#Sewage Treatment Equipment Suppliers

Text

Sewage Treatment Plant By- Kelvin Water Technologies... .

#water treatment plant#effluent treatment plant manufacturers#sewage treatment plant in india#wastewater#etp plant manufacturers#sewage treatment equipment suppliers

0 notes

Text

Fenton Technologies Pvt. Ltd. is a professional Engineering equipment’s Manufacturing and Environmental research and development, production and sales of science and technology enterprises. Since its inception, we always adhere to the spirit of craftsmanship, to provide the industry with water treatment equipment and services and systematic solutions, Company Work in Three Verticals- Sewage Water Projects , Wastewater Products, Swimming Pools Products include MBR Membrane , Oil Skimmer, Screw Press, MBR STP Plant, Bar Screen, Dissolved Air Flotation (DAF) many More water treatment Equipment’s . Fenton is also Associating with Overseas partners to Keep in Forefront . Our Water Treatment Equipment Company always welcome innovation & Advance Technologies Developers for Association in Market .

In product quality improvement, the water treatment equipment company “customer first” philosophy for the development, adhering to the “quality, innovation and service” business purposes, the establishment of a set of international standards of quality assurance management system.

youtube

MBR Membrane Manufacturer

Sewage treatment plant manufacturer in india

water Treatment Equipment Manufacturer

water Treatment Equipment Supplier

Belt Type Oil Skimmer Manufacturer

swimming pool manufacturer in india

2 notes

·

View notes

Text

Sewage Treatment Plant Manufacturer in India

Sewage Treatment Plant Manufacturer

The sewage treatment plant is a critical component of the sanitation system. It removes harmful materials from our wastewater before it can enter the environment. The process of treatment typically includes three stages: primary, secondary and tertiary. Primary treatment removes solids and floating materials from the wastewater by screening or skimming, followed by gravity settling to remove lighter particles. Secondary treatment uses microorganisms to break down organic matter in a series of tanks called activated sludge units (ASUs).

Tertiary treatment involves removing any residual chemicals or microorganisms that could harm the environment with additional chemical treatments or chlorination before releasing it into the environment.

A sewage treatment plant is the foundation of a healthy community. It reduces the risk of infectious diseases and protects our water supply. But the sewage treatment industry is not without its challenges - like how to keep up with increasing population growth, climate change, and stricter regulations.

Sewage Treatment Plant Manufacturers are companies that provide solutions to the problem of waste water treatment. They make sure that the sewage is treated in a safe, efficient and cost-effective way.

A sewage treatment plant manufacturer supplier is an important part of any community because they provide a solution to a major problem. The wastewater from homes and businesses go to the plant where it undergoes a series of treatments before it's discharged back into the environment or used for irrigation or other purposes.

Sewage Treatment Plant Manufacturers are responsible for making sure that all of this takes place in an environmentally friendly manner, which means they have to use some form of renewable energy.

The sewage treatment plant manufacturer is the company that manufactures and installs sewage treatment plants. These plants are used in the municipal water treatment process to clean raw sewage before it is released into rivers and streams.

A STP manufacturer can be a private company or a government agency, such as a municipality, county, or state. The plant may be owned by a public utility or operated by a private company under contract to the government.

The sewage treatment plant manufacturer needs to comply with all applicable federal, state, and local regulations governing the design and operation of wastewater systems.

Thanks & Regards

Advance Equipment & Project Pvt Ltd .

#sewage_treatment_plant_manufacturer_supplier_in_noida sewage_treatment_plant_manufacturer_supplier_in_ncr sewage_treatment_plant_manufactur#sewagetreatment#effluent#effluenttreatmentplant#purewaterplant#watertreatmentplantmanufacturerinnoida#water_treatment#water_treatment_plant_manufacturer_in_gurgaon#advancve_equipment

2 notes

·

View notes

Text

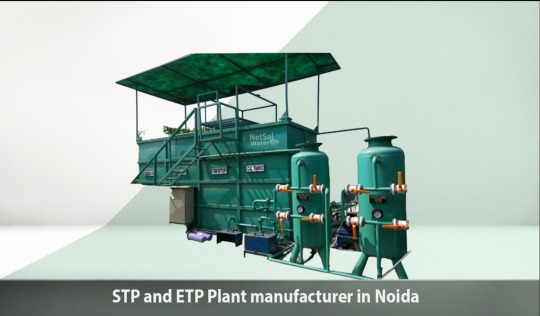

Find The Top STP & ETP Plant Manufacturer In Noida

The Netsol Water-managed sewage treatment plant & effluent treatment plant are excellent facilities designed to effectively treat & cleanse the wastewater. These treatment facilities can remove a wide range of contaminants & toxins out of sewage, including chemicals, bacteria, viruses, & biological waste, thanks to their cutting-edge technology & sturdy structural construction.

Netsol Water has achieved great success in the market by providing its clients with an economical wastewater treatment plant facility along with all the guarantees both before & after the machine is produced. Getting this plant would be easy if you got in touch with a Noida-based STP & ETP plant manufacturer, like Netsol Water. Netsol Water has sites around the country & is always here to help our customers.

Among the treatment procedures incorporated in this kind of treatment plant system are filtration, sedimentation, biological component treatment, disinfection, & screening out. Modern sensors & control systems have been added to ensure optimal & efficient operation. As the most reasonably priced manufacturer of STP-ETP treatment plant systems in Noida, Netsol Water is ascending to the top rapidly.

An overview of STPs & ETPs

The technology applied to STPs is easy to maintain & set up. Generally speaking, you may get it from the STP Manufacturer in Noida. It may be useful in a wide range of instances, notably residential, commercial, as well as industrial ones.

Manufacturer of stp & etp plants in Noida

Yet, either sewage or industrial effluent wastewater must be treated & cleaned before being discharged into the environment-ecosystem. An ETP, which can be purchased from Noida ETP Plant Suppliers, cleans & disposes of waste material generated by industrial activity. The job of an ETP is to purge or purify wastewater of dangerous contaminants & toxins so that it satisfies legal & environmental requirements. Netsol Water is the best stp and etp plant manufacturer in noida at best affordable price.

