#Samarium Cobalt Magnets

Text

Loss of Permanent Magnet Magnetization Due to Cold Temperatures Exposure

Loss of Permanent Magnet Magnetization Due to Cold Temperatures Exposure

Loss of magnetization due to cold temperatures exposure is a phenomenon that occurs in various types of materials, particularly in magnetic materials. This phenomenon is commonly known as the “superparamagnetic effect” or “temperature-dependent magnetization.” It results from the thermal agitation of the atomic spins in the…

View On WordPress

#ceramic ferrite magnets#Ferrite Magnets#Ferrite Magnets Applications#hard ferrite magnet#High Temperature Resistance Magnet#high temperature resistant magnet#Magnet Magnetization#Magnet Raw Material#Magnetic Materials#magnetic properties#magnetic strength#magnetization#Neodymium rare earth magnets#permanent magnet demagnetization#Permanent rare earth magnets#Rare Earth Magnets#raw magnets#raw material price#samarium cobalt#Samarium Cobalt Magnets#Samarium Cobalt Rare Earth Magnets#Sintered Ferrite magnets#sintered hard ferrite magnets#Sintered rare earth magnets#Sintered Samarium Cobalt Magnets#SmCo#SmCo magnets

3 notes

·

View notes

Text

Working With Magnets in High or Low Temperatures

Working With Magnets in High or Low Temperatures

The ambient temperature surrounding your magnets during work impact their strength significantly, but each magnetic material is different. Which magnet works best in your conditions?

High or Low Temperatures | Get the Right Magnets for Your Application in High or Low Temperatures

Temperature and magnetic strength have a turbulent relationship.

Some…

View On WordPress

#Alnico magnets#Ceramic Ferrite Magnets#Ceramic magnets#electromagnets#ferrite magnets#General Questions#licensed neodymium magnets#magnet question#magnetic domains#neodymium iron boron#Neodymium magnets#permanent magnets#Protect Magnets#rare earth magnets#Rare Earths#Samarium Cobalt magnets#Stainless Steel Case Magnets#Stainless Steel Magnetic

0 notes

Text

High Performance SmCo Magnet Manufacturers

Sm2Co17-based magnets are still playing an irreplaceable role in the permanent magnet industry due to its unique high temperature magnetic properties and superior magnetic stability, then it always serving to the high-speed motors, electronic communication, and aerospace. High energy product magnets are the important basis to accelerate miniaturization and high efficiency of the device. Thus, obtain high performance SmCo magnet has always been a goal since the advent of Sm2Co17.

Although the remanence and magnetic energy product of high-performance samarium cobalt (XGS33H and XGS35H) are lower than the N42EH and N38AH grades of neodymium iron boron at lower temperatures, their remanence and magnetic energy product are significantly higher at higher temperatures than the N42EH and N38AH grades of neodymium iron boron. With the increase of temperature, the remanence and magnetic energy product of N42EH and N38AH grades of neodymium iron boron deteriorate rapidly, especially the coercivity. However, high-performance samarium cobalt still retains high magnetic properties and exhibits excellent thermal stability.

0 notes

Text

Periodic Table Championship:

Round 1, Day 4, Xenon vs. Samarium

The second match of day 4 has element 54, xenon, competing against element 62, samarium.

Xenon is a dense, colorless gas belonging to the group of noble gases on the periodic table and existing in the Earth's atmosphere only in trace amounts. While extremely nonreactive, alongside the other noble gases, xenon was the first of this group to be synthesized in a compound, xenon hexafluoroplatinate. It is known for its applications in lighting, lasers, and as a general anesthetic. Its name comes from the Greek for foreigner, stranger, or guest.

Samarium is a hard, silvery, rare earth metal and lanthanide that crystalizes in the rhombehedral system at room temperature. It has one of the largest atomic radii of any element (only five elements are larger), and its known for its magnetic properties. Samarium-cobalt magnets aren't as well known as neodymium magnets, but can withstand higher temperatures and can be used in specialized applications. The name comes from the mineral samarskite, which was itself named for Vassili Samarsky-Bykhovets, making samarium the first element to be named after a person, albeit indirectly.

11 notes

·

View notes

Text

Pentagon stops F-35 deliveries after discovery of engine part manufactured in China

Fernando Valduga By Fernando Valduga 09/07/2022 - 17:00in Military

The Pentagon stopped accepting new F-35 jets after discovering that a magnet used in the stealth engine was made with unauthorized material from China, a U.S. official said on Wednesday.

