in the venture emphatically influence the general undertaking and significantly lessens project cost. Framed beneath are 3 different ways early coordination of configuration groups will save your undertakings a lot of time and cash.

Reduce project rework and material waste.

The primary cash saving tip is to decrease the time and material spent rectifying botches. Utilizing our mep bim demonstrating MEP drawing clashes eliminated right off the bat decline how much venture adjust. Limiting waste and further developing venture fabricate proficiency is a certain method for fulfilling clients.

Offer more competitive bids.

Utilizing more precise MEP drawings and point by point models, your group will enjoy the benefit of offering a more cutthroat BID. Project costs are all the more precisely assessed utilizing demonstrating to recognize any expensive plan clashes almost immediately.

Streamline the build process

Utilizing virtual venture arranging and 3D demonstrating to decrease postpones in project consummation and smooth out the form cycle. Smooth out with the utilization of week after week configuration survey gatherings to address clashes right off the bat to set aside both time and cash. As you can see MEP coordination administrations are fundamental to guarantee quality and savvy development. Planning right off the bat will stay away from numerous potential struggles subsequently decreasing venture squander. The capacity to all the more precisely foresee project cost considers a more serious bid. We at The Designing Plan offer MEP coordination administrations for undertakings of any size. For more data visit The Designing Plan site.

0 notes

Text

Best Mechanical Design Software 2024

There are many CAD tool for Mechanical engineering design some Paid and some are open source and free to use like FreeCAD. Every CAD software has their own unique feature and based on these unique feature companies used it for example CATIA is very good in Surface design therefore many big aerospace companies use it surface design. In this article we will discuss Best Mechanical Engineering Design Software in 2024

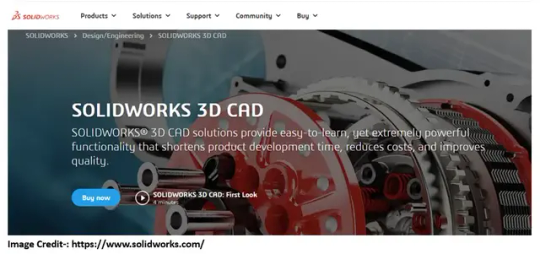

SolidWorks:

It is one of the best 3D modeling software available in the market. It is owned by Dassault System the same company that owns CATIA. As compared to any 3D modeling software SolidWorks is very easy to learn. SolidWorks has an extremely user-friendly interface and is used for creating complex machinery parts.

SolidWorks is a 3D CAD design software that allows users to create, analyze, and manage complex models and assemblies. SolidWorks is used by engineers, designers, and manufacturers for various applications, such as product development, simulation, testing, and data management. SolidWorks is a brand within Dassault Systems, a leader in 3D and digital solutions. SolidWorks offers a range of products and services, such as cloud-based collaboration, 2D CAD drafting, and professional certification.

Also Read:

- Basic Guide to Choosing ISO or ASME Standard for 2D Drawing

- Beginner Guide to Computer Aided Design

- Basic Guide to Autodesk Inventor and How Does It Work?

Autodesk Inventor:

It is one of the best 3D modeling software available in the market. This software not only helps in design mechanical project but also in simulation. This software helps in design of complex H frame transmission structure and various type of steel structure. Autodesk Inventor also integrates with other Autodesk products, such as Revit, Fusion 360, and AutoCAD, to enable BIM interoperability, cloud-based collaboration, and design automation.

Solid Edge:

It is a 3D modeling software own by Siemens. It is one of the best software for mechanical design. Solid Edge also comes with powerful simulation capabilities. Solid Edge offers a comprehensive portfolio of product development tools for mechanical and electrical design, simulation, manufacturing, technical publications, data management, and more. one of the best things about Solid Edge is It uses synchronous technology to combine the speed and simplicity of direct modeling with the flexibility and control of parametric design.

Also Read:

- Select Shaft Diameter with respect to Bearing Number

FreeCAD Integration with KiCAD

- Top 10 Courses to Join After Mechanical Engineering

CATIA:

It is one of the robust 3D modeling software owned by Dassault system.it is mainly use for surface design in aerospace industries. CATIA have many other workbenches to design the product. CATIA is a 3D CAD software suite that enables users to design, simulate, and manage complex products and systems. CATIA is developed by Dassault Systèmes, the same company that created SolidWorks. CATIA is widely used in various industries, such as aerospace, automotive, industrial equipment, and architecture. CATIA offers a range of features and functions, such as cloud-based collaboration, 2D CAD drafting, electrical and fluid engineering, and systems engineering.

Creo:

Creo is develop by parametric technology and one of the robust software for design of complex mechanical product. It was previously known as Pro/Engineer and later it renamed as Creo. It is well known for its 3 major feature which are Assembly modeling, Finite Element Analysis NURBS surface modeling.

Creo is a 3D CAD software suite that enables users to design, simulate, and manage complex products and systems. Creo is widely used in various industries, such as aerospace, automotive, industrial equipment, and architecture. Creo offers a range of features and functions, such as cloud-based collaboration, 2D CAD drafting, electrical and fluid engineering, and systems engineering.

Also Read:

- Basic Guide to Choosing ISO or ASME Standard for 2D Drawing

- Beginner Guide to Computer Aided Design

- Basic Guide to UC Bearing Number Designation

Fusion 360:

It is cloud based 3D Modeling Software offered by Autodesk. Fusion 360 is a cloud-based 3D CAD tool with capablity of CAM and CAE. It is an integrated platform that combines design, simulation, and manufacturing capabilities, making it a powerful tool for product development and engineering.

KeyCreator:

It is geometry centric 3D modeling software. It provides flexible design with the help of 2 and 3 axis machining. KeyCreator, formerly known as CADKEY, is a 3D direct modeling computer-aided design (CAD) software developed by Kubotek3D. It is used for creating, editing, and analyzing 2D and 3D designs and models. KeyCreator is known for its flexibility in design workflows and its emphasis on direct modeling techniques.

Also Read:

- Select Shaft Diameter with respect to Bearing Number

FreeCAD Integration with KiCAD

- Top 10 Courses to Join After Mechanical Engineering

“Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!”

Disclaimer: The views expressed in this review are solely those of the author and do not necessarily reflect the views of the software developer, publisher, or any other affiliated parties. The author is solely responsible for the accuracy, completeness, and validity of the information presented in this review. Any errors, omissions, or inaccuracies are the author’s own and not the fault of any other entity or organization. The author does not endorse or recommend any products, services, or websites mentioned in this review, unless explicitly stated otherwise. The author is not a licensed professional and the information in this review is for educational and entertainment purposes only. The author does not assume any liability or responsibility for any consequences or damages that may arise from the use or misuse of the software or the information in this review. The reader is advised to consult a qualified professional before taking any action based on the information in this review.

Read the full article

0 notes