Throughout the treatment process, physical, chemical, & biological methods are frequently implemented to eliminate pollutants & poisons from wastewater. Physical techniques including screening, sedimentation, & filtration are employed to get rid of solid & suspended pollutants from wastewater.

Various retarders as well as other Chemical compounds categorized as flocculants or coagulants are applied in the tanks to get rid of dispersed, dissolved materials or particles from the raw wastewater. Microorganisms play a significant part in biological processes by breaking down organic compounds found in wastewater.

Numerous applications of STP-ETP treatment plants

Factories related to clothing: The textile industry requires a lot of operations related to ETPs & STPs to treat wastewater that is produced during the printing, dying, & finishing operations. because hazardous substances including dyes, solvents, & even heavy metals can be found in wastewater that may deteriorates the current condition of the environment-ecosystem if released hysterically untreated.

The production of wastewater, often known as effluent or sewage, by the pharmaceutical industry, have constituents such as active pharmaceuticals & is hazardous to both the environment & human health. ETPs serve to eliminate contaminants & make sure wastewater satisfies regulatory requirements before it is released into the environment. They are readily available from ETP treatment plant manufacturers.

The beverage & food industries: ETPs are typically utilized for the control & treatment of wastewater from manufacturing processes including brewing, bottling, condensing, along with distilling, as well as wastewater sewage or effluent water from sanitation & processing equipment. Wastewater from effluent sources needs to be cleaned, refined, & treated in order to remove extraneous contaminants, organic debris, & other types of surplus organic nutrients.

Chemical Production Industry: ETPs play a critical role in wastewater treatment during manufacturing processes including purification & several types of chemical synthesis. Hazardous compounds, bases, & acids that are bad for the environment & people's health might be present in the effluent.

Conclusion

Remember that only a reliable & trustworthy STP-ETP manufacturer can handle all of the following challenges & procedures to provide their clients top-notch treatment plants in Noida. One of the top manufacturers, Netsol Water, has always been steadfast providing all resources to this industry & provides a wide range of these equipment & components.

One of the best choices among the several manufacturing companies in the Noida area is Netsol Water because of their reliability & efforts, which also determine how much technology they can provide & combine into their products.

#netsolwater#industrial ro plant manufacturers#commercial ro plant#industrial ro plant#sewage treatment plant manufacturer#effluent treatment plant#sewage treatment plant#effluent treatment plant manufacturer#watertreatment plant

0 notes

Text

Are you Looking for Sewage Pump Manufacturer?

If you are looking for Sewage Pump, Creative Engineers have been offering ISO-9001:2008 certified Sewage Pump Manufacturer We are the best Sewage Pump manufacturer and Supplier in the industry providing premium Sewage Pump.

Sewage pumps are key equipment for discharging and treating sewage, and play an important role in municipal, industrial and commercial fields. Sewage Pump has features like sturdy construction, precision engineering, superior quality, excellent functionality, efficient output and high durability, our offered products have gained huge appreciation by clients

APPLICATIONS OF SEWAGE PUMP

Scum pumping at waste water treatment plant

Municipal projects

Industrial packaged pump station

Home and domestic application (Special for kitchen)

Pumping agricultural manure (dairy, hog and poultry)

For More Details

Click here : https://www.sspumpsindia.com/

0 notes

Text

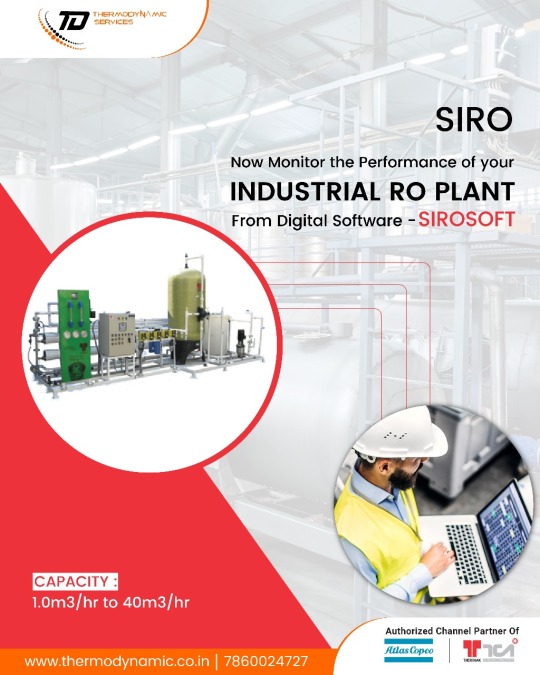

Comprehensive Solutions in Thermodynamic Services: A Leading Partner in Uttar Pradesh

Introduction: In the bustling industrial landscape of Uttar Pradesh, Thermodynamic Services emerges as a beacon of excellence, catering to a diverse range of thermodynamic needs. With a rich history of collaboration with industry giants like Thermax Limited, Atlas Copco (India) Limited, and Buhler India Pvt. Limited, Thermodynamic Services stands as a trusted partner offering comprehensive solutions. Specializing in industrial air compressors, compressed air dryers, thermic fluid heaters, industrial water treatment plants, STP plants for hospitals, and ETP plants for industrial use in Kanpur and beyond, Thermodynamic Services is committed to addressing the most challenging issues in heat, energy, air, water, solar, and grain processing.

Industrial Air Compressor Manufacturer & Supplier in Kanpur: As a premier industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services delivers top-of-the-line equipment tailored to meet the rigorous demands of modern industries. Drawing from years of expertise and partnerships with leading manufacturers, we provide cutting-edge solutions that ensure optimal performance and efficiency for our clients' operations.

Compressed Air Dryer / Refrigerated Air Dryer Supplier in Kanpur: Recognizing the critical importance of quality compressed air in industrial processes, Thermodynamic Services offers premium compressed air dryers and refrigerated air dryers. Our products guarantee the delivery of clean, dry air, free from moisture and contaminants, thereby safeguarding the integrity of our clients' operations and prolonging the lifespan of their equipment.