An investigation in mid-August found that an alloy in the engine lubrication pump did not comply with U.S. purchasing laws that prohibit unauthorized Chinese content, Pentagon spokesman Russell Goemaere said.

"We confirm that the magnet does not transmit information or harm the integrity of the aircraft and there are no risks of performance, quality, safety or protection associated with this problem and flight operations for the fleet in service of the F-35 will continue normally," Goemaere said.

Lockheed Martin, which manufactures the jets, said that "the problem is related to a magnet in the F-35 Turbomachine manufactured by Honeywell that includes cobalt and samarium alloy".

At the end of August, Honeywell was notified by one of its 3rd level suppliers for the turbomachine that they were using an alloy from China that was then magnetized in the United States, according to a statement from Lockheed.

"With great caution, there is a temporary pause in deliveries," the statement said, noting that the magnet does not provide visibility or access to confidential information of the program and there are no security problems for the F-35 currently in use.

Honeywell International, which manufactures the part, said it “continues to be committed to providing high-quality products that meet or exceed all the requirements of the customer's contract”.

An alternative source for the league will be used in the future, the Joint Program Office said in its statement.

There are other magnets of Chinese origin on the jet that received exemptions from former Pentagon officials.

Tags: Military AviationF-35 Lightning IILockheed Martin

Previous news

Tu-95MS crews test the air defense systems of East Russia in the final phase of the Vostok 2022 exercise

Next news

IMAGES: FAB aircraft brighten the September 7 parade in Brasilia

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. It has works published in specialized aviation magazines in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

SMOKE SQUAD

IMAGES: FAB aircraft brighten the September 7 parade in Brasilia

07/09/2022 - 19:29

MILITARY

Tu-95MS crews test the air defense systems of East Russia in the final phase of the Vostok 2022 exercise

09/07/2022 - 16:00

MILITARY

Singapore wants to purchase two versions of the F-35

07/09/2022 - 14:00

HMS Queen Elizabeth leaves Portsmouth.

MILITARY

With HMS Prince of Wales out of action, HMS Queen Elizabeth leaves for the U.S.

07/09/2022 - 10:46

BRAZILIAN AIR FORCE

Brazilian Air Force participates in Homeland Week

09/07/2022 - 09:31

BRAZILIAN AIR FORCE

FAB: TÁPIO 2022 performs unprecedented missions in this fifth edition of the Exercise

07/09/2022 - 09:17

homeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

7 notes

·

View notes

Text

Magnet Market increase by USD 17.54 billion, at a CAGR of 7.89% between 2023 and 2028

Magnet Market Size 2024-2028

The magnet market is expected to grow by USD 17.54 billion, with a CAGR of 7.89% from 2023 to 2028. Magnets, materials with a magnetic field that attract iron, nickel, cobalt, and similar metals, are primarily composed of ferromagnetic metals such as nickel and iron. This market growth is driven by increasing demand in the automobile sector, the growing need for defense aircraft, rising government defense expenditures, and the expanding application of magnets in storage technology. Our report analyzes historical data from 2018-2022 and examines the current market scenario.

Market Forecast and Size

The magnet market is influenced by several factors, including GDP growth, inflation, and government purchases. Rising consumer spending and investments in business and inventory have led to increased demand for magnets across various sectors, including industrial applications and automotive segments. Magnets are essential components in products like computer cables, DVDs, and mobile phones. Regulatory authorities also impact market dynamics through residue management and mining licenses. Key magnet types include neodymium iron boron (NdFeB), ferrite, and alnico, which are crucial in electric motors and voice coil motors.

Download Magnet Market Sample PDF Report

Market Segmentation

Type:

Ferrite: Widely used in industrial applications for their high magnetic strength and durability, ferrite magnets are common in fax stepper motors, printer machine rollers, and automotive components.

External Suppliers: These magnets find applications in consumer electronics, including recorders, cameras, watches, and earbuds, due to their lightweight and efficient properties.

Application:

Industrial: Magnets are essential in machinery and equipment for efficient operations and precise control.

Consumer Electronics: Utilized in products like smartphones and personal electronics, driving significant demand.

Type Insights

Permanent Magnets: Expected to see significant growth, permanent magnets are made from special alloys like nickel, samarium cobalt, and iron. These magnets retain their magnetic properties even when removed from the magnetic field. The automotive industry, particularly in developing nations, drives this segment, which was valued at USD 21.73 billion in 2018.

End-user Insights

Consumer Goods and Electronics: This segment will account for the largest market share. Major consumers include China, Japan, South Korea, and India in APAC, followed by the US and Canada in North America, and the UK and Germany in Europe. Magnets are crucial in devices like hard drives, earphones, and microphones.

Regional Insights

APAC: Expected to contribute 44% to global market growth, driven by rapid industrialization and expansions in automotive, industrial, energy, and consumer electronics sectors. The demand for permanent magnets in consumer electronics is increasing due to rising disposable incomes and improved living standards. Applications include air conditioners, washing machines, computers, and loudspeakers.

Market Dynamics and Customer Landscape

The magnet market is growing steadily, influenced by factors such as increased consumer spending and demand for industrial and automotive applications. Innovations and supply-demand balance play crucial roles. The market benefits from the increased applicability of magnets in storage technology and the use of nanocrystalline magnetic particles in the biomedical industry. However, high R&D costs present a significant challenge.

Key Market Drivers

Storage Technology: Magnets enable compact, lightweight, and efficient energy storage systems, making them ideal for integrating renewable energy sources into power grids.

Nanocrystalline Magnetic Particles: Their use in the biomedical industry, particularly in sensors, biosensors, MRI scanners, and drug delivery, is shaping market growth.

Download Magnet Market Sample PDF Report

Major Market Challenges

High R&D Costs: Developing novel and advanced magnet materials requires significant financial resources, qualified personnel, and extensive laboratory facilities.

Customer Landscape

The market report includes the adoption lifecycle, focusing on different regional penetration rates. It also covers key purchase criteria and price sensitivity drivers, helping companies evaluate and develop their growth strategies.

Key Companies

Key players implement various strategies such as alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches. The report includes detailed competitive landscape analyses and information about 20 companies, including Adams Magnetic Products, Arnold Magnetic Technologies Corp., Daido Steel Co. Ltd., and TDK Corp.

Conclusion

The magnet market is poised for robust growth, driven by diverse applications across sectors like automotive, consumer electronics, and industrial applications. Despite challenges like high R&D costs, the increasing demand for efficient, reliable, and versatile magnet solutions will continue to propel market expansion during the forecast period.

Download Magnet Market Sample PDF Report

0 notes

Note

i’m the tin man because you’ve stolen my heart and you are samarium cobalt magnet (but please tell me your opinions on magnets and metals)

okok love this but if you’re gonna go for permanent magnets, at least go for neodymium magnets (they’re stronger <3)

1 note

·

View note

Text

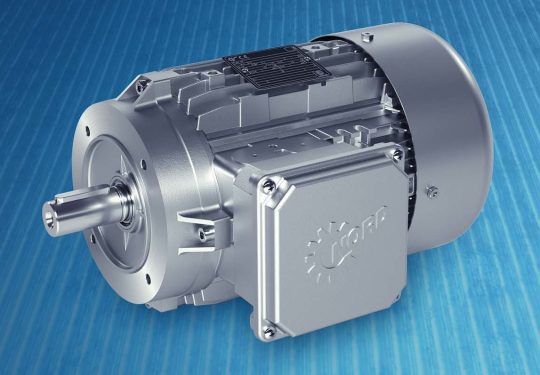

Unlocking Growth: Exploring the IE4 Permanent Magnet Synchronous Motor Market

The global economy is undergoing a significant shift towards sustainability and energy efficiency, driven by environmental concerns and regulatory mandates. In this transformative landscape, the IE4 Permanent Magnet Synchronous Motor (PMSM) market has emerged as a critical enabler of progress. According to a study by Next Move Strategy Consulting, the global IE4 Permanent Magnet Synchronous Motor Market size is predicted to reach USD 308.6 million with a CAGR of 8.97% by 2030. This underscores the growing importance of these advanced electric motors in various industries worldwide.

Request for a sample, here: https://www.nextmsc.com/ie4-permanent-magnet/request-sample

Understanding IE4 Permanent Magnet Synchronous Motors:

IE4 Permanent Magnet Synchronous Motors represent a paradigm shift in electric motor technology. Unlike conventional motors that rely on electromagnetic induction, PMSMs utilize permanent magnets to generate magnetic fields, resulting in higher efficiency, precision control, and reduced energy consumption. These motors are characterized by their synchronous operation, where the rotor rotates at the same speed as the magnetic field produced by the stator, enabling precise speed control and torque regulation.