Thermic Fluid Heater Supplier/Manufacturer in Uttar Pradesh: In the realm of thermic fluid heating systems, Thermodynamic Services stands as a distinguished supplier and manufacturer in Uttar Pradesh. Our thermic fluid heaters are engineered to deliver efficient heat transfer, ensuring consistent performance and reliability across various industrial applications. With a focus on innovation and quality, we empower our clients to optimize their processes while minimizing energy consumption.

Industrial Water Treatment Plants Supplier/Manufacturer in Uttar Pradesh: Water is a precious resource, and Thermodynamic Services is committed to its responsible management through advanced water treatment solutions. As a leading supplier and manufacturer of industrial water treatment plants in Uttar Pradesh, we offer customized systems designed to meet the unique needs of each client. From filtration to purification, our solutions ensure the availability of clean water for industrial processes, enhancing productivity and sustainability.

STP Plant for Hospitals: Ensuring safe and sustainable wastewater management is imperative for healthcare facilities, and Thermodynamic Services provides tailored solutions with our STP (Sewage Treatment Plant) plants for hospitals. Compliant with regulatory standards and designed for efficiency, our STP plants effectively treat wastewater, mitigating environmental risks and promoting a healthier community.

ETP Plant for Industrial Use in Kanpur: Industries in Kanpur rely on efficient wastewater treatment, and Thermodynamic Services meets this demand with our ETP (Effluent Treatment Plant) plants for industrial use. Through advanced technologies and expert engineering, our ETP plants efficiently remove pollutants from industrial effluents, ensuring compliance with environmental regulations and fostering sustainable industrial practices.

Conclusion: Thermodynamic Services stands as a testament to excellence in thermodynamic solutions, driven by a commitment to innovation, quality, and customer satisfaction. With a proven track record of serving esteemed clients and addressing complex challenges, we continue to be the preferred partner for industries across Uttar Pradesh. Whether it's industrial air compressors, compressed air dryers, thermic fluid heaters, water treatment plants, or wastewater management solutions, Thermodynamic Services remains at the forefront, empowering industries to thrive in an ever-evolving landscape.

#Industrial air compressor manufacturer & supplier in kanpur#Air compressor dealers in Kanpur/ Uttar Pradesh#compressed air dryer / refrigerated air dryer supplier in kanpur#STP plant for hospitals#ETP Plant for industrial use in kanpur

0 notes

Text

Are You Looking for Sewer Suction Machine Manufacturers in India

We are a successful manufacturer and supplier of Sewer Suction Mchines in India, which is used to create a vacuum that is essential for siphoning of various materials like mud, slurry, and grit from storm, sanitary, and combined sewerage systems. This machine is manufactured using the best grades of material that ensures its finest quality and high performance. This hydraulic sewer suction machine comes with an unloader or a pressure relief valve that is used for controlling the pressure.

Sewer Suction Machine Manufacturers play a vital role in the efficient removal of sewage and waste materials from various drainage systems. These machines are designed to suction and transport liquid and solid waste, helping to maintain clean and functional sewer networks.

What is a Sewer Suction Machine?

A sewer suction machine, also known as a vacuum tanker or sewer cleaning truck, is a specialized vehicle equipped with powerful suction pumps and storage tanks. It is used for clearing blockages, cleaning sewer lines, and transporting sewage and sludge to treatment facilities.

How Does a Sewer Suction Machine Work?

Sewer suction machines utilize vacuum technology to create suction pressure, which effectively pulls waste materials into the storage tank. The collected waste is then transported to disposal sites or treatment plants for proper disposal or processing.

Types of Sewer Suction Machines

There are various types of sewer suction machines available, including truck-mounted units, trailer-mounted units, and skid-mounted units. Each type offers unique features and capabilities to suit different applications and environments.

Applications of Sewer Suction Machines

Sewer suction machines are used in a wide range of applications, including municipal waste management, industrial cleaning, and emergency response services. They are essential for maintaining clean and functional sewer systems in urban and rural areas alike.

Benefits of Using Sewer Suction Machines

Efficiency: Sewer suction machines offer efficient waste removal, reducing the risk of blockages and backups in sewer lines.

Versatility: These machines can handle various types of waste, including liquid and solid materials, making them versatile tools for waste management.

Cost-Effectiveness: By preventing costly repairs and minimizing downtime, sewer suction machines help save money in the long run.

Safety Precautions When Operating a Sewer Suction Machine

Operating a sewer suction machine requires adherence to strict safety protocols to prevent accidents and injuries. Always wear appropriate personal protective equipment (PPE), follow operational guidelines, and exercise caution when working near sewer lines.

Contact us right away, if you want to learn more about our wide range of sewer suction machine products. Call us at .+919311309436 or send an email to [email protected], we are India’s largest sewer suction machine manufacturers and suppliers.

#sewer suction machine manufacturers#sewer suction machine#sewer suction machine manufacturers in India#sewer suction machine manufacturers in Ghaziabad#sewer suction machine manufacturers in Uttar Pradesh#sewer suction machine suppliers#sewer suction machine suppliers in India#sewer suction machine suppliers in Ghaziabad#sewer suction machine suppliers in Uttar Pradesh

0 notes

Text

Understanding Float Switch Sensors: Applications, Prices, and Varieties in UAE

Float switch sensors are critical components used in various industries and applications to monitor liquid levels effectively. Whether it's water, sewage, sump, wastewater, or diesel fuel, these sensors play a pivotal role in automation and control systems. In this article, we'll delve into the functionality, prices, and varieties of float switch sensors available in the UAE market, particularly in Sharjah and Dubai.

What is a Float Switch Sensor?

A float switch sensor is a simple yet efficient device used to detect liquid levels in tanks or reservoirs. It consists of a buoyant float attached to a switch mechanism. As the liquid level rises or falls, the float moves accordingly, activating or deactivating the switch to signal the level change. This signal can be utilized to control pumps, valves, alarms, or other automated processes.

Applications of Float Switch Sensors

Water Management: Float switches are commonly employed in water tanks for residential, commercial, and industrial purposes. They ensure timely refilling or draining of tanks, preventing overflow or dry running of pumps.