Key Drivers of Market Growth:

The growth of the IE4 Permanent Magnet Synchronous Motor market is driven by several key factors. Firstly, stringent environmental regulations aimed at reducing carbon emissions and improving energy efficiency have prompted industries to adopt eco-friendly technologies, including high-efficiency electric motors. IE4 PMSMs offer significant energy savings compared to traditional motors, making them an attractive choice for applications where energy efficiency is paramount.

Moreover, the rapid expansion of industrial automation and the adoption of smart manufacturing technologies have fueled the demand for high-performance motors capable of delivering optimal efficiency and reliability. IE4 PMSMs are well-suited for use in robotics, CNC machines, conveyor systems, and other automated processes, where precision control and high torque density are essential.

Furthermore, the growing adoption of electric vehicles (EVs) and hybrid vehicles is driving demand for IE4 PMSMs in the automotive sector. These motors play a crucial role in powering electric propulsion systems, offering superior efficiency, power density, and torque characteristics compared to traditional internal combustion engines. As governments worldwide implement policies to reduce vehicle emissions and promote electric mobility, the demand for IE4 PMSMs in the automotive industry is expected to surge in the coming years.

Challenges and Opportunities:

Despite the promising growth prospects, the IE4 Permanent Magnet Synchronous Motor market faces several challenges. One of the primary challenges is the high initial cost associated with these motors, primarily due to the use of rare-earth magnets such as neodymium and dysprosium. The limited availability of these materials and their fluctuating prices pose a significant risk to manufacturers and end-users alike. However, ongoing research and development efforts aimed at alternative magnet materials, such as ferrite and samarium cobalt, are expected to mitigate this challenge in the long term.

Additionally, the complexity of motor design and integration presents challenges in terms of manufacturing, installation, and maintenance. IE4 PMSMs require sophisticated control systems and advanced manufacturing techniques to achieve optimal performance and efficiency. Moreover, the customization requirements for different applications and industries add further complexity to the production process, potentially increasing lead times and costs.

Despite these challenges, the IE4 Permanent Magnet Synchronous Motor market presents significant opportunities for growth and innovation. The emergence of new applications and industries, such as renewable energy, robotics, and IoT, is driving demand for high-performance motors with enhanced efficiency, reliability, and durability. For instance, the rise of wind and solar power generation has created a growing need for IE4 PMSMs in wind turbines, solar tracking systems, and grid stabilization solutions. Similarly, the integration of robotics and IoT technologies in manufacturing, logistics, and healthcare sectors is driving demand for IE4 PMSMs in robotic arms, automated guided vehicles (AGVs), and medical devices.

Adoption Challenges in Traditional Industries: Despite the advantages of IE4 Permanent Magnet Synchronous Motors, the adoption rate in traditional industries such as HVAC, pumping systems, and material handling equipment has been relatively slow. This can be attributed to factors such as entrenched reliance on conventional motor technologies, lack of awareness about the benefits of PMSMs, and concerns about compatibility with existing infrastructure. Overcoming these adoption challenges will require targeted education and awareness campaigns, along with incentivization programs to encourage businesses to transition to more energy-efficient motor solutions.

Regulatory Compliance and Standards: Compliance with industry standards and regulations poses another challenge for the IE4 Permanent Magnet Synchronous Motor market. Manufacturers must ensure that their products meet stringent performance, safety, and efficiency standards set forth by regulatory bodies and industry associations. Failure to comply with these standards can result in costly recalls, penalties, and damage to brand reputation. Therefore, investing in research and development to develop motors that not only meet but exceed regulatory requirements will be essential for gaining a competitive edge in the market.

Inquire before buying, here: https://www.nextmsc.com/ie4-permanent-magnet/inquire-before-buying

Supply Chain Vulnerabilities: The IE4 Permanent Magnet Synchronous Motor market is susceptible to supply chain disruptions, particularly concerning the procurement of rare-earth magnets and other critical components. Dependence on a limited number of suppliers, geopolitical tensions, and trade restrictions can lead to shortages, price fluctuations, and delays in production. To mitigate supply chain vulnerabilities, manufacturers must diversify their supplier base, invest in vertical integration, and explore alternative sourcing options to ensure a reliable and resilient supply chain.