Sewage and Wastewater Systems: In sewage treatment plants and wastewater management systems, float switches monitor levels in collection tanks, facilitating efficient pumping and preventing overflow incidents.

Sump Pump Control: Sump pumps equipped with float switches automatically activate when water levels rise in basements or underground spaces, safeguarding against flooding.

Fuel Tanks: Float switches are utilized in diesel fuel tanks to monitor fuel levels in generators, vehicles, or industrial machinery, ensuring uninterrupted operation.

Industrial Processes: Various industrial applications, including chemical processing, food and beverage production, and manufacturing, rely on float switches for liquid level monitoring and control.

Types of Float Switches

Vertical Float Switches: These switches feature a vertically mounted float that moves up and down with liquid levels.

Horizontal Float Switches: Horizontal float switches have a float that moves horizontally along a guide rod, making them suitable for narrow tanks or limited space installations.

Multi-Level Float Switches: Designed with multiple floats at different levels, these switches provide precise level control and versatility for complex applications.

Reed Switch vs. Mechanical Switch: Float switches employ either reed switch technology or mechanical switches. Reed switches offer high reliability and are suitable for corrosive or hazardous environments, while mechanical switches are cost-effective and suitable for standard applications.

Where to Find Float Switches in Sharjah and Dubai

Float switches are readily available in hardware stores, industrial suppliers, and online marketplaces in Sharjah and Dubai. Popular brands such as Creative Automation offer a wide range of options to suit different requirements and budgets.

In conclusion, float switch sensors are indispensable devices for liquid level monitoring and control across various industries and applications in the UAE. Understanding their functionality, types, and prices can help businesses make informed decisions when selecting the appropriate float switch for their specific needs.

#Wastewater Float Switch#Diesel Fuel Float Switch#Multi-Level Float Switch#Sump Float Switch#Water Level Float Switch#Industrial Float Switch#Float Switch Sensor#Float Switch Price

0 notes

Text

Control Valve Supplier in Nigeria

African Valve stands as a leading Control Valve supplier in Nigeria. Control valves are devices designed to manipulate the flow rate, pressure, or direction of a fluid in various industrial processes. They are used in a wide range of industries including oil and gas, chemical processing, power generation, water treatment, and many others where precise control of fluid flow is critical for efficient and safe operation.

Here are some features of Control valve:

Flow control: These valves provide precise control over the flow of fluids, gases, or other process variables;this feature is crucial for maintaining optimal performance and efficiency in various industrial applications.

Pressure Regulation: Help to regulate pressure within a system by adjusting the valve opening in response to changes in upstream or downstream pressure conditions.

Safety: Control valves can be used to regulate the flow of hazardous fluids or gases, ensuring that they are handled safely and minimizing the risk of accidents.

Temperature Control: Control valves equipped with temperature sensors or actuators which regulate the fluid temperature by adjusting the flow of heating or cooling media.

Reduced maintenance: They are designed to operate reliably for extended periods with minimal maintenance, reducing downtime and maintenance costs.

Versatility: Control valves are available in a variety of materials, including stainless steel, brass, bronze, to accommodate different fluid types, temperatures, and corrosive environments. Proper material selection is essential to ensure long-term reliability and performance of control valves in specific applications.

Types of Control valve we supply:

Globe control valves

Electric control valve

Pneumatic control valve

Electric double seat control valve

Electric single seat control valve

Pneumatic angle control valve

Three-way control valves

Industries:

Chemical processing: These valves are widely used to regulate the flow of fluids and gases during chemical processes.

Power generation: They are used to regulate the flow of steam and other fluids used in the generation of electricity.

Water and Wastewater Treatment: Control valves are essential components in water treatment plants, where they regulate the flow of water, chemicals, sewage, sludge, and treatment chemicals.

Oil and Gas Industry: Control Valve are used extensively in the oil and gas industry to regulate the flow of fluids, gases, and other process variables during the production and processing of oil and gas. as well as control pressure and temperature.

Description:

Body Materials: Ductile Iron, Cast iron (WCB, WCC, WC6) LCC, LCB, Stainless Steel (SS316, SS304), Super Duplex (F51, F53, F55)

Class: 150 to 2500, PN10 to PN450

Operations: Electro Pneumatic and Pneumatic

Size: DN15 to DN600

Ends: Flanged, butt weld, socket weld, threaded

Electric actuator details:

Torque – 3 – 9 nm

Operating pressure- 8 Bar

Port Connection-NPT 1.4”

Mounting Base-ISO5211

Temperature–20°C – +80°C

Configuration of a Pneumatic Actuator:

4-20 amp

Pneumatic single acting actuators

Pneumatic double acting actuators

Pneumatic rotary actuators

Pneumatic Scotch and Yoke actuators

Pressure: 228 bar

Temperature:

Standard -4°F to 200°F (-20°C to 93°C)

Low -40°F to 176°F (-40°C to 80°C)

High 0°F to 300°F (-18°C to 149°C)

Visit our website for more detail: https://www.africanvalve.com/product-category/control-valve/

0 notes

Text

KSB Drainage Mud Pump cost, installation and repairing in Bangladesh

The KSB Drainage mud pump Bangladesh is used for draining pits and deep roadway underpasses, and for dewatering basements and courtyards subject to a flooding risk or groundwater for your project. KSB MUD Drainage pump Bangladesh usually installed vertically, the motor situated above the pump is sealed by mechanical seals and shaft sealing rings. The chamber of KSB MUD Drainage pump Bangladesh is located between the sealing elements installed in pairs is filled with grease or oil. The KSB MUD Drainage pump Bangladesh is usually started automatically via float switches. The water to be handled depends on the pump size and impeller also depend on the contain dirt and solids whose permissible particle size. KSB MUD Drainage pump Bangladesh compact design makes the motor pump a transportable pump suitable for draining and portable.