Technological Innovation and Advancements: Continuous technological innovation is imperative for driving growth and differentiation in the IE4 Permanent Magnet Synchronous Motor market. Manufacturers must invest in research and development to enhance motor efficiency, reliability, and performance while reducing costs and environmental impact. Advancements in materials science, motor design, power electronics, and digital control systems offer opportunities to develop next-generation PMSMs that meet the evolving needs of industries and consumers alike.

Lifecycle Sustainability and End-of-Life Management: Ensuring the sustainability of IE4 Permanent Magnet Synchronous Motors throughout their lifecycle presents both challenges and opportunities for manufacturers. From raw material extraction to manufacturing, use, and end-of-life disposal, minimizing environmental impact and maximizing resource efficiency are paramount. Implementing circular economy principles, such as remanufacturing, recycling, and responsible disposal, can help reduce waste and extend the lifespan of PMSMs, thereby contributing to a more sustainable and circular economy.

Market Fragmentation and Competition: The IE4 Permanent Magnet Synchronous Motor market is characterized by intense competition and market fragmentation, with numerous players vying for market share across different regions and industry verticals. As a result, manufacturers must differentiate their products through innovation, quality, and value-added services to stand out in the crowded marketplace. Strategic partnerships, mergers and acquisitions, and market consolidation may also be necessary to strengthen market position and achieve economies of scale.

Skills Gap and Talent Shortage: Addressing the skills gap and talent shortage in the IE4 Permanent Magnet Synchronous Motor industry is essential for driving innovation and sustaining market growth. As technology advances and the demand for specialized skills increases, manufacturers must invest in workforce development, training programs, and knowledge transfer initiatives to cultivate a skilled workforce capable of designing, manufacturing, and servicing advanced PMSM systems. Collaboration with educational institutions, vocational training centers, and industry associations can help bridge the skills gap and ensure a steady supply of talent for the future.

Conclusion:

In conclusion, the IE4 Permanent Magnet Synchronous Motor market is poised for substantial growth and innovation in the coming years. With increasing emphasis on energy efficiency, sustainability, and technological advancement, IE4 PMSMs are expected to play a pivotal role in powering the industries of the future. By leveraging their superior efficiency, reliability, and performance, these advanced electric motors are unlocking new opportunities for growth and transformation across various sectors. However, addressing the challenges associated with cost, materials, and complexity will be crucial for realizing the full potential of IE4 PMSMs and driving widespread adoption. As manufacturers, researchers, and policymakers collaborate to overcome these challenges, the IE4 Permanent Magnet Synchronous Motor market will continue to evolve and thrive, shaping a more sustainable and efficient future for generations to come.

#IE4 Permanent Magnet Synchronous Motor#construction and manufacturing#market research#market trends#business insights

0 notes

Text

From Magnetite to Magnificence: The Role of Magnets in Cape Town on Industries

In Cape Town, which is well-known for its beautiful scenery and rich cultural heritage, magnets play a crucial role in industrial activities. Magnets are essential to many of the city's industries, including manufacturing, technology, and healthcare. This article will examine the various uses of magnets Cape Town on industries, emphasising their importance and influence.

Magnetic Materials & Manufacturing

Magnets are necessary parts of a wide range of products produced in Cape Town's manufacturing sector. Permanent magnets are used in the production of electric motors, generators, and magnetic bearings. They are formed of materials like neodymium, ferrite, and samarium-cobalt. These magnets are also essential for the manufacturing of magnetic actuators and sensors, which are used in the consumer electronics, automotive, and aircraft industries.

Magnets in Technology & Innovation

Cape Town uses magnets in several innovative and technological applications. Strong magnets are used by magnetic resonance imaging (MRI) machines, which are used in medicine to produce precise images of the interior organs. Additionally, the city is home to research and development centres that are investigating novel uses for magnets, such as magnetic records storage and magnetic lifting technologies.

Healthcare & Magnetic Therapy

Magnets are being used therapeutically in Cape Town's healthcare system. The use of magnets to relieve pain and encourage healing is known as magnetic therapy, and it is becoming more popular in the city. Products with magnetic therapy, like mattress pads and bracelets, are used to treat ailments like migraines, back pain, and arthritis. Furthermore, magnets are used in medical equipment like hearing aids and pacemakers.

Environmental Impact & Sustainability

The city of Cape Town is dedicated to environmental preservation and sustainability, and magnets are part of that. Waste management facilities use magnetic separators to extract ferrous materials from waste streams so that valuable materials can be recovered and recycled. In addition, treatment plants for water employ magnets to eliminate impurities from the water, guaranteeing that the city's citizens have a source of safe and clean water to drink.