The challenges of building and premises drainage:

Every building has its own set of drainage requirements in everywhere in Bangladesh. The chamber of KSB MUD Drainage pump Bangladesh is the first choice of consultants, distributors, and installation contractors in Bangladesh. The application is a major construction project or the equipping of a private house and apartment’s drainage always requires precisely tailored solutions that operate effectively and sustainably without creating and noise, so they need a trusted brand’ s MUD pump. Also consultants, distributors, and installation contractors demand drainage systems that save long-term costs effective and work smoothly. After all, the ultimate goal is to achieve reliable protection for your home, industries, projects, factories, garments and property.

KSB MUD Drainage Pump Bangladesh offers a high efficient with high quality of pumps, valves and services:

KSB MUD Drainage pump Bangladesh is sure to include the optimum solution for every type of drainage challenge in building services regardless of whether the installation is stationary or portable in your Showers, toilets, garages or parking spaces area. KSB use of high-quality materials make sure long-term service lives and high operating reliability for KSB MUD Drainage pump Bangladesh. KSB MUD Drainage pump Bangladesh products for drainage also meet necessary national and international standards. As a result that you stand to get benefit from long-term savings for costs and time spent on maintenance, repairs and servicing. KSB MUD Drainage pump Bangladesh to be able to offer economical and high-quality comprehensive solutions in all areas of your drainage system. Millat Pumps Limited is a full-range supplier; KSB MUD Drainage pump Bangladesh not only offers across-the-board, but also comprehensive service from installation, commissioning to inspections, maintenance work and repair of pumps from any brands in Bangladesh including its spare parts. Millat Pumps Limited has own service experts and specialists for KSB MUD Drainage pump Bangladesh. KSB MUD Drainage pump Bangladesh also offers for drainage applications with sewage lifting units, waste water pumps, submersible motor pumps or pump stations.

KSB MUD / Waste Water Pump / Submersible Drainage Pumps:

KSB MUD Drainage pump Bangladesh is Suitable for handling waste water, especially waste water containing long fibers and solid substances, fluids containing gas/air, removing waste water from flooded rooms or surfaces. Vertical single-stage fully floodable waste water KSB MUD Drainage pump Bangladesh in close-coupled design, non-explosion-proof. Application Areas are Waste water management, Drainage systems, Waste water treatment plants, Drainage of rooms and areas at risk of flooding. water KSB MUD Drainage pump Bangladesh Suitable for handling waste water, especially waste water containing long fibers and solid substances, fluids containing gas/air, removing waste water from flooded rooms, areas or surfaces in your projects. A vertical single stage KSB MUD Drainage pump Bangladesh for wet installation.

KSB MUD / Waste Water Pump / Submersible Drainage Pumps Applications:

KSB MUD Drainage pump Bangladesh has Frame-cooled enclosed motor. Permits operation even when motor is not submerged and is protected against overheating, however not advised as a conscious method of operation. KSB MUD Drainage pump Bangladesh have Long service life with the low-weight design and corrosion-proof thanks to high-quality plastic casing. Noise-absorbing, abrasion-proof and impact- resistant. KSB MUD Drainage pump Bangladesh Economic operation optimized the hydraulic systems and motors for large pump output at high efficiency. Its Vertical discharge nozzle allows installation in narrow sumps KSB MUD Drainage pump Bangladesh is High operating reliability with the triple shaft seal lubricated by the barrier fluid makes for high motor reliability. Lubrication of the seal faces in the event of dry running. KSB MUD Drainage pump Bangladesh does not need drainage of the discharge pipe with the Integrated swing check valve.

KSB MUD Drainage pump Bangladesh know how to handle pressure:

All KSB MUD Drainage pump Bangladesh stations are available as single-pump or dual- pump systems. Millat Pumps Limited is rapidly available standard products or a solution customized to your requirements for your industries factories and organization. Whatever it is Rainwater, grey water, waste water and containing faces For projects surrounding pumped drainage KSB MUD Drainage pump Bangladesh offer a broad range of different, powerful pump stations, so we can find an optimum solution for your application. KSB MUD Drainage pump Bangladesh is Protected against overload which grants integrated motor protection. KSB MUD Drainage pump’s Magnetic switch with adjustable, variable level control and anti-over winding device, and it is very Easy to replace cable with plug-type connector. Straightforward adaptation to external control system with locking disc.

KSB MUD Drainage pump Bangladesh Importer, Wholesalers Distributors and dealer:

Millat Pumps Limited is a trusted Importer, Wholesalers Distributors and Dealer of KSB MUD Drainage pump Bangladesh. KSB Sewage Pump is a prominent brand that offers a wide range of high-quality High-efficient sewage pumps in Bangladesh which technology came from Germany and manufacturing factory in India. KSB MUD Drainage pump Bangladesh are designed to handle wastewater and sewage efficiently, making them ideal for a variety of industries and applications. Millat Pumps Limited work closely with KSB MUD Drainage pump Bangladesh to ensure that the pumps meet all the necessary requirements and are delivered to the Indian market on time. Millat Pumps Limited play a significant role in promoting with KSB MUD Drainage pumps Bangladesh globally, making it a well-known brand in the international market. Millat Pumps Limited work closely with KSB MUD Drainage pump Bangladesh to ensure that the pumps are available to customers in different parts of Bangladesh. Millat Pumps Limited work closely with KSB MUD Drainage pump Bangladesh to ensure that they have a constant supply of sewage pumps to meet the demand of customers.

Principle of KSB MUD Drainage pump Bangladesh:

Sewer pipes tend to rely on gravity for the movement of wastewater, with the fluid being allowed to move gradually downhill until it reaches a low point. KSB MUD Drainage pump Bangladesh drainage system is routinely used to pump the wastewater back uphill, until it reaches a high point at which gravity can once again help the water along on its journey. The principle of a KSB MUD Drainage pump Bangladesh drainage system is to enable foul water, surface water and sewage to be efficiently and economically removed in areas of low gravity, or where it may otherwise be difficult to achieve a connection to the main drain. The KSB MUD Drainage pump Bangladesh drainage system, therefore, tends to be situated underground, with foul, surface water or sewage being discharged into it, and the fluid then being pumped through a discharge pipe to the main sewer.

KSB MUD Drainage pump Bangladesh is important for Right Drainage System:

We know, basement floors often being too low to even enable sewage to flow by gravity in Bangladesh. To unsurprising that a lot of the enquiries we receive here at Pumping Solutions relate to the pumping of water from basements so KSB MUD Drainage pump Bangladesh is the best choice for its solution. Floods seem to be hitting the headlines more and more in recent years amid ongoing climate change and increasingly extreme weather events. We therefore wouldn’t wish you to be anything less than completely prepared against the risk of floods, which can cause so much damage and in the most extreme cases, even homelessness. Existing drainage systems in basements can naturally differ from one property to the next. A typical arrangement in many Victorian properties, however, is a gully pot being situated in a light well or at the base of an external stairwell, with the gully running to the sewer There are many reasons to invest in a pump station at your property because it being a more cost-effective alternative to the groundwork that may be required to allow sewage to flow by gravity, a gravity system not having even been built.

1 note

·

View note

Text

#water treatment plant#wastewater#waste management#sewage treatment equipment suppliers#jobsearch#latest jobs#jobopportunity#job interview#jobalert

0 notes

Text

Sewage Treatment Plant manufacturer in India

Sewage Treatment Plant Manufacturer, Water treatment plant manufacturer

The treatment process of a water treatment plant manufacturer is to remove the impurities from the water and make it suitable for consumption.

Sewage Treatment services in Noida ..

The main aim of this process is to make sure that the drinking water is safe for human consumption.

The is responsible for treating and managing sewage in order to reduce pollution and protect public health.

The sewage treatment plant manufacturer is the one that produces the equipment for the sewage treatment plants. The equipment includes pumps, valves, tanks and other parts that are used in the process of wastewater treatment. This company is also in charge of providing the chemicals and solutions needed to keep the water clean.

Effluent Treatment Plant

A sewage treatment plant manufacturer is an important company in a community because they are responsible for making sure that all wastewater is treated so it can be reused or disposed of safely.

The treatment process starts with the primary clarifiers, which remove solids from the wastewater. The wastewater then passes through the secondary clarifiers and aeration tanks, where bacteria break down organic matter to produce carbon dioxide and hydrogen sulfide. This is followed by the oxidation ponds, which provide a surface for bacteria to grow on.

A water treatment plant is a facility that removes impurities from water by physical, chemical, and biological processes. The process begins with the water being pumped from its source to the treatment facility.

There it is fed into large tanks called clarifiers, where heavy solids such as sand settle out.

Sewage Treatment Plant Manufacturers Suppliers in India are responsible for providing customers with a solution to their sewage problems. They are capable of handling all types of wastewaters on a commercial or residential level.

The sewage treatment plant manufacturer is responsible for the design and construction of sewage treatment plants. These plants are used to treat wastewater before it is released back into the environment.

It is important to note that the sewage treatment plant manufacturer needs to have a degree in civil engineering, environmental engineering, or chemical engineering. They also need experience in designing and constructing various types of water and wastewater infrastructure projects.

Thanks & Regards

Advance Equipment & Projects Pvt Ltd

https://www.advanceequipment.in/

#water_treatment_plant#sewage_treatment#sewage_treatment_plant_manufacturers_suppliers_in_india#water_treatment_plant_services#clean_water

2 notes

·

View notes

Text

Find The Top STP & ETP Plant Manufacturer In Noida

The Netsol Water-manufactured & operated sewage treatment plant, also the effluent treatment plant, is an excellent facility designed to effectively treat & purify wastewater. These treatment facilities can eliminate a variety of contaminants & toxins from sewage, such as chemical compounds, bacteria, viruses, or biological waste, thanks to their cutting-edge contemporary technology & sturdy structural construction.

By offering its clients an affordable wastewater treatment plant facility & all the assurances, both before & after the machinery & equipment are created, Netsol Water has achieved remarkable market success. Obtaining this unit would be simple if you contacted Noida-based Netsol Water, a manufacturer of STP or ETP facilities. Netsol Water is always available to assist our clients & has locations around the nation.

This sort of wastewater treatment plant system includes the following significant sedimentation(for the setting of fine impure particles), filtration, organic constituents treatment, disinfection, & screening-out among its treatment processes. Control systems & contemporary sensors have been integrated to guarantee finest (almost closer to an ideal condition) & effective operation. Netsol Water is quickly establishing itself as Noida's most affordable STP-ETP treatment plant system manufacturer. Netsol Water is the best stp and etp plant manufacturer in noida at best affordable price.

A summary of implementation strategy for ETPs-STPs

The technology utilized in STPs is easy to set up & keep up. In general, you may get it from the STP Manufacturer in Noida. It might be beneficial in various circumstances, especially in home, business, & industrial ones.

Manufacturer of STPs-ETP Treatment Plants based in Noida

However, wastewater, whether sewage or industrial effluent, is required to be purified & treated prior to being reintroduced into the environment-ecosystem. Waste material produced by industrial activities is cleaned & disposed of by an ETP, which can be acquired from Noida ETP Plant Suppliers. An ETP's responsibility is to remove harmful substances as well as pollutants from wastewater so that it meets all legal & environmental criteria.

Physical, chemical, or biological techniques are utilized extensively in the treatment process to remove contaminants & toxins from wastewater. Wastewater is subjected to physical methods such as screening, sedimentation, & filtration to remove suspended & solid contaminants.

To eliminate scattered, dissolved materials or particles from the raw wastewater, a variety of retarders along with additional chemical compounds classified as flocculants or coagulants are injected into the tanks. Microorganisms are essential to biological processes because they decompose organic materials present in wastewater.

Numerous applications of STP-ETP treatment plants

Clothing-related Factories: The textile sector needs a lot of ETP-STP operations to handle wastewater generated by printing, dying, & finishing processes. Because wastewater can include dangerous materials like dyes, solvents, & even heavy metals that, if dumped haphazardly untreated, might worsen the state of the ecosystem & the environment.