Economic Growth & Job Creation

Magnets are used in Cape Town's industries to create jobs as well as promote economic growth. The manufacturing and technology industries, which primarily rely on magnets, employ the majority of the city's workforce. With Cape Town's industrial capacity and inventiveness continuing to grow, magnets along with related technologies are going to grow more necessary, which will add even more to the city's economic success.

Magnetic Energy & Power Generation

Magnets are being investigated for their potential applications in energy generation and storage in Cape Town. In generators and turbines, magnets are used to transform mechanical energy into electrical energy. Magnesium batteries are also being studied because they can store a lot of energy to be used during times of high demand. These developments in magnetic technology may facilitate Cape Town's shift away from fossil fuels and towards greener, more sustainable energy sources.

In summary, magnets have a variety of functions in Cape Town's industries, fostering innovation, assisting with sustainability initiatives, and fostering economic expansion. As Cape Town becomes a centre of business activity, the magnets will become more and more significant in the town's industrial landscape.

0 notes

Text

Custom NdFeB Magnets

NdFeB magnets, also known as the "King of Permanent Magnets", is one of the most significant members of the rare earth magnet family. Sintered NdFeB is a rare earth permanent magnet material produced by powder metallurgy. NdFeB magnets can be customized varying from size, shape, magnetic direction to coating according to specific needs and applications by customers.

Different Types of NdFeB Magnets

Sintered NdFeB Magnets

These are the most powerful commercialized permanent magnets available today, with maximum energy product ranging from series of N, M, H, SH, UH, EH to AH.

Magnet Assembly

This refers to components that incorporate magnets, often designed to optimize the magnetic circuit for maximum performance. Magnetic components are finished or semi-finished permanent magnets or other parts composed of one or more magnetic materials. Components typically use adhesives to bond small components together to achieve certain functions that independent magnets cannot achieve. Magnetic components not only enhance the strength of the magnetic field, but also reduce eddy currents and provide good protection for fragile magnets. They can be used in a variety of applications including wind power, industrial automation, automotive industries, home appliances and etc.

Non-sintered NdFeB Magnets

ALNICO magnets are made from an alloy of aluminum, nickel, and cobalt, known for their excellent temperature stability and high residual induction. SMCO NdFeB magnets, made from samarium, cobalt, neodymium, iron, and boron, are powerful rare-earth magnets with high magnetic energy. Ferrite magnets, made from iron oxide and other metals, are cost-effective and have good resistance to demagnetization.

Quality Assurance

At Ningbo Ketian Magnet Co., Ltd., quality assurance is at the heart of our operations. Since 2001, we have been committed to producing high-grade sintered NdFeB magnets, consistently improving our product quality through technical innovation, lean production, and intelligent manufacturing. As a reliable NdFeB magnets factory, our dedication to quality has earned us trust from customers globally, reinforcing our position as a leading magnet manufacturer.

What Are the Applications of Neodymium Magnets?

Neodymium magnets, the most powerful permanent magnets, known for their strong magnetic properties, are widely used in various industries such as electric and hybrid vehicles, home appliances, industrial automation, wind turbines, and consumer electronics, contributing to improved performance and efficiency.

0 notes

Text

Loss of Permanent Magnet Magnetization Caused by Heat Exposure

Loss of Permanent Magnet Magnetization Caused by Heat Exposure

Loss of Magnetization Caused by Heat Exposure – Exposing a magnet to high temperatures can decrease its strength or permanently damage its structure. Usually this happens at very high temperatures, but for certain neodymium magnets this can happen as low as 60°C.

Magnets are characterized by two temperature thresholds: the working…

View On WordPress

#ceramic ferrite magnets#Ferrite Magnets#Ferrite Magnets Applications#hard ferrite magnet#High Temperature Resistance Magnet#high temperature resistant magnet#Magnet Magnetization#Magnet Raw Material#magnetic properties#magnetic strength#magnetization#Neodymium rare earth magnets#permanent magnet demagnetization#Permanent rare earth magnets#Rare Earth Magnets#raw magnets#raw material price#samarium cobalt#Samarium Cobalt Magnets#Samarium Cobalt Rare Earth Magnets#Sintered Ferrite magnets#sintered hard ferrite magnets#Sintered rare earth magnets#Sintered Samarium Cobalt Magnets#SmCo#SmCo magnets#Vehicle Magnets

3 notes

·

View notes

Text

How Magnets Work

How Magnets Work

You probably know that magnets attract specific metals and they have north and south poles. Opposite poles attract each other while like poles repel each other. Magnetic and electrical fields are related, and magnetism, along with gravity and strong and weak atomic forces, is one of the four fundamental forces in the universe.