The pharmaceutical business produces wastewater, sometimes referred to as effluent or sewage, which contains active medications & poses a risk to human health & the environment. Before wastewater is discharged into the environment, ETPs serve to remove impurities & ensure that it complies with legal criteria. The producers of ETP treatment plants have them easily accessible.

The food & beverage industries: ETPs frequently serve for wastewater treatment & control from industrial operations including distilling, bottling, or condensing, as well as wastewater from sanitation & processing equipment. Cleaning, refining, & treating wastewater from effluent sources is necessary to get rid of organic detritus, excess organic nutrients, & other impurities.

Chemical Production Industry: During industrial operations such as purification & various forms of chemical synthesis, wastewater treatment is a crucial function of ETPs. The effluent may contain bases, acids, & hazardous chemicals that are harmful to human health & the environment.

Conclusion

Be aware that just an established & reliable STP-ETP producer can handle all of the ensuing procedures & issues to provide their customers with top-notch treatment facilities in Noida. Offering a wide range of various products & parts, Netsol Water, one of the top producers, has continuously been an anchor as well as foundation of the industry.

Netsol Water is a leading manufacturing company in the Noida area because of their efforts & reliability, which also affects how much technology companies may add to their products.

#netsolwater#industrial ro plant manufacturers#commercial ro plant#industrial ro plant#sewage treatment plant manufacturer#effluent treatment plant#sewage treatment plant#effluent treatment plant manufacturer#watertreatment plant

0 notes

Text

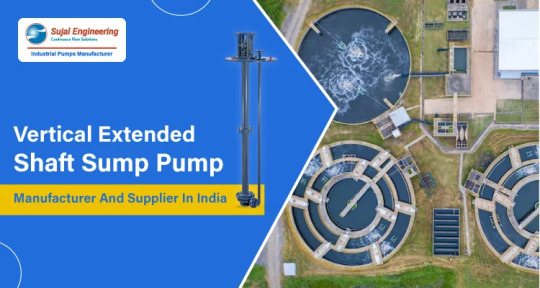

Vertical Extended Shaft Sump Pump Manufacturer and Supplier in India

Introduction

Industries where space saving is an important factor, rely on Vertical Sump Pumps for the pumping operation.

Vertical Shaft Pump is commonly used to pump various types of fluids, including water, oil, chemicals, or sewage, from one place to another. It is highly suitable for applications with limited space and locations where the pump is required to operate from a deep sump or tank.

These pumps are designed to pump normal to high-temperature liquids containing solid and abrasive particles without affecting the performance.

If you are interested in purchasing a Vertical Sump Pump from a trusted Vertical Pump Manufacturer but want to know more about the pump, you are in the right place.

In this blog, we will explore everything related to Vertical Shaft Pumps, including working features, features and functions, and applications and advantages.

We will also discover the importance of choosing the best quality Vertical Sump Pumps and factors to consider when choosing the Vertical Pump Manufacturer.

What Is A Vertical Sump Pump?

Vertical sump pump is a type of centrifugal pump designed specifically for pumping liquids from deep reservoirs, underground borewells, deep sumps, and tanks.

Also known as vertical long shaft pumps, these pumps are used for various applications such as mineral processing, effluent handling, seawater desalination, chemical processing, wastewater treatment plants, and sewage and slurry applications.

Various industries highly prefer these vertical sump pumps due to their excellent capabilities to handle contaminated, fibrous slurries and large solids containing liquids easily.

Pump Design:

Vertical sump pumps are usually designed to operate fully submerged and lift liquid at high levels efficiently and reliably.

Motor And Impeller:

The pump motor drives the drive’s impeller, which creates a centrifugal force that moves the liquids toward the pump outlet.

Sump Pit:

The pump is usually installed in a sump pit located at a lower elevation. This allows the liquid to flow towards the pump, ensuring efficient pumping.

Suction And Discharge:

The role of the suction pipe of the pump is to pull out the liquid from the sump pit and push it out via the discharge pipe.

Float Switch:

Vertical sump pumps are equipped with a float switch that controls the pump operations. For example, when the pit water level rises, it activates the pumps, whereas when the water level goes down, it deactivates the pump.

To Read Full Blog : Vertical Extended Shaft Sump Pump Manufacturer and Supplier in India

#centrifugal pumps#centrifugal pump manufacturers#industrial pumps#centrifugal pump#centrifugal pump manufacturer#business

0 notes

Text

What are pipe elbows used for?

Pipe elbows are a fundamental component in piping systems, essential for altering the direction of the flow of liquids or gases. In various industries, their utility is indispensable, facilitating smooth fluid movement and enhancing the efficiency of operations. As a leading Pipe elbow manufacturer and supplier of pipe elbows, Bu-Lok is committed to delivering top-quality products that ensure optimal performance in diverse applications.

What Are Pipe Elbows?

Pipe elbows, a type of pipe fitting, are curved pieces designed to join pipes at a specific angle to redirect flow. They come in various angles, typically 45 or 90 degrees, but can also be customized as per specific project requirements. These fittings are crucial in accommodating changes in direction, thereby preventing obstacles in the pipeline and ensuring seamless fluid transfer.

Uses and Applications:

Pipe elbows find extensive use across a spectrum of industries:

1. Plumbing: In residential and commercial buildings, pipe elbows are vital for directing water flow around corners and obstacles, ensuring an efficient plumbing system.

2. Industrial Applications: Industries such as petrochemical, oil and gas, and chemical processing heavily rely on pipe elbows to manage complex piping networks efficiently.

3. HVAC Systems: Heating, ventilation, and air conditioning systems utilize pipe elbows to redirect airflow and maintain optimal temperature control.

4. Infrastructure Projects: Water treatment plants, sewage systems, and infrastructure projects necessitate pipe elbows to maneuver pipelines effectively.

5. Oil and Gas Industry: In oil refineries and gas processing plants, pipe elbows play a critical role in managing the flow of various liquids and gases throughout the complex network of pipelines.

6. Chemical Processing Plants: Industries dealing with chemical processes rely on pipe elbows to ensure the safe and efficient movement of corrosive liquids and chemicals.