But none of those facts answers the most basic…

View On WordPress

#Alnico magnets#Ceramic magnets#Ferrites magnets#Industrial Magnetics#Magnet Strength#magnetic materials#magnetic performances#Magnetics technology#Making Magnets#Neodymium magnets#permanent magnet materials#permanent magnetic materials#permanent magnets#powerful magnets#regular magnets#Samarium Cobalt magnets#Shipping Magnets

0 notes

Text

Cylindrical Magnets Axially Oriented, Disc Magnets, Manufacturer, India

Cylindrical Magnets Axially Oriented, Disc Magnets, Rare Earth Magnets, Rectangular Shape Magnets, Power Magnets, Round Bars, Manufacturer, Supplier, Exporter, Satara, Maharashtra, India.

Cylindrical Magnets Axially Oriented, Disc Magnet, Disc Magnets, Alnico Cylindrical Magnet, Alnico Cylindrical Magnet Axially Oriented, Alnico Cylindrical Magnets, Alnico Cylindrical Magnets Axially Oriented, Alnico Permanent Magnet, Alnico Permanent Magnets, Alnico Rectangular Bar, Alnico Rectangular Bars, Alnico Ring Magnet, Alnico Ring Magnets, Alnico Ring Magnets Axially Oriented, Alnico U-Shape Oriented Magnet, Alnico U-Shape Oriented Magnets, Alnico U-Shaped Oriented Magnets,Aluminium Nickel Cobalt Magnet, Aluminium Nickel Cobalt Magnets, Cast Alnico Magnet, Cast Alnico Magnets, Cylindrical Magnet, Cylindrical Magnets, Generator Magnet, Generator Magnets, Manufacturer, Supplier of Cast Alnico, Nd-Fe-B Disc Magnet, Nd-Fe-B Disc Magnets, Nd-Fe-B Permanent Magnet, Nd-Fe-B Permanent Magnets, Neodibium Iron Boron Magnet, Neodibium Iron Boron Magnets, Neodymium Iron Boron Disc Magnet, Neodymium Iron Boron Disc Magnets, Neodymium Iron Boron Permanent Magnet, Neodymium Iron Boron Permanent Magnets, Neodymium-Iron-Boron Magnet, Neodymium-Iron-Boron Magnets, Oriented Rectangular Bar, Oriented Rectangular Bars, Oriented Rectangular Block, Oriented Rectangular Blocks, Oriented Rectangular Blocks & Bars, Oriented Rectangular Blocks And Bars, Oriented Round Bar, Oriented Round Bars, Permanent Magnet, Permanent Magnets, Power Magnet, Power Magnets, Rare Earth, Rare Earth Magnet, Rare Earth Magnets, Rectangular Bar, Rectangular Bars, Rectangular Bars With Slot, Rectangular Bars With Slots, Rectangular Bars With Slots At The End, Rectangular Shape Magnet, Rectangular Shape Magnets, Ring Magnet, Ring Magnet Axially Oriented, Ring Magnets, Ring Magnets Axially Oriented, Round Bar, Round Bars, Samarium Cobalt Permanent Magnets, Speedometer Ring Magnet, Speedometer Ring Magnets, Temperature Stable Magnet, Temperature Stable Magnets, U-Shape Oriented Magnet, U-Shape Oriented Magnets, Manufacturer, Supplier, Exporter, Satara, Maharashtra, India.

0 notes

Text

Guiding the Decade: Navigating the Brush Motor Control Unit Market's Journey Towards Tomorrow's Control

The market for brush motor control units is anticipated to reach a value of US$ 1,968.3 million in 2023 and US$ 3,236.9 million by 2033. During the projection period, sales of brush motor control units are anticipated to grow significantly at a CAGR of 5.1%.

The brush motor control unit provides precise speed control, and it has an electric power system (EPS) that controls the torque of the motor drive. The brush motor control unit system makes precise current adjustments based on torque signals detected by torque sensors. As a result, it provides vehicle drivers with some steering assistance during vehicle operation.