7. Manufacturing and Construction: Industrial manufacturing units and construction sites utilize pipe elbows for hydraulic systems, ensuring effective control and movement of fluids in machinery and equipment.

8. Agricultural Sector: Irrigation systems in agriculture also incorporate pipe elbows to channel water efficiently, ensuring proper distribution to crops.

Pipe Elbow Manufacturing Process:

Manufacturing high-quality pipe elbows involves precision engineering and adherence to stringent standards. Bu-Lok, as a prominent Pipe elbow manufacturer, employs cutting-edge technology and robust materials to produce durable, reliable pipe fittings. Processes such as hot forming, cold forming, or machining are used based on material specifications and end-use requirements.

Benefits of Pipe Elbows:

Pipe elbows offer several advantages:

- Durability: Made from stainless steel, high nickel steel, and other premium materials, ensuring longevity and resilience.

- Dimensional Accuracy: Precision engineering guarantees accurate fittings, critical for seamless integration into pipelines.

- High-End Finishing: Their products boast superior finishing, reducing friction and ensuring optimal fluid flow.

Types of Pipe Elbows:

Short Radius Elbows: These elbows have a smaller radius, making them more suitable for tight spaces or areas requiring a sharper turn in the pipeline.

Long Radius Elbows: Long radius elbows offer a smoother flow of fluid due to their larger curvature, reducing friction losses and pressure drop in the system.

Reducing Elbows: These elbows have varying inlet and outlet sizes, allowing for a change in pipe diameter while altering the direction of flow.

Factors Influencing the Choice of Pipe Elbows:

Fluid Characteristics: The nature of the fluid being transported, whether corrosive, abrasive, or sensitive to flow disruptions, determines the material and design of the elbow.

Operating Conditions: Factors like temperature, pressure, and flow rate impact the selection of the right type of elbow to ensure optimal performance and safety.

Space Constraints: The available space for installation often dictates whether a short radius or long radius elbow is more appropriate.

Testing and Quality Assurance:

Reputable manufacturers subject their pipe elbows to rigorous quality checks and testing procedures to ensure compliance with industry standards and specifications.

Testing procedures may include hydrostatic testing, non-destructive testing (NDT), and dimensional inspections to verify the product's quality and reliability.

Customization and Tailored Solutions:

They offers customization options to meet specific project requirements, providing tailored solutions in terms of size, angle, material, and additional features as needed.

Environmental Considerations:

Pipe elbows manufactured by them prioritize eco-friendly practices, ensuring minimal environmental impact during production and disposal.

Service and Support:

They are renowned not just for its high-quality products but also for its dedicated customer service and technical support. They provide expert guidance in selecting the right fittings and offer assistance throughout the installation process.

Conclusion:

In conclusion, pipe elbows play a pivotal role in the functionality and efficiency of piping systems across various industries. They stand as a premier manufacturer and supplier of top-notch pipe elbows, offering durability, precision, and superior finishing. For unparalleled quality and reliability in pipe fittings, Bu-Lok remains the trusted choice. Contact us for quotations and further details on our range of stainless steel, high nickel steel, alloy steel, carbon steel pipe elbows, fittings, and more.

0 notes

Text

What are the Functions of Sewage Suction Machine?

sewage suction machine is a specialized vehicle equipped with a vacuum system designed to efficiently collect and transport liquid waste, such as sewage, sludge, and industrial effluents, for proper disposal or treatment.

The sewage suction machine, also known as a vacuum truck or vacuum tanker, serves several important functions in waste management and sanitation:

· Wastewater Collection: The primary function of a sewage suction machine is to collect wastewater from various sources, including residential, commercial, and industrial areas. This includes sewage from households, as well as liquid waste from restaurants, factories, and other establishments.

· Drainage and Cleaning: Sewage suction machines are used to clean and clear drainage systems, including sewers, stormwater drains, and culverts. They can remove debris, silt, and other obstructions that might block the flow of wastewater, preventing backups and flooding.

· Septic Tank Emptying: In areas where homes and buildings rely on septic tanks for wastewater treatment, sewage suction machines are used to empty these tanks when they become full. Regular maintenance of septic tanks is essential for preventing overflows and groundwater contamination.

· Grease Trap Cleaning: Restaurants and food service establishments use grease traps to capture grease and oil from wastewater before it enters the sewer system. Sewage suction machines can effectively clean out these grease traps, preventing clogs and foul odors.

· Emergency Response: During emergencies such as floods, sewage overflows, or industrial spills, sewage suction machines play a crucial role in quickly removing excess water and contaminated liquids from affected areas. This helps mitigate the damage and prevents further environmental contamination.

· Transportation and Disposal: Once wastewater is collected, sewage suction machines transport it to treatment facilities for proper disposal or processing. Depending on the type of waste, it may undergo treatment to remove pollutants or be safely disposed of according to regulations.

Industrial Sewer Suction Machine

An industrial sewer suction machine is a powerful apparatus used to extract and transport large volumes of industrial wastewater, sludge, and debris from sewer systems, aiding in the maintenance and cleanliness of industrial facilities while ensuring compliance with environmental regulations.

Overall, sewage suction machines are essential tools in maintaining public health, sanitation, and environmental quality. By efficiently collecting and managing wastewater, they help prevent the spread of disease, protect water resources, and ensure the cleanliness of our communities.

Best Sewage Suction Machine Manufacturer in India

If you are looking for a best sewage suction machine manufacturer and supplier in India, look no further then, supertech engineers. Supertech Engineers is a leading manufacturer and supplier of Sewage Suction Machine in India. If you want to know Sewage Suction Truck Price in India, Please let us know your requirements!

For more details, please contact us!

Website : www.supertechengineer.co.in

Contact No. — +91–9910715032, +91–9311309436

Email — [email protected]

Address — MORTA INDUSTRIAL AREA, MORTA GHAZIABAD, Ghaziabad, Uttar Pradesh, India.

#sewer suction machine manufacturer in ghaziabad#sewer suction machine#sewer suction machine manufacturer#sewage suction machine in India#Sewage Suction Machine Manufacturer in India#supertech engineers

1 note

·

View note