Ready to make informed decisions for your business? Get our market overview sample and discover growth opportunities today

https://www.futuremarketinsights.com/reports/sample/rep-gb-4183

Brush Motor Control Unit Market Overview

The brush motor control unit provides precision control of the speed, and it has an electric power system (EPS), which is responsible for controlling the torque of the motor drive. Brush motor control unit system makes precise current adjustments based on the steering of torque signals; which are detected by torque sensors. It thus offers vehicle drivers a little steering assistance in the vehicle operation.

Brush motor control unit consumes energy only when the steering assist is necessary. The brush motor control unit system is comparatively more fuel efficient than the conventional hydraulic power steering systems.

The electrical control unit (ECU) of the brush motor control unit calculates the torque necessary for the steering assist from the engine speed and the torque sensor signal, etc. and ultimately supplies the maximum electric power to the brush motor control unit. Choosing a right type of motor control unit is critical for the overall performance of vehicle or machine in which it is used in as a component.

Brush Motor Control Unit Market: Market Dynamics

The increasing demand for fuel-efficient automobiles coupled with the fact that the fuel reserve levels are going down constantly; is fueling the growth of the brush motor control unit market. The increasing demand for cost-effective automotive parts coupled with the fact that the companies are constantly trying to reduce their operational and overall cost of production; is contributing to the growth of brush motor control unit market.

However, the high initial cost of investment is a restraining factor. Another challenge faced in the expansion of the brush motor control unit market is the wide acceptance and proven performance of hydraulic steering systems. The launch of the brushless motor control units is a threat to the brush motor control unit market as they have less cost of maintenance (brushes require maintenance).

The use of brush motor control units in the cabin pressure, navigation and target servos, trim controls, utility actuation, and valve drives, etc., is one of the prevailing trends. Companies are also manufacturing brush motor control units with a range of magnetic materials such as samarium cobalt alloys and neodymium.

These units have weight with a durable performance which makes these ideal for use in a helicopter and small aircraft applications. There is an increasing preference for the brush motor control unit because it can alter or vary the speed-torque ratio in all possible ways.

0 notes

Text

Unveiling the Power of Permanent Rare Earth Magnets - A Blog By IHR Insights

Permanent rare earth magnets, notably neodymium and samarium-cobalt magnets, stand as remarkable marvels in the world of modern magnetism. These magnets owe their extraordinary strength and magnetic performance to the unique atomic structure of rare earth elements, transforming numerous industries and applications.

Unmatched Strength and Versatility:

Neodymium Magnets:

Neodymium magnets, the strongest known type of permanent magnets, shine in applications ranging from renewable energy systems and electronics to medical devices and automotive technologies. Their exceptional magnetic properties make them indispensable in miniaturized yet powerful applications and innovative designs.

Samarium-Cobalt Magnets:

Samarium-cobalt magnets, resilient in corrosive environments and high-temperature conditions, find pivotal roles in aerospace, military, and automotive sectors, demonstrating remarkable stability and longevity under extreme operating conditions.

Transformative Applications:

Renewable Energy:

Rare earth magnets contribute significantly to the efficiency of wind turbines, generators, and electric vehicle motors, powering the transition towards sustainable energy solutions on a global scale.

Electronics and Technology:

In the realm of electronics, rare earth magnets enable the miniaturization of speakers, headphones, and high-performance hard disk drives, embodying the core of modern audiovisual experiences and data storage systems.

Healthcare and Biomedical:

These magnets play a critical role in various medical devices, including MRI machines, diagnostic equipment, and prosthetic devices, showcasing their indispensable contributions to healthcare technology and patient care.

Pursuit of Excellence and Discovery:

The ongoing research and quest for improved rare earth magnet materials promise advancements in energy efficiency, compact design, and magnetic performance, fostering a future where these magnets will continue to redefine technological boundaries and propel innovation across industries.

Read more from our latest study on Permanent Rare Earth Magnets Market Type (Neodymium Magnets And Samarium Magnets), Application (Industrial, Consumer Electronics, Home Appliances, Automotive, Wind Turbines And Others) And Geography (North America, Europe, APAC And RoW)-Forecast Up To 2028.

Conclusion:

The pervasive influence of rare earth magnets, with their unparalleled strength and adaptability, reverberates through the fabric of modern technology and industry. As these magnets continue to elevate the standards of magnetic performance and applicability, the possibilities for further advancements and groundbreaking innovations are both promising and transformative.

– Analyst Team

IHR Insights

[email protected]

0 notes